INSTALLATION AND OPERATION INSTRUCTIONS

1-2

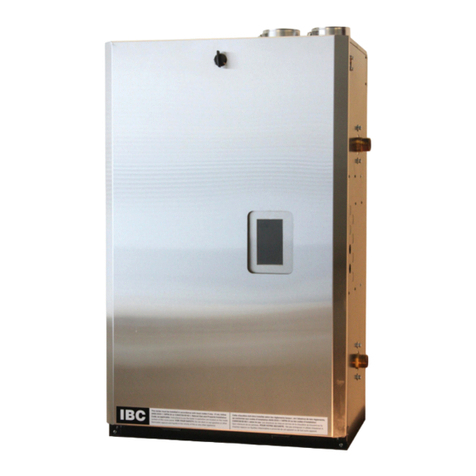

HC SERIES BOILERS HC 13-50, HC 15-95, HC 15-96, HC 20-125, HC 33-160

CODE REQUIREMENTS

The HC 13-50, HC 15-95, HC 15-96, HC 20-125, HC 33-160 models were tested

to and certied under CSA 4.9 / ANSI Z21.13.

The installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, and/or Natural Gas and Propane Installation Code,

CAN/CSA B149.1. The installation must also conform to the Canadian Electrical

Code Part 1 CSA C22.2 No.1 and/or the National Electrical Code ANSI/NFPA

70. Where required by jurisdiction, installation must conform to the Standard for

Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

If there is any conict, then the more stringent will apply.

LOCATION

The HC series boilers are designed and approved for indoor installation

(wall), with signicant exibility of location provided with the available venting

options. The boiler can be placed in an alcove, basement, closet or utility room.

Surrounding ambient conditions shall be 0°C to 50°C and less than 90% relative

humidity.

Install the boiler in areas where the combustion air source is not subject to

chemical fouling or agricultural vapours. Exposure to corrosive chemical

fumes such as chlorinated and/or uorinated hydrocarbons can reduce

the life of a boiler. Cleaners, bleaches, air fresheners, refrigerants, aerosol

propellants, dry-cleaning uids, de-greasers and paint-removers all contain

vapours which can form corrosive acid compounds when burned in a gas ame.

Airborne chlorides such as those released with the use of laundry detergents are

also to be avoided. Similarly, ensure any direct vent air source is not adjacent to

a clothes dryer exhaust terminal. Avoid agricultural applications where the

boiler and/or the intake air source are affected by ammonia and/or dust.

Locate the boiler where water leakage will not result in damage to the area. If a

location such as this cannot be found, a suitable drain pan should be installed

under the appliance. The boiler is not to be installed above carpeting.

Boiler Weight – approximately 96 lbs / 44 kg. For support fasteners, use the

supplied 4 x 1/4" x 2-1/2" long lag screws. Installer to supply 1/4" bolts if metal

mounting systems are used. Fasteners are to be attached to solid material capable

of supporting the combined weight of the boiler and piping assembly components.

Other factors affecting potential mounting sites:

•Ensure minimum clearance requirements for combustible materials (see

Table 2) are satised.

•Minimum 24" clearance at the front and 10" above is recommended for

adequate servicing. Check local codes for additional access and service

clearance requirements.

•

At a new construction site, or during renovations, action must be taken

to protect the boiler from drywall dust or other construction related

contaminants; combustion air should be drawn from a CLEAN source (e.g.

outdoors) and the boiler should be isolated from interior dust sources.

1.2

1.3

WARNING

Keep boiler area free and clear

of combustible materials,

gasoline, and other ammable

vapours and liquids.

WARNING

Combustion air must not be

drawn from areas containing

corrosive air from swimming

pools or spas, including air

directly next to outdoor pools

and spas.

WARNING

The boiler shall not be exposed

to water leaks from piping or

components located overhead.

This includes condensation

dropping from un-insulated

cold water lines overhead.

WARNING

Ensure the gas ignition

system components are

protected from water (dripping,

spraying, rain, etc.) during

appliance operation and when

servicing (pump replacement,

condensate trap servicing,

control replacement, etc.)