2332462A

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Floor Preparation . . . . . . . . . . . . . . . . . . . . . . . . 6

Lifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . 7

PLC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Information . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Auto Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 9

Perform Auto Scan . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part Table Feed Rate . . . . . . . . . . . . . . . . . . . . 10

Hopper Feed Rate . . . . . . . . . . . . . . . . . . . . . . 10

Control Menu Layout . . . . . . . . . . . . . . . . . . . . . 12

Manual Operation in Override Mode . . . . . . . . . 13

Detailed Control Adjustment . . . . . . . . . . . . . . . . 13

Amplitude Power Setting . . . . . . . . . . . . . . . . . . 13

Limiting Maximum Output of Control . . . . . . . . . 13

Setting Minimum Output of Control . . . . . . . . . . 13

Soft-Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CFR Positive and Negative Gain . . . . . . . . . . . 13

Frequency Settings . . . . . . . . . . . . . . . . . . . . . . 13

Resonate Threshold Level . . . . . . . . . . . . . . . . 14

AutoTrack Dead Band . . . . . . . . . . . . . . . . . . . . 14

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Security Settings . . . . . . . . . . . . . . . . . . . . . . . . 14

Default Memory . . . . . . . . . . . . . . . . . . . . . . . . . 14

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Over Current Protection . . . . . . . . . . . . . . . . . . 14

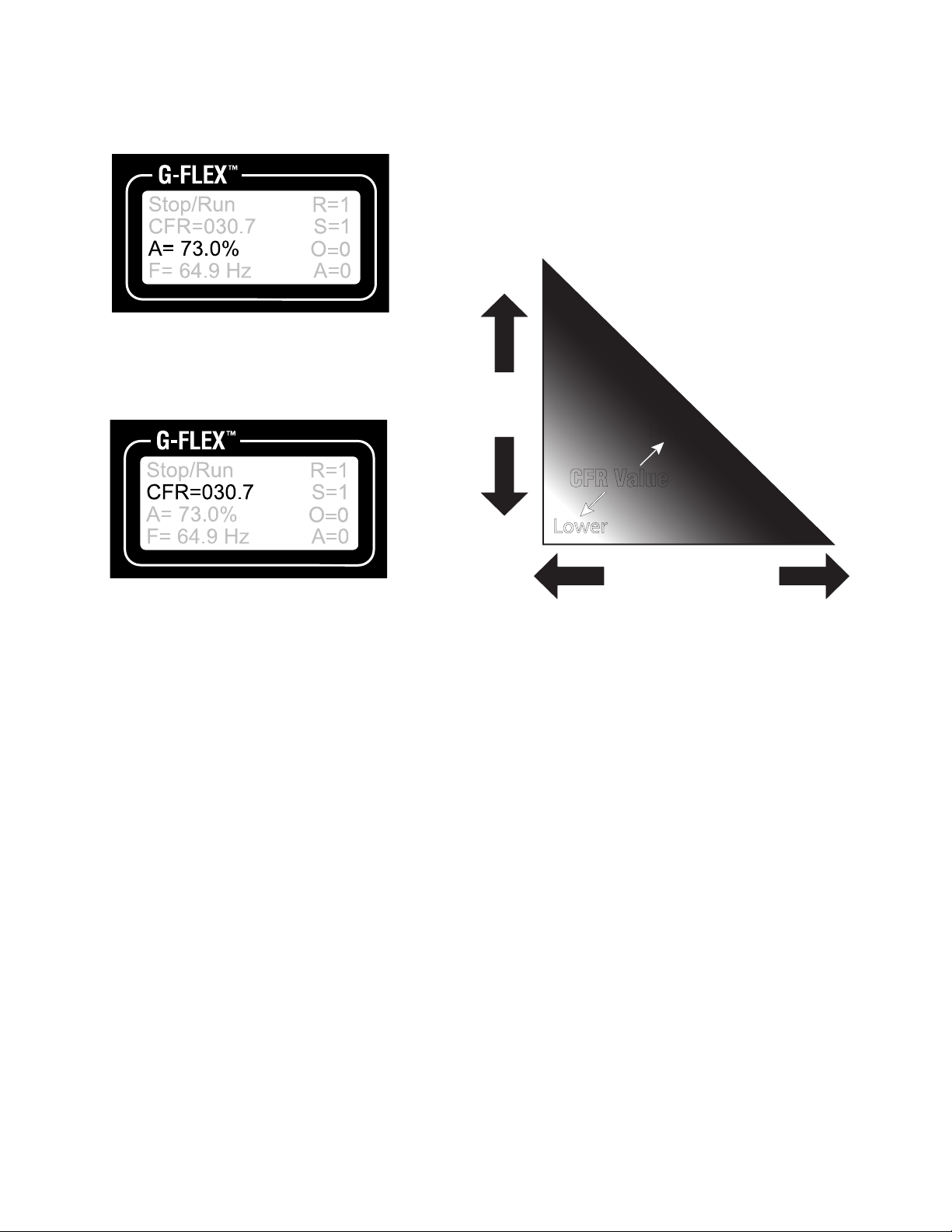

CFR Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Disconnect . . . . . . . . . . . . . . . . . . . . . . . 16

Air Gap Specifications . . . . . . . . . . . . . . . . . . . . 16

Table and Brush Spacing . . . . . . . . . . . . . . . . . . 16

Table Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 16

Brush Adjustment . . . . . . . . . . . . . . . . . . . . . . . 16

Electromagnet and Armature Spacing . . . . . . . . 17

Spring Replacement . . . . . . . . . . . . . . . . . . . . . 17

Electromagnet Replacement . . . . . . . . . . . . . . . 18

Display (Keypad) Replacement . . . . . . . . . . . . . 20

Accelerometer Replacement . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Technical Specifications . . . . . . . . . . . . . . . . . . . . 30

Box Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CFR Values Table . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 34