3.3

Operational Notices

4 -

Operating Guide

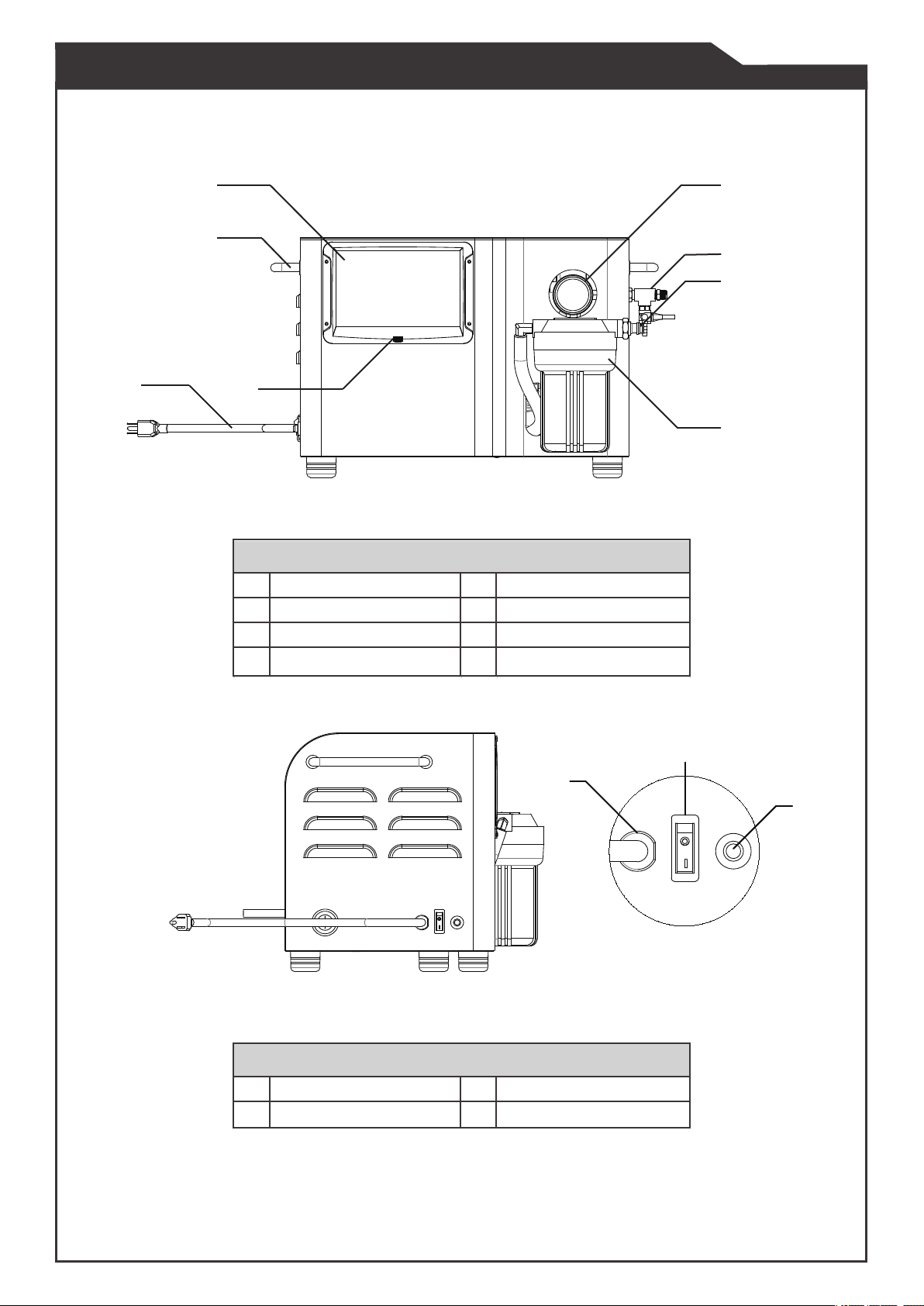

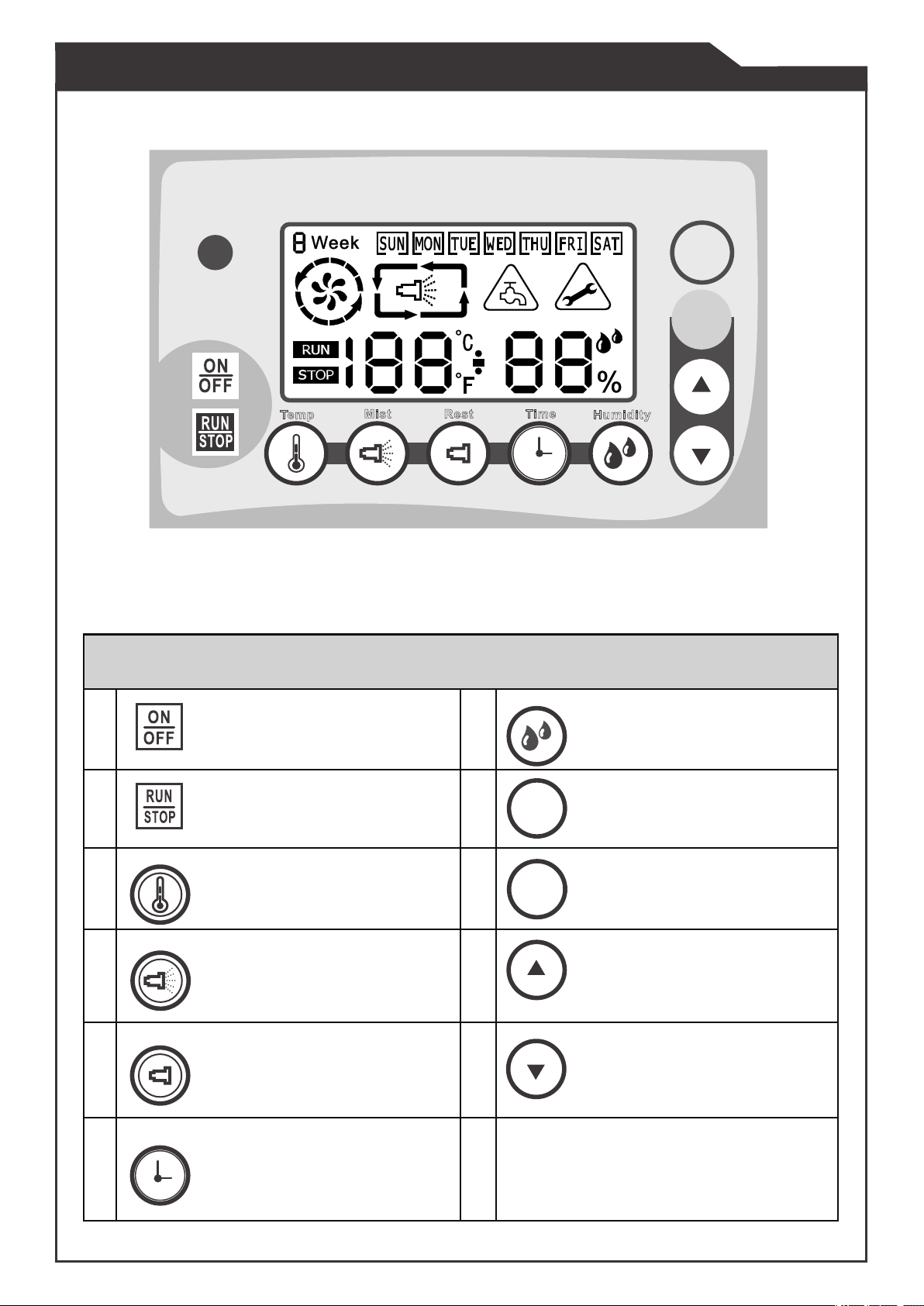

4.1.1 Acceptable power sources include AC 100V-240V, 50Hz or 60 Hz.

4.1.2 Ambient Temperature must be between 32-120oF and relative

humidity between 5% - 95%.

4.1.3 Internal power for controls is DC 12V.

4.1.4 3 relays control the functions.

RY1:drives the electric motor.

RY2:drives the inlet solenoid valve.

RY3:drives the by-pass solenoid valve

4.1.5 Blue back-light LED screen.

4.1.6 Infrared transmission remote control.

4.1.7 RTC time control, programmable.

4.1.8 6 operating modes available.

4.1.9 Both Celsius and Fahrenheit systems are available.

4.1.10 Detecting function for humidity.

4.1.11 Buzzer/alarm for timer.

7

4.1 Control Box Specifications

3.3.1

The water supply hose must be at least 3/8" size garden hose.

3.3.2

3.3.3

Verify the flow rate for water supply is at least 1 gpm. The water pressure at pump

inlet should be at least 40 PSI.

3.3.4

Water temperature must not exceed 140 oF, and must be well-filtered. Poor water

quality will decrease the service life of the pump and components.

3.3.5

Where applicable, install a pressure relief device in the event that excess pressure

over 1500 PSI occurs in the misting system.

3.3.6 A valve installed at the end of a misting system is recommended. It will help purge

the system of air inside the pipes or lines. This can also be useful to flush lines before

winter weather to prevent freezing water damage due to expansion.

3.3.7 When misting, check all nozzles and ensure none are blocked. If blocked,

clean or replace the damaged nozzle.

Check that all connections are watertight ant not leaking. Leaking connections

will decrease the system pressure and affect misting nozzle performance.

For winter storage, run the pump, shut off the water supply, and allow the pump to

shut off due tothe inlet water sensor. Remove water from filter housing and purge

any lines or pipes connected to the high pressure side of the misting system.

Extension cables should not be used to power the unit. If necessary, keep the cable

length below 25 feet, and use an adequately rated cord designed for outdoor use.

3.3.8

3.3.8