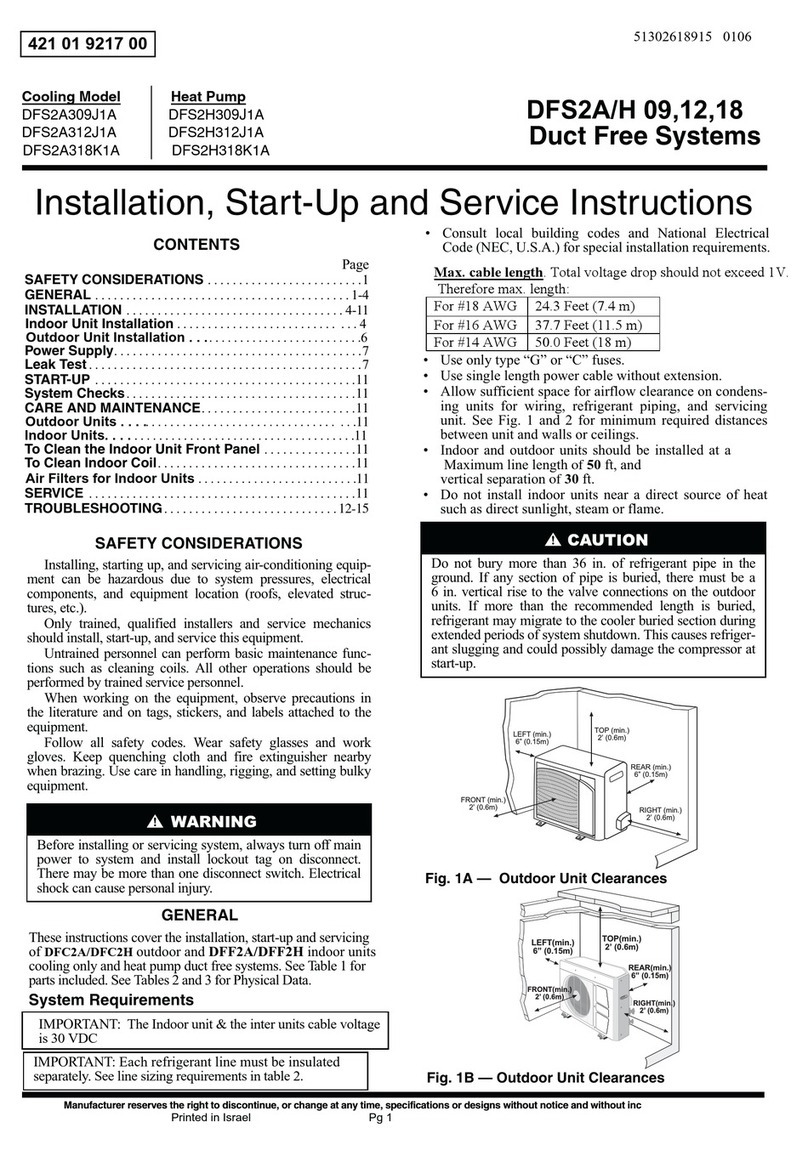

Installation Instructions

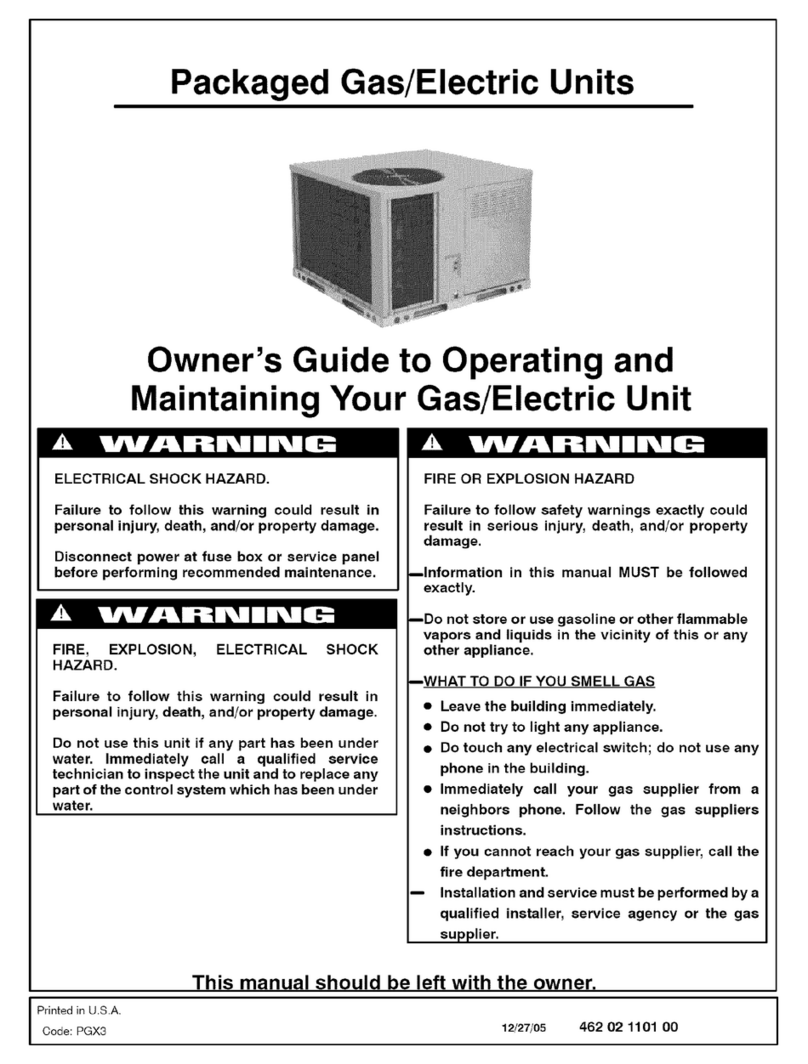

IPGAA /PGAC /PGAD -11/2 to 5 TON

PGMD/PGME

COMBINATIONUNITS

GASHEAT/ELECTRICCOOL

TABLEOFCONTENTS

1. SAFETY LABELING AND SIGNAL WORDS .................... 2

DANGER,WARNINGAND CAUTION ............................... 2

SIGNALWORDS ............................................... 2

SignalWordsin Manuals ........................................ 2

PRODUCTLABELING ........................................... 2

DangerLabel ................................................ 2

WarningLabel ............................................... 2

CautionLabel................................................ 2

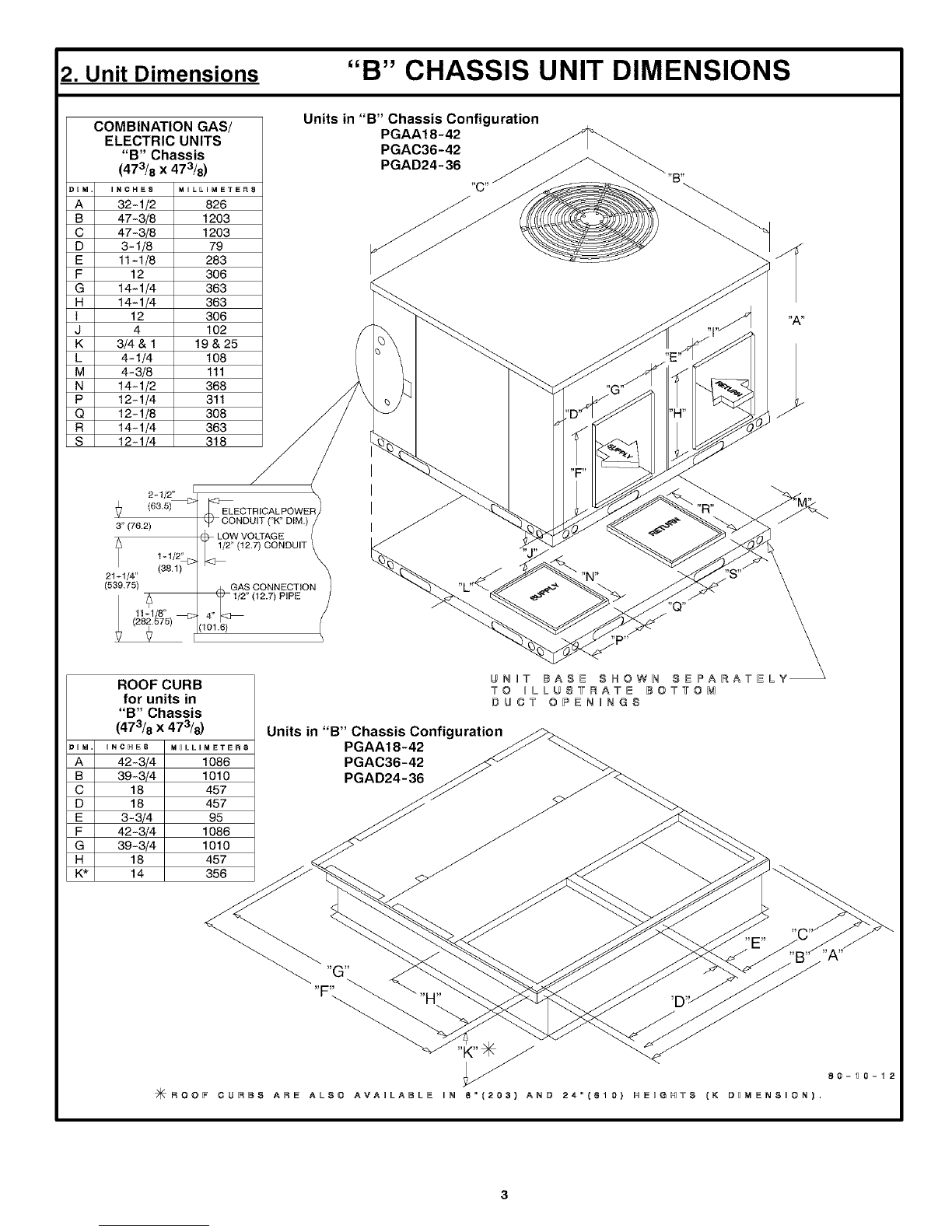

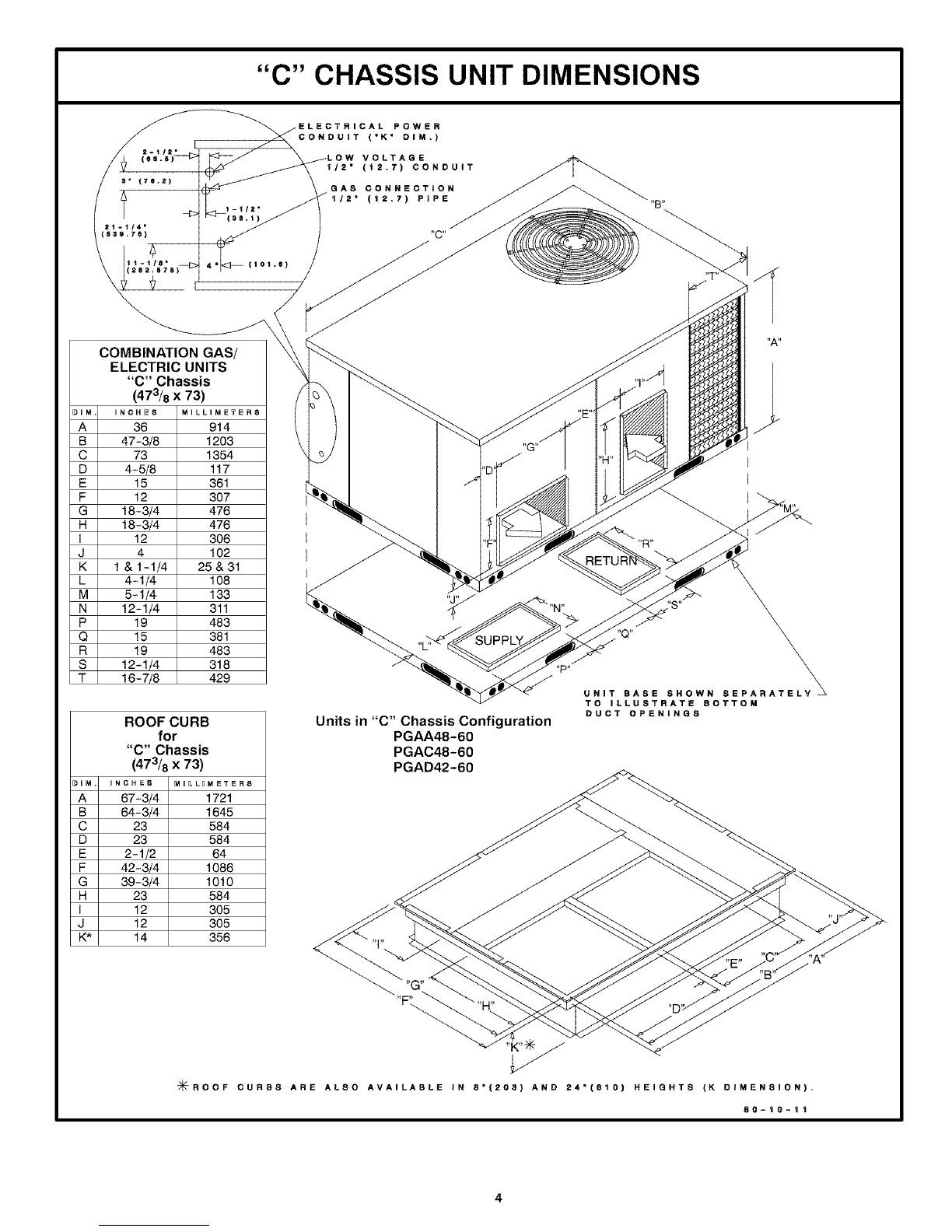

2. UNIT DIMENSIONS ..................................... 3-4

3. SAFE INSTALLATION REQUIREMENTS ...................... 5

4. LOCATING THE UNIT .................................... 5

ACCESSPANELS .............................................. 5

CLEARANCES................................................. 5

MinimumClearancesto CombustibleConstruction...................... 5

GROUNDLEVEL INSTALLATION................................... 5

ROOFTOPINSTALLATION...................................... 5-6

HOISTING .................................................... 6

DownflowConversion........................................... 6

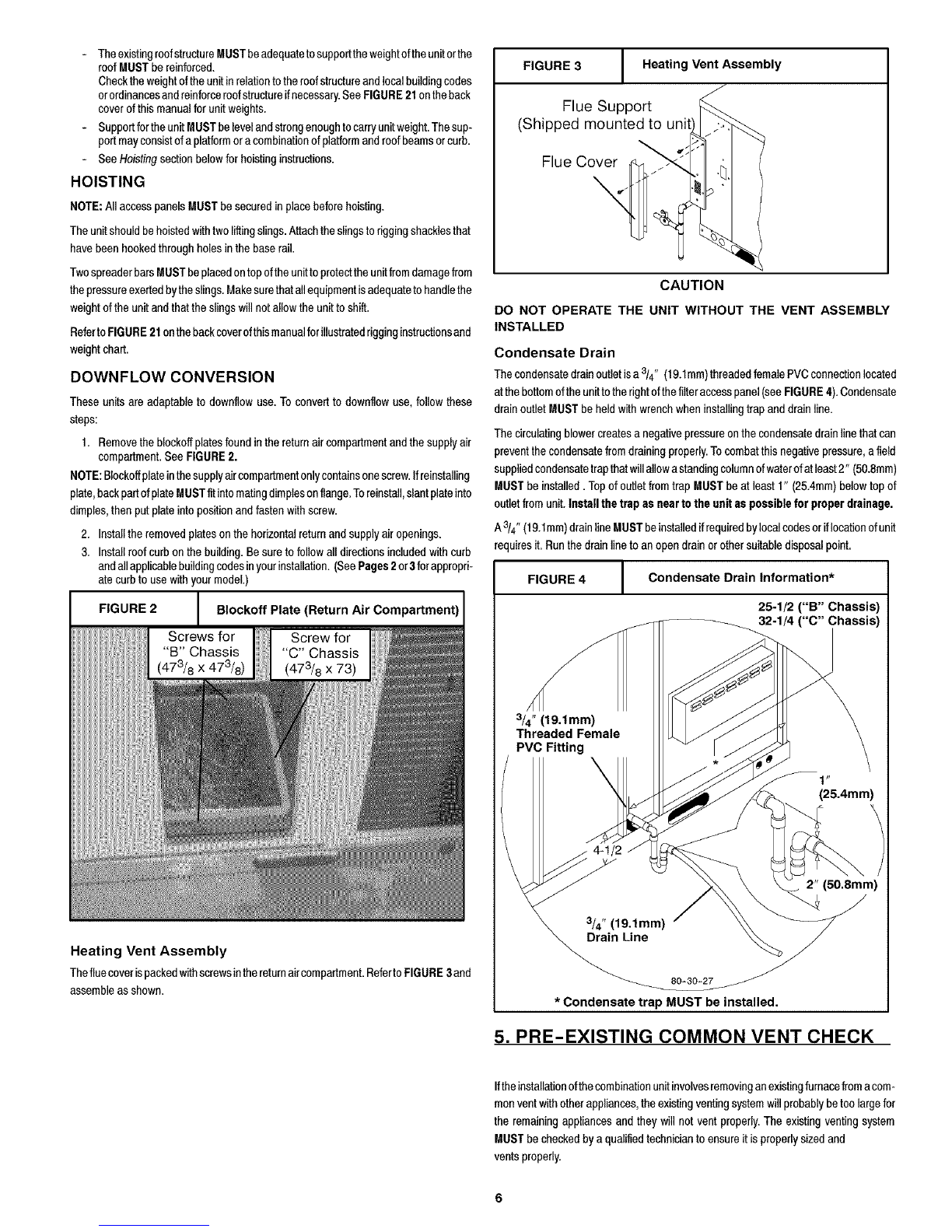

HeatingVentAssembly ......................................... 6

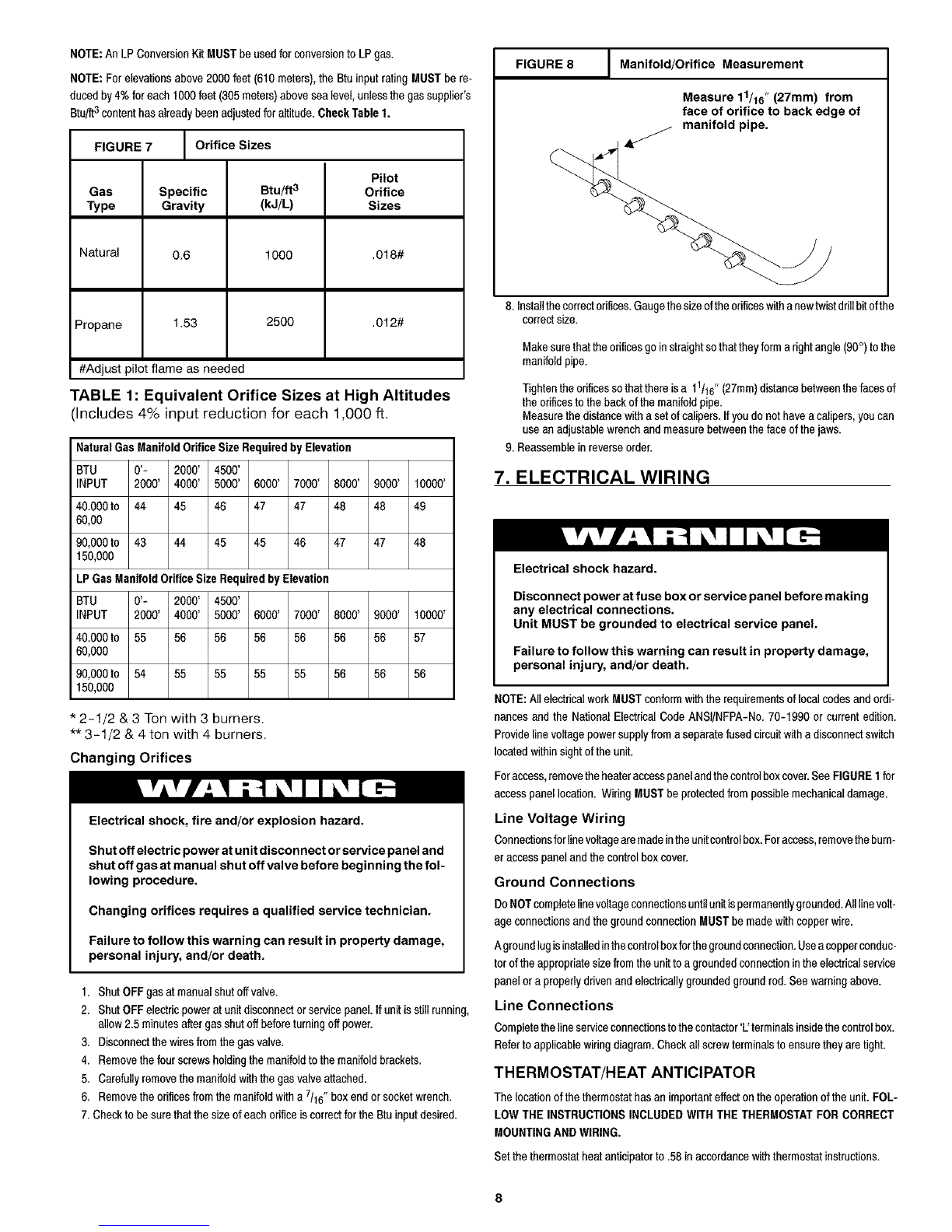

CondensateDrain ............................................. 6

5. PRE- EXISTING COMMON VENT CHECK ...................... 7

6. GAS SUPPLY AND PIPING ................................ 7

GASPIPING .................................................. 7

GasPipeSize ............................................... 7

PIPINGATUNIT................................................ 7

Connections................................................. 7

ORIFICES .................................................... 7

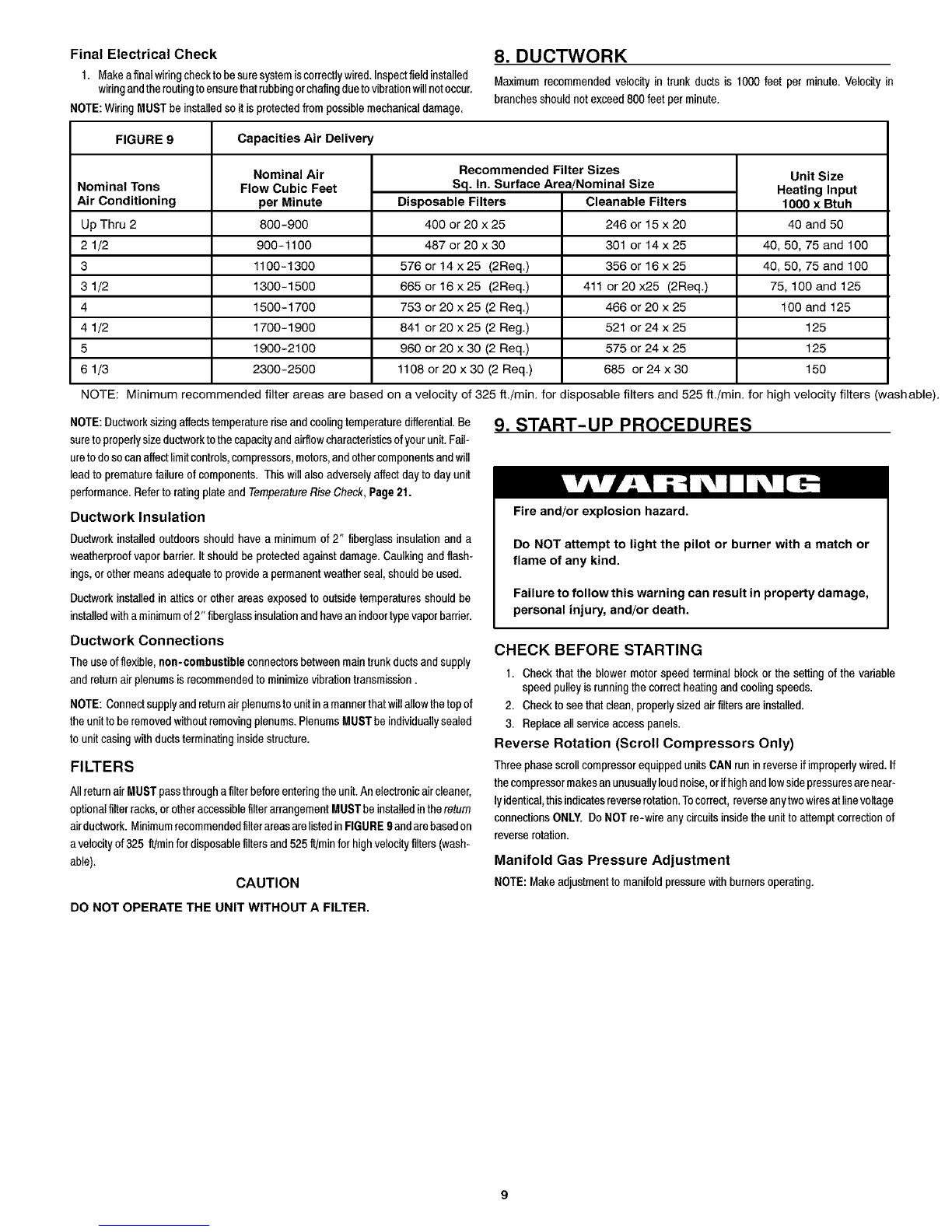

OrificeSizes ................................................. 7

ChangingOrifices ............................................. 8

7. ELECTRICAL WIRING .................................... 8

UneVoltageWiring ............................................ 8

GroundConnections ........................................... 8

UneConnections .............................................8

THERMOSTAT/HEAT ANTICIPATOR ...............................8

FinalElectricalCheck .......................................... 8

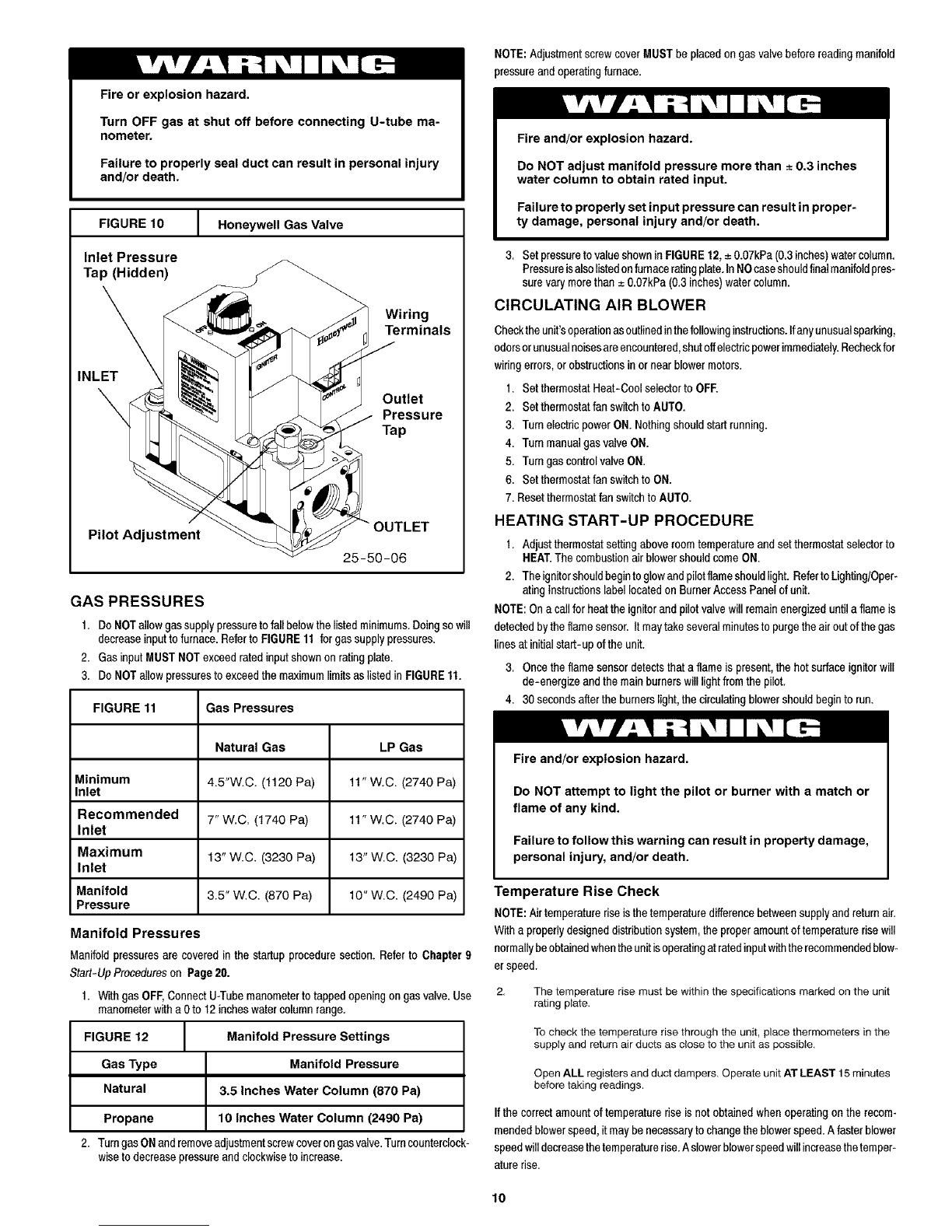

8. DUCTWORK ........................................... 8

DuctworkInsulation ........................................ 9

DuctworkConnections.......................................... 9

FILTERS ..................................................... 9

9. START- UP PROCEDURES ................................ 9

CHECKBEFORESTARTING ...................................... 9

ReverseRotation(ScrollCompressorsOnly) .......................... 9

ManifoldGasPressureAdjustment................................. 9

GASPRESSURES.............................................. 9

CIRCULATINGAIRBLOWER ..................................... 10

HEATINGSTAR-UP PROCEDURES................................ 10

TemperatureRiseCheck ....................................... 10

FANCONTROLCHECK ......................................... 10

SPEEDTAPS................................................. 11

CONTINUOUSFANOPERATION .................................. 11

COOLING ................................................... 11

10. OPERATION ......................................... 12

COMBUSTIONIINDOORFANCONTROL............................. 12

SCROLLANTI-CYCLETIMER .................................... 12

11. MAINTENANCE ....................................... 12

MONTHLYMAINTENANCEANDINSPECTIONCHECKS ................. 12

Air Filters .................................................. 12

HEATINGSEASONCHECKS (MONTHLY) ........................... 12

Pilot Flame ................................................. 12

MainBurnerFlame ........................................... 12

ANNUALMAINTENANCEANDINSPECTION ......................... "12

CondenserFan Motor ......................................... 12

VENTASSEMBLY ............................................. 13

BLOWERMOTORACCESS ...................................... 13

Method1 .................................................. 13

Motorremovalandreplacement.................................. 13

Method2 .................................................. 13

Burners/HeatExchangers/FlueGasPassages ...................... t3

INSPECTIONANDCLEANINGOF BURNERASSEMBLY

/HEATEXCHANGERS/FLUEGASPASSAGES..................... 13-14

ForOaaiifiedServiceTechnicianOnly ........................... t3-t4

12. RIGGING INSTRUCTIONS .............................. 15

13. NOTES ............................................. 16

462 01 1004 00 10-23-01

Printed in U.S.A.