Rev. 21B RM-Refrigeration Unit - electrics_EN page 3 of 25

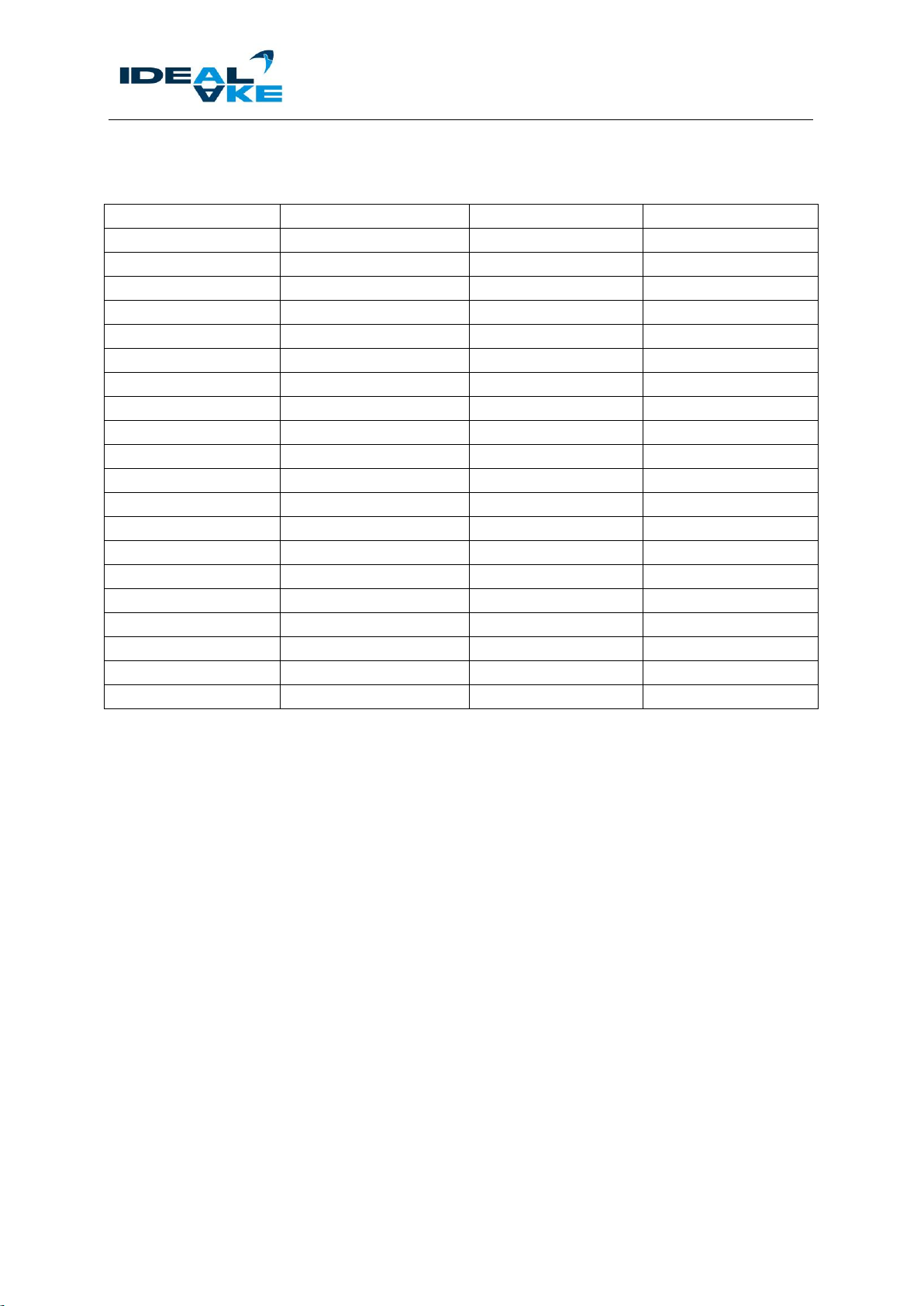

Table of contents

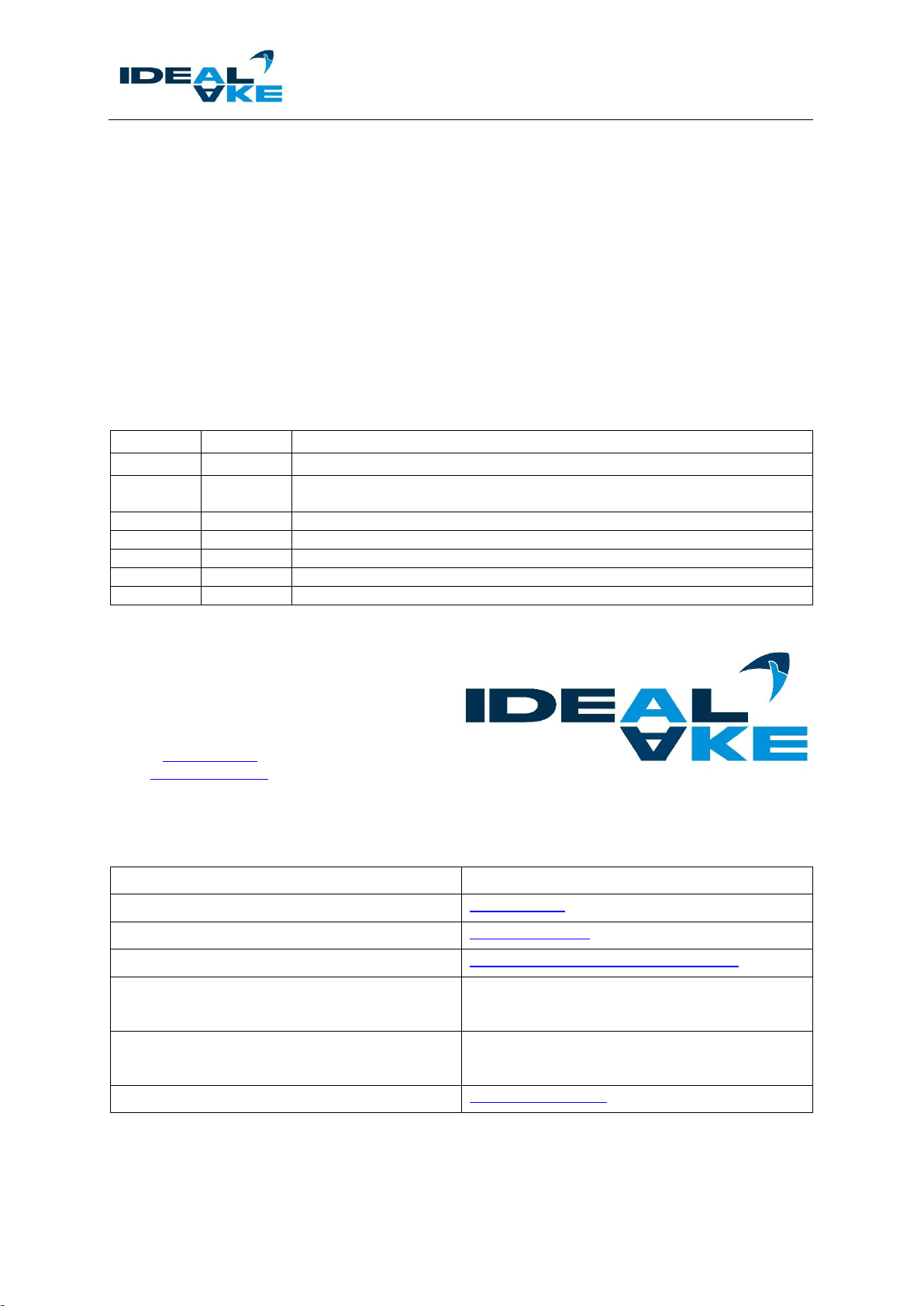

1General Information on this Repair Manual ..................................................................................... 4

1.1 Release notes.......................................................................................................................... 4

1.2 Information about the manufacturer ........................................................................................ 4

1.3 Contact information manufacturer/service............................................................................... 4

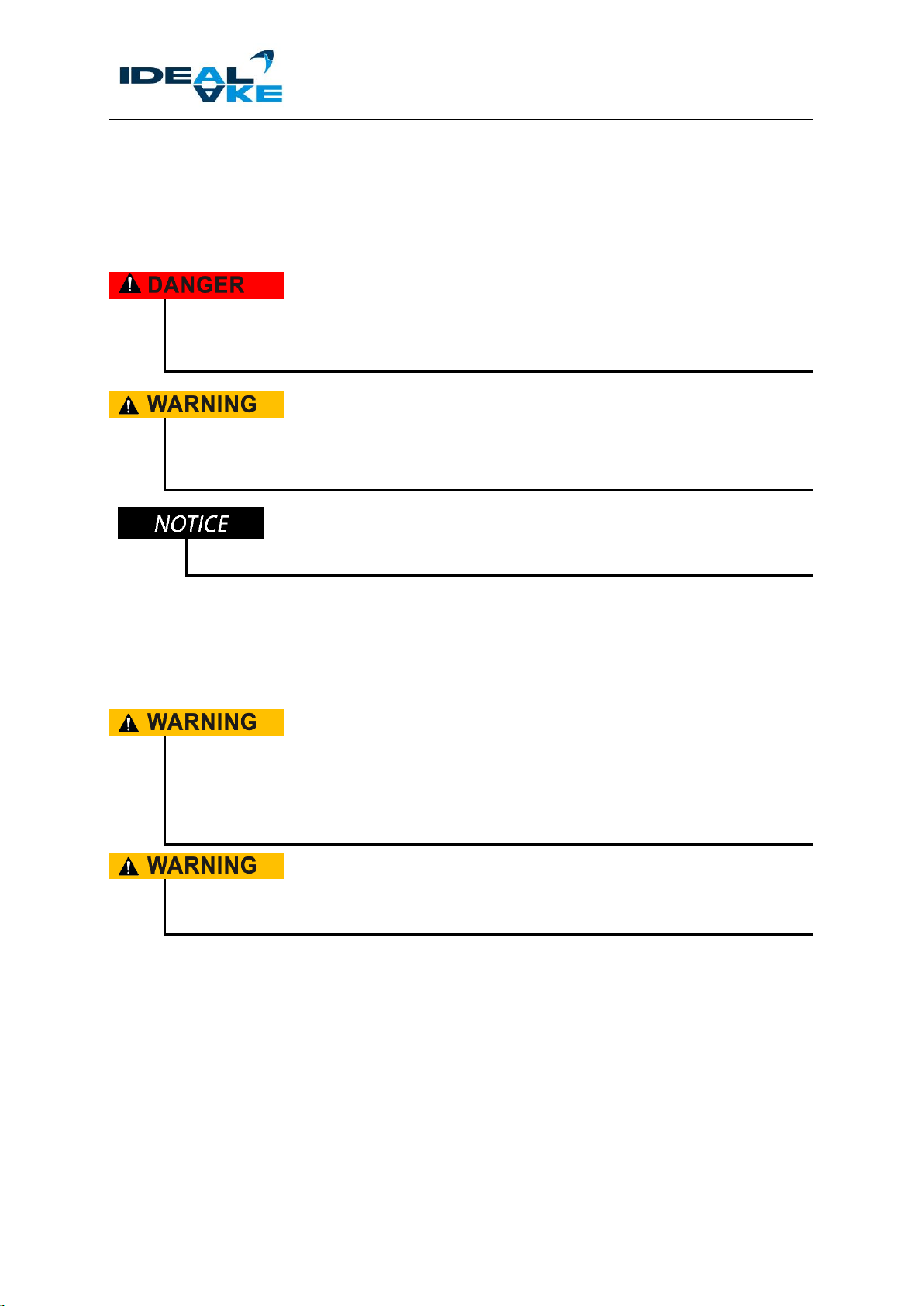

2Information about this Repair Manual.............................................................................................. 5

2.1 Safety information.................................................................................................................... 5

2.1.1 Special safety instructions for refrigerants .......................................................................... 6

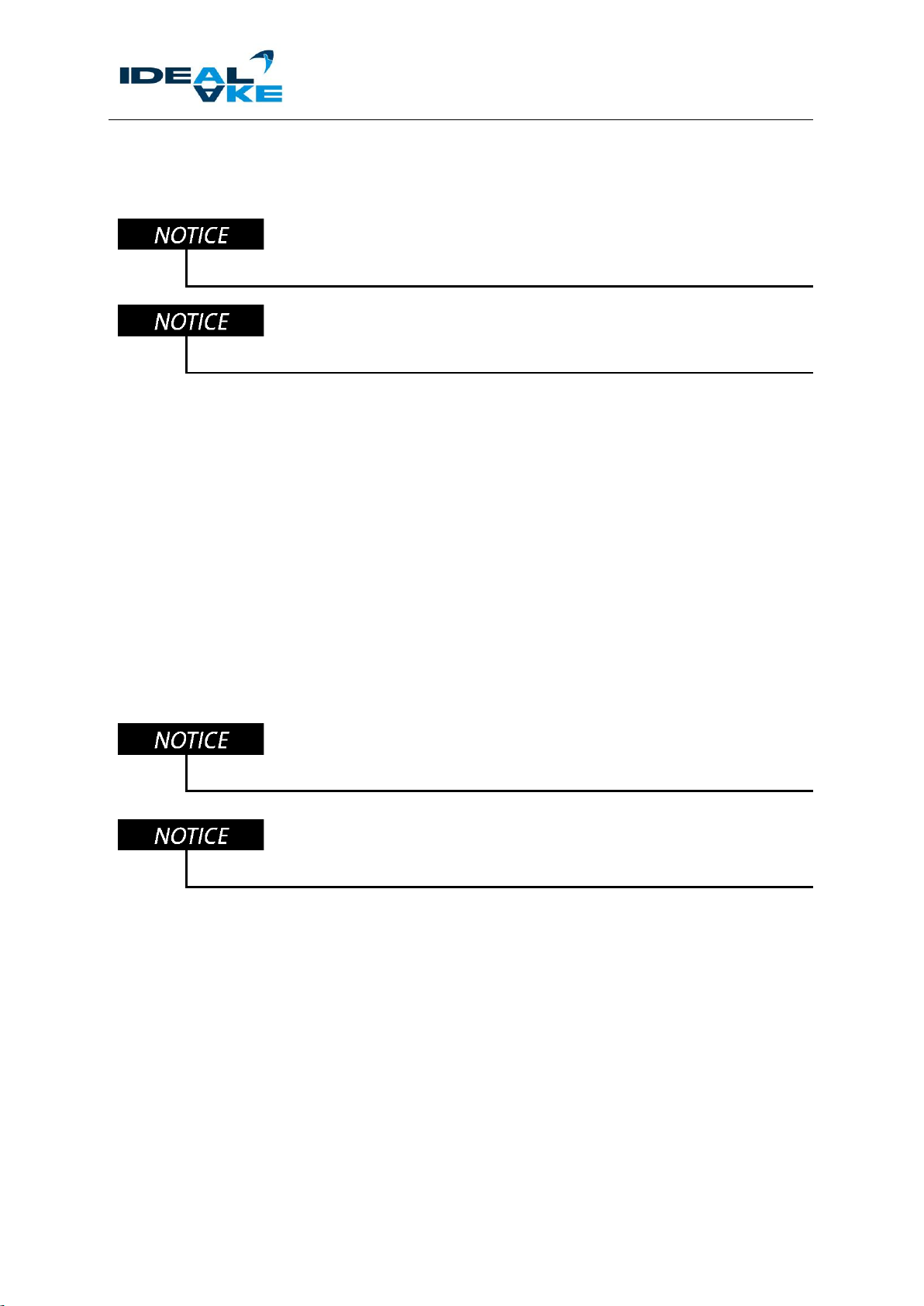

2.2 Repair equipment / test equipment / material.......................................................................... 6

2.2.1 Tool...................................................................................................................................... 6

2.2.2 Material................................................................................................................................ 6

2.3 Disposal information................................................................................................................ 7

2.4 Information on custom designs................................................................................................ 7

3Repair of electrical components....................................................................................................... 8

3.1 Disconnect from the mains...................................................................................................... 8

3.2 Overview of components......................................................................................................... 8

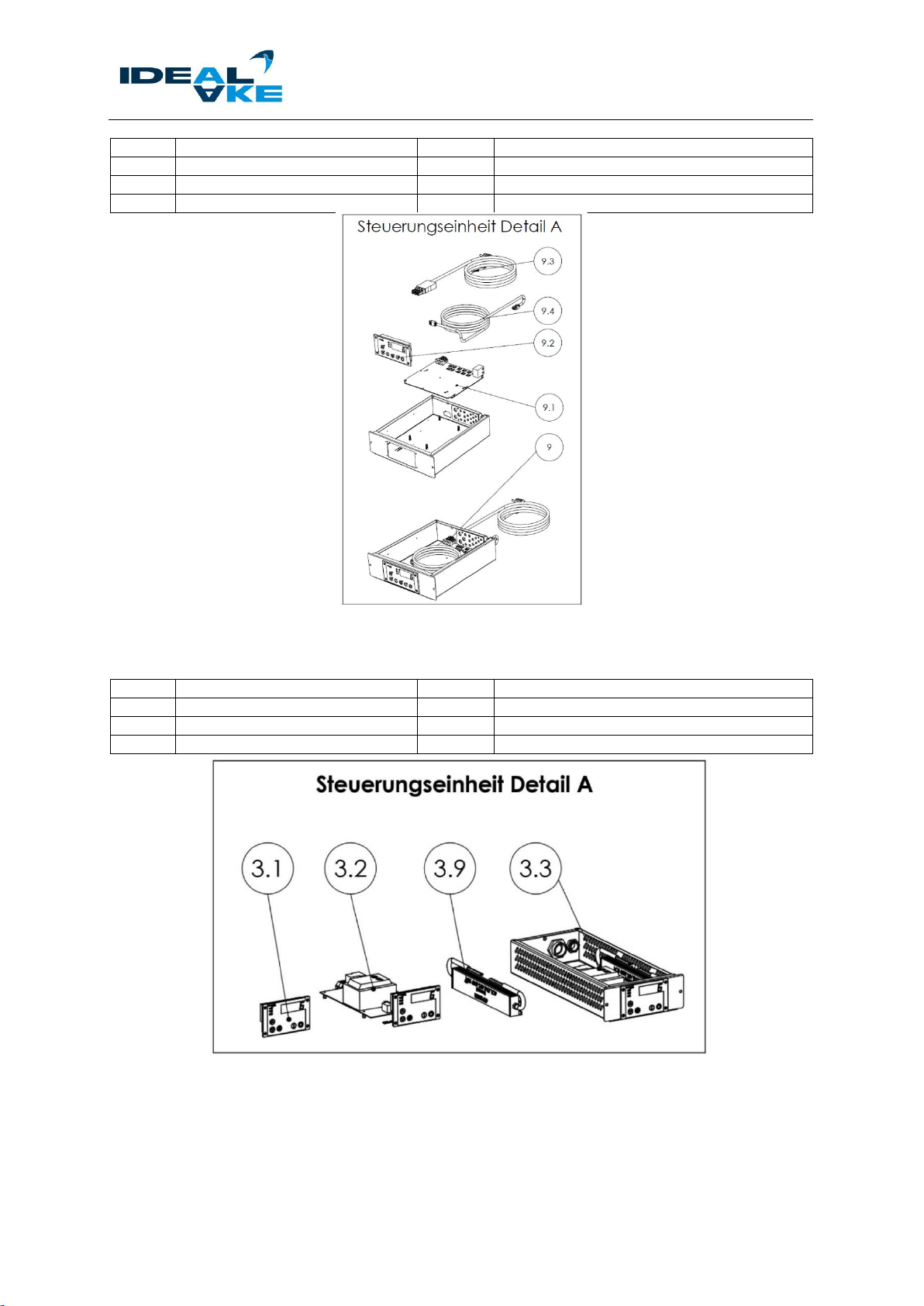

3.2.1 Parts of control unit ST200F................................................................................................ 8

3.2.2 Parts of control unit ST501.................................................................................................. 9

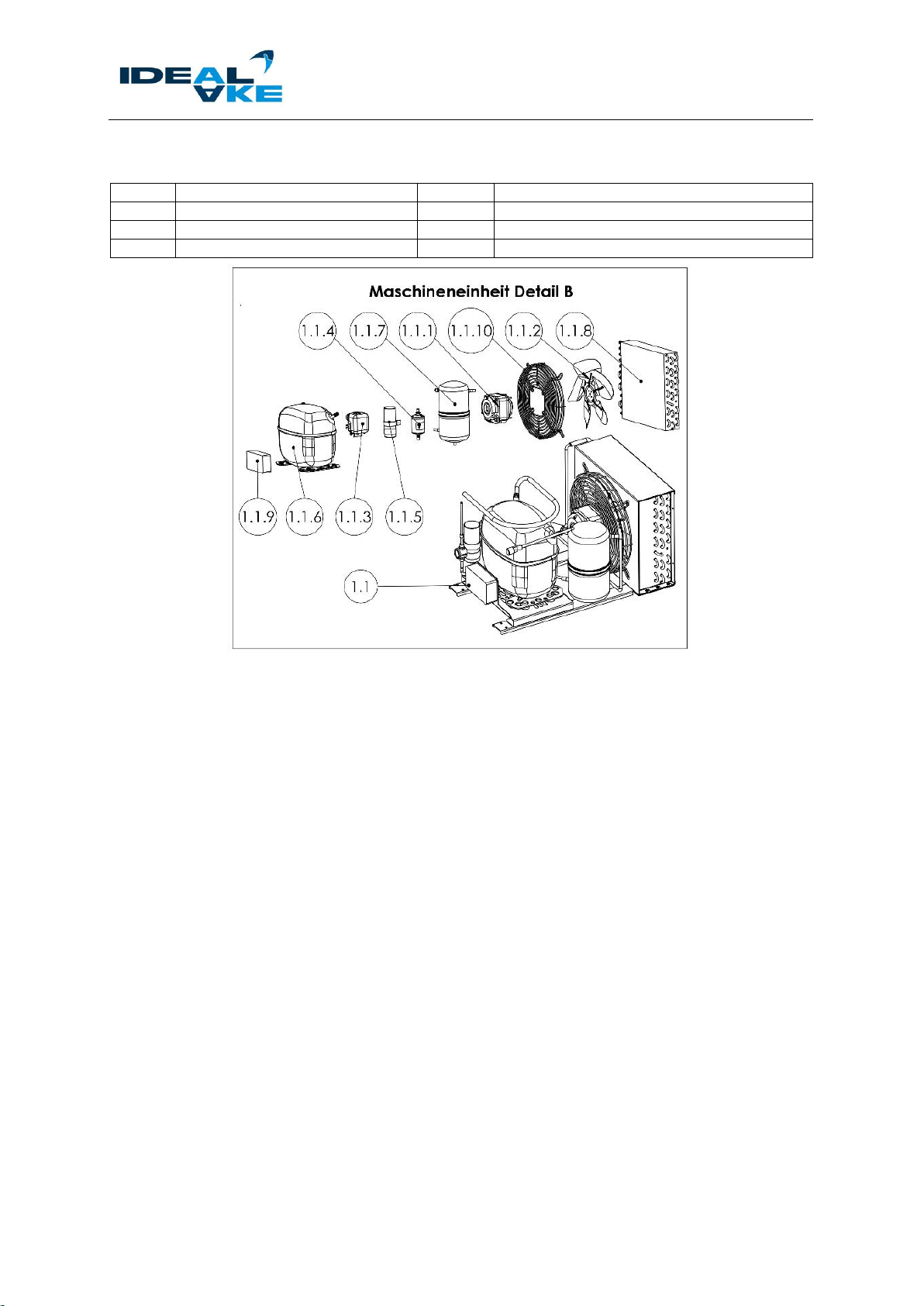

3.2.3 Condensing unit parts........................................................................................................ 10

3.3 Repair of the control unit ....................................................................................................... 11

3.3.1 Replacement of controller display ..................................................................................... 12

3.3.2 Replacement of controller board ....................................................................................... 12

3.4 Repair of the parts on the condensing unit............................................................................ 13

3.4.1 Fan motor repair................................................................................................................ 15

3.4.1.1 Replace fan blade...................................................................................................... 15

3.4.1.2 Replace fan motor ..................................................................................................... 16

3.5 Repair of the fan on the evaporator unit................................................................................ 17

3.5.1 Evaporator fan................................................................................................................... 18

3.6 Repair of temperature sensor / sensors................................................................................ 19

3.6.1 Repair of the sensors on the evaporator unit .................................................................... 19

3.6.1.1 Evaporator sensor ..................................................................................................... 19

3.6.1.2 Return air sensor on the evaporator.......................................................................... 20

3.6.1.3 Room sensor (supply air) in the air duct (special design) ......................................... 20

3.7 Repair of lighting unit............................................................................................................. 21

3.7.1 Repair of LED light strips................................................................................................... 21

3.7.2 Repair of LED transformer................................................................................................. 22

3.8Repair of frame heater........................................................................................................... 23

3.8.1.1 Frame heater "copper pipe"....................................................................................... 24

3.8.1.2 Frame heater “stuck on” ............................................................................................ 24

4Cleaning and Final Inspection........................................................................................................ 25