IDEAL Stripmaster 950 User manual

#45-950

#45-954

#45-950-1

Stripmaster

®Model 950™& Model 954

Wire Stripper

2

Table of Contents

Introduction..................................................................... 3

Warranty & Service Policy............................................... 3

Technical Data.................................................................

3

Unpacking....................................................................... 3

Operation

Hook-up Air............................................................... 4

Hook-up Air Regulator............................................... 4

Display ...................................................................... 4

Strip Length............................................................... 5

Service

Replacement Adjustment ........................................... 6

Replacement Guide.................................................... 7

Adjustments Clamp Stop ........................................... 7

Adjustments Partial Strip ........................................... 7

Circuit Board Adjustment........................................... 8

Stripmaster®Model 950™ & 950-1™

Alignment Adjustments.............................................. 9

Stripmaster®Model 954™

Adjustments............................................................... 10

Tips and Troubleshooting ............................................... 11

Ordering Blades and Wire Guides ................................... 12

Stripmaster®Model 950 & 954 Wire Stripper

3

Introduction

The IDEAL Stripmaster®Models 950™, 950-1 and 954 Wire Strippers are electrically operated, pneumatic precision production tools designed to strip a

variety of insulation types in the 10 to 30 AWG range.

Each unit is equipped to accommodate up to six different wire guide/blade and strip length configurations, allowing operators to strip multiple wire diame-

ters and insulations without switching tools or re-installing blade sets.

Consult the factory for standard guide and blade set availability. Special guides and blades are available upon request.

Warranty and Service Policy

Each unit is warranted to be free from defects in materials and workmanship under normal use and service for a period of 12 months after the date of

purchase. The obligations of IDEAL under this warranty shall be limited to repairing at the Sycamore, Illinois manufacturing facility any unit which

shall, within the 12 month period, be returned to use with the transportation charges prepaid, and with our examination shall disclosed to our satisfac-

tion to have been defective. This warranty shall not apply to any model which has been altered or repaired outside the factory in any way so as to affect

its operation nor which has been subject to misuse, negligence, accident or installed or operated in any other way than in accordance with our instruc-

tions, nor shall this warranty extend to repairs or replacement made necessary by the use of accessories not recommended by IDEAL.

Technical Data

Strip Lengths........................... Minimum: .125 inches (3mm)

Maximum: .63 inches (16mm)

Strip Capacity.......................... Minimum: #30 AWG (.05mm2)

Maximum: #10 AWG (6.0mm2)

Accuracy: ................................................. Meets Military specifications in most applications

Voltage:.................................................... 12 volts required for operation

120V/60Hz transformer supplied as standard

For 220V/50Hz application, order 45-951 transformer

Air Pressure: ............................................ 65 PSI max.

Air Filter:.................................................. Recommended, but not required

In-line Oiler:............................................. Not required

Blade Type: .............................................. Heat treated steel knife or die-type blades are available

Guide Bushings:....................................... Precision molded and machined Delrin

Strip Cycle: .............................................. Electronically adjustable strip and return speed

Dimensions:.................................. Width: 4-7/8 inches (124mm)

Depth: 10-1/2 inches (267mm)

Height: 5-1/4 inches (133mm)

Warranty:.................................................. 1-year limited warranty

Unpacking

Your IDEAL Stripmaster®Model 950™ and Stripmaster®Model 954 Wire Strippers have been factory preset and tested with the blades and wire guides

specified. Installation and hook-up of the unit to a CLEAN, DRY, REGULATED AIR SUPPLY IS REQUIRED FOR PROPER PERFORMANCE.

Models 950, 954 and 950-1 come equipped with a 12-volt adapter, air hose, IDEAL Mini T®Cutter (45-260), regulator mounting bracket, air regulator

kit and a set of hex key wrenches.

Description Cat. No.

Stripmaster®Model 950™ 45-950

Stripmaster®Model 954™ 45-954 (45-950 w/permanent face plate)

Special Stripmaster Model 45-950-1 45-950-1

Permanent Gripper Assembly (faceplate only) 45-950-4

Replacement Blades Consult Factory

Replacement Bushings Consult Factory

Air Regulator Kit 45-906

120V/60Hz Adapter K-7156

220V/50Hz Adapter 45-951

T®-Cutter Lite 45-260

Hex Key Set 691.02

Air Hose 45-807

Regulator Mounting Bracket LB-1135

Operation

Hook-up Electrical

Connect 12-volt supply to power jack located at the rear of the unit.

Plug wall mount transformer in standard 115V outlet (use 45-951 and

proper cord set for 220V service).

Hook-up Air

Connect 1/4” coiled air hose to the air inlet fitting located at the rear of the unit. This is a reusable compression type fitting.

Connect the air hose by inserting hose firmly into the compression fitting.

Hook-up Air Regulator

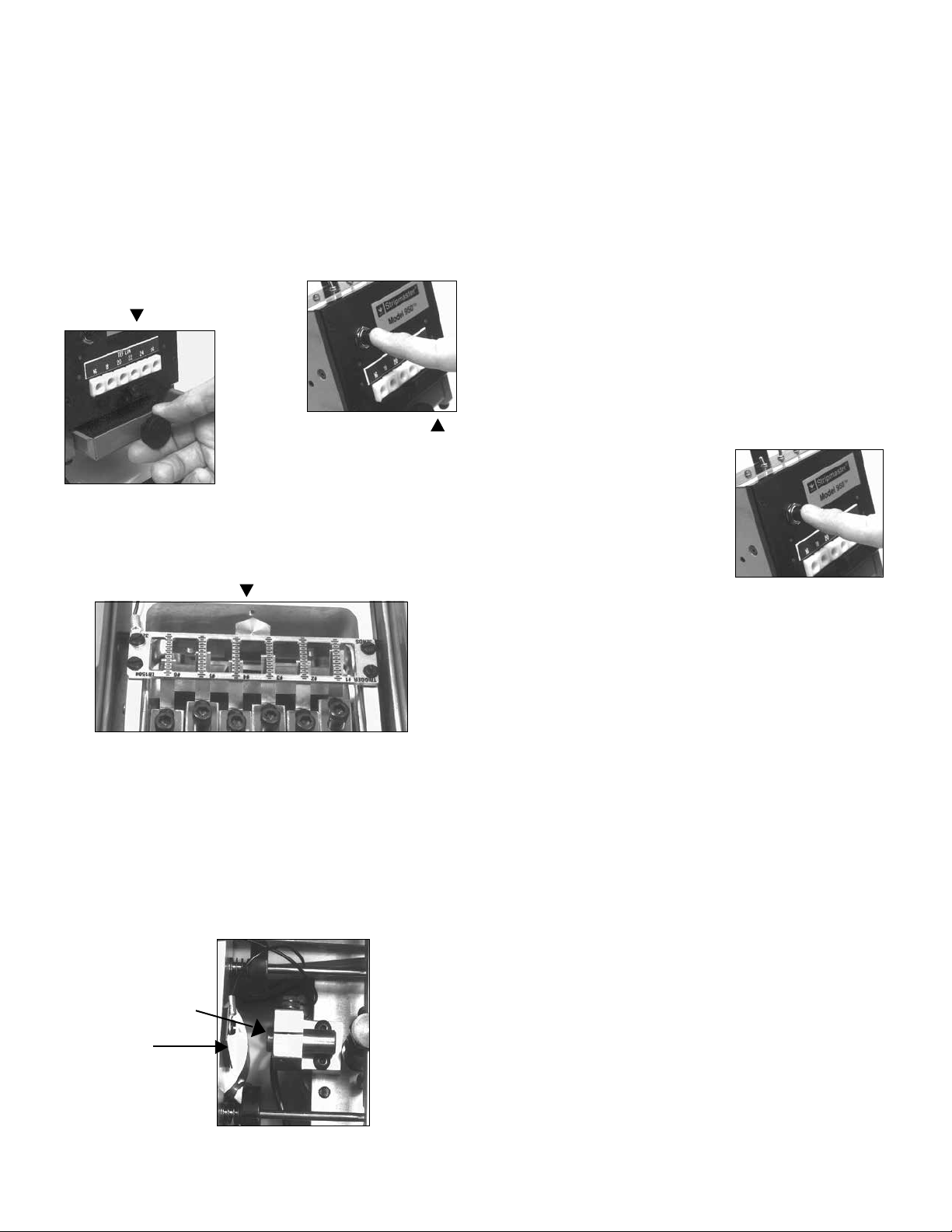

1. Attach regulator mounting

bracket to either side of the

unit, using two button-head

socket screws provided.

(#45-906)

2. Remove the retaining nut from the regulator body,

locate the regulator in the mounting bracket and

replace the retaining nut securely.

Thermal Head Rotation Speed

4

Connect the air line to a clean, dry,

regulated air supply.

Air pressure must be regulated to a

maximum 65 PSI.

To disconnect, simply depress the

red ring and pull on the air hose.

CAUTION: Do not attempt to

connect or disconnect the air

hose with compressed air in

the line.

1. Turn the power switch

to the ON position.

Green power indicator

light will illuminate.

2. Place the AUTO/SET-UP switch to the AUTO position.

Red indicator light will illuminate.

3. Actuate single-cycle switch to cycle the unit. This will show

unit is ready for operation.

Note: CYCLE IN PROGRESS

light will illuminate

during stripping cycle.

Display

With proper air and electrical connections, the unit is now ready for operation.

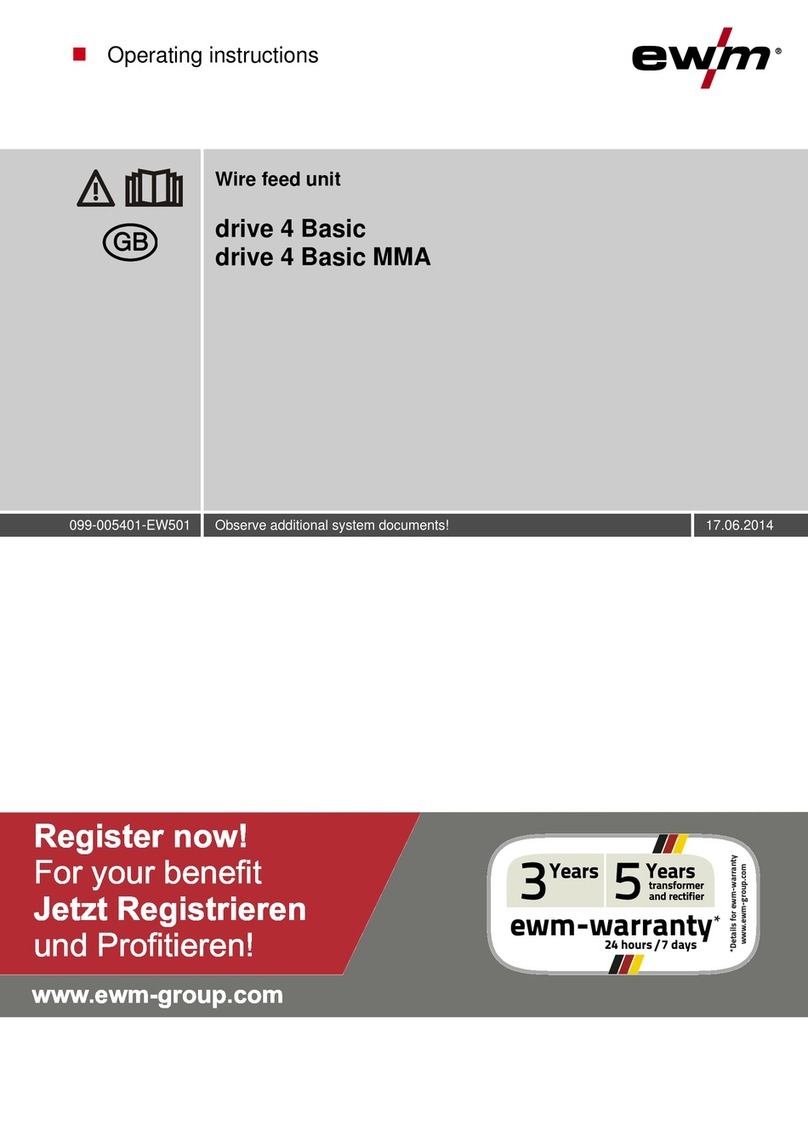

4. Observe the position of the trigger relative

to the indicating scale and loosen the

#8-32 socket head cap screw (use 5/32

hex wrench). Slide trigger to desired loca-

tion and retighten cap screw. Repeat this

procedure until all six triggers have been

set in their desired position.

Strip Length

Unit is equipped with six individual triggers. This allows

each wire port to be set-up to its own unique strip length.

1. Turn power switch to the OFF position. Leave air

supply connected.

2. Remove slug tray (Item 21)*.

3. Note position of wire port numbers 1 thru 6 from left to right with matching numbers

which correspond to the indicating scales on the contact plate (Item 19)*.

CONTACT PLATE (ITEM 19)*

TRIGGER ASSEMBLY (ITEM 16)*

8-32 CAP SCREW (ITEM 16)*

INDICATING SCALE 5. To check strip length, turn machine to its upright position and turn

power switch on. Strip several sample wires and verify proper strip

lengths. Repeat strip length adjustments as required.

CAUTION: Strip length range is 1/8” to 5/8”. Setting

strip length less than 1/8” may cause uncontrolled

cycling. Reset as required.

#2 #3

5

Operation (continued)

4. Insert the wire to be stripped into the wire guide hole until it engages the

trigger. Machine should cycle completely.

Note: Excessive force should not be required to

insert the wire into the proper wire guide.

CAUTION: The unit is designed to strip one wire per

cycle. DO NOT load multiple wires

simultaneously.

The unit is designed to accommodate as many as six blade and wire guide

configurations to speed production stripping jobs where more than one wire

type and size are to be stripped.

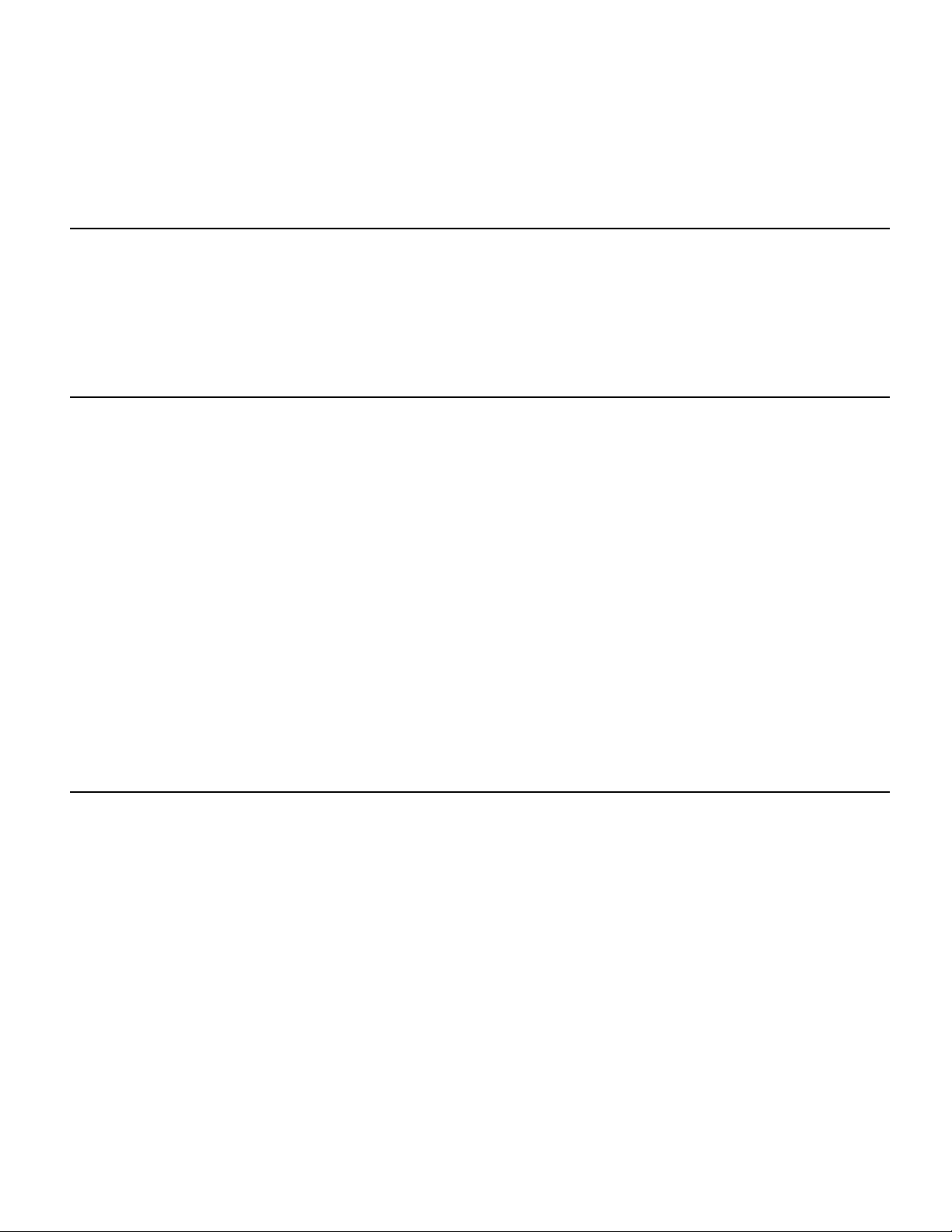

For increased operator comfort and efficiency the unit may also be adjusted to

operate at different angles from 00 (flat) to 450. Loosen knobs and spread the

6

Service (Qualified personnel only)

Replacement/Adjustment

Blade Installation

1. Disconnect the unit from air supply and turn power switch off.

2. Remove the four socket head screws (use 7/64 hex wrench)

located at the corners of the front cover plate.

5. Install the blade halves. Insert the #4-40 button head cap

screw (use 1/16 hex wrench) and lock washers but do not

tighten completely.

6. Back out all (6) set screws (use .050 hex wrench) located at

the bottom of the blade holder.

WARNING: Keep fingers away from the blade area.

7. Connect air supply and turn power switch on. Switch the AUTO

SET-UP switch to the SET-UP position. This will close all blades

firmly.

8. Check all blade sets for gaps. Adjust blade set screws accord-

ingly to ensure proper seating of blade sets. Care must be taken

not to over extend any one blade. This will result in gaps in

remaining blade sets.

9. With blades properly adjusted, tighten all blade holding screws.

10. Reconnect air line to the face plate

by inserting hose into the com-

pression fitting firmly.

11. Reinstall front cover plate, making

sure clamp dowel pins are

properly aligned with the clamp

yoke (Item 22)*.

12. Securely tighten the front cover

plate screws.

13. Turn AUTO/SET-UP switch to the AUTO position.

NOTE: Anytime blade adjustments are made, it is helpful to

back out the blade set screws.

3. Remove the front

cover plate. For

better access, dis-

connect the air line

leading to the face

plate by pushing in

red ring on connec-

tor.

4. Install the matched die type blades behind the

appropriate wire guides. Note that blade pairs have

been carefully matched and should remain as a set.

DO NOT MIX BLADES. Blades should be mounted

with the etched “HA” part

numbers facing outwards

on both halves. The 3-digit

serial numbers face inward.

Knife-type blades are not

serialized and can be locat-

ed with beveled surface

facing either direction.

Insure that both male and

female blade halves are of

the same part numbers.

110

HA2202

HA2202

110

FACE PLATE

Service (Qualified personnel only; continued)

Replacement Guide

Adjustments Clamp Stop

2. Remove old wire guide and insert new wire

guide, making sure that the cross slot of

each bushing faces downward.

If the wire guides have all been

removed it may be necessary

to spread the wire guide clamp

“slightly” to install the

first bushing. It is not

recommended to spread or

separate the wire guide clamp

any more than necessary

during installation.

3. Relocate retaining plate (Item 13)*

and thumb screw (Item 14)*.

1. Remove the guide

retaining plate (Item 13)*

by removing the thumb

screw (Item 14)*.

Adjustments Partial Strip

Cross slot at bottom position

It may become necessary to adjust the gripping action to increase or

decrease the gripping force. This unit is factory preset to increase or

decrease the grip with full force. Softer insulations may require less force

to minimize deformation.

1. Disconnect unit from air and power supply.

2. Remove face place (use 7/64 hex wrench).

3. Raise or lower set screws evenly (use 1/16 hex wrench). This will

allow for an increase or decrease in the gripping force of the bush-

ings.

4. Replace face plate.

NOTE: One clamp stop setting may not permit satisfactory gripping on dif-

ferent wires, due to the variety of wire types and gripping requirements.

B A

It may be desired to allow the stripped slug to remain on the wire to protect the con-

ductor during handling. The unit is factory preset to remove the slug completely. In

this initial position, the unit automatically actuates an air blasting device to aid in slug

removal. When a partial strip is set, the air blast is disarmed.

1. Disconnect air and power supply.

2. Remove slug tray and invert unit.

3. Loosen Socket head cap screw (A) (use 5/32 hex wrench) and reposition basket

stop pin (B) to obtain the desired

strip length.

4. Tighten Socket head cap screw to ensure basket stop pin is secure. Strip wire

to verify partial strip. Dissimilar wires will behave differently when stripped.

Therefore, it may be necessary to change the partial strip adjustment.

5. Turn the unit upright and insert the slug tray.

7

8

Service (Qualified personnel only; continued)

Circuit Board Adjustment

Strip Delay

Return Delay

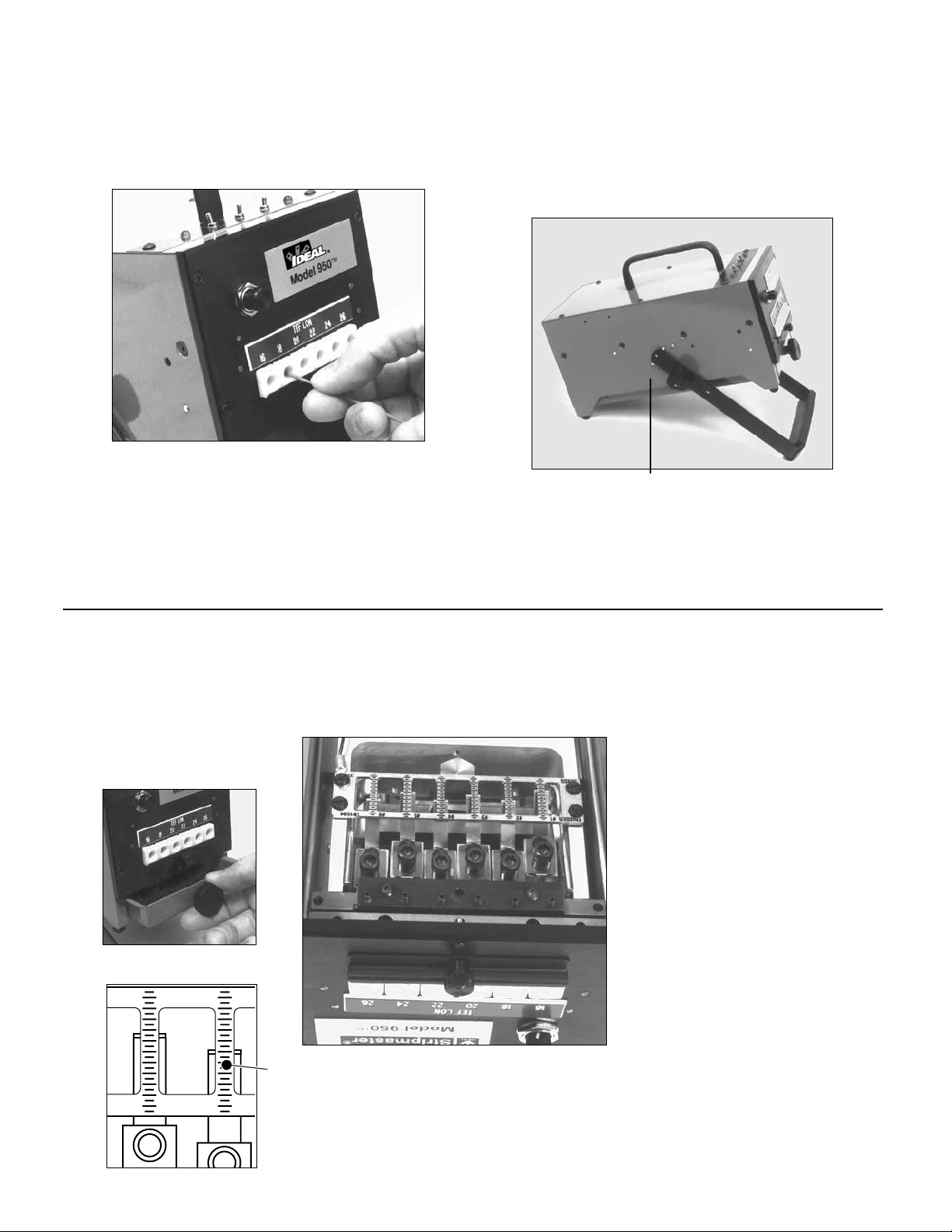

It may be desirable to increase the time delay after cutting/gripping and

before pulling the slug off a wire. This will insure a more secure grip

and a better cut.

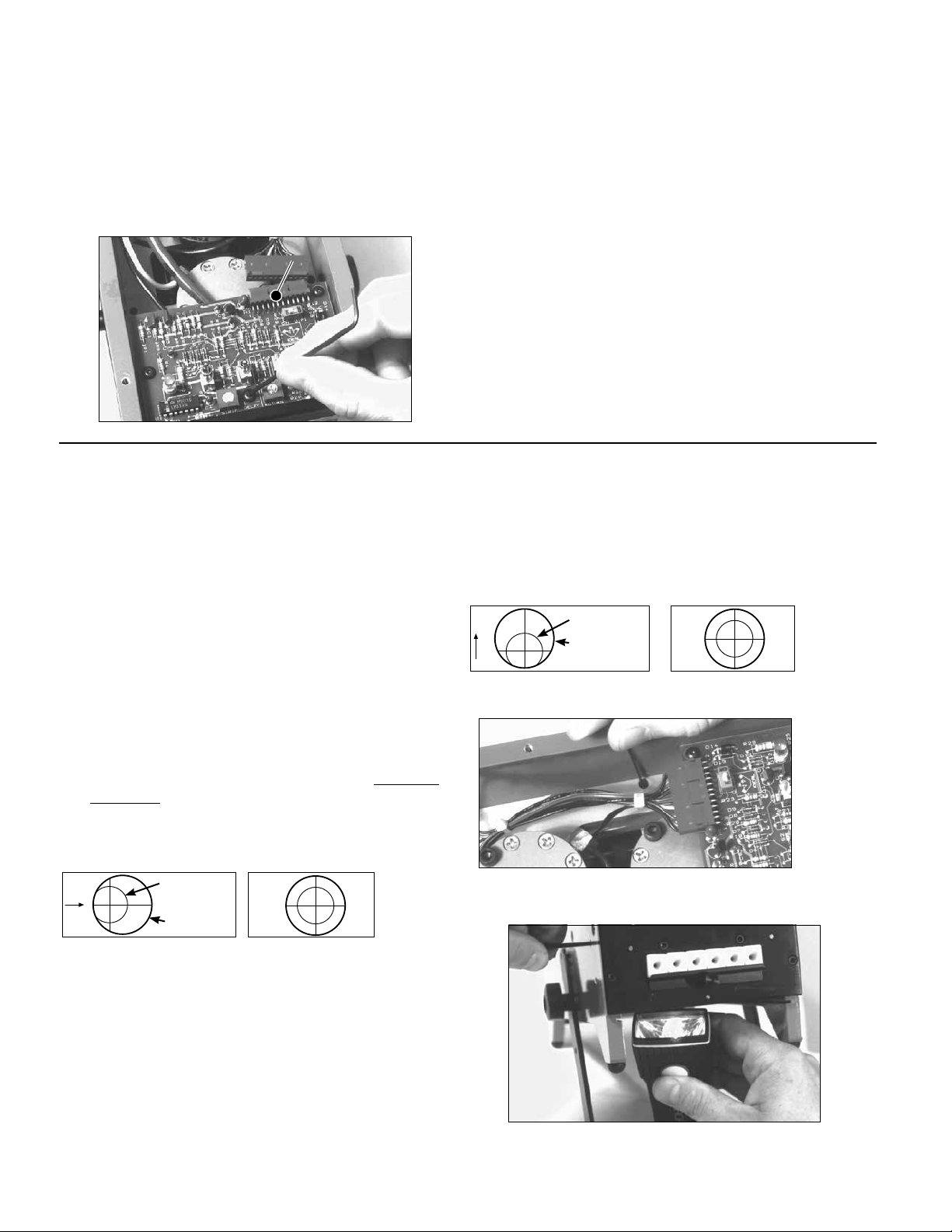

1. Remove the six #6-32 button head

cap screws (use 5/64 hex wrench)

and the top plate. Locate the circuit

board near the front of the unit.

2. Locate and adjust the “strip” delay by turning the potentiome-

ter screw with a small electronic screwdriver. Clockwise (+) to

increase delay and counterclockwise (-) to reduce delay.

3. Cycle the machine and continue to readjust as required.

4. Replace top plate.

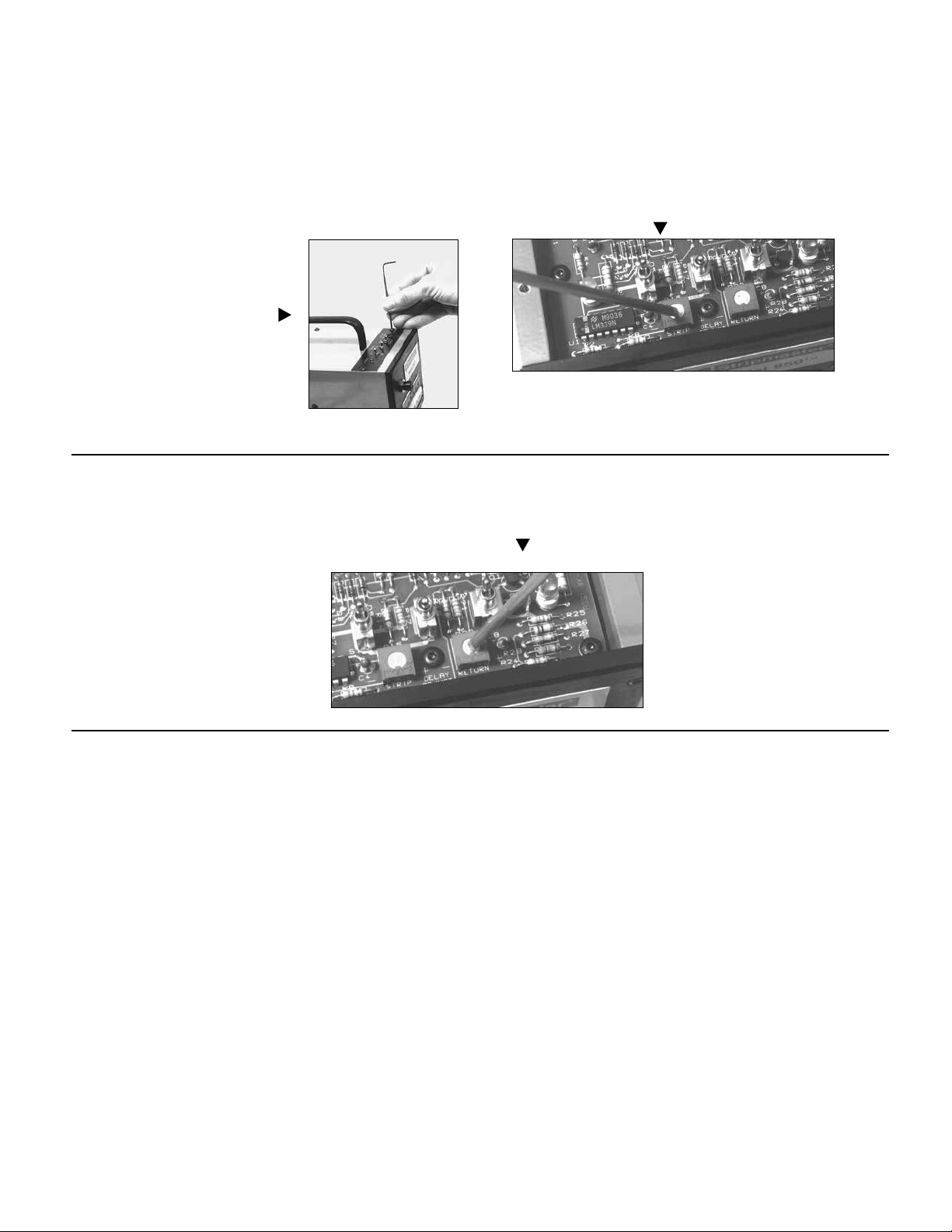

It may be desired to increase the time delay after stripping a wire to

allow the operator more time to remove the wire before the unit resets

itself.

1. Remove the six #6-32 button head cap

screws (use 5/64 hex wrench) and the

top plate. Locate the circuit board near

the front of the unit.

2. Locate and adjust the “return” delay by turning the potentiom-

eter screw with a small electronic screwdriver. Clockwise (+) to

increase delay and counterclockwise (-) to reduce delay.

3. Cycle the machine and continue to read

just as required.

4. Replace top plate.

Service (Qualified personnel only; continued)

Circuit Board Adjustment

Replacement Circuit Board

Stripmaster®Model 950™ & 950-1™ Wire Strippers

Alignment Adjustments

Alignment

WIRE HARNESS CONNECTION

It may become necessary to replace the circuit board, in the unlikely

event of an electrical failure.

Your IDEAL Stripmaster®Model 950™ Wire Stripper has been aligned by IDEAL. After time, it may become necessary to realign. The following section

describes three different adjustments that are necessary to insure proper blade and guide alignment.

Adjustment Vertical

1. Remove top plate and slug tray.

2. Close blades using set up switch at top of machine.

It is helpful to use a light source beneath the machine to

illuminate the hole through the blade and bushing. Visually

check bushing and blade cutting holes for proper alignment.

3. Adjust set screws (use 1/16” hex wrench) located near both side

plates approximately 3 1/2” from the face plate, to raise or lower all

six blades to their proper vertical position if needed. Adjust both

sides evenly.

4. Install slug tray and top plate.

Adjustment Horizontal

1. Remove slug tray.

2. Close blades using set up switch at top of machine. It is

helpful to use a light source beneath the machine to illuminate the

hole through the blade and bushing. Visually check bushing and

blade cutting holes for proper alignment.

3. By turning both front left and front right set screws (use 3/32 hex wrench), repo-

sition the carriage left or right to obtain the proper alignment.

4. Install slug tray.

Important: Minimal side play is required for proper

alignment. But over tightening set screws will prohibit

carriage movement.

1. Remove the six #6-32 button head cap screws (use 5/64 hex

wrench) and the top plate. Locate the circuit board near the front

of the unit.

2. Remove the wire harness connector at the rear of the circuit

board.

3. Remove the four #6-32 button head cap screws (use 5/64 hex

wrench) on the circuit board.

4. Install the new circuit board and reverse removal procedures.

INCORRECT CORRECT

BLADE HOLE

GUIDE HOLE

9

INCORRECT CORRECT

BLADE HOLE

GUIDE HOLE

10

Stripmaster®Model 954™ Permanent Gripper Wire Stripper

Your IDEAL Stripmaster®Model 954™ Permanent Gripper Wire Stripper has been aligned by IDEAL. After time, it may become necessary to realign.

The following section describes three different adjustments that are necessary to insure proper blade and clamp bar alignment.

Permanent Gripper Faceplate

Adjustments Permanent

Faceplate Vertical

1. Remove top plate and slug tray.

2. Close blades using set up switch at top of machine. It is helpful to

use a light source beneath the machine to illuminate the hole through the

blade and bushing. Visually check bushing and blade cutting holes for

proper alignment.

3. Adjust set screws (use 1/16” hex wrench) located near both side plates

approximately 3 1/2” from the face plate, to raise or lower all six blades to

their proper vertical position if needed. Adjust both sides evenly.

4. Install slug tray and top plate.

Adjustments Permanent Faceplate Horizontal

1. Remove slug tray.

2. Close blades using set up switch at top of machine. It is helpful to use a light source beneath the machine to illuminate the hole through the blade

and bushing. Visually check bushing and blade cutting holes for proper alignment.

3. By turning both front left and front right set screws (use 3/32 hex wrench), reposition the carriage left or right to obtain the proper alignment.

4. Install slug tray.

Adjustments Permanent Faceplate Clamp Bar

1. With air connected to machines, turn power off and remove slug tray.

2. To raise gap of the clamp bar, turn setscrews clockwise. To reduce gap of the clampbar, turn setscrews counter-clockwise.

3. Replace Slug tray.

Note: Over extending one or both setscrews may result in wire being “pulled” into the machine during the stripping action. Not enough setscrew adjustment

could result in an excessive amount of clamping force resulting in damage to outer insulation.

Service (Qualified personnel only; continued)

Alignment Adjustments (continued)

Adjustments Clamp Yoke Stop

1. With air connected to machine, turn power off and remove slug tray.

It is again helpful to use a light source positioned at or between blade and

trigger area to illuminate the hole through the blade and bushing.

2. With blades in open position, look through all wire guides to see if blades are

obstructing the wire entry path. No part of the blade should be

visible.

3. If an adjustment is needed, disconnect the air supply and raise or lower clamp

yoke stop screws evenly (use 7/64 hex wrench). This will raise or lower blades,

thus ensuring a clear path for wire entry in all six bushings.

4. Insert slug tray.

INCORRECT CORRECT

BLADE EDGES

GUIDE HOLE

INCORRECT CORRECT

BLADE HOLE

GUIDE HOLE

INCORRECT CORRECT

BLADE HOLE

GUIDE HOLE

THIS PIN SHOULD

CONTACT THIS

PLATE DURING

CYCLE

11

Tips and Troubleshooting

CAUTION: Always disconnect air and power supply before ser-

vicing unit.

UNIT WILL NOT CYCLE

n Actuate manual switch.

n Check to see that you have proper air supply.

n Empty slug tray and make sure all slugs have

been removed from the unit.

n Check to see that no slugs are

trapped in the blade or trigger area. If

a slug is present, clear with a blast of

air (Item 11)*.

n Check to see that all triggers are clean and making necessary

contact with the contact plate (Item 19)*. These surfaces should be

lubricated with IDEAL Noalox®Anti-Oxidant: Part number 30-024.

Unit Will Not Cycle Remaining in Tripped Position

n Actuate manual switch.

n Check basket stop pin to see that contact is being made.

n Check basket stop pin and carriage plate contact for excessive

wear or contamination. Wipe both mating surfaces clean.

n Insure basket stop contact wire is properly connected and not broken.

Multiple or Continuous Cycling

On occasion the unit may repeat cycles while clearing a slug. If the con-

dition becomes excessive, the following steps may help you in identifying

and eliminating the problem.

n Make sure stripped wire is removed promptly after each cycle.

n Empty the slug removal tray and make sure that all slugs have been

removed from the unit.

n Disconnect the unit from the air and power supply and check to see that

no insulation slugs are trapped between the blades and triggers.

n If a slug is trapped, remove carefully.

Unit Will Not Strip Wire

n Use air switch slug blast (Item 11)* to clear any slugs away from the

blade/guide area and manually actuate the

machine.

n Check to see that the wire is being

inserted into the proper wire guide/blade.

n Check to see that the wire being used is

proper mil. spec. and within the proper

tolerance.

n Insure proper alignment and installation of blades (see Blade and Wire

Guide Installation).

n Check to see that the blades and wire guides are not damaged or worn.

If there is any question, replace the affected guides and blades or

consult IDEAL.

Wire Strip is Incomplete or Damages the Conductor

n Use air switch slug blast (Item 11)* to clear any slugs away from the

blade/guide area and manually actuate the machine.

n Check to see that the wire is being inserted into the proper guide/

blade.

n Check to see that the wire being used is proper mil. spec. and within

the proper tolerance.

n Insure proper alignment and installation of blades (see Blade and Wire

Guide Installation).

n Check to see that the blades and wire guides are not damaged or worn.

If there is any question, replace the affected guides and blades or con-

sult IDEAL.

1 2 3 4 5 6

LABEL FORMAT

1 Single Line

2 Single line Plus

3 Double Line Plus

4 Character max each

port

Top line 30 character

max. 4 character max.

each port

5 character max. each

line each port

Wire Information

AWG Insulation Mil Spec Stripping Comments

1

2

3

4

5

6

Comments

Ordering Blades and Wire Guides

Due to varying manufacturing techniques, standard wire gauge sizes have begun to indicate “nominal” wire sizes and no longer indicate conductor

diameters accurately. Therefore, in order to maintain accurate precision wire stripping, IDEAL requests that exact mil spec. information for the types of

wire and insulation you will be stripping be provided to IDEAL when ordering blades and wire guides.

IDEAL also requests wire samples when ordering. If an IDEAL Custom Stripmaster™ Wire Stripper® hand tool is currently being used to strip the par-

ticular wire please specify the blade number being used with each wire type and size.

Due to varying outside diameter dimensions on every wire, IDEAL recommends ordering multiple wire guide bushings to match a given wire.

Depending upon wire tolerances, it may be necessary to order a wire guide one size larger and one size smaller than supplied with the machine. Guides

are easily interchanged to match varied wire size

When ordering, please specify the preferred face plate location and number designation for each blade/guide set.

For larger wire sizes (e.g. 10 AWG, 12 AWG, 14 AWG) blade location is preferred in the center ports of the machine.

Specification Chart Instructions

List the wire size, insulation type and mil. spec. per each wire size and type for which you are ordering stripping blades and wire guides under the

location/s (1 thru 6) you prefer.

Indicate numerical wire gauge legends (10 thru 30) or any identification you wish to appear above each corresponding air guide/blade configuration.

(Choose and complete the desired label format below. 1, 2 or 3)

Note: For better stripping results, locate 10, 12, 14 gauge wires nearest to center ports.

12

13

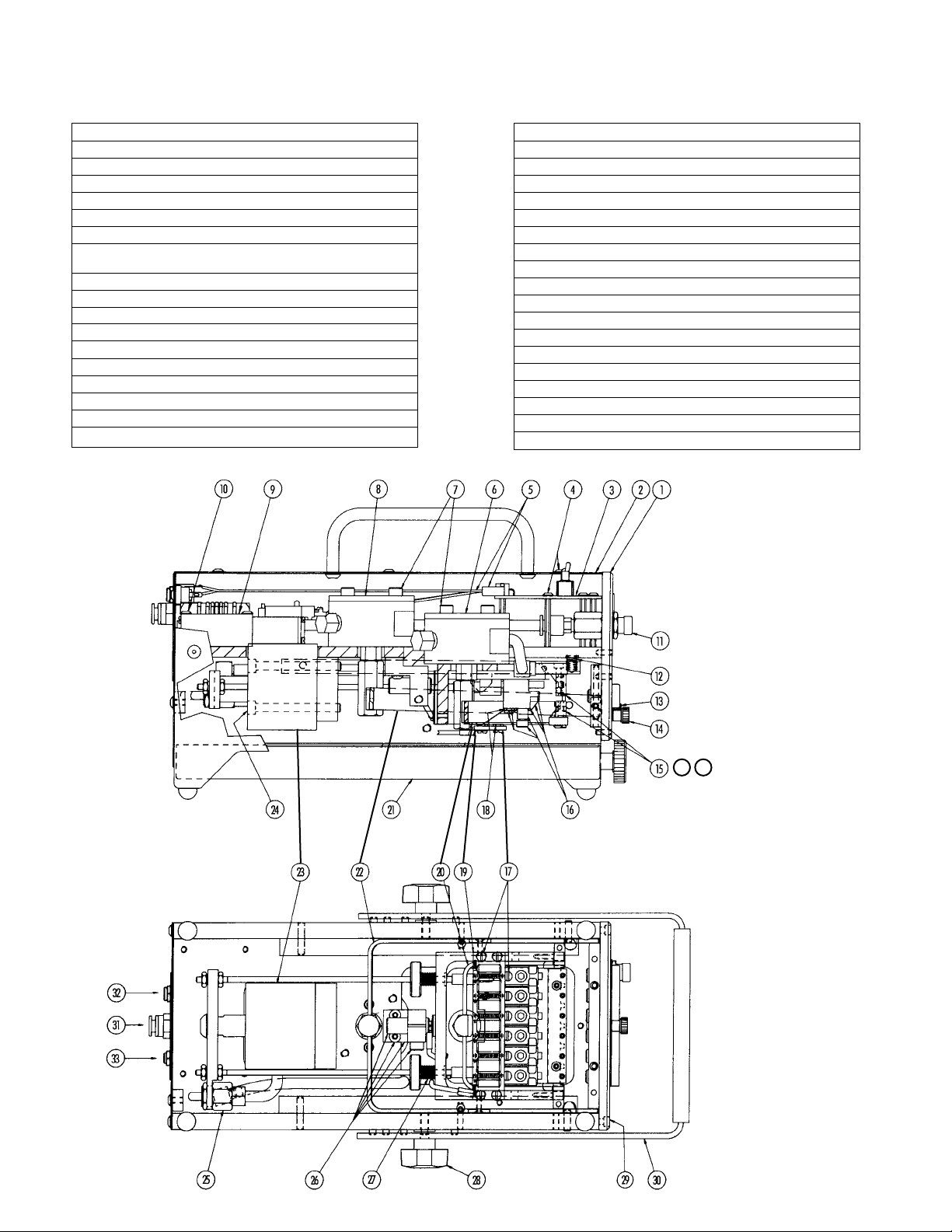

ITEM REQ NAME PART NO.

1 1 FRONT PLATE ASSEMBLY IA1819

2 1 TOP PLATE ASSEMBLY LB1523RP

3 1 CIRCUIT BOARD ASSEMBLY K-7109

4 14 SCREW #6-32 X .25 BHCS 115.002

5 1 WIRE HARNESS IA1892

6 1 BLADE CYLINDER ASSEMBLY K-7124RP

7 4 SCREW 113.095

#10-32 X 1.50 SHCS

8 1 CLAMP CYLINDER ASSEMBLY K-6863RP

9 2 SOLENOID VALVE 1532.007

10 4 SCREW #6-32 X 1.00 BHCS 115.028

11 1 AIR SWITCH SLUG BLAST LB1524

12 2 SPRING LB1513

13 1 BUSHING RETAINING PLATE K-6940

14 1 RETAINING SCREW LB1525

15 1 BLADE HOLDER H-2472

16 6 TRIGGER ASSEMBLY LB1526RP

17 5 SCREW #4-40 X .25 PH NYLON 358.033

ITEM REQ NAME PART NO.

18 4 WASHER #4 NYLON 637.006

19 1 CONTACT PLATE LB1504

20 1 CUT YOKE K-6806

21 1 SLUG TRAY ASSEMBLY K-7112RP

22 1 YOKE CLAMP K-6800

23 1 STRIP CYLINDER ASSEMBLY K-6864RP

24 2 SCREW #10-32 X 2.00 SHCS 113.096

25 1 AIR BLAST VALVE ASSEMBLY K-7153RP

26 1 BASKET STOP ASSEMBLY LB1527RP

27 2 SPRING LB1514

28 2 KNOB 341.016

29 4 SCREW #6-32 X .38 SHCS 113.100

30 1 HANDLE LB1528RP

31 1 AIR HOSE K-6865

32 1 PLUG-IN TRANSFORMER K-7156

BLADE MOUNTING SCREWS 115.010

BLADE MOUNTING WASHERS 633.051

NAMEPLATE HOLDER LA-2675

NOT SHOWN

NOT SHOWN

NOT SHOWN

NOT SHOWN

MANUAL SLUG BLAST

34 35

Stripmaster®Model 950™

Notes:

Notes:

IDEAL INDUSTRIES, INC.

1375 Park Avenue, Sycamore, IL 60178 – 800-435-0705 in U.S.A.

Ajax, Ontario, L1S 2E1, Canada – 800-527-9105 in Canada

Warrington, Cheshire WA55TN, England – 44 1925 444.446

www.idealind.com

Warranty limited solely to repair or replacement; no warranty of merchantability, fitness for a particular purpose or consequential damages.

1000 Park Avenue, Sycamore, IL 60178 — Manufacturing facility

Rev. 12/15

Printed in U.S.A.

Form No. ND 3558-2

©2015 IDEAL INDUSTRIES, INC.

This manual suits for next models

4

Table of contents