S858/4

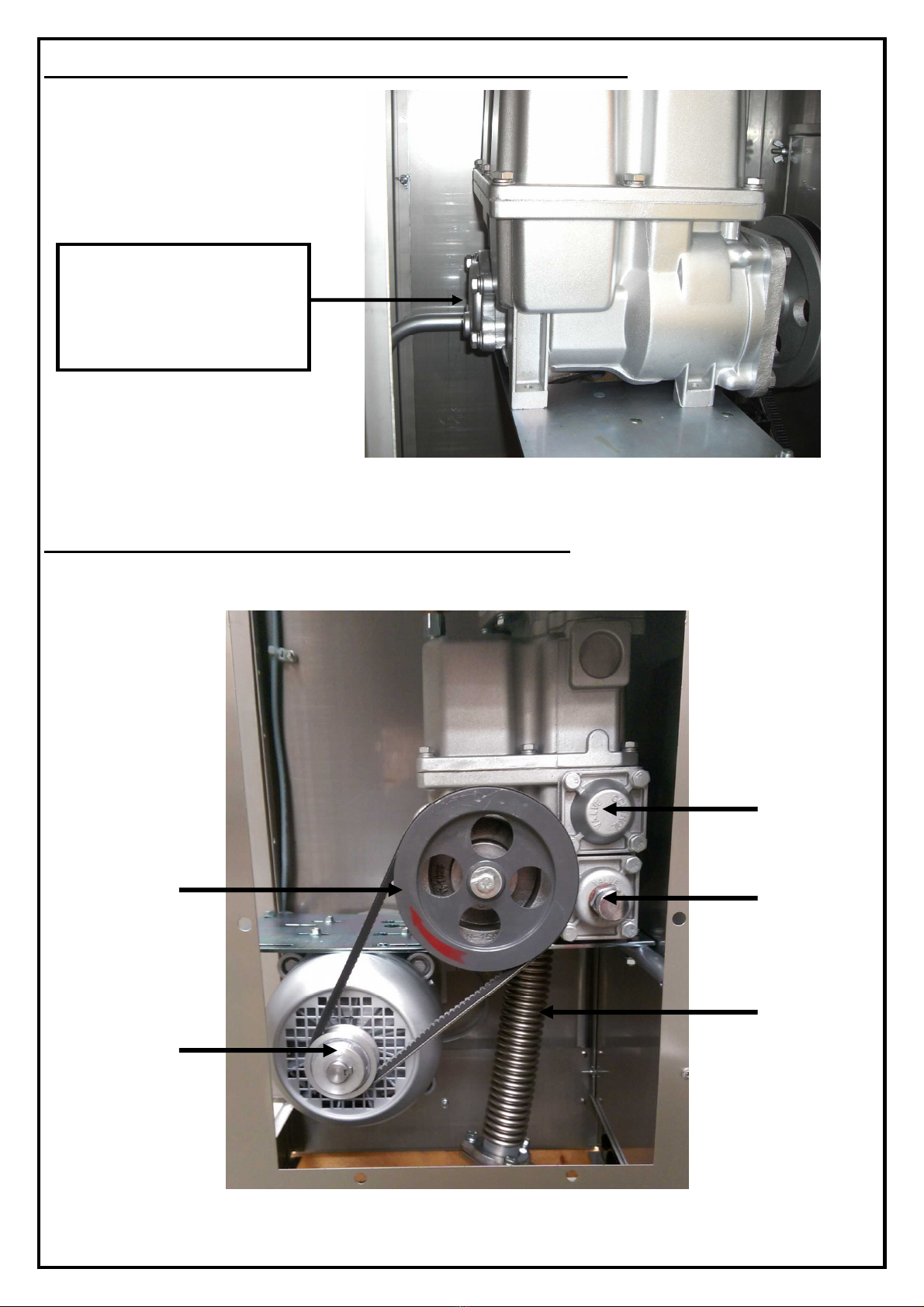

6. Connect one end of the delivery hoses into the outlet elbow.

Ensure the nylon hose-sealing washers are in place on the

hose end. It should be hand tight plus a quarter turn.

7. Screw the nozzles onto the other ends of the hoses, again

ensuring the nylon washers are in place. No other sealing

compound is necessary. Hand tight plus a quarter turn.

ELECTRICAL

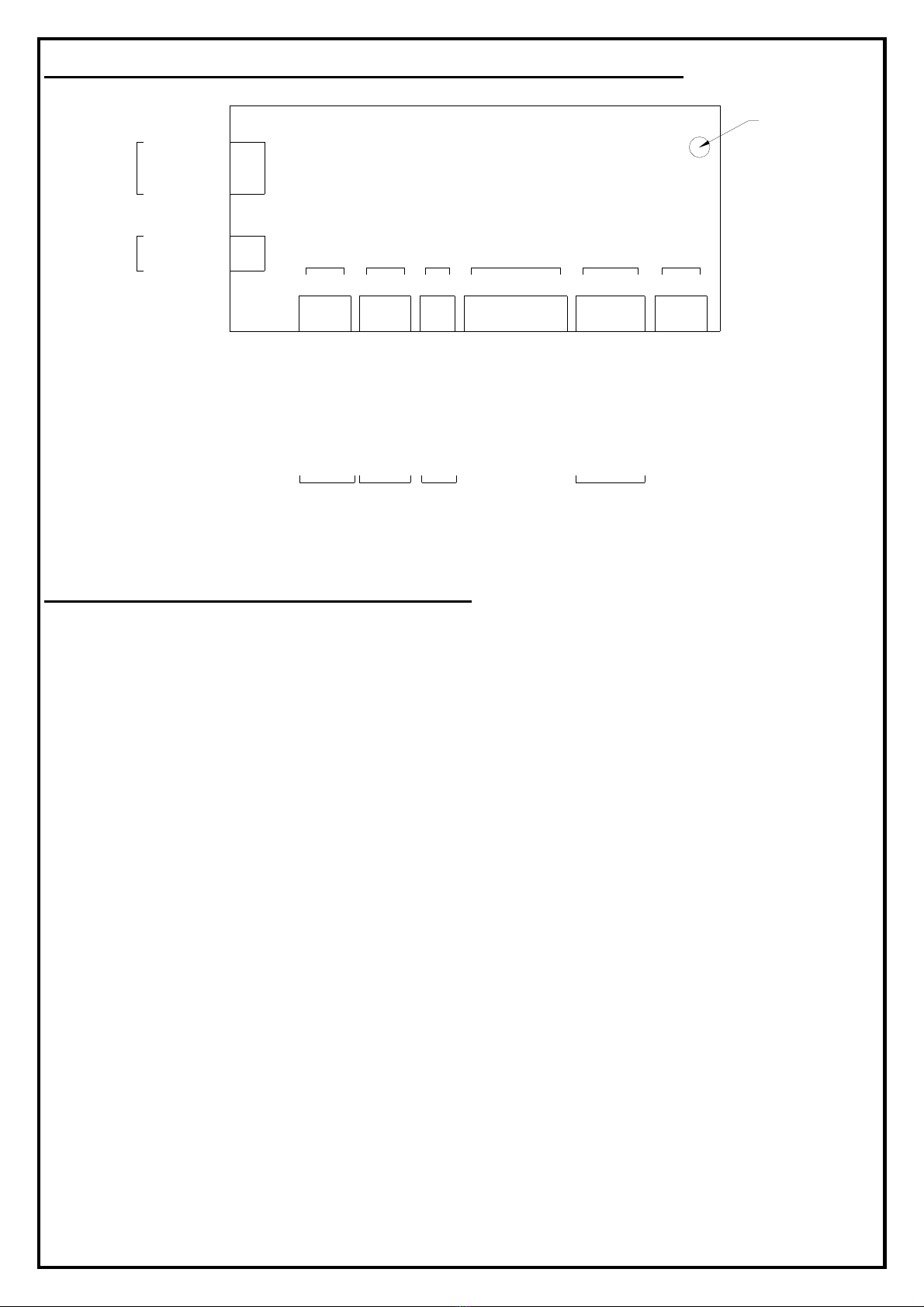

8. Remove the cover from the junction box.

9. Connect two constant 220/240V AC 50 Hz supplies, fused at

16 amps, to the terminal blocks in the junction box as shown

on the wiring details diagram.

NB:The Alpha pump must have a continual 220/240V AC

supply, even when not in use

10.If the Alpha is to be operated in conjunction with a key/card

system, remove the links in the junction box (shown on the

Alpha Installation Wiring Diagram) and connect so that the

control system makes and breaks the connections.

Make connection - Pump on

Break connection - Pump off

Alternatively remove the links and connect a switched live

supply (230V AC 16A max.) to each terminal 4 (shown on the

Alpha Installation Wiring Diagram)

Live supply switched on - Pump on

Live supply switched off - Pump off

11. A pulse output for connection to key/card systems is available

from the separate terminals located in the junction box. This is