Original Language Version

© Jack Sealey Limited

8DO NOT touch compressor cylinder, cylinder head or pipe from head to tank as these may be hot and will remain so for some time

after shut down.

8DO NOT attempt to move the compressor by pulling the air tool hose. Only move the compressor by the handle.

8DO NOT use this product to perform a task for which it is not designed.

8DO NOT deface the certification plate attached to the compressor tank.

8DO NOT cover the compressor or restrict air flow around the machine whilst operating.

8DO NOT operate the compressor without an air filter.

8DO NOT allow anyone to operate the compressor unless they have received full instructions.

▲DANGER! DO NOT direct the output jet of air towards people or animals.

WARNING! The air tank is a pressure vessel and the following safety measures apply:

8DO NOT tamper with the safety valve.

8DO NOT modify, weld or alter the tank in any way and DO NOT strap anything to the tank.

8DO NOT subject the tank to impact, vibration or to heat and DO NOT allow contact with abrasives or corrosives.

9DO drain condensation from tank daily and inspect inside walls for corrosion every three months and have a detailed tank

inspection carried out annually.

9The tank shell must not fall below the certified thickness at any point.

WARNING! If an electrical fuse blows, ensure it is replaced with an identical fuse type and rating.

9 When not in use for a long period, store the compressor carefully in a safe, dry, childproof location.

9 When the compressor is not in use, it should be switched off, disconnected from the mains supply and the air drained from the tank.

IMPORTANT WARNING - Air contaminants taken into the compressor will affect optimum performance. Example: Body filler dust or

paint overspray will clog the pump intake filter and may cause internal damage to pump/motor components. Please note that any parts

damaged by any type of contamination will not be covered by warranty.

2. INTRODUCTION

Aluminium cylinder head with cast iron lining gives reduced weight and improved resistance to wear.

Suitable for general purpose workshop applications. Oil free, single piston pump is belt driven by a

2hp motor and fixed to a vertical type tank, saving space around the workshop. Precision welded

receiver tank manufactured to meet the Pressure Vessel Directive. Fitted with fully automatic

pressure cut-out switch and air regulator with gauge. Supplied with handle and wheels for easy

manoeuvrability. Fitted with ASTA/BS approved non-rewireable plug.

3. SPECIFICATION

Model no.................................................................. SAC05030

Motor Output: ......................................................................2hp

Voltage/Phase: ........................................................ 230V - 1ph

Input Current: .................................................................... 6.5A

Max. Air Displacement:...................................................7.3cfm

Max. Free Air Delivery: ...................................................5.1cfm

Tank Capacity:.....................................................................50L

Max. Pressure: .....................................................145psi/10bar

Size (W x D x H)........................................ 380 x 400 x 875mm

Outlet.................................................... Quick release coupling

Noise Power: .................................................................. 97dBA

4. OPERATION

WARNING! Ensure that you have read, understood and apply Section 1 safety instructions.

IMPORTANT The use of extension leads to connect this compressor to the mains is not recommended as the resulting voltage drop

reduces motor, and therefore pump, performance.

4.1. Take care when selecting tools for use with the compressor. Air tool manufacturers normally express the volume of air required to

operate a tool in cubic feet per minute (cfm). This refers to free air delivered by the compressor (‘air out’) which varies according to the

pressure setting. Do not confuse this with the compressor displacement which is the air taken in by the compressor (‘air in’). ‘Air out’ is

always less than ‘air in’ - due to losses within the compressor.

4.2. STARTING THE COMPRESSOR.

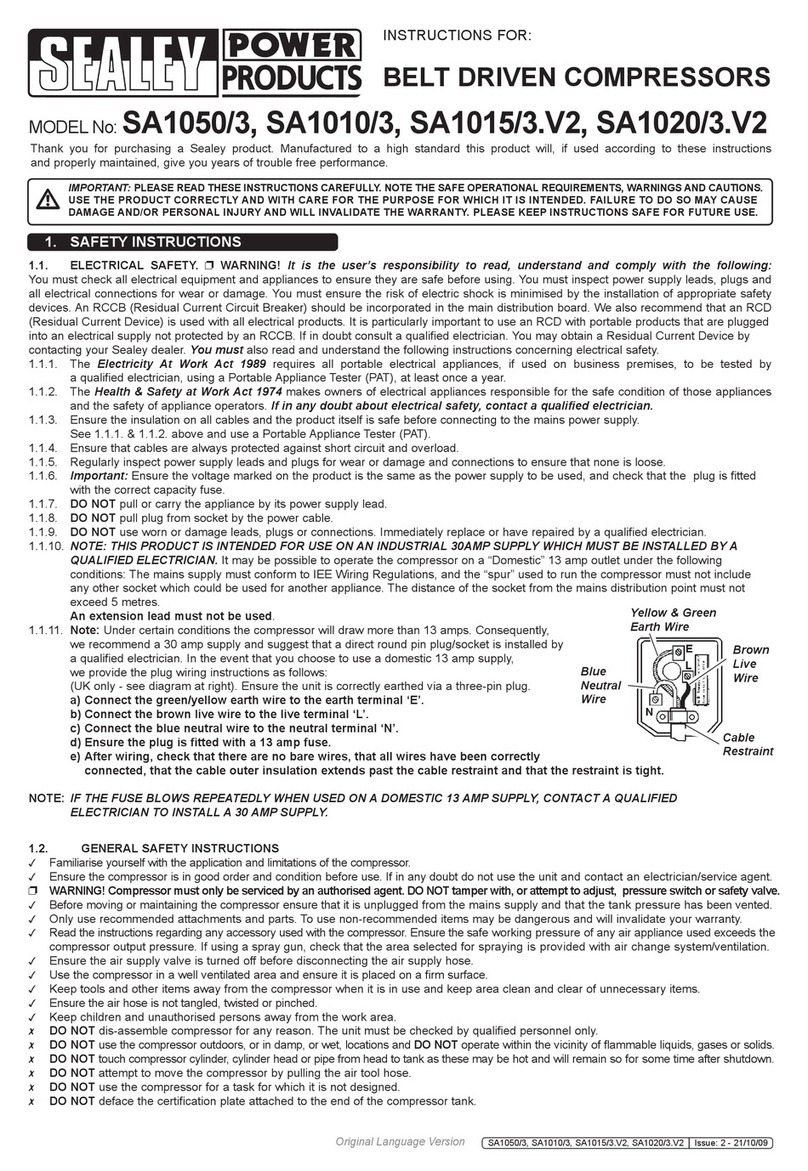

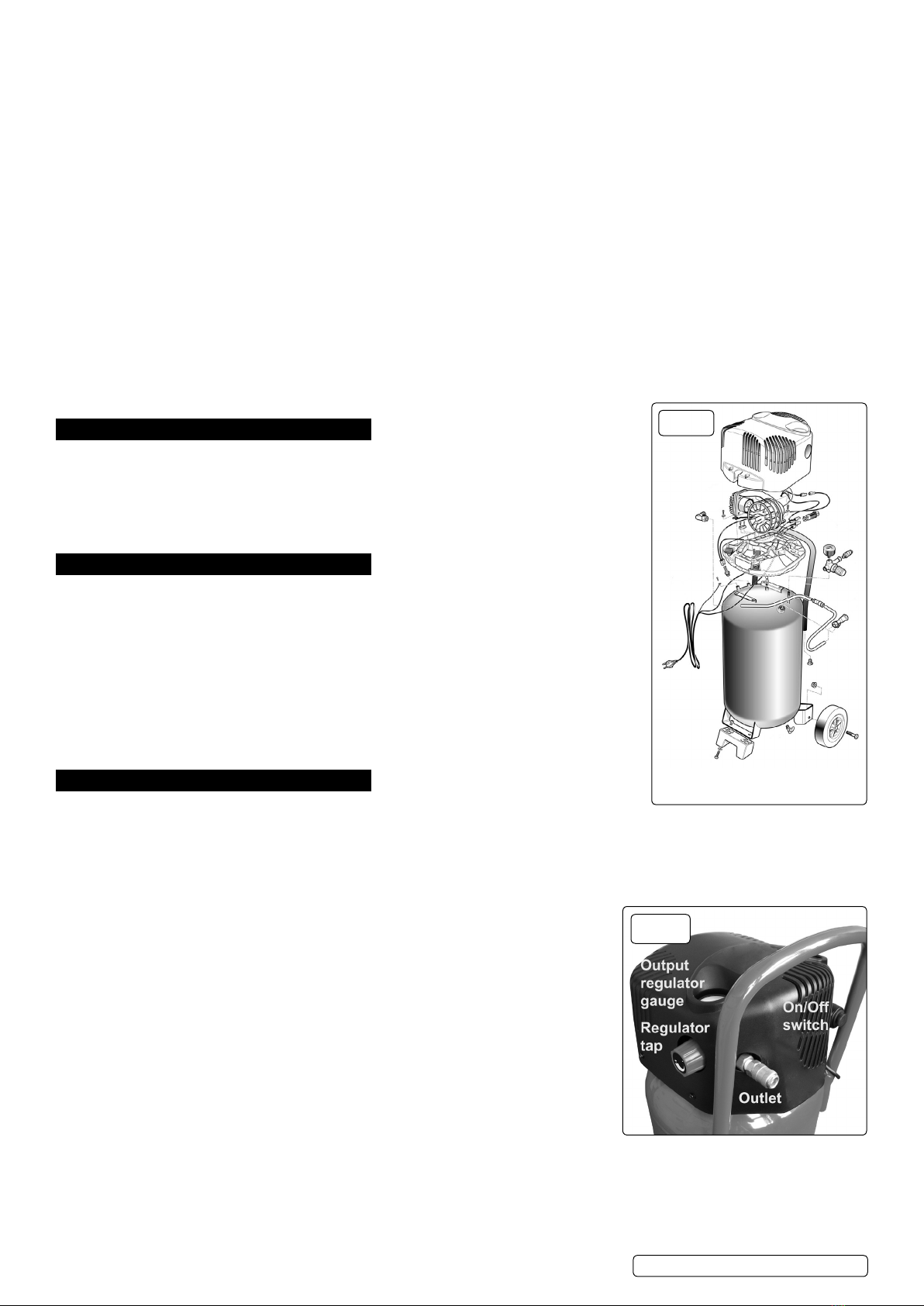

4.2.1. The compressor is tted with a push ON/OFF switch (g.2).

4.2.2. To turn the compressor ‘ON’ push the switch. To turn the compressor ‘OFF’ push the

switch again.

4.2.3. Check that the ON/OFF switch is in the “OFF” position and the regulator tap (g.2) is

closed (Zero ‘0’ bar, Anti-clockwise).

4.2.4. Plug mains lead into mains supply and start the compressor by pushing the ON/OFF switch.

4.2.5. Leave the compressor running with the regulator tap (fig.2) set to maximum pressure.

Make sure that the pressure in the tank rises and that the compressor stops automatically

when the maximum pressure value allowed - written on the specification plate is achieved.

The compressor will now operate automatically.

4.2.6. The pressure switch stops the motor when the maximum tank pressure is reached, and will

restart it when pressure falls below the minimum threshold - approx. 2 bar (29psi) less than

the maximum pressure.

4.2.7. Stop the compressor by pushing the ON/OFF switch (g.2). The compressed air inside the compressor head will flow out, making the

restart easier and preventing the motor from being damaged.

8DO NOT, other than in an emergency, stop the compressor by switching off the mains socket, or by pulling the plug out of the socket,

as the pressure relief will not then occur and motor damage may result upon restart.

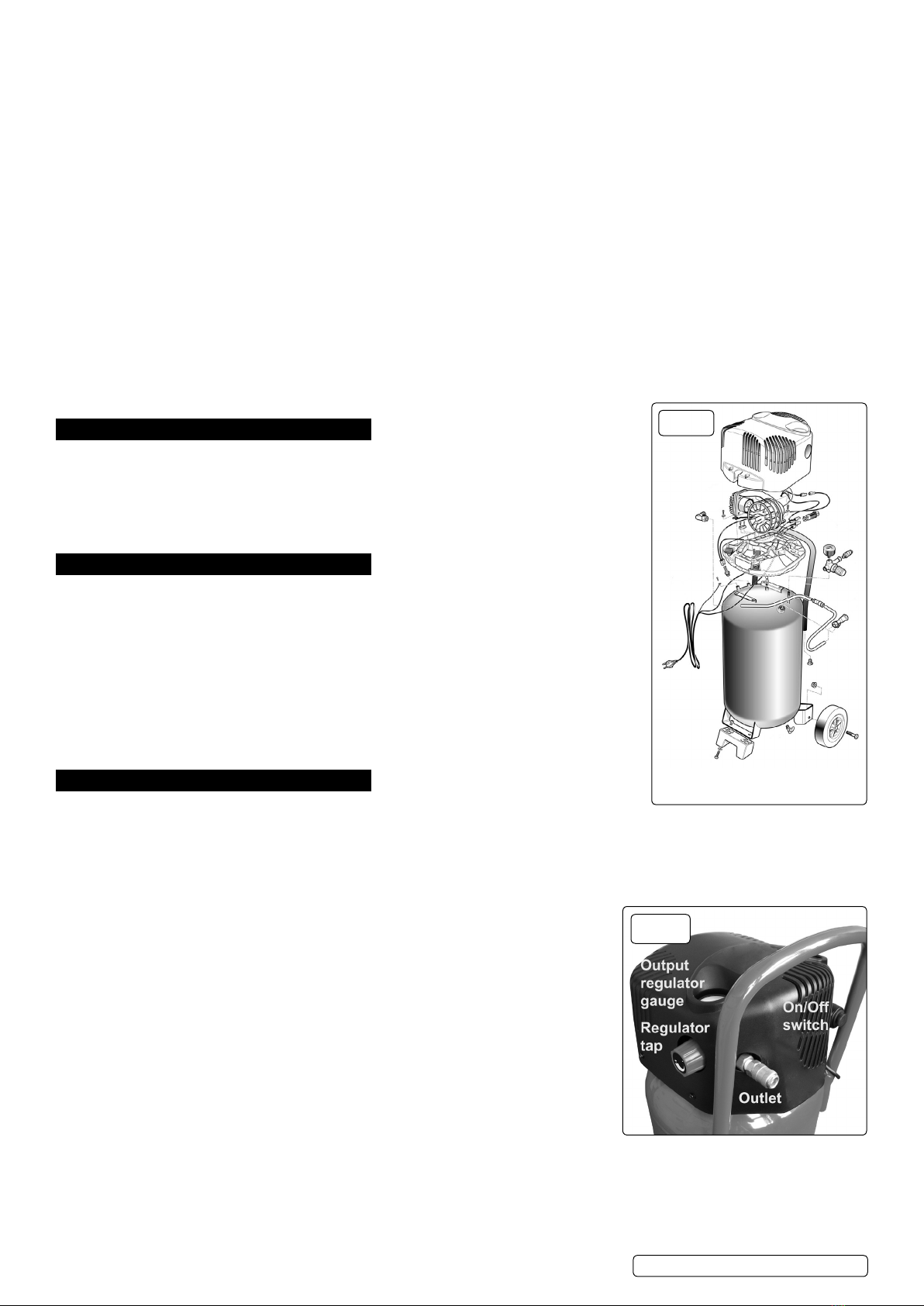

fig.1

fig.2

SAC05020 | Issue:3 (H,F) 01/08/19