54 55

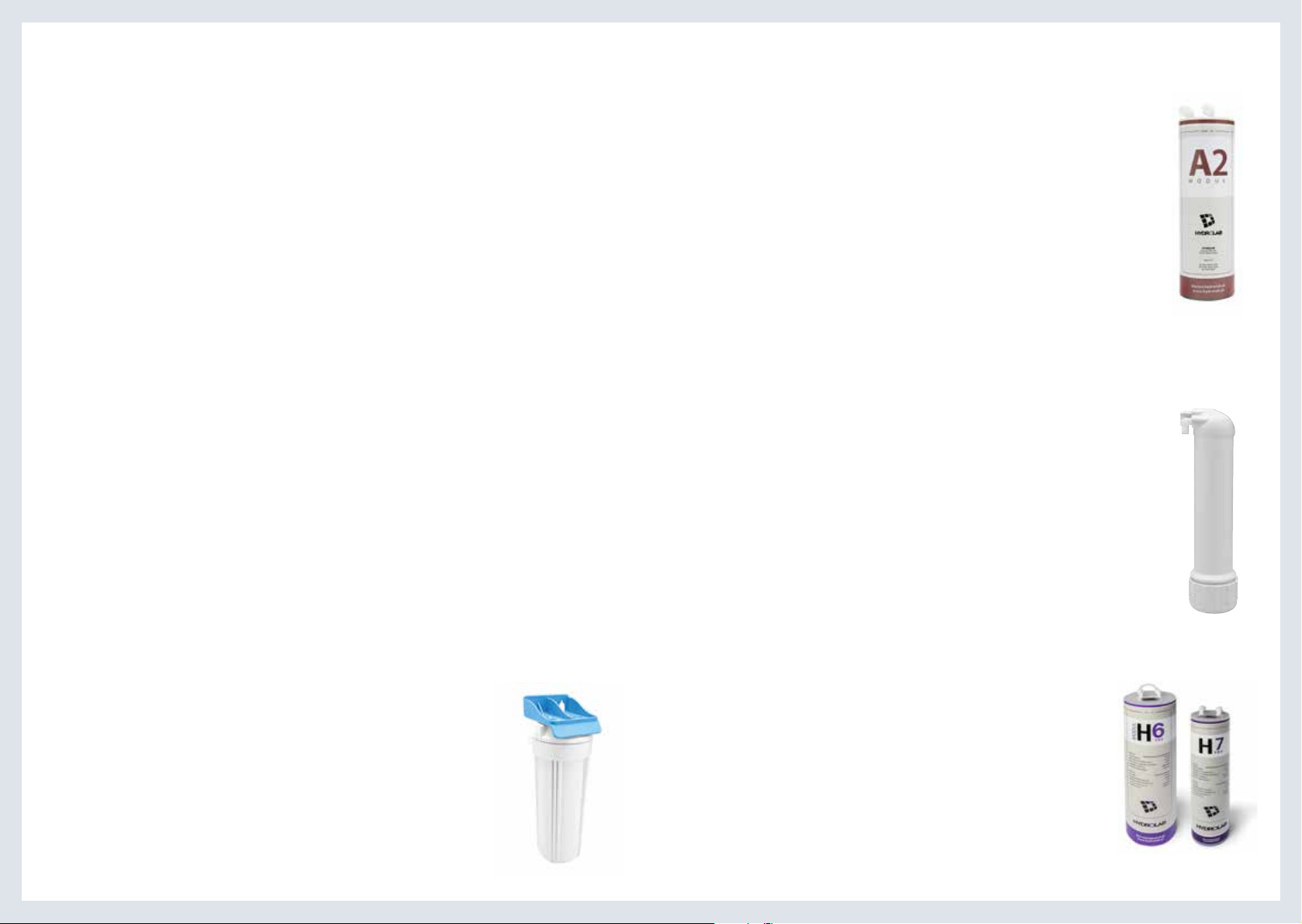

Moduł A2 (sediment-carbon-softening):

• Granulated activated carbon - prepares water for the reverse osmosis process. It

lters out all organical and chlorine-based contamination. Contaminants are sorped

on the activated carbon.

• Softening bed removes calcium and magnesium ions, that are responsible for

water hardness.

• 1 μm sediment lter - the last element of pre-ltration, protecting the water for

re-contamination. It lters out all of the mechanical contamination >1 μm.

2.3 Reverse osmosis module – RO

RO membrane holds up to 96-99% dissolved contamination (organic and non-orga-

nic), heavy metals, and radioactive elements of a 0.01 micron size.The osmotic water

conductivity varies between 8-20 μS/cm. Semi-permeable osmotic membrane con-

sists of many perforated layers wrapped around a core located inside the membrane.

Contaminated water is pushed underpressure on thesurface, where waterparticles by

diusion permeate through the membrane. The contamination is rejected and direc-

ted to the outow. Puried water passes through pores to the core, and under pressure

is directed outside the membrane.

2.4 Ion exchange bed demineralization

TOC ion exchange module - contains ion exchange beds in H+/OHˉ ion forms.

Osmotic water is puried by deionization columns, where all remaining mineral

salts are captured. In the ion exchange process ions and particles in water that

have a particular current are bound by ion exchangers (ionites). After this process

conductivity drops to 0,055 μS/cm.

2.0 GENERAL INFORMATION

The fully automated and unattended device has a microprocessor control and measurement system, that

constantly monitors all the stages of water purication process. Obtained water ts the requirements of the

PN-EN ISO 3696:1999, FP, ASTM standard for rst water purity class.

It has extensive automation enabling work monitoring, data archiving, individual setting of alarm thresholds

for parameters of feed water, reverse water osmosis and ultra-pure and control of the recirculation function

and the automatic ushing of membrane modules.The systems are equipped with a number of safeguards

allowing for comfortable operation of the device.

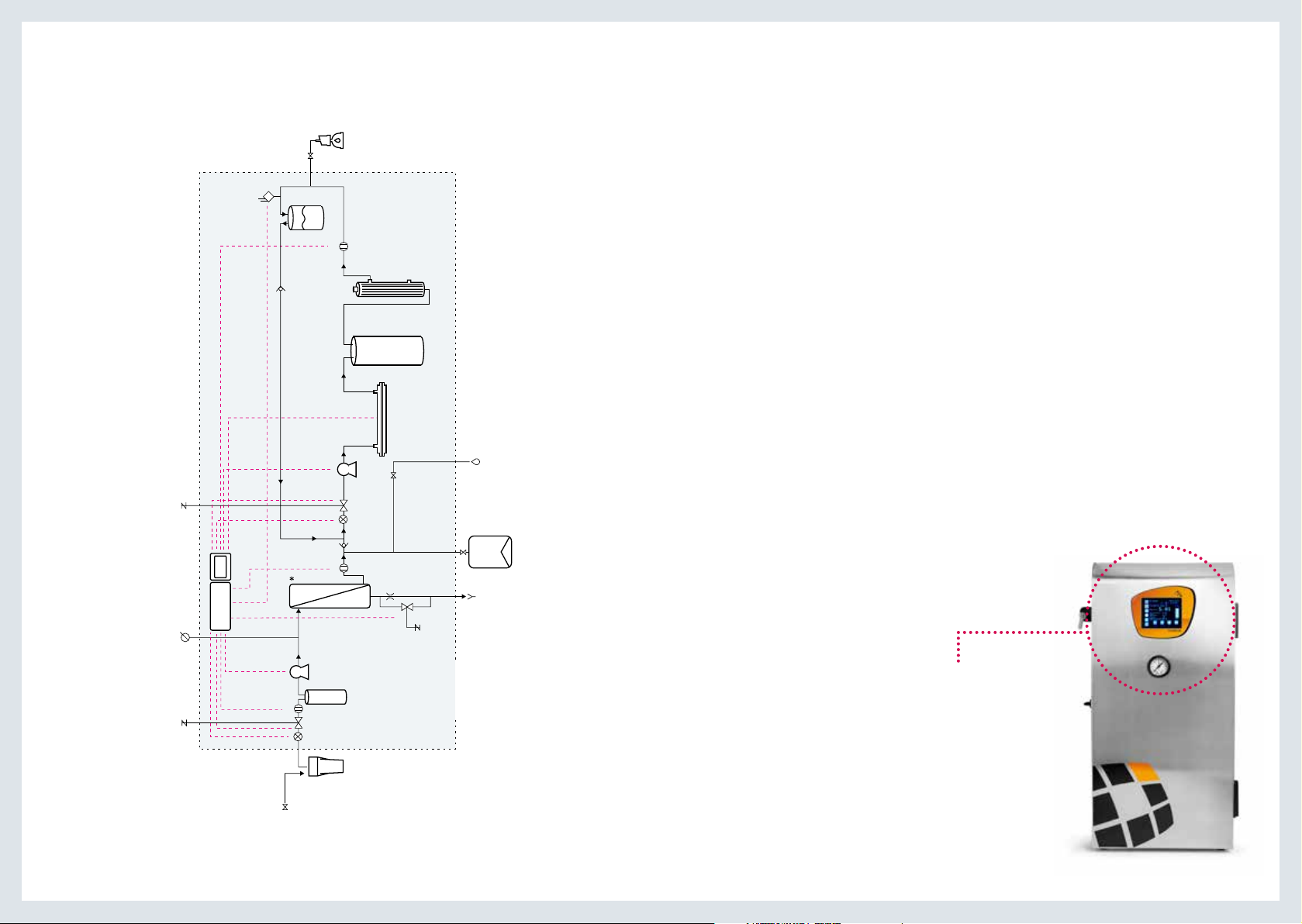

2.1 How it works

The demineralizer operates under tap water pressure. Water purication processes are fully automated

and unattended. The purication process consists of the following stages:

* depends on the model

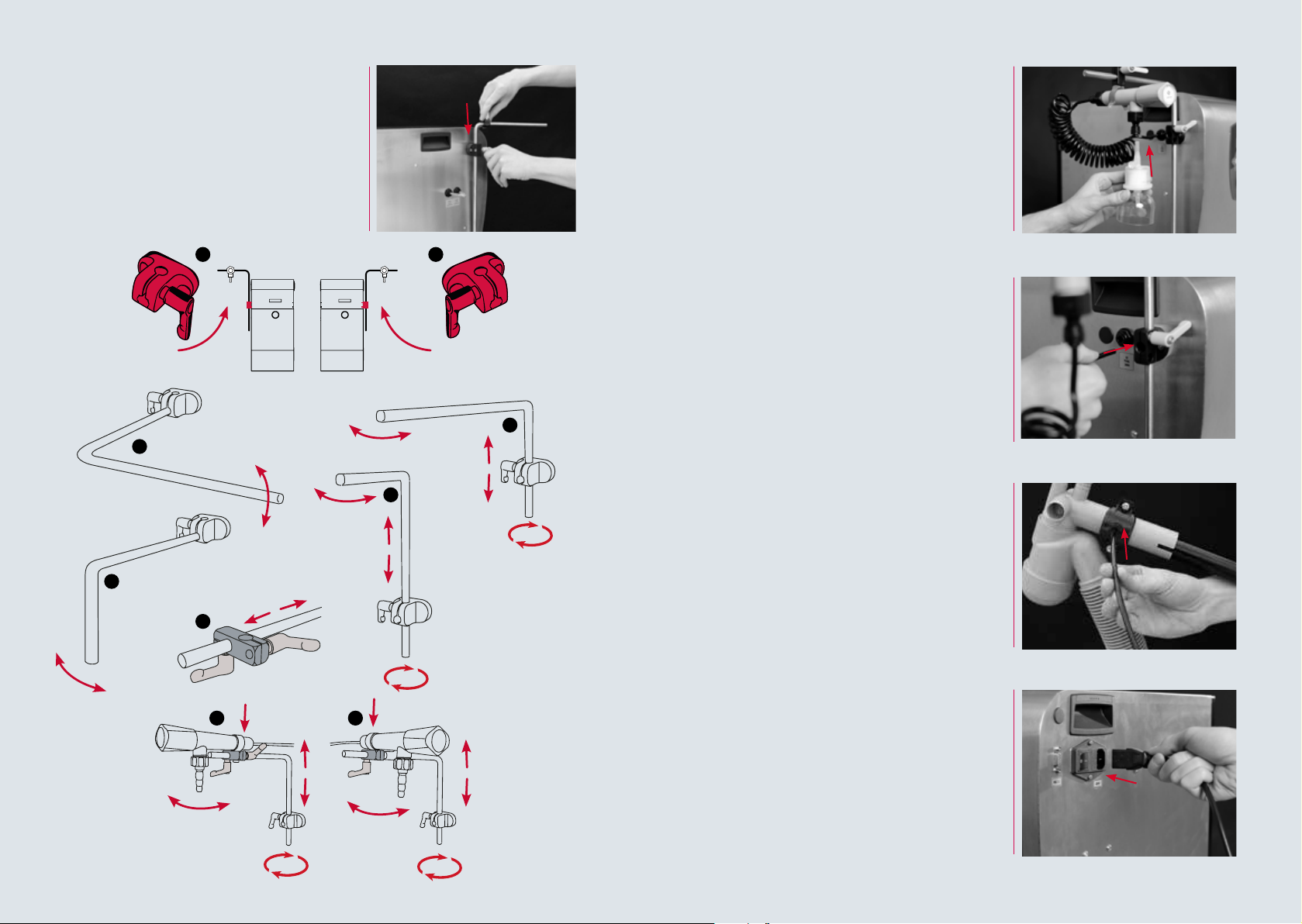

2.2 Mechanical-sediment-softening ltration

5 μm pre-lter - sediment lter is used for preparing water for further treatment with

the reverse osmosis. It consists of a polypropylene cartridge located in a transparent lter

housing. It holds all types of mechanical contamination of a diameter larger than 5 μm.

1. Mechanical ltration

2. Sediment-carbon-softening ltration

3. Reverse osmosis (RO)

4. Mixed TOC bed demineralization

5. UV lamp 254 nm*

6. UV lamp 185 / 254 nm*

7. Microltration capsule

8. UF ultraltration module*