B. Outdoor Thermostat (Heat Pump Units Only)

If the setscrew is left at the factow setting (in the heat pump

position), the unit will operate in the reverse cycle heating

mode. See Fig. 16. When the temperature of the outdoor coil

drops below 20 F (approximately 35 F outdoor air tempera

ture), the compressor will be disabled and only the electric

heater will be allowed to operate. The electric heater

remains enabled until the temperature of the outdoor coil

rises above 40 F; at which time the electric heater will be dis

abled attd the compressor will be enabled.

To set unit to operate in electric heat mode only, turn the set-

screw to the electric heat position. See Fig. 16.

IMPORTANT: If setscrew on standard heat pump unit is set

to electric heat mode operation, the compressor is disabled

for bofh heating and cooling operations. If setscrew on heat

pump unit with wall thermostat control is set to electric heat

mode operation, the compressor will be disabled only for

heating operation.

III. OPERATING MODES (See Fig. 17 and 18)

A. Outside Air

To bring outside air into occupied space, turn the vent

handle to the full open position, See Fig. 15.

B. Off

The OFF mode terminates unit operation,

C. Fan

The FAN mode will circulate air it] the space at high speed

attd at high or low speed for cooling only models,

D. High Heat or High Cool

Select mode and rotate temperature knob to desired comfort

level. This fimction provides maxinmm heating or cooling,

attd is recommended to raise or lower the room temperature

quickl3z

E. Low Heat or Low Cool

Select mode and rotate temperature knob to desired comfort

level. This fimction provides mininmm heating or cooling

with maximum dehumidification and quietest operation.

F. Fan Speed Control for Wall Thermostat Models

For maxinmm comfort, fat] speed is user selectable at the

unit. See Fig. 18.

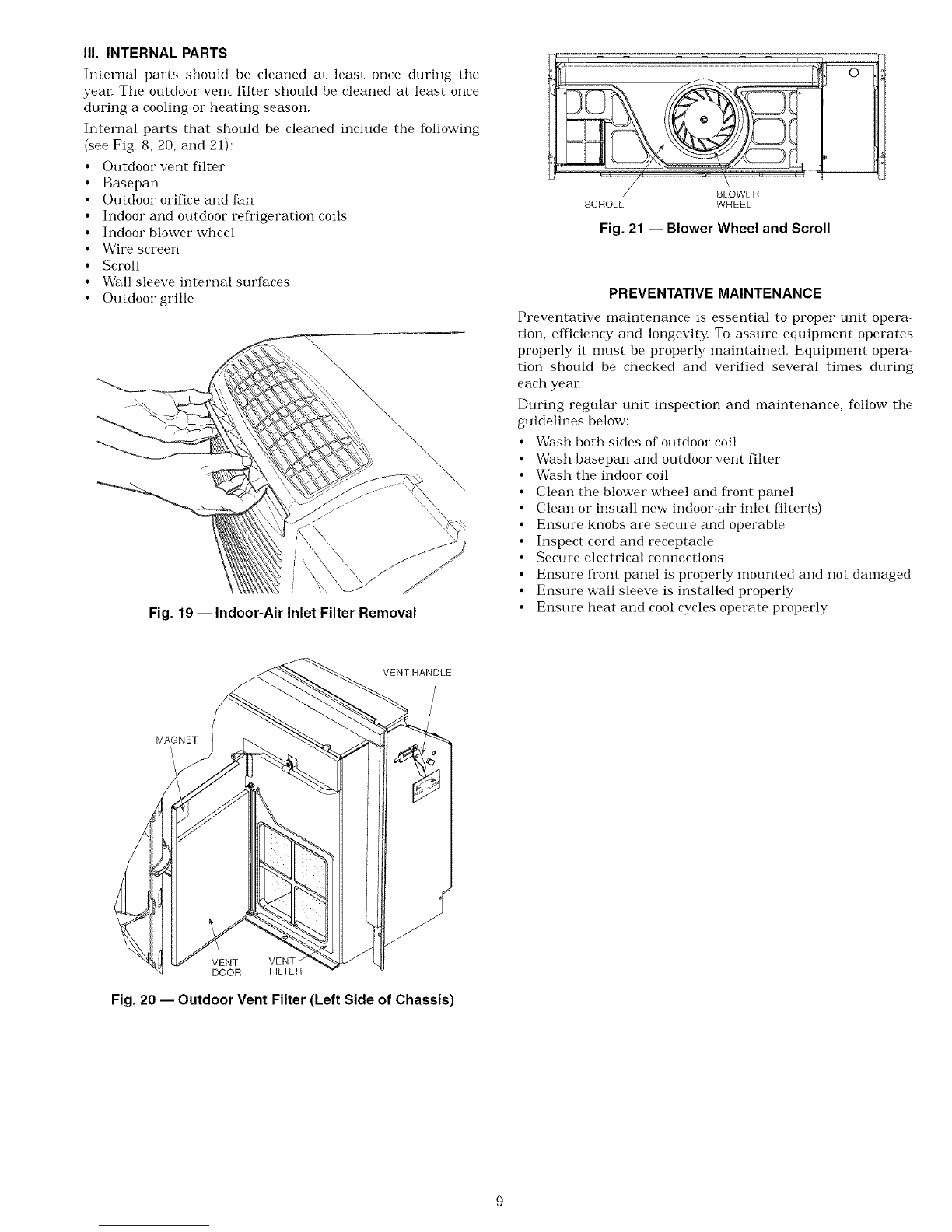

CARE AND MAINTENANCE

In order to maintain proper performance of your packaged

terminal air conditioner or heat pump, it is very important

that the fat] and outdoor coil, the blower wheel, blower scroll,

electric heateL and all drain passages are thoroughly

cleaned at least once per year. Manufacturer i'ecommends

nlinimumly, cleaning should be conducted prior to the start

of each heating season. The air inlet filters should be cleaned

every month.

Depending on local conditions, more fi'equent cleaning of the

unit may be required to ensure optinmm performance and

long operating life. Examples of these special conditions

include areas where construction dust or heavy airborne dirt

is found, or enviromnents that promote the growth of fungus,

[[ H!>[ RA [kJkl m

M0[)I

OFF i

, ARHER COOLER EA I • COOL

Fig. 17 -- Standard Unit Controls

FAN SPEED

LO_

YuuRROOMIS EDUlPPED*ITHA _ALLtHERMOSTAt

kUJUSTFAN SPEEUHEREFO_ kUUEUC0MFO_r.

Fig. 18 --Wall Thermostat Control (Blank Plate)

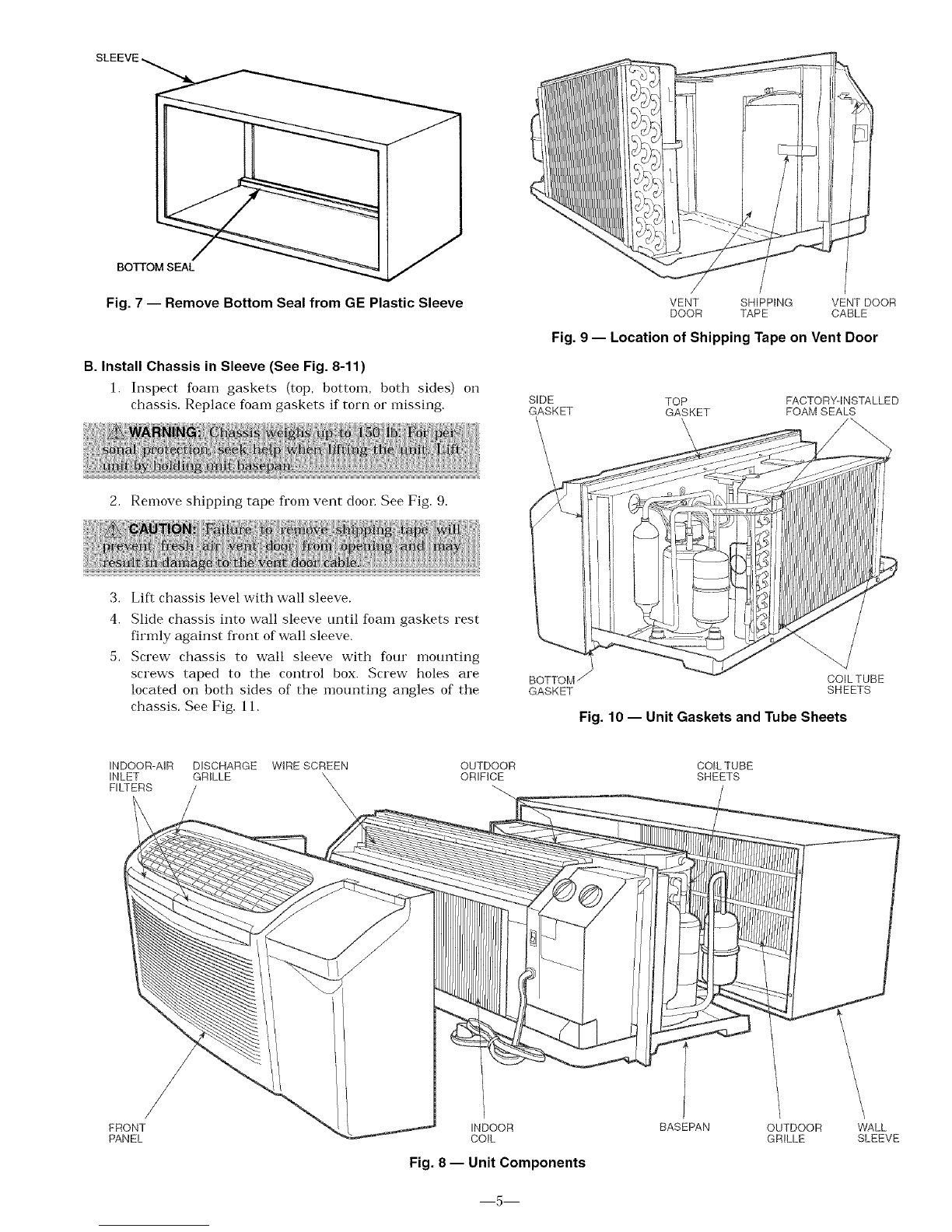

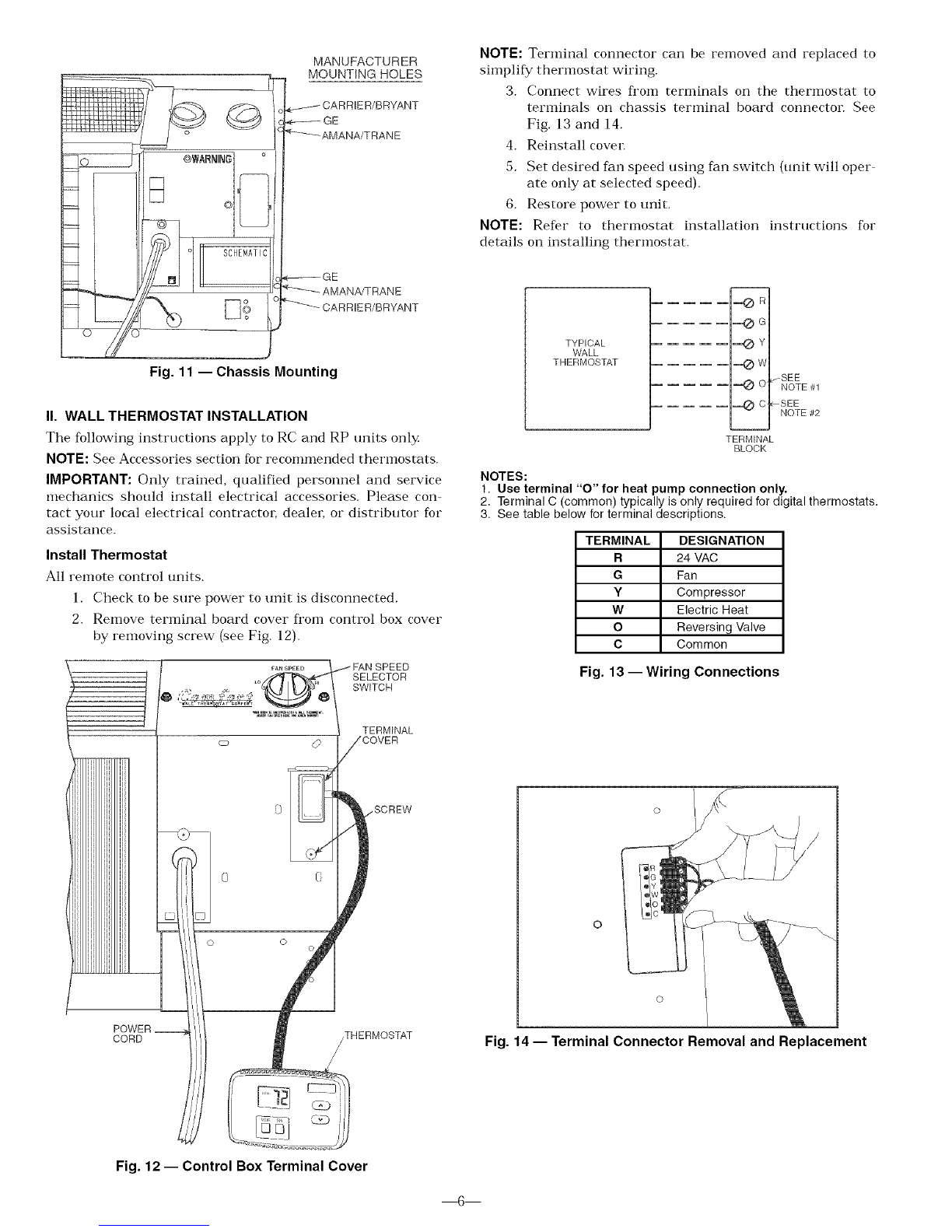

I. INDOOR-AIR INLET FILTERS

Indoor-air inlet filters should be cleaned once each month.

IMPORTANT: Filters may become clogged if not cleaned prop

erl3< Clogged filters will restrict airflow which may lead to

severe component damage and efficiency loss.

Cleaning Indoor-Air Inlet Filter

Two interchangeable air filters are located on the backside of

the front panel. Each can be removed and cleaned one at a

time. To remove and clean the filter, follow the steps below:

1, Grasp filter with both hands,

2. Gently pull the filter up and away from the unit. See

Fig. 8 attd 19.

3. To cleat] firm; use a vacuum or soft bristle brush with

a small amount of mild detergent.

NOTE: If detergent is used, remove any detergent residual

with a gentle stream of clean water

4. Allow filters to air dry

5. Re insert dry filters back into front panel.

Additional filters are available in multi-packs. Refer to

Accessories section.

II. EXTERNAL PARTS

External parts include the polymer sleeve and grilles. The

sleeve manufacturer recommends cleaning the surface,

including the grilles, with household detergent and water

8