Contents

About This Document................................................................................................................ ii

1 System Installation................................................................................................................. 1

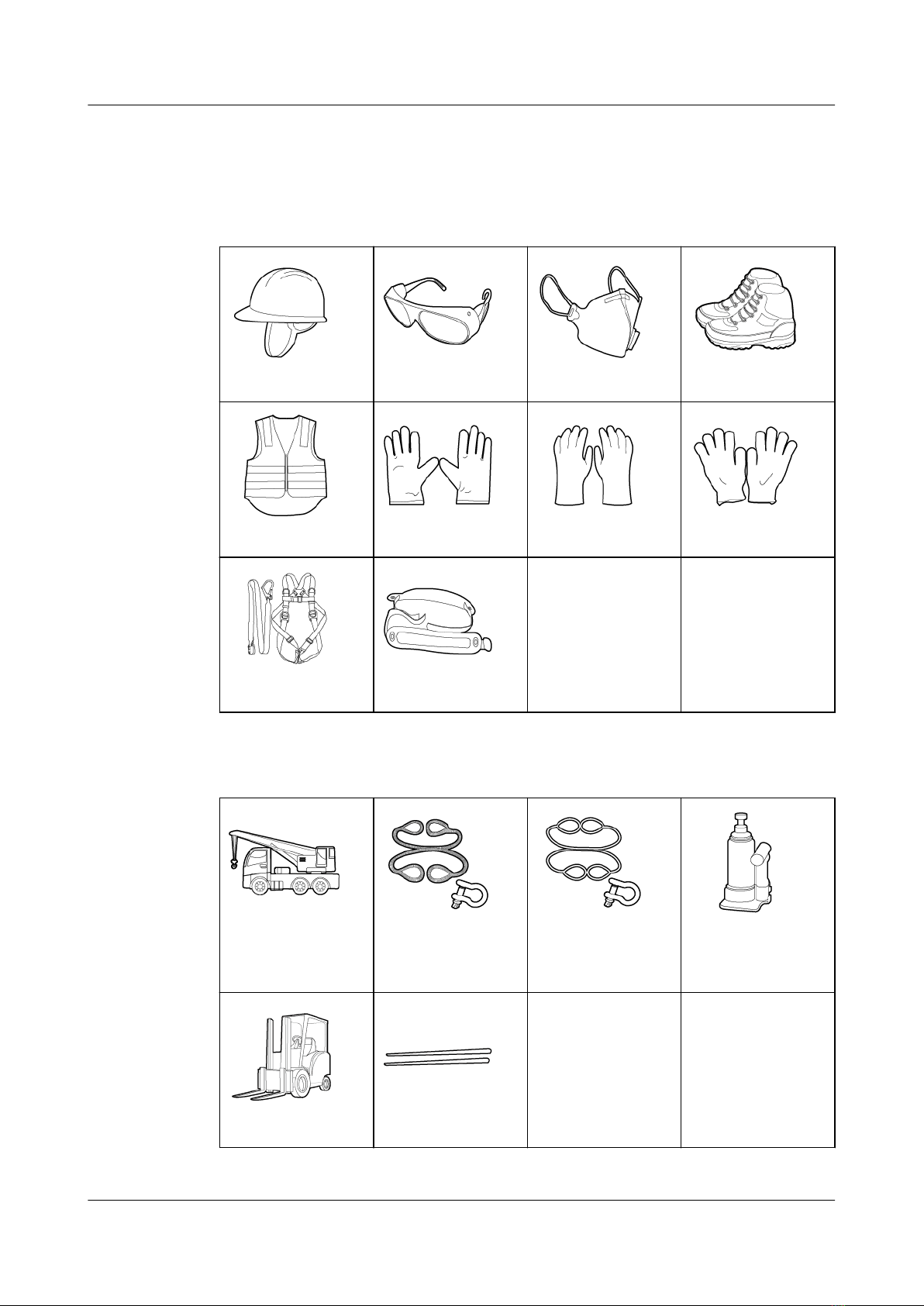

1.1 Installation Precautions.........................................................................................................................................................1

1.1.1 Installation Requirements................................................................................................................................................. 1

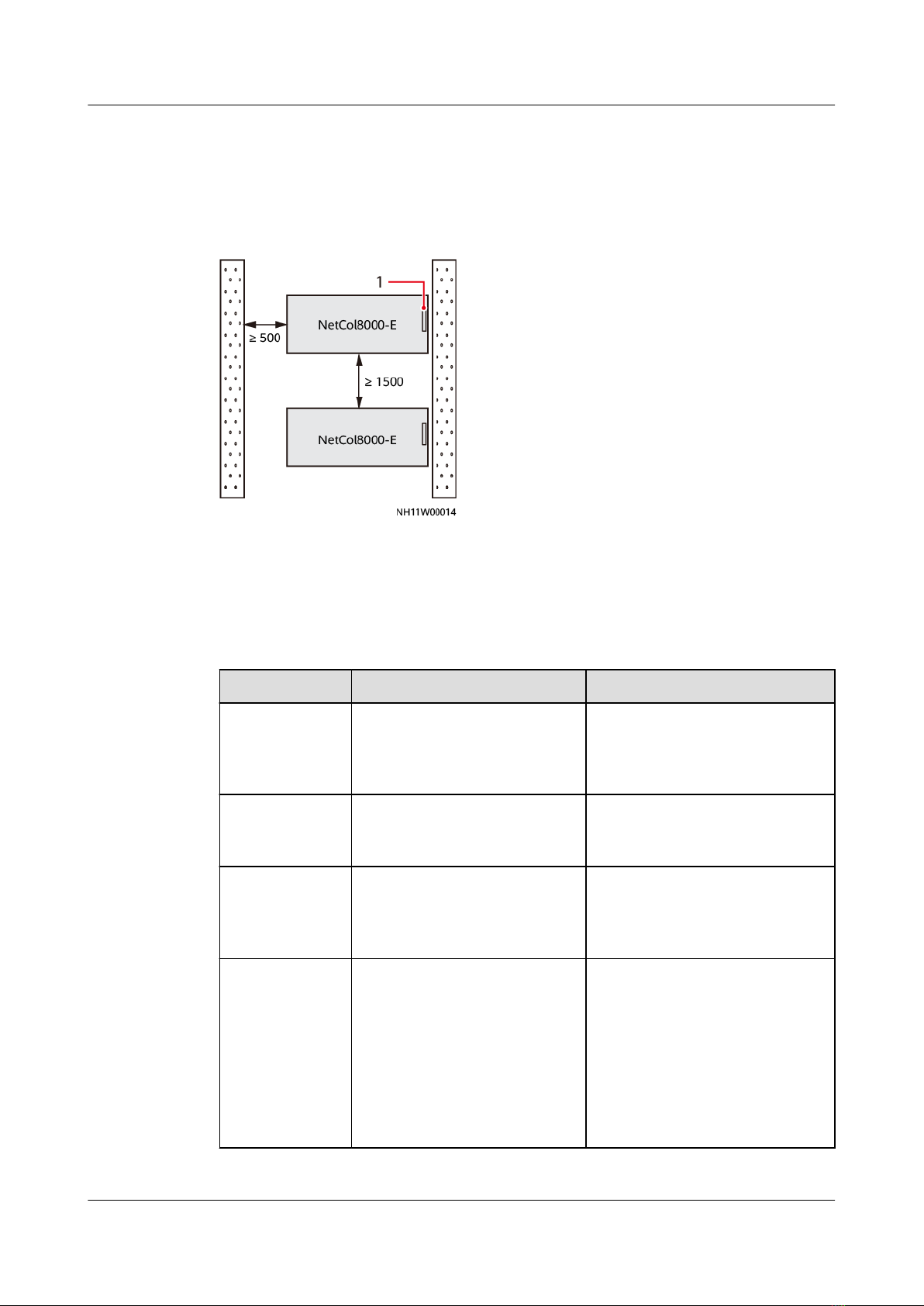

1.1.2 Layout Principles.................................................................................................................................................................. 3

1.2 Materials.....................................................................................................................................................................................3

1.2.1 Tools......................................................................................................................................................................................... 4

1.2.2 Water Rell Pipe and Drainpipe..................................................................................................................................... 7

1.2.3 Pipe Support.......................................................................................................................................................................... 8

1.2.4 Preparing Cables.................................................................................................................................................................. 9

1.3 Installing the Equipment.................................................................................................................................................... 10

1.3.1 Unpacking and Checking................................................................................................................................................ 10

1.3.2 Securing the Equipment.................................................................................................................................................. 11

1.3.3 Installing an Equipotential Ground Cable or Ground Lug...................................................................................12

1.3.4 Installing a Door Handle.................................................................................................................................................13

1.3.5 Installing Air Ducts............................................................................................................................................................14

1.3.5.1 Installing a Supply Air Duct........................................................................................................................................ 14

1.3.5.2 Installing a Return Air Duct........................................................................................................................................15

1.3.6 Connecting Water Pipes.................................................................................................................................................. 18

1.3.7 Removing the Transport Fasteners and Protective Covers.................................................................................. 22

1.4 Connecting Cables................................................................................................................................................................ 25

1.4.1 Precautions.......................................................................................................................................................................... 25

1.4.2 Putting Down the Pedal.................................................................................................................................................. 25

1.4.3 Connecting Power Cables............................................................................................................................................... 26

1.4.4 (Optional) Connecting Signal Cables......................................................................................................................... 27

1.4.5 (Optional) Connecting Teamwork and Monitoring Communications Cables.............................................. 29

1.4.5.1 Preparing a Network Cable........................................................................................................................................ 29

1.4.5.2 CAN Teamwork + FE Monitoring..............................................................................................................................30

1.5 Verifying the Installation.................................................................................................................................................... 31

1.6 Turning Up the Pedal...........................................................................................................................................................33

2 Power-On and Commissioning...........................................................................................34

2.1 Preparing for Power-On...................................................................................................................................................... 34

FusionCol8000-E140 Modular Indirect Evaporative

Cooling System

Quick Guide (2021, Ireland) Contents

Issue 02 (2023-08-03) Copyright © Huawei Digital Power Technologies Co., Ltd. iv