11. Monitor ...........................................................................................................................199

12. RC Gateway Function Setting ........................................................................................223

13. How to Reset an Absolute Encoder ................................................................................224

13.1 Orthogonal Axis (Absolute Specification) (excluding XSEL-RA/SA, RAX/SAX) ................................... 224

13.2 Orthogonal Axis (Battery-less Absolute Specification and XSEL-RA/SA, RAX/SAX) ........................... 227

13.3 Scara Axis ............................................................................................................................................. 230

13.3.1 Absolute Reset Preparation ......................................................................................................... 230

13.3.2 Starting the Absolute Reset Menu................................................................................................ 231

13.3.3 Absolute Reset Procedure for Arm 1 or 2 .................................................................................... 232

13.3.4 Absolute Reset Procedure for Rotation Axis + Vertical Axis ........................................................ 239

13.4 IX-NNN10040 and 12040 SCARA Axes................................................................................................ 249

13.4.1 How to Operate the Push Type Absolute Reset ............................................................................ 250

13.4.2 How to Acquire the Stopper Interfering Point................................................................................. 262

13.5 IXP SCARA Axis.................................................................................................................................... 275

13.6 ZR Unit .................................................................................................................................................. 284

13.6.1 Absolute Reset on ZR Unit (Absolute Type Only).......................................................................... 284

13.6.2 Ball-screw spline adjustment on ZR unit (Incremental type) ......................................................... 299

13.7 Simple absolute Unit for PSEL Controller (Option) ............................................................................... 308

13.7.1 Instructions of Absolute Reset ....................................................................................................... 308

13.8 IXA SCARA Axes................................................................................................................................... 312

13.8.1 Stopper Pressing System Absolute Reset Operation .................................................................... 313

13.8.2 Procedure for Stopper Pressing Position Acquirement Operation................................................. 329

14. Supplemental Information on Controller Menu Items......................................................349

14.1 Software Reset...................................................................................................................................... 349

14.2 Reset Error ............................................................................................................................................ 349

14.3. Drive-source Recovery Request and Operation-pause Reset Request ............................................... 350

14.3.1 In the cases of Controllers Other Than SSEL, ASEL or PSEL Controllers.................................... 350

14.3.2 In the cases of SSEL, ASEL or PSEL Controllers.......................................................................... 351

14.4 Setting Time .......................................................................................................................................... 352

14.5 SEL Global Data Backup....................................................................................................................... 352

14.6 Control Constant Table Management Information ................................................................................ 354

14.7 Execution Stop of Positioner Mode of SSEL, ASEL or PSEL Controller............................................... 355

14.8 Getting Positioner Mode Information from SSEL, ASEL and PSEL Controllers ................................... 356

14.9 Positioner Mode Management Information for SSEL, ASEL or PSEL Controller ................................. 357

14.10 Excel File Save and Readout (Version V13.01.00.00 and later)........................................................... 358

14.10.1 Excel File Save .............................................................................................................................. 358

14.10.2 Excel File Readout......................................................................................................................... 360

14.10.3 Excel File Create and Edit ............................................................................................................. 361

14.10.4 Caution........................................................................................................................................... 361

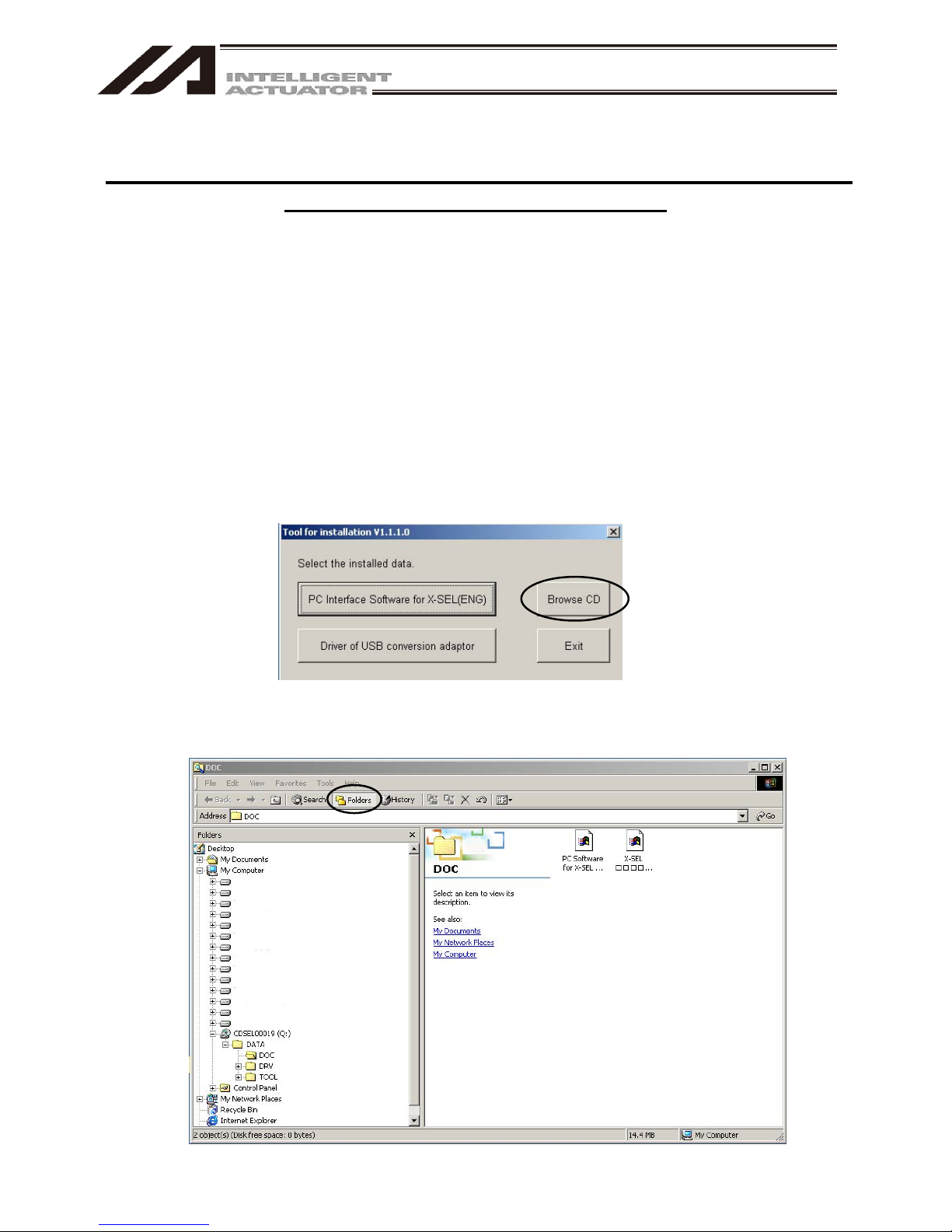

15. Tool.................................................................................................................................362

16. Appendix ........................................................................................................................366

16.1 Parameter Recovery Method for X-SEL-P/Q, PX/QX, R/S, RX/SX, RXD/SXD, RA/SA, RAX/SAX,

RAXD/SAXD Controllers ....................................................................................................................... 366

16.2 Error Level Control ................................................................................................................................ 372

16.3 X-SEL PC Software Error Table............................................................................................................ 373

Change History .....................................................................................................................379