INSTALLATION

Specifications subject to change without notice - please ensure you are using

the latest manual found at the manufacturer website: www.huayu-energy.com

When AC power is applied but Microinverter is not started up, about 0.1A

current and 25VA(W) power for each Microinverter may be measured by a

power meter, this power is reactive power, not from grid.

NOTE:

NOTE:

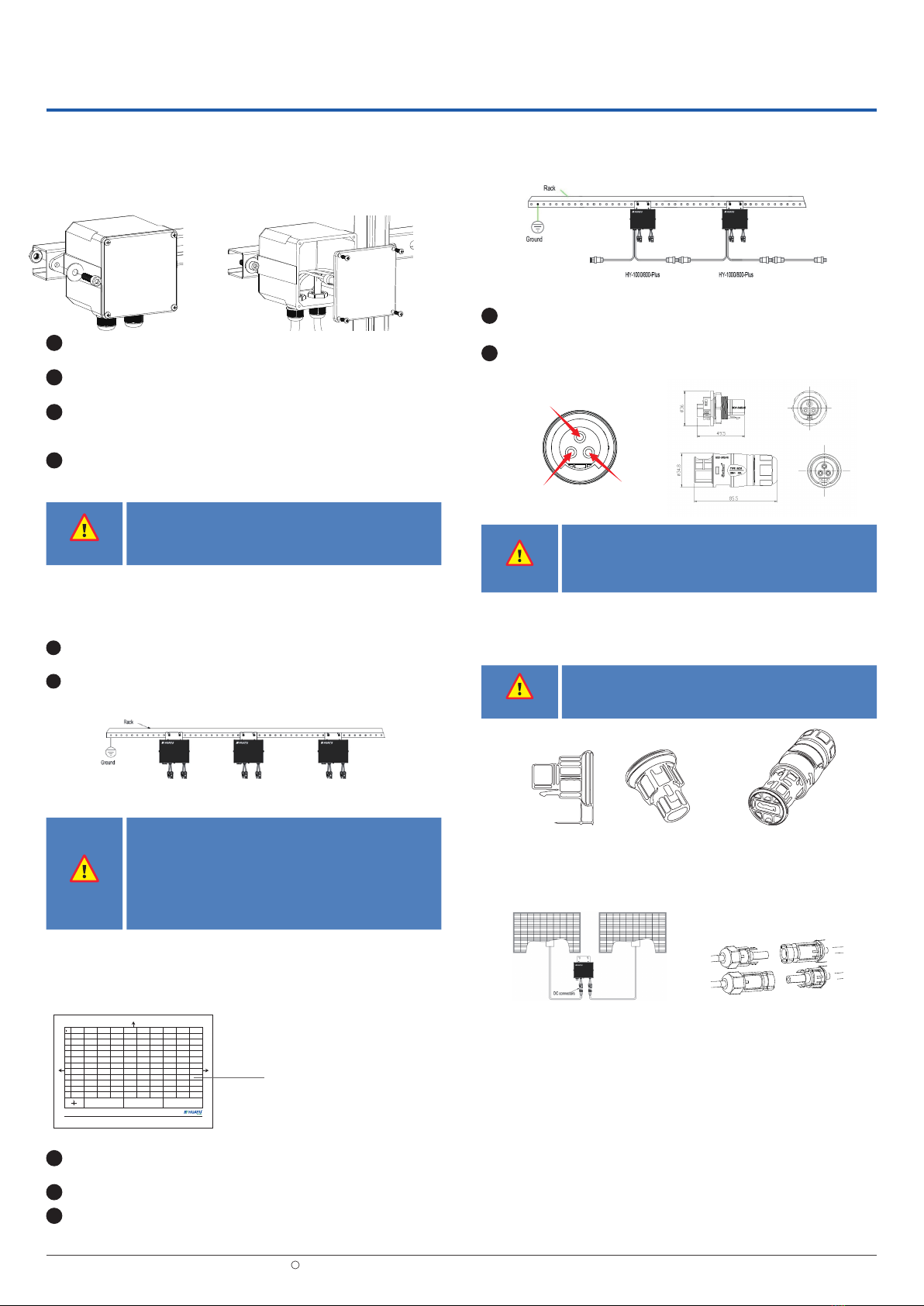

Step 5- Install an AC Cable Protective End Cap at the End

of AC Cable

7.5

NOTE:

The microinverter is powered on when sufficient DC voltage from the module

is applied. The status LED will start flashing after sufficient DC power is applied

as an indication that the microinverter is live.

Completely install all HY-1000/800-Plus and all system inter-wiring connections

prior to installing the PV modules.

Step 6- Connect Microinverter to PV Modules

WARNING

DO NOT exceed maximum number of Microinverters in an AC branch

circuit.For 12awg trunk cable, each HY-1000/800-Plus ac branch circuit

must be sourced from a dedicated branch circuit protected by a 20a

maximum breaker.

WARNING

Installed on all unused ac connectors. Unused ac HY-1000/800-Plus

wire harness connectors are live when the system is energized by the

utility system.

L(L1) N(L2)

PE

Installation Procedure

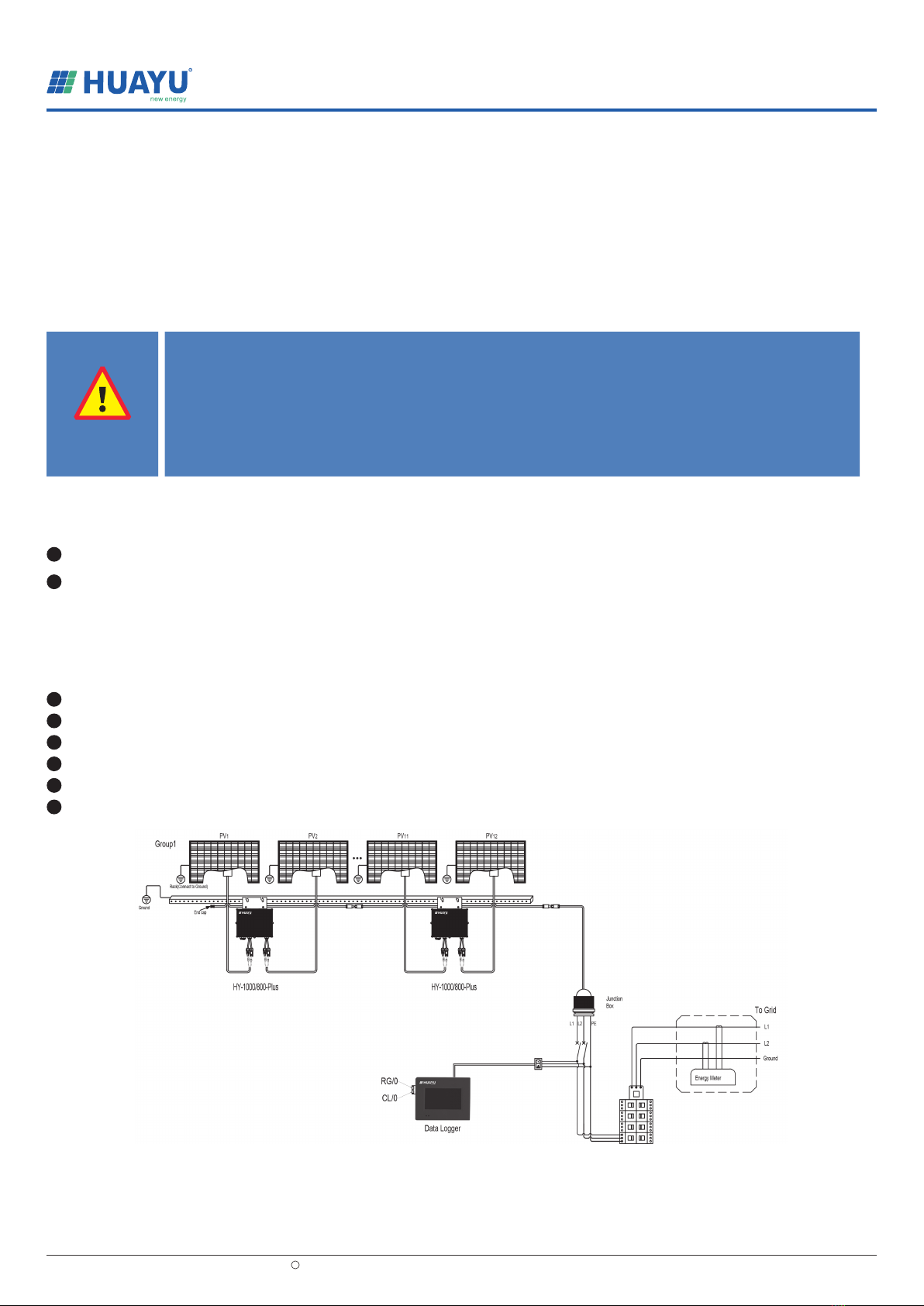

Step 1- Install AC Branch Circuit Junction Box

Install an appropriate junction box at a suitable location on the PV racking

system(typically at the end of a branch of modules).

Connect the open wire end of the AC cable into the junction box using an

appropriate gland or strain relief fitting.

Wire the conductors of the AC(127/220/230): L - red; N - black;

PE - yellow green. Wire the conductors of the AC(208/240): L1- red;

L2 - black; PE - yellow green.

Connect the AC branch circuit junction box to the point of utility

Interconnection.

1

2

3

4

Huayu(Ningbo)New Energy Technologies Co.,Ltd. All rights reserved.

c

Step 2- Attach Microinverters to Racking System or

the PV Module Frame

Prior to installing any of Microinverters, verify that the utility voltage at

the point of common connection matches the voltage rating on

Microinverter label.

Do not place the Microinverter(including DC and AC connectors)

where exposed to the sun, rain or snow, even gap between modules.

Allow a minimum of 3/4 inch(2cm). between roof and bottom of the

Microinverter to allow proper air flow.

WARNING

Wiring colour code can be different according to local regulation,check

all the wires of the installation before connecting them to the AC cable.

Wrong cabling can damage irreparably Microinverters,such an issue is

not covered by the warranty.

Mark the location of the Microinverter on the rack, with respect

to the PV module junction box or any other obstructions.

Mount one Microinverter at each of these locations by

recommended hardware.

1

2

1

2

3

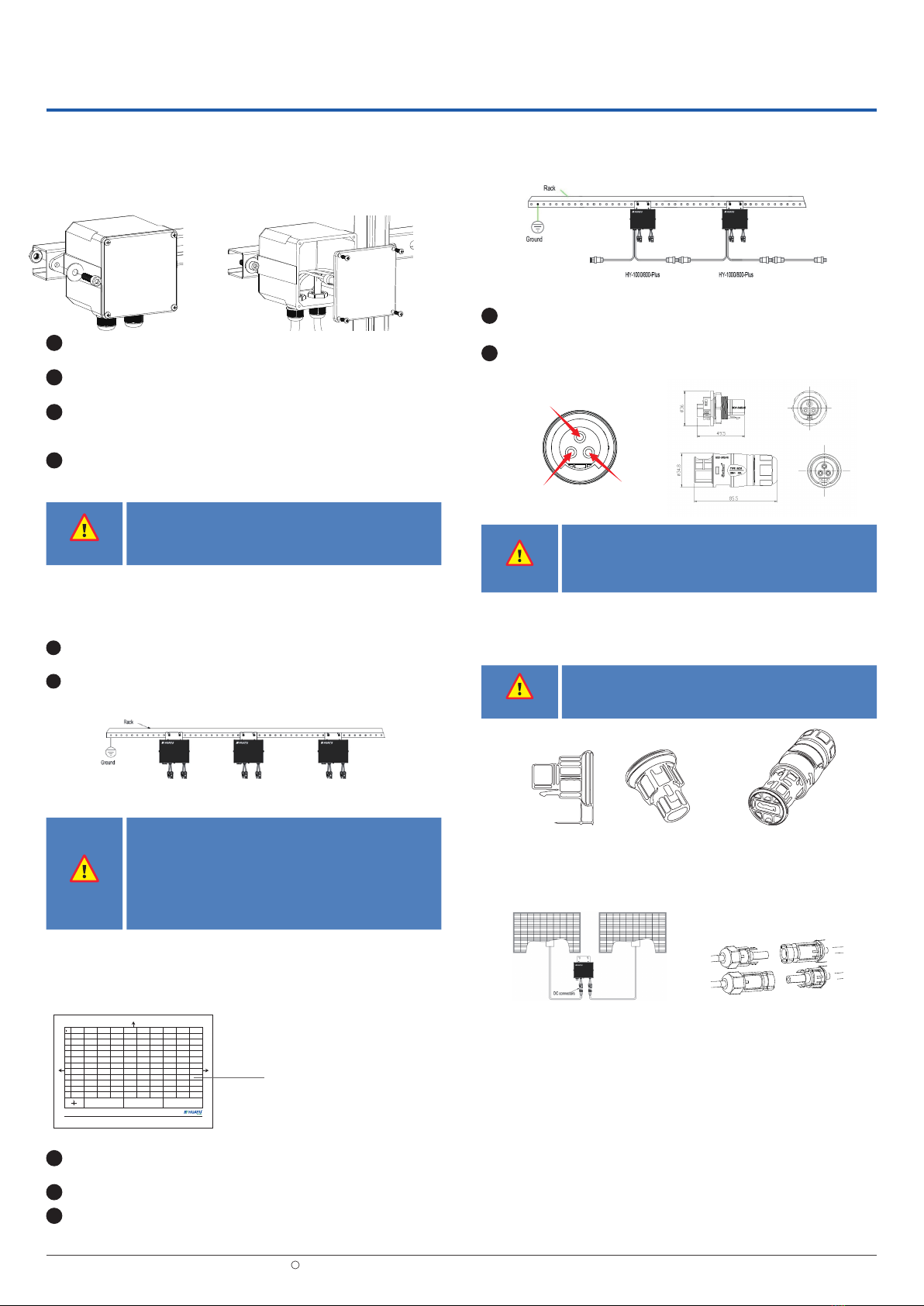

Step 3- Create an Installation Map

Peel the removable serial number label from each microinverter and affix

it to the respective location on the paper installation map.

Fill in the monitoring system account information to the installation map

Create a paper installation map to record microinverter serial numbers and position

in the array.

Always keep a copy of the installation map for your records.

Affix serial number labels

WARNING

A

12345678910

Customer:

1. Affix the serial number label to the respective location of the map.

2. Scan related QR Code of Microinverter and upload it to Huayu Monitoring platform.

Panel Group:

Azimuth:

Tilt:

Sheet____of____

Monitoring System Account:

Installer:

B

C

D

E

F

G

H

J

K

L

W E

N

S

N

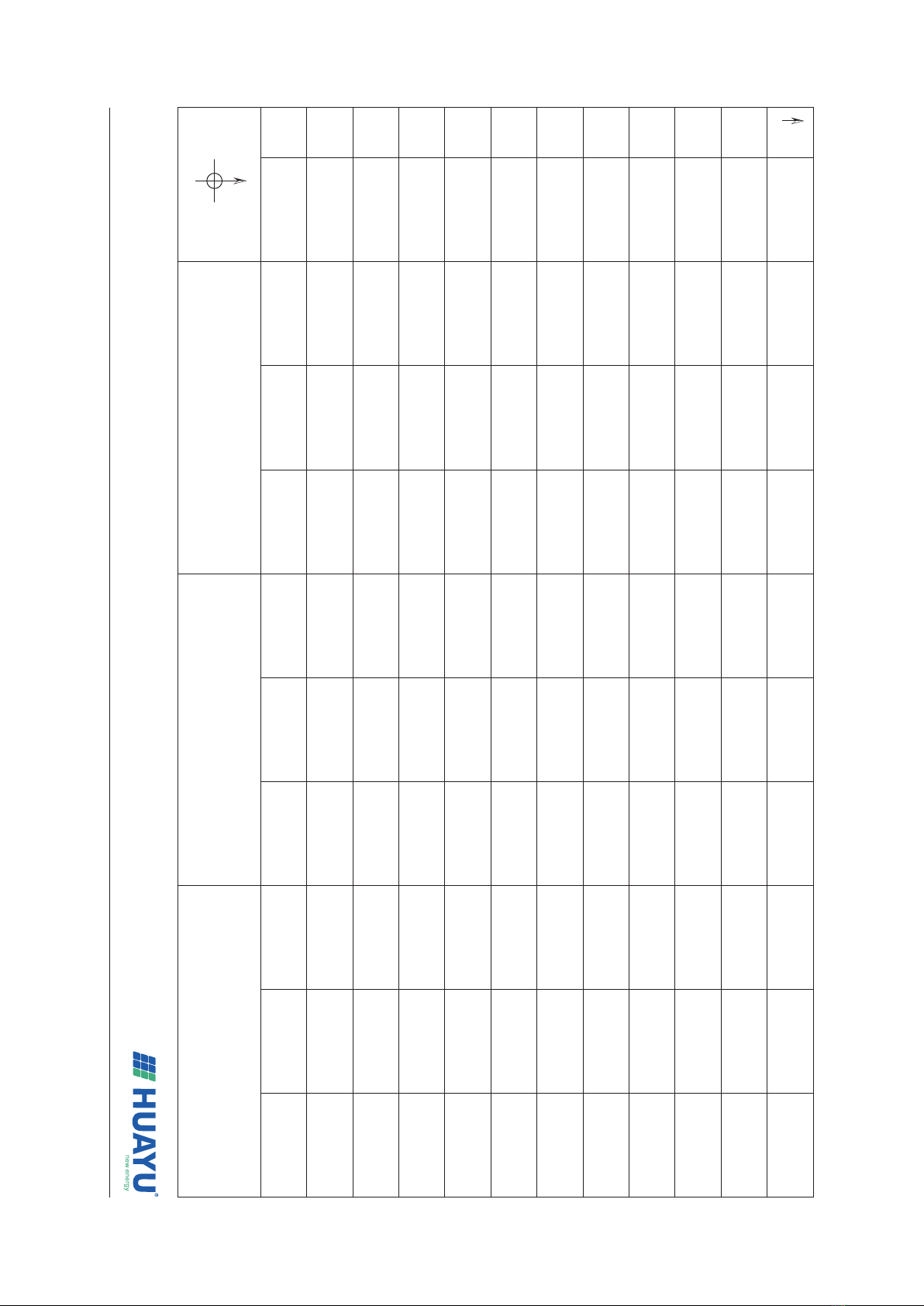

Step 4- Connect the Microinverters in Parallel

2Plug the male AC connector of Microinverter into the female connector to

get it connected. AC connector interface is as follows.

1Check Microinverter technical data for the maximum allowable number of

Microinverters on each AC branch circuit.

HY-1000/800-Plus