Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without inc

Printed in Israel Pg 1

Installation Start-Up and Service Instructions

CONTENTS

Page

SAFETY CONSDERATONS . . . . . . . . . . . . . . . . . . . . . . . . .1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

NSTALLAT ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

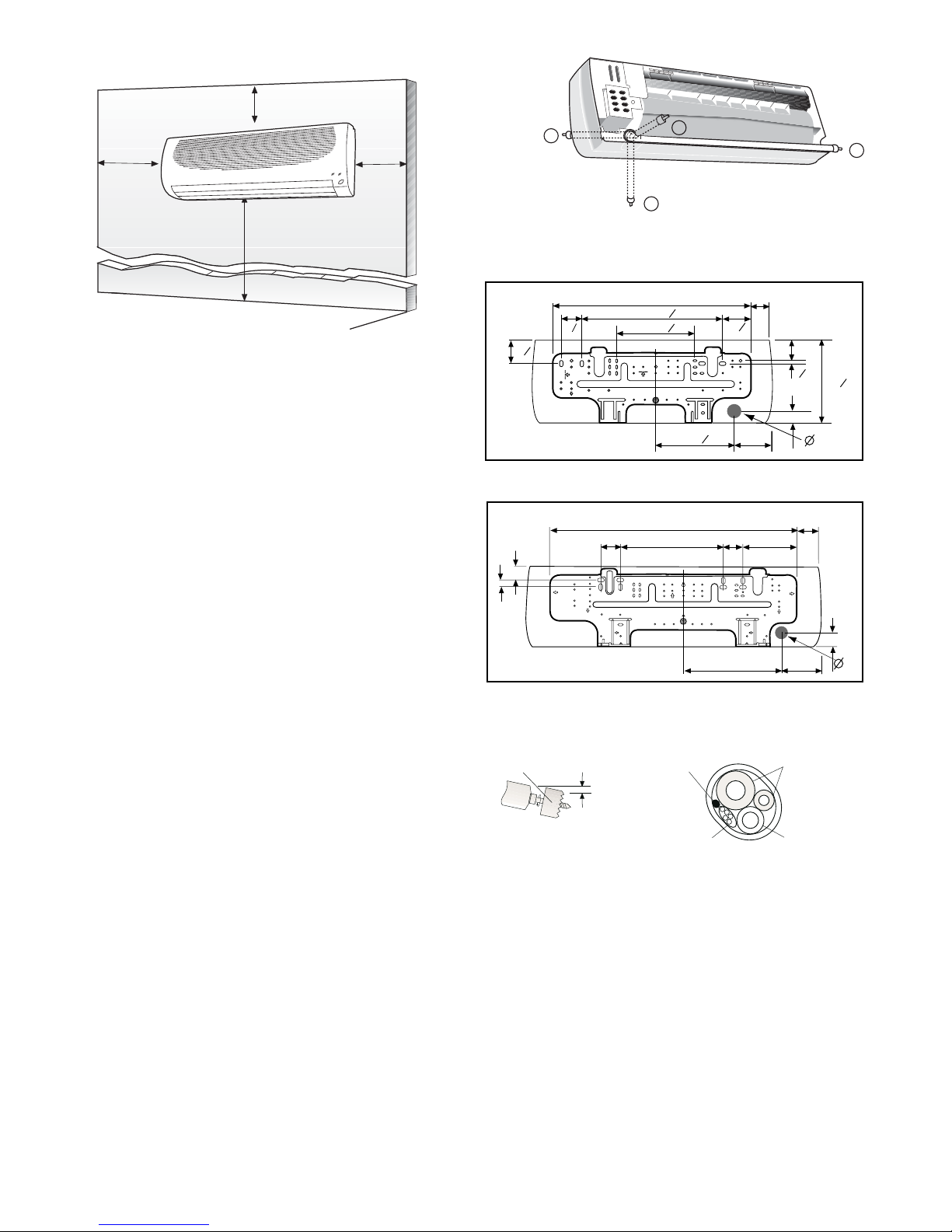

ndoor Unit nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . .6

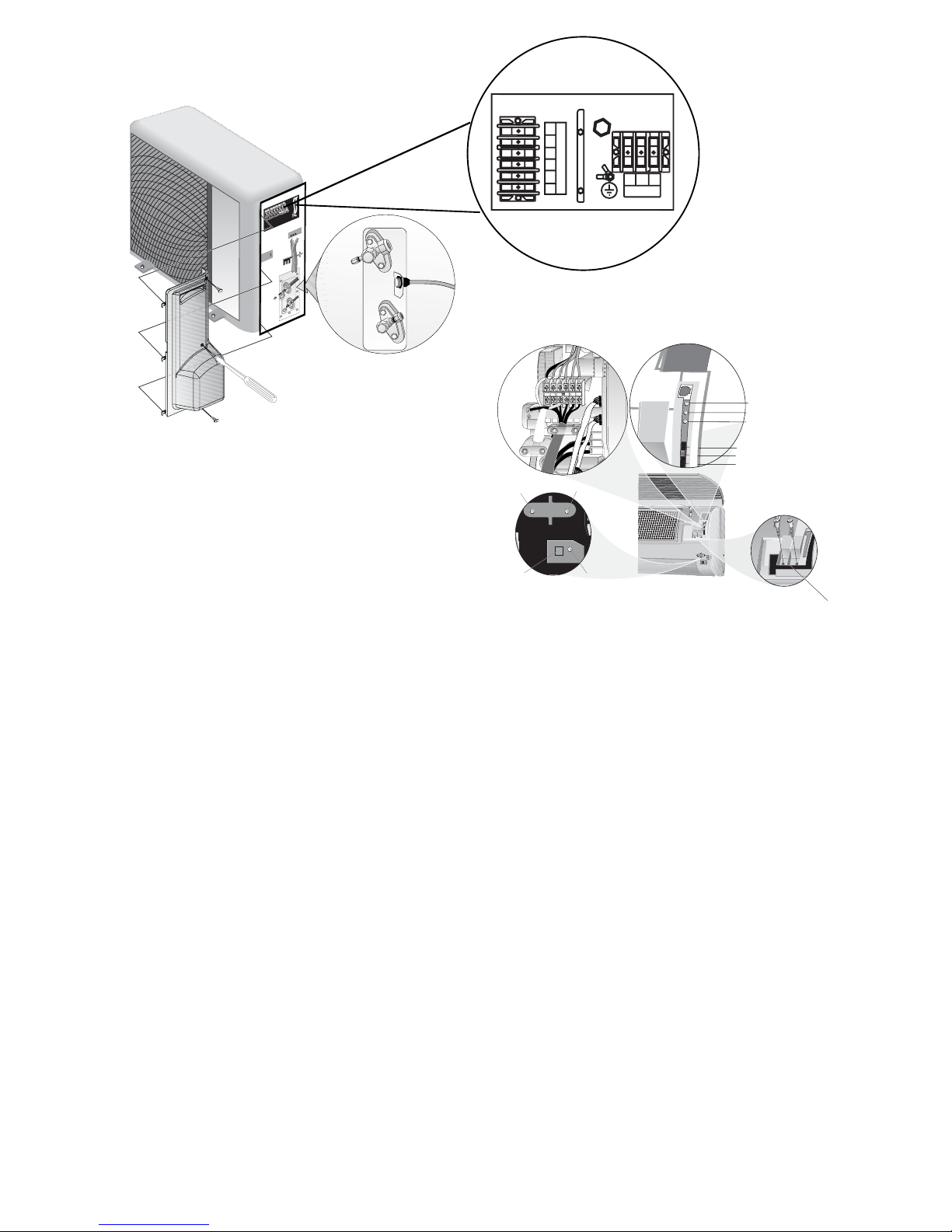

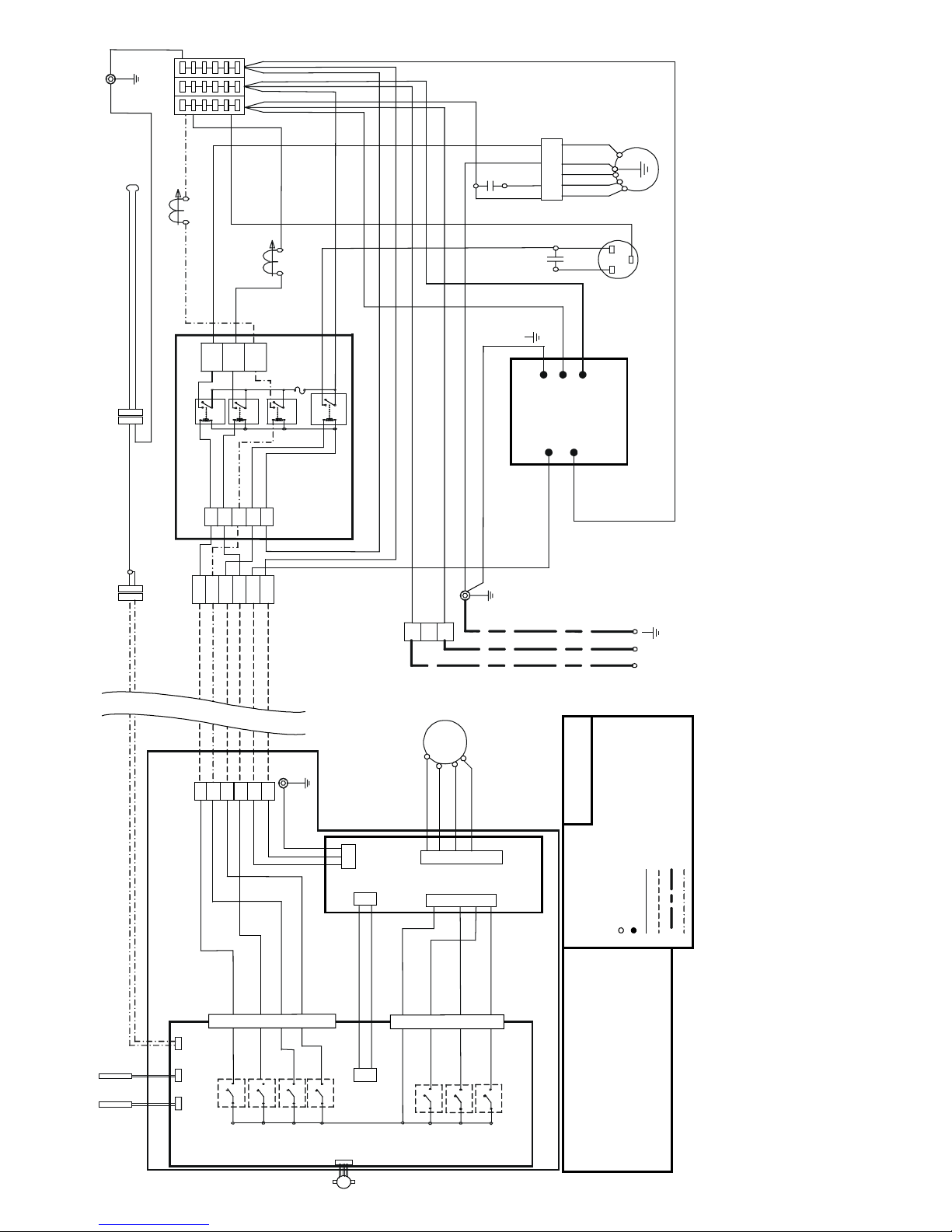

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

System Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CARE AND MA NTENANCE. . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Indoor Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

To Clean the ndoor Unit Front Panel . . . . . . . . . . . . . . .11

To Clean ndoor Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . .11

SERVCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

TROUBLESHOOTNG. . . . . . . . . . . . . . . . . . . . . . . . . . . .12-15

SAFETY CONS DERAT ONS

Installing, starting up, and servicing air-conditioning equip-

ment can be ha ardous due to system pressures, electrical

components, and equipment location (roofs, elevated struc-

tures, etc.).

Only trained, qualified installers and service mechanics

should install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance func-

tions such as cleaning coils. All other operations should be

performed by trained service personnel.

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work

gloves. Keep quenching cloth and fire extinguisher nearby

when bra ing. Use care in handling, rigging, and setting bulky

equipment.

GENERAL

System Requirements

Consult local building codes and National Electrical

Code (NEC, U.S.A.) for special installation requirements.

Use only type G or C fuses.

Use single length power cable without extension.

Allow sufficient space for airflow clearance on condens-

ing units for wiring, refrigerant piping, and servicing

unit. See Fig. 1 and 2 for minimum required distances

between unit and walls or ceilings.

Indoor and outdoor units should be installed at a

Maximum line length of 50 ft, and

vertical separation of 30 ft.

Do not install indoor units near a direct source of heat

such as direct sunlight, steam or flame.

Before installing or servicing system, always turn off main

power to system and install lockout tag on disconnect.

There may be more than one disconnect switch. Electrical

shock can cause personal injury.

IMPORTANT: The Indoor unit & the inter units cable voltage

is 30 VDC

IMPORTANT: Each refrigerant line must be insulated

separately. See line sizing requirements in table 2.

Do not bury more than 36 in. of refrigerant pipe in the

ground. If any section of pipe is buried, there must be a

6 in. vertical rise to the valve connections on the outdoor

units. If more than the recommended length is buried,

refrigerant may migrate to the cooler buried section during

extended periods of system shutdown. This causes refriger-

ant slugging and could possibly damage the compressor at

start-up.

DFS2A/H 09,12,18

Duct Free Systems

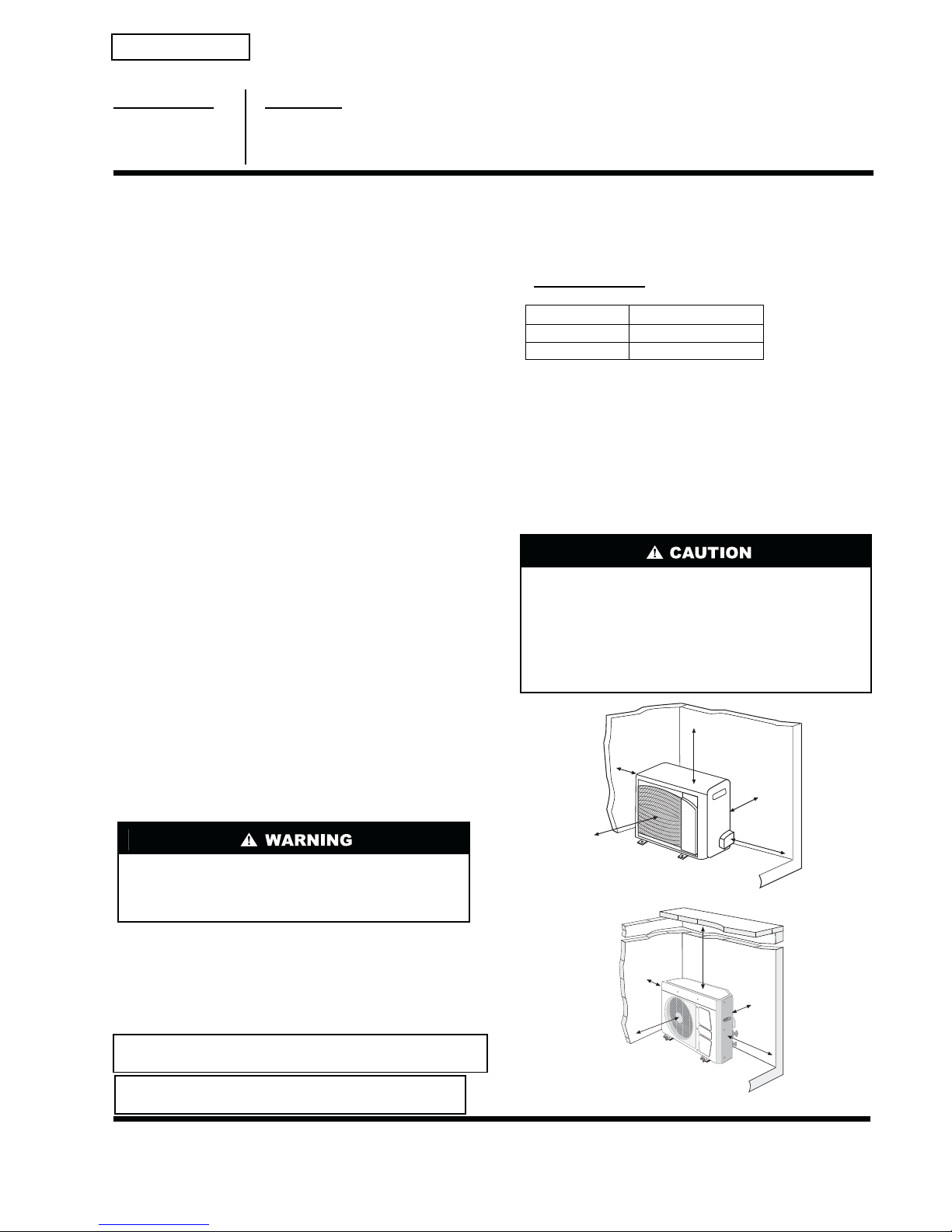

Fig. 1B Outdoor Unit Clearances

Fig. 1A Outdoor Unit Clearances

These instructions cover the installation, start-up and servicing

of DFC2A/DFC2H outdoor and DFF2A/DFF2H indoor units

cooling only and heat pump duct free systems. See Table 1 for

parts included. See Tables 2 and 3 for Physical Data.

51302618915 0106

TOP (min.)

2 (0.6m)

LEFT (min.)

6 (0.15m)

RIGHT (min.)

2 (0.6m)

FRONT (min.)

2 (0.6m)

REAR (min.)

6 (0.15m)

Max. cable length. Total voltage drop should not exceed 1V.

Therefore max. length:

For #18 AWG 24.3 Feet (7.4 m)

For #16 AWG 37.7 Feet (11.5 m)

For #14 AWG 50.0 Feet (18 m)

Outdoor Units . . . .

Outdoor Unit Installation . . .

Air Filters for Indoor Units

LEFT(min.)

6 (0.15m)

TOP(min.)

2 (0.6m)

REAR(min.)

6 (0.15m)

RIGHT(min.)

2 (0.6m)

FRONT(min.)

2 (0.6m)

Cooling Model Heat Pump

DFS2A309J1ADFS2H309J1A

DFS2A312J1A DFS2H312J1A

DFS2A318K1ADFS2H318K1A

421 01 9217 00