Part No.: INST-HHD2500 02/12

3.0 START-UP

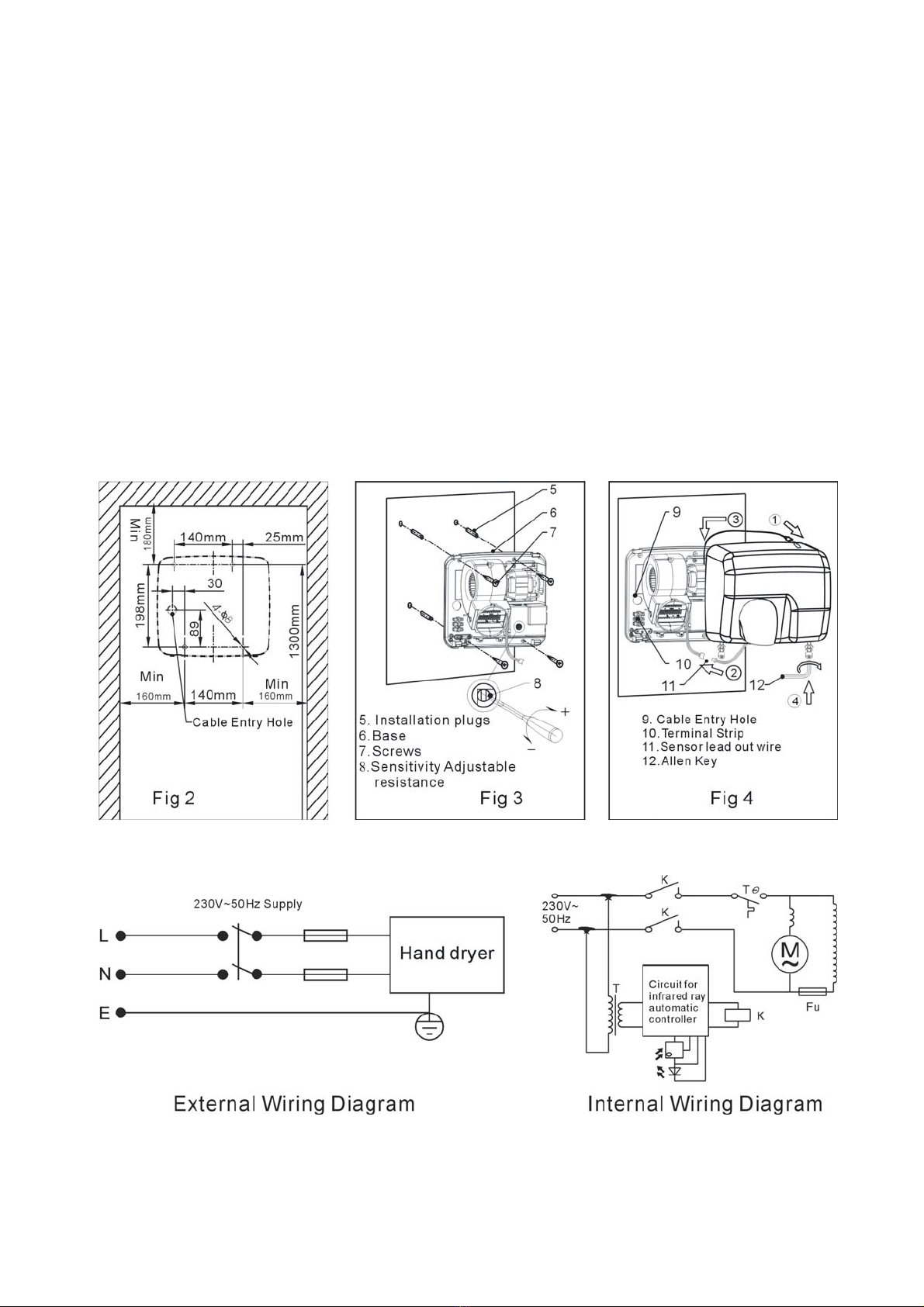

3.1 Before power is supplied to the unit, ensure that the wiring is correct as per the connection

diagram.

3.2 The infrared sensor will automatically activate the hand dryer if movement is detected up to

110mm from the sensor. The hand dryer will stop operating once movement is no longer

detected. The hand dryer will also stop operating after one minute of continuous operation.

3.3 The activation sensitivity can be adjusted per Fig. 3.

3.4 Check that the motor amperage draw does not exceed the nameplate rating.

4.0 FAN MAINTENANCE

4.1 Inspection of the hand dryer at least once every 12 months is recommended to ensure that the

motor, fan blades, and supporting guards, are clean. Any build up of dust and deposits on the

blades or guards should be removed using a non-abrasive cleaner.

4.2 All fastenings should be checked for tightness. In addition, all rotating items should be checked.

4.3 Bearings are of the ‘sealed for life’ type and will not need a detailed inspection.

WARNING – Do not cover the air inlet and outlet. The hand dryer is fitted with thermal protection

which switches the heating element off in the event of a fault condition.

Only a suitably qualified and competent person may carry out maintenance after the electrical

supply has been isolated.

GUARANTEE

HYDOR or its agents will, within a period of 1year from the date of dispatch from their works,

repair or, at its option, replace any goods, which are proven to have defects as a result of

defective materials or workmanship. The goods MUST be returned to HYDOR, carriage paid, for

examination.

Hydor Ltd.

8 Parkers Close, Downton Business Centre

Downton, Salisbury, Wiltshire

SP5 3RB, UK

Hydor Ventilation Aust

42-62 Pound Road West

Dandenong South

Vic 3175

TEL: 1300 655 730 FAX: 1300 134 319 email: info@hydor.com.au

Hydor Ventilation SA

11 Ingrid Road

Montague Gardens

Capetown

7441

Part No.: INST-HHD2500 Issue 7: 6-2-2012