2

1. Usage safety

Before connecting and launching the device we advise to read carefully this manual, which includes all important

information about safe installation, usage and maintenance of the demineralizer. This manual should be kept in

case of any issues that might appear during the running process.

1.1 Installation and service

•Every installation and service should be performed by an authorized technician. Installation or service

performed by a person without qualifications can may lead to incorrect system running or be dangerous

for the user.

•Before launching, the demineralizer should be unpacked and checked if it is damaged. In case of any

damage noticed, it should be described in the delivery documentation.

•Service should be performed only by an authorized technician. It is forbidden to perform a service by the

user himself.

•Before plugging in the device you should close the main valve.

•Water supplying the demineralizer should fit the requirements described in point 1.3. You shouldn't use

water that does not fit the bacteriological requirements or of unknown quality.

•Before plugging in the device make sure, that tension is compatible with the electric network.

•It is forbidden to run the device when the plug, supplying cable or the device itself is damaged.

•While moving the device, watch out for the supplying cable, as it might break or be damaged.

•Warning, the demineralizer is heavy. Be careful while moving it.

•The device and tank should be located in a place with easy access.

•To keep a good lifetime and long-term efficient work, the maintenance should be performed regularly.

•The producer is not responsible for any damages incurred from impropriate device installation.

1.2Supplying water parameters

•Demineralizer devices are intended for purifying tap water.

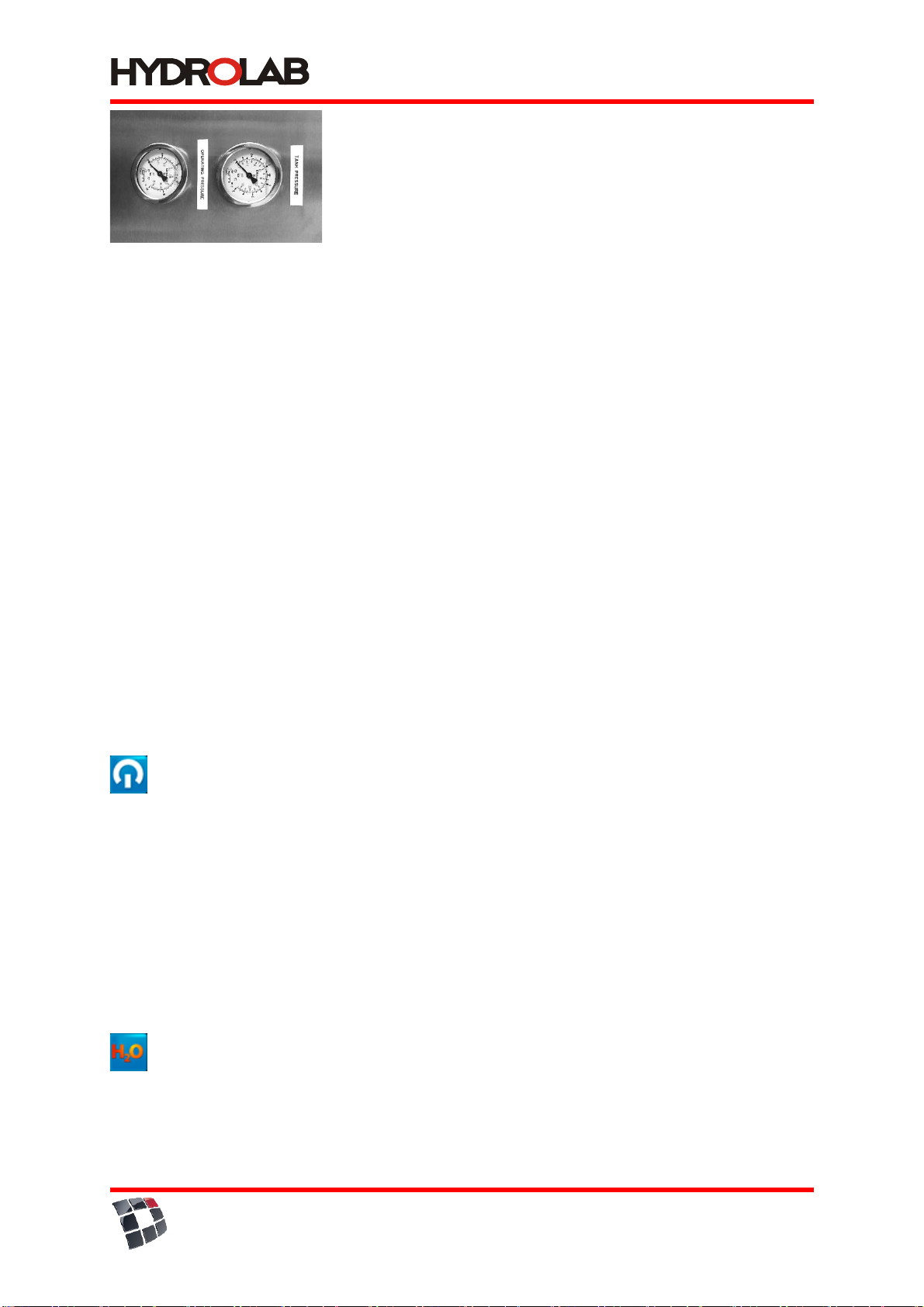

•Pressure –demineralizer can be supplied by water with 3,5 bar (min.) pressure up to 6.0 (max.) bar. If it

is necessary, you should use the reduction valve.

•Temperature –demineralizer should not be situated in locations of high or low temperature. Supplying

water temperature should fit between 4°C and 38°C. Supplying the demineralizer water of temperature

higher than 38°C may damage the device.

•Salinity (TDS) –amount of salts dissolved in supplying water should not excess 900mg/dm3.

•Humidity –relative humidity in the room should not be greater than 80%.

•Water hardness –Water hardness should not be greater than 280 mg CaCO3/dm3.

•Iron –should not be greater than 0,2 mg/dm3.

If any of this parameters is higher than recommended, better preliminary filtration is highly advised. In

that case, you should contact with our service.

1.3 Power supply voltage

•Rated voltage: 220-240V

•Frequency: 50 Hz

•Maximum consumption of power: 4A

2.General information

TECHNICAL demineralizers are devices perfect for washers, analyzers, autoclaves, environmental chambers,

water baths, as well as, through developing a proper network, supplying several laboratory rooms and

floors. They are fully-automated and maintenance-free.

Allows obtaining third class water, according to PN-EN ISO 3696:1999.