Contents

1. Safety Precautions 1........................................................................................................................................

1.1 Important Notice 1.................................................................................................................................

1.2 Signs and their Meanings 1...................................................................................................................

2. Product Information 2......................................................................................................................................

2.1 Model Implication 2..............................................................................................................................

2.2 Description of Nameplate 2...................................................................................................................

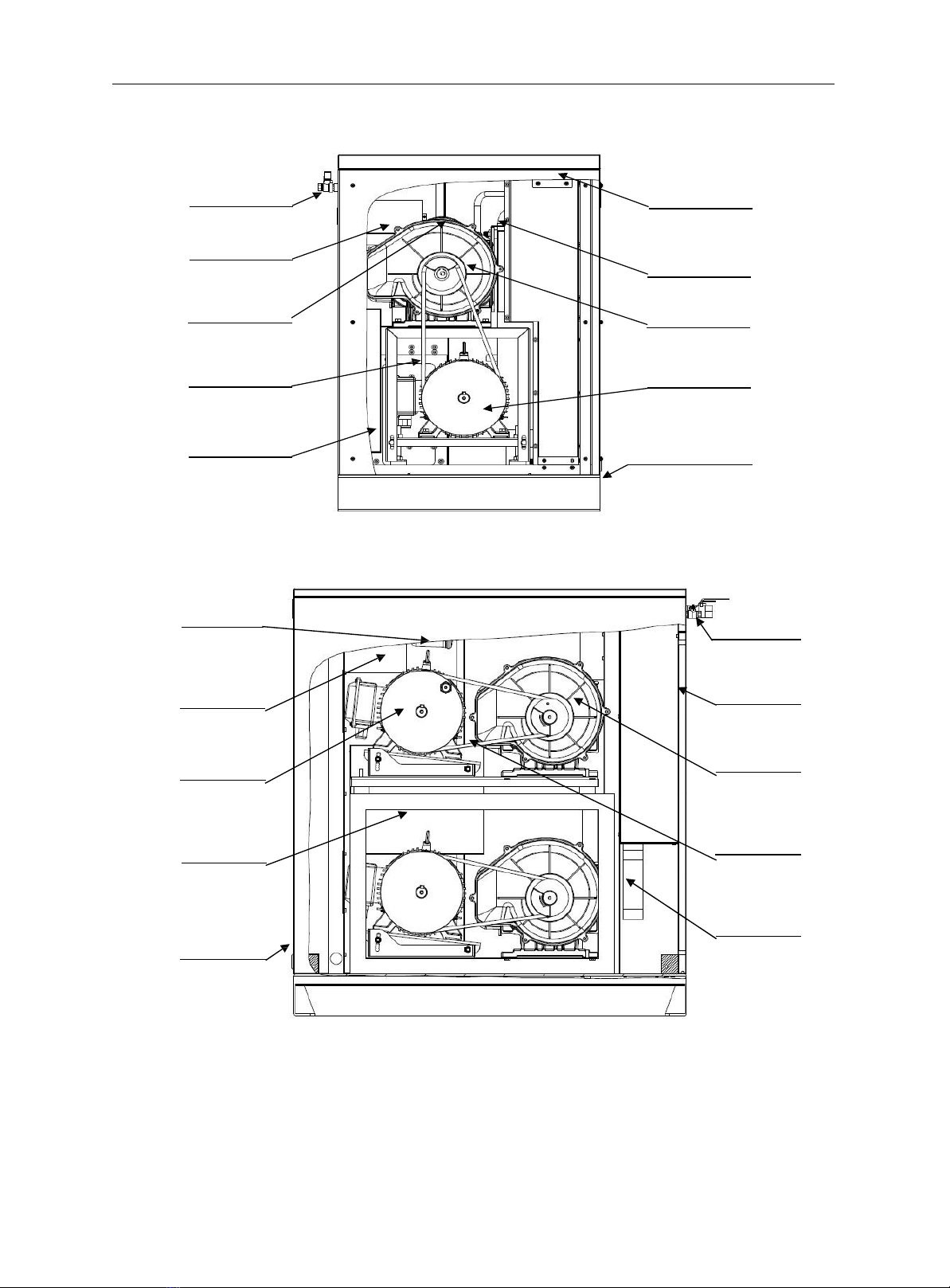

2.3 Description of Components 3................................................................................................................

2.4 Technical Specifications 4.....................................................................................................................

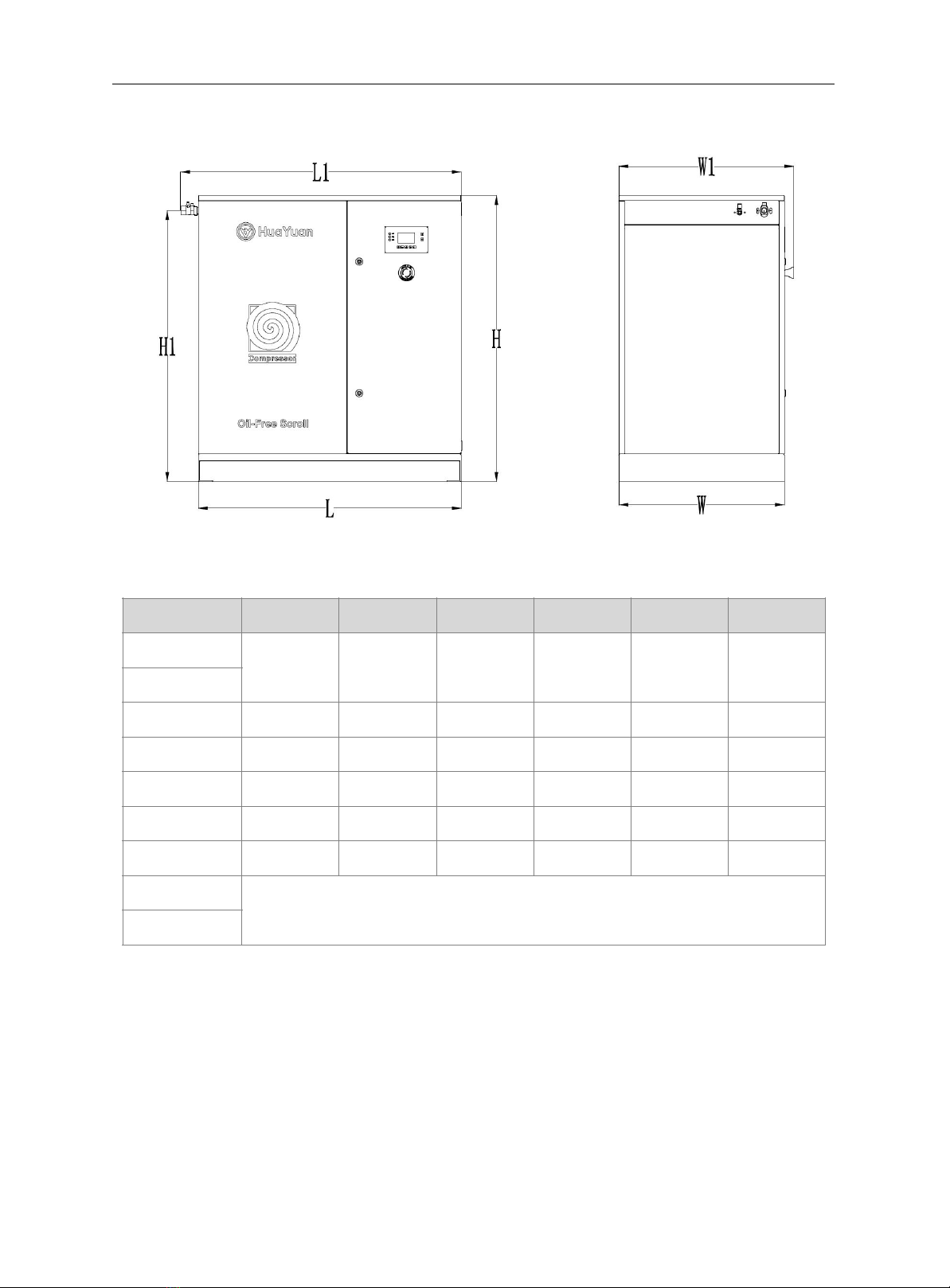

2.5 Dimensions 5.........................................................................................................................................

3. Installation 6....................................................................................................................................................

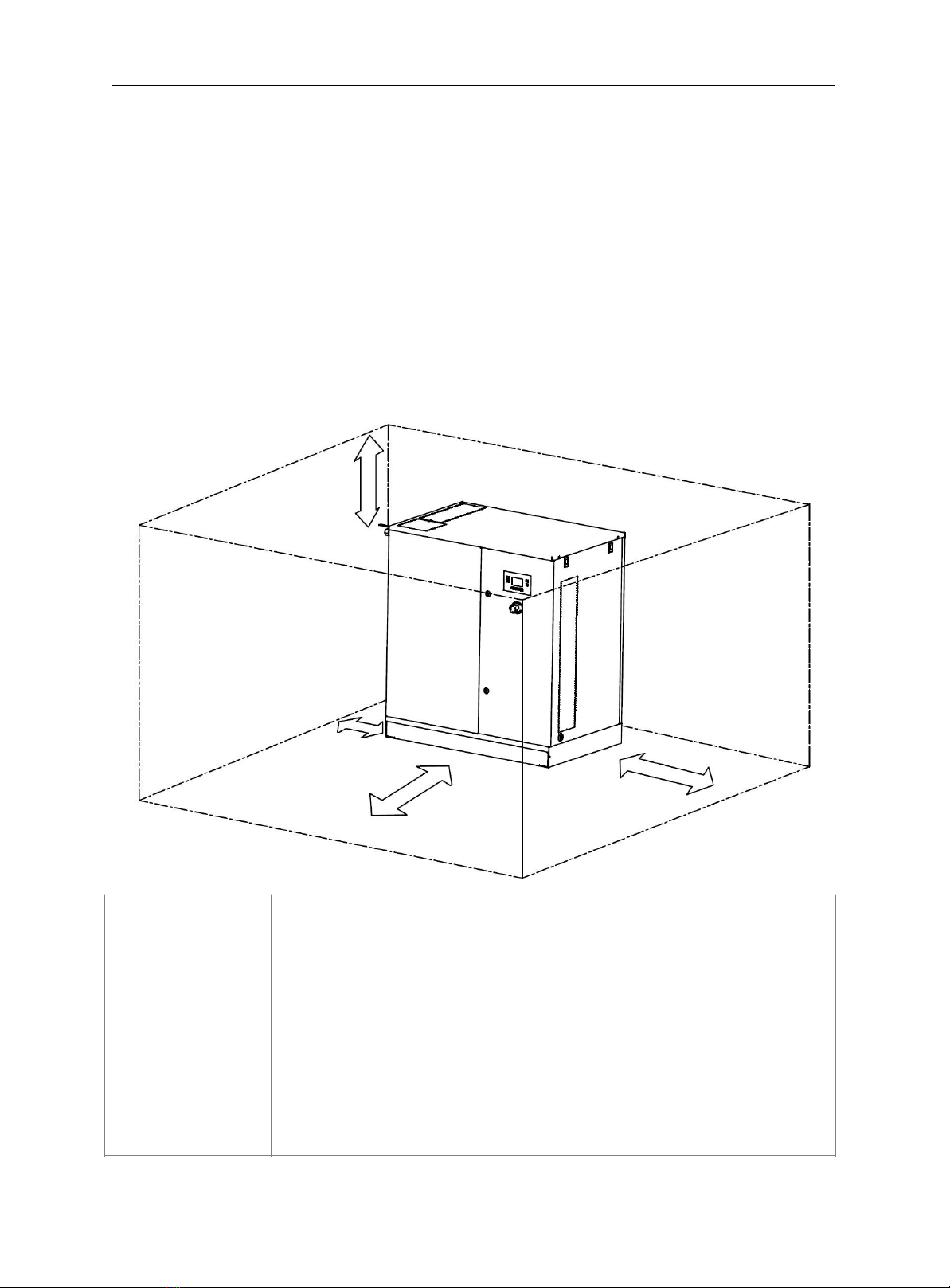

3.1 Operating Environment 6......................................................................................................................

3.2 Check before Installation 6....................................................................................................................

3.3 Installation Requirements 7...................................................................................................................

3.4 Piping and Air Storage 8........................................................................................................................

3.5 Main Circuit and Terminal Definition 9................................................................................................

3.6 Wiring and Connection 10.....................................................................................................................

4. Debugging and Use 11....................................................................................................................................

4.1 Description of Operation Panel 11........................................................................................................

4.2 Power-on and Trial Operation 12..........................................................................................................

4.3 Instructions on Use 13...........................................................................................................................

4.4 Precautions for Use 13..........................................................................................................................

5. Maintenance and Check 14.............................................................................................................................

5.1 Check Items 14......................................................................................................................................

5.2 Routine Maintenance 15........................................................................................................................

6. Troubleshooting 17..........................................................................................................................................

7. After-sales Service and Warranty 18...............................................................................................................

7.1 Installation and Training 18..................................................................................................................

7.2 Warranty Service 18..............................................................................................................................