S886/3

INSTALLATION INSTRUCTIONS

1. Check you have the following items:

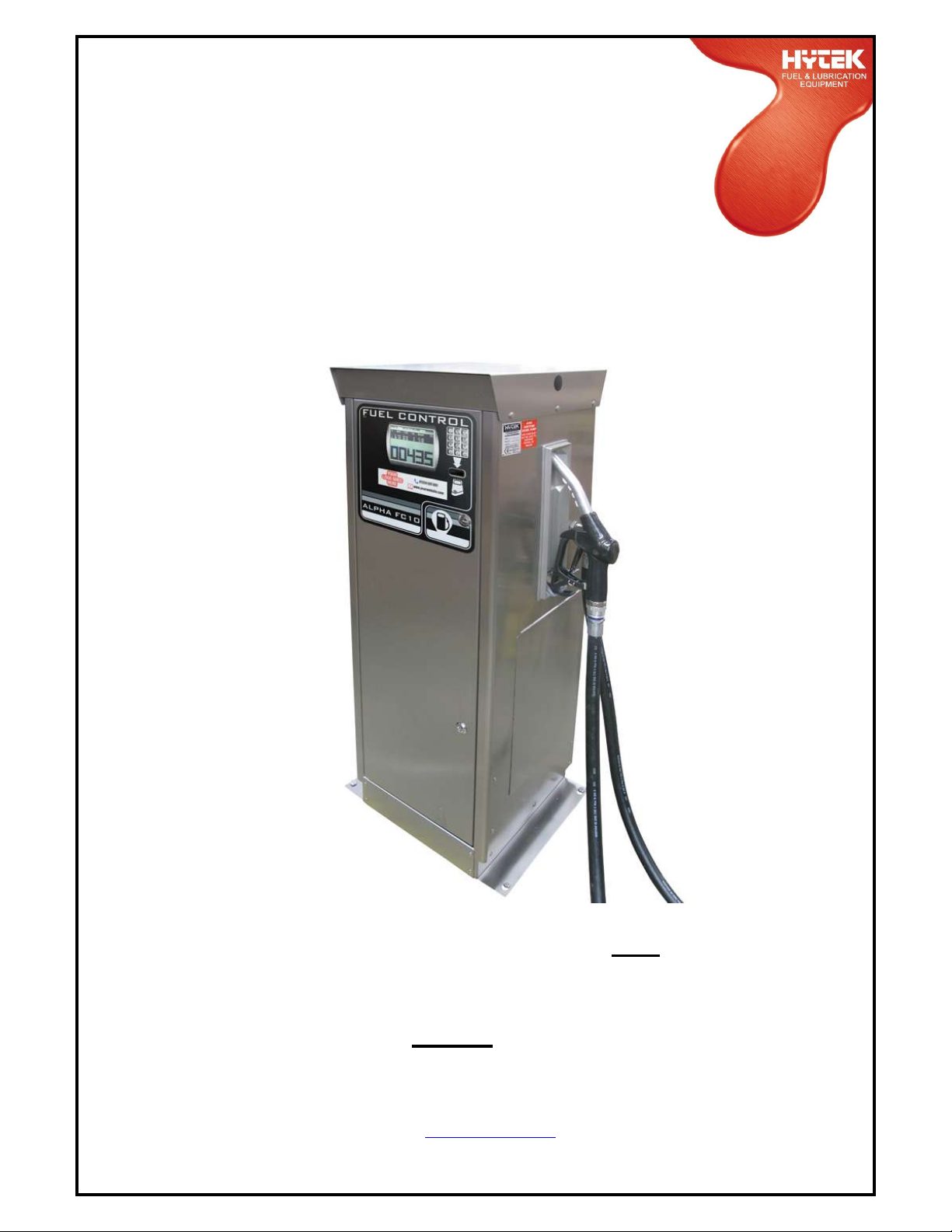

1 off Alpha FC10 pump

1 off delivery hose

2 off front door keys

2. Open the front panel using the key provided.

3. Remove the rear panel, if necessary, and store safely.

MOUNTING

4. Bolt the pump to a firm level foundation by means of the four 14 mm

diameter-mounting holes provided.

NB: If the optional drip tray is to be fitted to the pump it must be

sealed to its foundation, with a suitable elastomeric substance,

to prevent leaked fuel "wicking" back underneath the pump. To

maintain the environmental integrity of the drip tray any possible

leak path through the pump mounting holes must also be

sealed.

PIPEWORK

5. Connect the 11/2” diameter pipe from the tank to the suction inlet

flexible connector of the pump. The inlet thread of the flexible

connector flange is 11/2” BSP taper female. Seal the joints with a

suitable thread sealing compound. The pipe work must be sealed to

the drip tray (if fitted) to ensure no leaking fuel can flow underground.

An alternative pipe work entry point, for above ground pipe work, is

provided at the rear of the pump base. Push out the plastic cover

plate if required.

NB: On above ground tanks an angle check valve fitted with the

appropriate spring or an anti-syphon valve must be fitted in the

suction line to prevent spillage or leakage in the event of damage.

6. Connect one end of the delivery hose into the outlet elbow. Ensure the

hose-sealing washer is in place on the hose end. It should be hand

tight plus a quarter turn.

7. Screw the nozzle onto the other end of the hose, again ensuring the

washer is in place. No other sealing compound is necessary. Hand

tight plus a quarter turn.