5

Keep your hands away from cutting area and the blade. Hold the

saw by insulated gripping surfaces only and second hand on the

auxiliary handle or motor housing. Keep the handle of the saw

dry, clean and free from oil. Keep your body positioned to either

side of the blade, but not in line with the blade.

Do not hold the material to be worked in your hands,your legs or

feet, it’s important that the material be adequately clamped

down, reducing the contact with the body and the possibility of

losing control.

Do not operate the tool on surfaces under which there might be

electrical wires, and water or gas pipes. The contact with wires

or water might cause electrical shocks. The motor generates sparks

that, if in contact with flammable gases, might cause explosion.

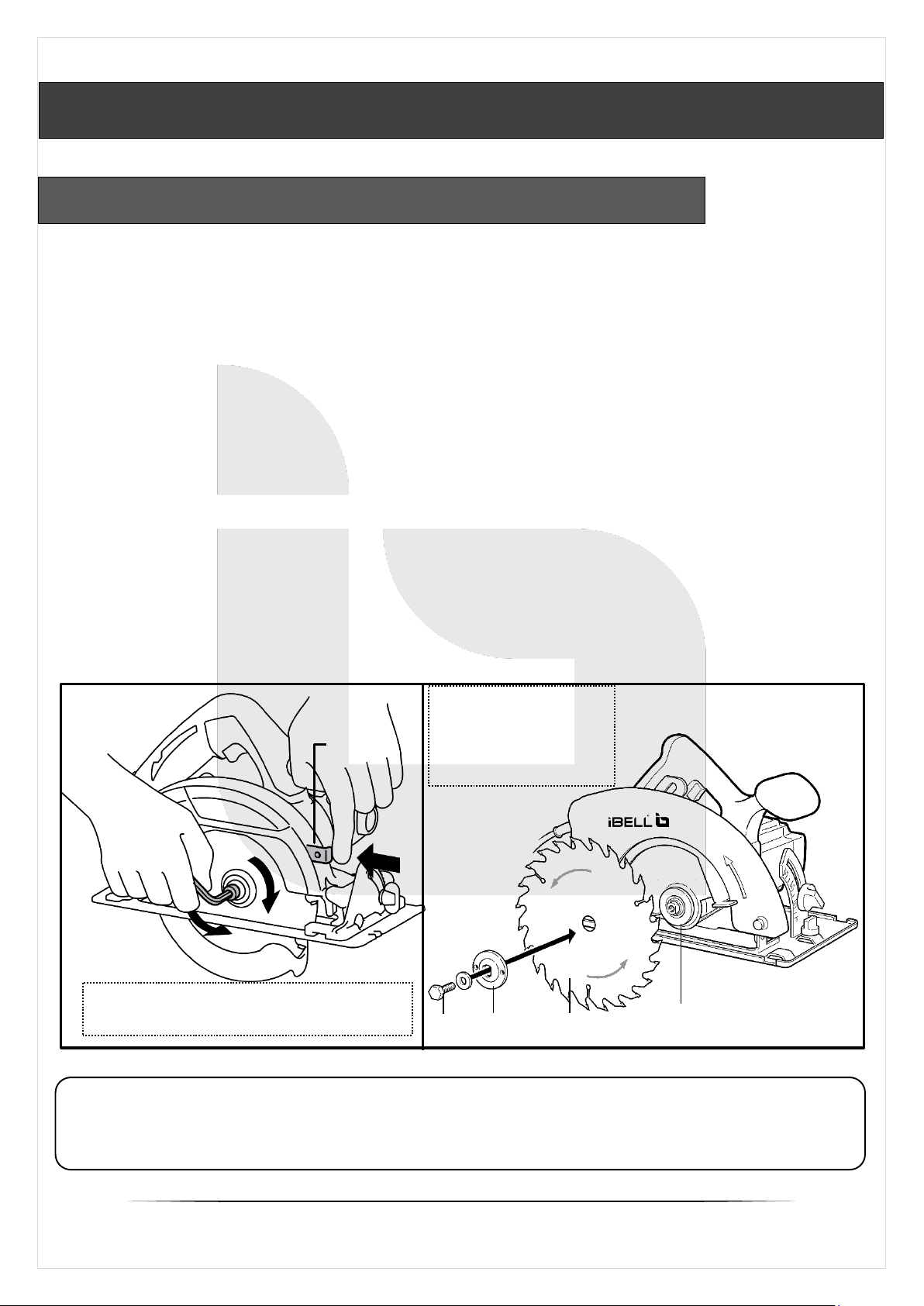

Always use saw blades of correct sizes. *Suitable blade might be

available with the product, use of it is highly recommended. Blades

with shapes that don’t match the backing flange on which they’ll

be assembled will work in an irregular way, causing loss of control

of the tool.

Do not overload the saw, use it only for the adequate purpose.

Using the saw for purposes that are different from what indicated

in this manual might lead to hazardous situations.

Wait for the blade to come to a complete stop, there is a period

of inertial movement before the tool stops after turned OFF.

Avoid sawing overhead. Be extra careful when cutting in high or

hard-to-reach locations.

The use of this tool create and/or spread dust that may cause

serious and permanent respiratory injuries. To reduce the

exposure to these substances, work in well-ventilated places and

always use dust mask.

Wear ear protectors. Exposure to noise can cause hearing loss.

Wear safety goggles or eye protection when using this power

tool. For additional protection against electric shock, be sure to

wear rubber gloves.