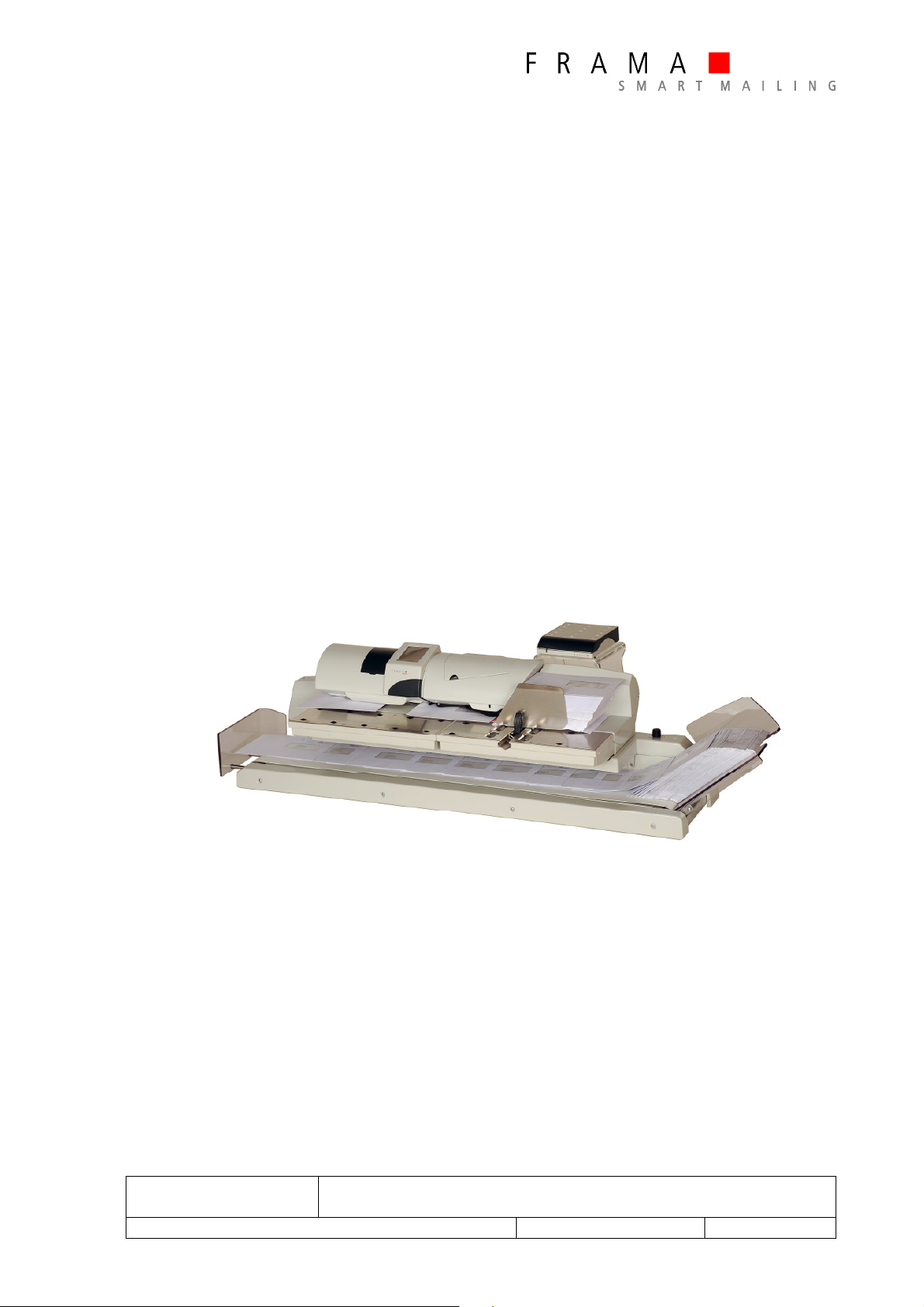

Figure 1 - Matrix F8 with Feeder AFS, Extension Table TR / TL ..................................................................................... 9

Figure 1 - Matrix F8 with Feeder AFS, Extension Table TR / TL ..................................................................................... 9

Figure 2: Parts Designation ...................................................................................................................................... 12

Figure 3: Parts Designation ...................................................................................................................................... 12

Figure 4: Parts Designation ...................................................................................................................................... 12

Figure 5: Parts Designation ...................................................................................................................................... 13

Figure 6: Parts Designation ...................................................................................................................................... 13

Figure 7: Parts Designation ...................................................................................................................................... 13

Figure 8: Parts Designation ...................................................................................................................................... 14

Figure 9: Parts Designation ...................................................................................................................................... 14

Figure 10: Main Board AF and AFS .......................................................................................................................... 15

Figure 11: Connector board AF and AFS .................................................................................................................. 15

Figure 12: Service Diagnostic ................................................................................................................................... 16

Figure 13: Service Diagnostic ................................................................................................................................... 17

Figure 14: Separation Matrix – Feeder ...................................................................................................................... 18

Figure 15: Removing – Sealer Unit ........................................................................................................................... 18

Figure 16: Disassembling – Top Cover ...................................................................................................................... 18

Figure 17: Disassembling - Upper Mechanics ........................................................................................................... 19

Figure 18: Disassembling – Upper Mechanics ........................................................................................................... 19

Figure 19: Disassembling - Upper Mechanics ........................................................................................................... 19

Figure 20: Disassembling - Upper Mechanics ........................................................................................................... 20

Figure 21: Disassembling – Upper Mechanics ........................................................................................................... 20

Figure 22: Disassembling - Upper Mechanics ........................................................................................................... 20

Figure 23: Disassembling - Label Dispenser .............................................................................................................. 21

Figure 24: Disassembling - Label Dispenser .............................................................................................................. 21

Figure 25: Disassembling – Clutch Separator ............................................................................................................ 22

Figure 26: Disassembling – Clutch Separator ............................................................................................................ 22

Figure 27: Disassembling - Lower Mechanics ........................................................................................................... 23

Figure 28: Disassembling – Lower Mechanics ........................................................................................................... 23

Figure 29: Disassembling - Lower Mechanics ........................................................................................................... 23

Figure 30: Disassembling - Main PCB ....................................................................................................................... 24

Figure 31: Disassembling – Gray Intake Rollers ......................................................................................................... 24

Figure 32: Disassembling - Gray Intake Rollers ......................................................................................................... 24

Figure 33: Disassembling - Red Intake Rollers ........................................................................................................... 25

Figure 34: Disassembling - Red Intake Rollers ........................................................................................................... 25

Figure 35: Disassembling - Red Intake Rollers ........................................................................................................... 25

Figure 36: Disassembling - Transport Rollers ............................................................................................................ 26

Figure 37: Disassembling - Transport Rollers ............................................................................................................ 26

Figure 38: Disassembling - Motor Replacement ........................................................................................................ 26

Figure 39: Disassembling - Motor Replacement ........................................................................................................ 27

Figure 40: Disassembling - Motor Replacement ........................................................................................................ 27

Figure 41: Disassembling - Motor Replacement ........................................................................................................ 27

Figure 42: Disassembling - Motor Replacement ........................................................................................................ 28

Figure 43: Disassembling - Motor Replacement ........................................................................................................ 28

Figure 44: Disassembling - Motor Replacement ........................................................................................................ 28

Figure 45: Assembling - Lower Mechanics ............................................................................................................... 29

Figure 46: Assembling - Lower Mechanics ............................................................................................................... 29

Figure 47: Assembling - Lower Mechanics ............................................................................................................... 29

Figure 48: Assembling - Label Dispenser .................................................................................................................. 30

Figure 49: Assembling - Label Dispenser .................................................................................................................. 30

Figure 50: Assembling - Upper Mechanics ............................................................................................................... 30

Figure 51: Assembling - Upper Mechanics ............................................................................................................... 31

Figure 52: Assembling - Upper Mechanics ............................................................................................................... 31

Figure 53: Assembling – Upper & Lower Mechanics ................................................................................................. 31

Figure 54: Assembling - Upper & Lower Mechanics .................................................................................................. 32

Figure 55: Assembling – Upper & Lower Mechanics ................................................................................................. 32

Figure 56: Assembling - Top Cover .......................................................................................................................... 32

Figure 57: Adjustments - Separation Roller .............................................................................................................. 33

Figure 58: Adjustments – Separation Roller .............................................................................................................. 33

Figure 59: Adjustments - Separation Roller .............................................................................................................. 33

Figure 60: Adjustments - Belt................................................................................................................................... 34

Figure 61: Adjustments - Belt................................................................................................................................... 34

Figure 62: Adjustments - Belt................................................................................................................................... 35

Figure 63: Adjustments - Belt................................................................................................................................... 35

Figure 64: Adjustments – Separator Lever ................................................................................................................ 36

Figure 65: Adjustments – Separator Lever ................................................................................................................ 36