iDeck iDecKing EasyClick system User manual

EasyClick

system

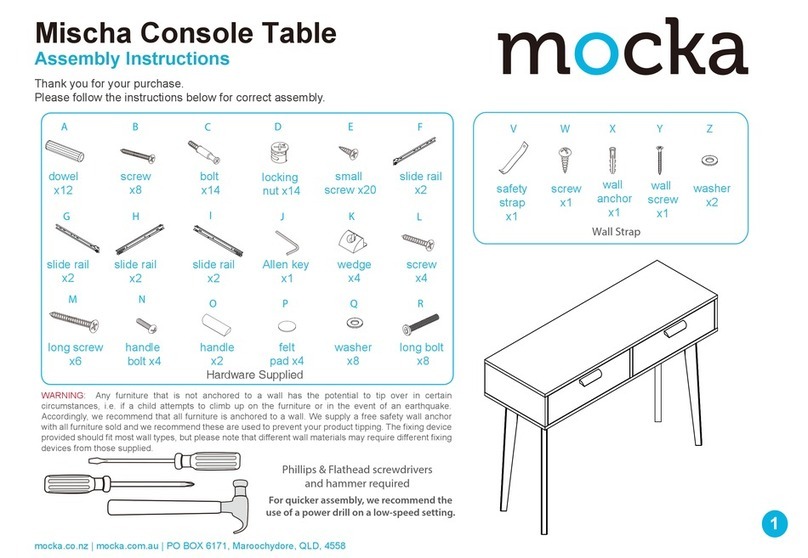

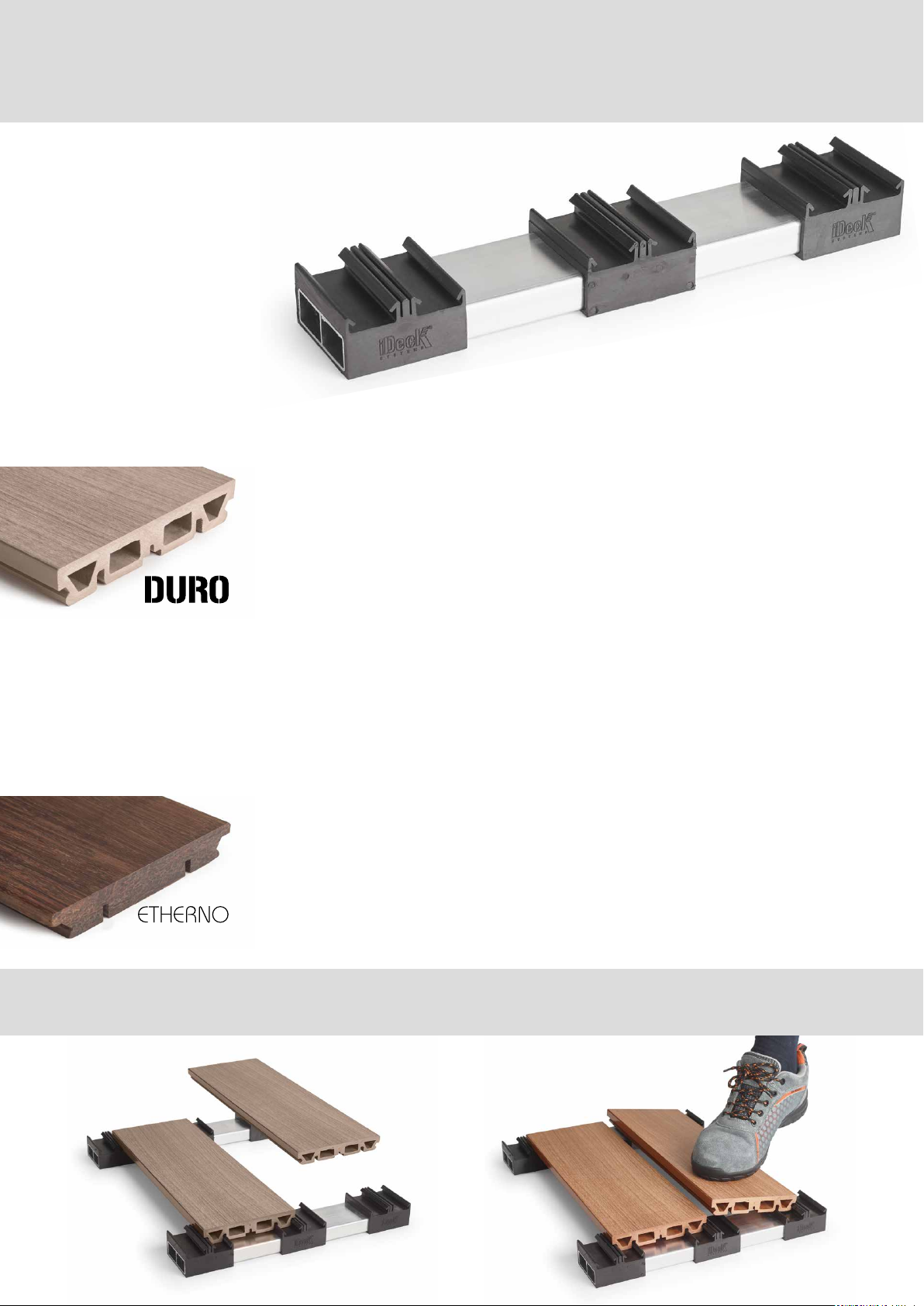

EasyClick system

components

EASYCLICK SYSTEM UNDERSTRUCTURE

IDECKING REVOLUTION BOARDS - DETAILS

CLICK!

just 1 click and the board is installed !

Duro boards are made from circa 50% RICE HUSK and 50% virgin PVC

and Minerals in order to deliver a product with as natural a look and feel as

possible. As it happens for wood, Duro composite material can encounter a

slight chromac change due to UV rays. Aer only a few months the boards

will stop further chromac change and become colour fast. For covered

or parally shaded areas this process will take longer. Using our specic

products (Duro Shield and Duro Drop) it is possible to protect Duro’s look

from stains and slow down the rate of fade. Furniture like ower boxes can

also couse colour change to the deck area so it is advised to change the

posion of this furniture during the rst 3-6 months in order to maximum

colour compensaon.

Minimal changes in colour and tone underline the natural aspect of Etherno

Bamboo, just like in any other noble wood (ie. IPE / TEAK). Colour variaons,

like prole and surface alteraons, are normal in the natural behaviour of any

wood and don’t represent vices or defects in the product so are not cause of

a claim. In order to get uniformity over the deck area, it is advised to mix up

the boards before installaon.

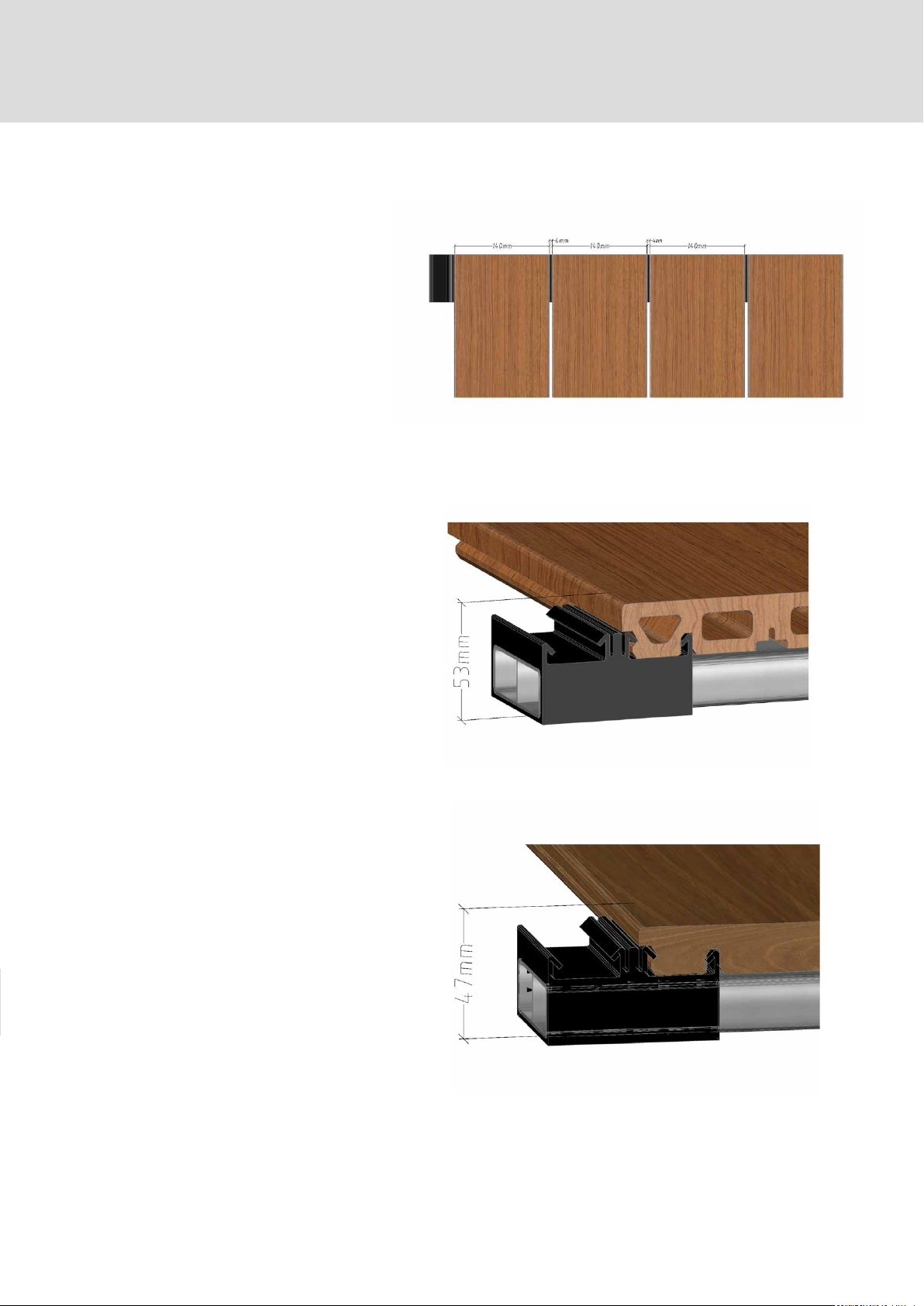

technical data on the system

EasyClick board standard width

140mm + 4 mm gap

Total Height of DURO Boards +

EasyClick Understructure: 53 mm

Total Height of ETHERNO boards +

EasyClick Understructure: 47 mm

Before the installation Dos and Donts

Duro is a non porous material so water will stand on the deck for longer than mber decking boards.

-

According to the principles of construcve wood preservaon, boards must always be installed with sucient gradient.

(1-2%). Gradient must always be in a longitudinal direcon with respect to the boards (direcon of the hollow chamber

and ung). The gradient direcon must always be away from the building. To ensure compliance, avoid water spots,

ponding, dirt deposits and other damage to the building.

-

The subsurface must be structurally sound and frost-protected and have sucient drainage.

-

For applicaons requiring approval by the building authories (e.g. balconies), you need a stacally weight-bearing

subsurface as support for the oor boards.

-

Permanent ground contact of DURO boards must be avoided!

-

When installing the deck up to a building or parapet wall, always leave at least 2 cm distance to allow

sucient expansion and contracon.

-

Drainage of adequate size is required for the subsurface. Avoid waterlogging and also ensure complete drainage during

heavy rainfall

-

Maximum distances for substructures must be adhered to!

-

Observe the minimum distances of the expansion joints to enable the unconstrained expansion of the structure where

applicable. Boards are 100% dry aer producon. Weathering causes them to absorb water and swell. Joints therefore

become smaller aer a few weeks/months. Thermal expansion must also be taken into account.

-

To guarantee a correct installaon and to preserve DURO’s surface look, the boards must be stacked out of direct

sun contact and in a dry place. When handling the boards, don’t slide boards one on top of the other in order to avoid

scratches. It is advised to deliver to boards to the site of the installaon a day or two before installaon to allow them

to acclimase to the condions. For best results, do not install iDecking boards in temperatures under +10°C.

-

Pre-drill screw connecons if any and use a low torque seng.

-

In case of any screw xaon, use only stainless steel screws

-

DURO boards will absorb heat. This heat eect has more of an impact on dark colours than light colours. Take this into

account when walking barefoot.

-

-

Fade is an unavoidable consequence of outdoor surfaces. To reduce the impact of UV related fade, two coats of

DUROSHIELD product must be applied at the me of installaon.

-

TOOLS: There are no special tools required. To achieve the best results, use saw blades and cung tools coated with

hard metal. If you use a mitre saw, we recommend a saw blade size of 254 - 305 mm with 40 teeth or fewer.

for any purpose other than for decking boards.You must use the iDecking substructures and assembly parts provided!

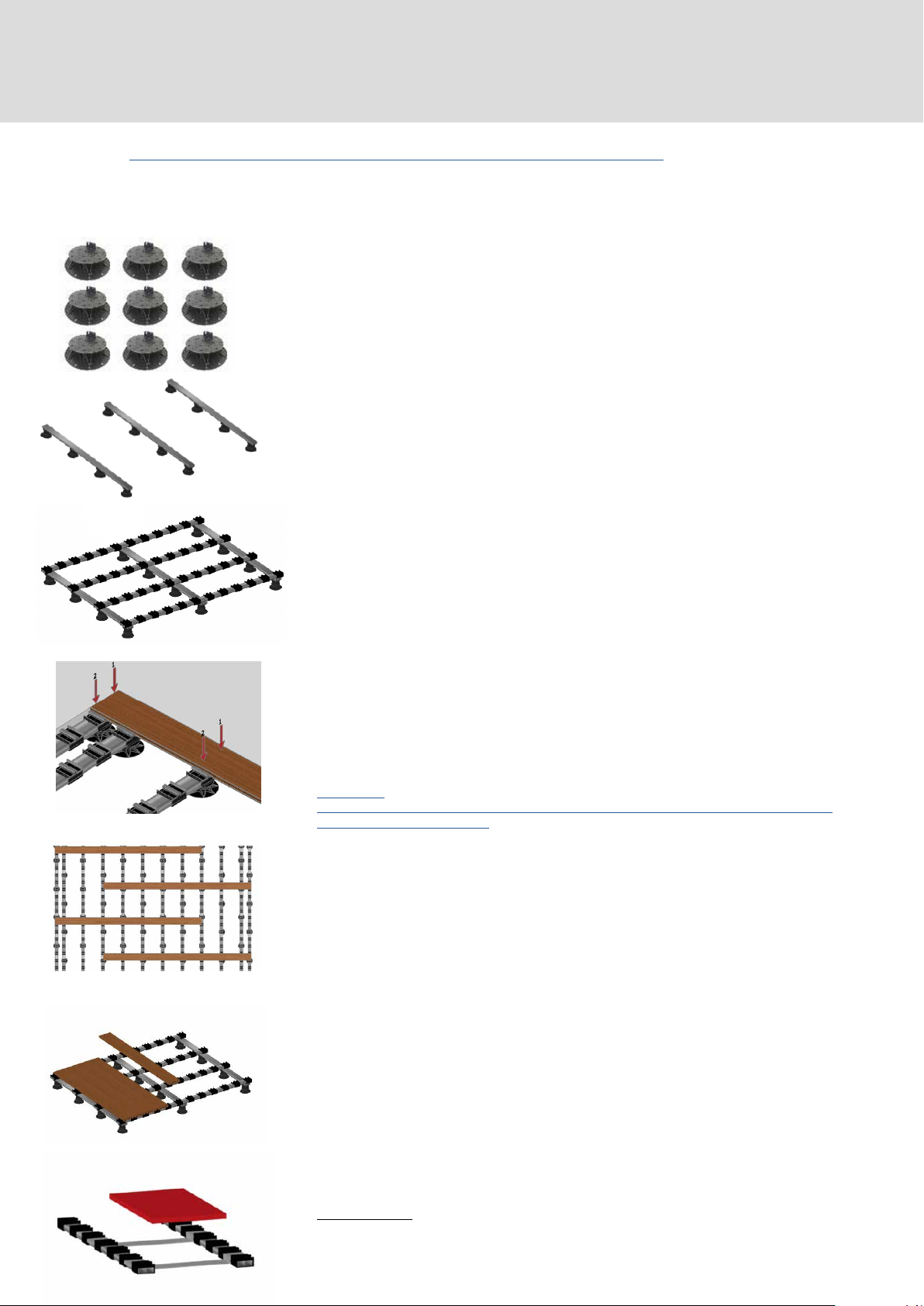

Installation: EasyClick system

• Scenario A : Installaons on concrete or exisng paving using rubber pads or adjustable pedestals

bonded or xed to understructure.

• Scenario B : Installaons on sensive roong membranes where mechanical xings are not possi-

ble using double aluminium rails on pedestals.

• Scenario C : Installaons over bare earth, using a primary frame with posts concreted

• into the ground

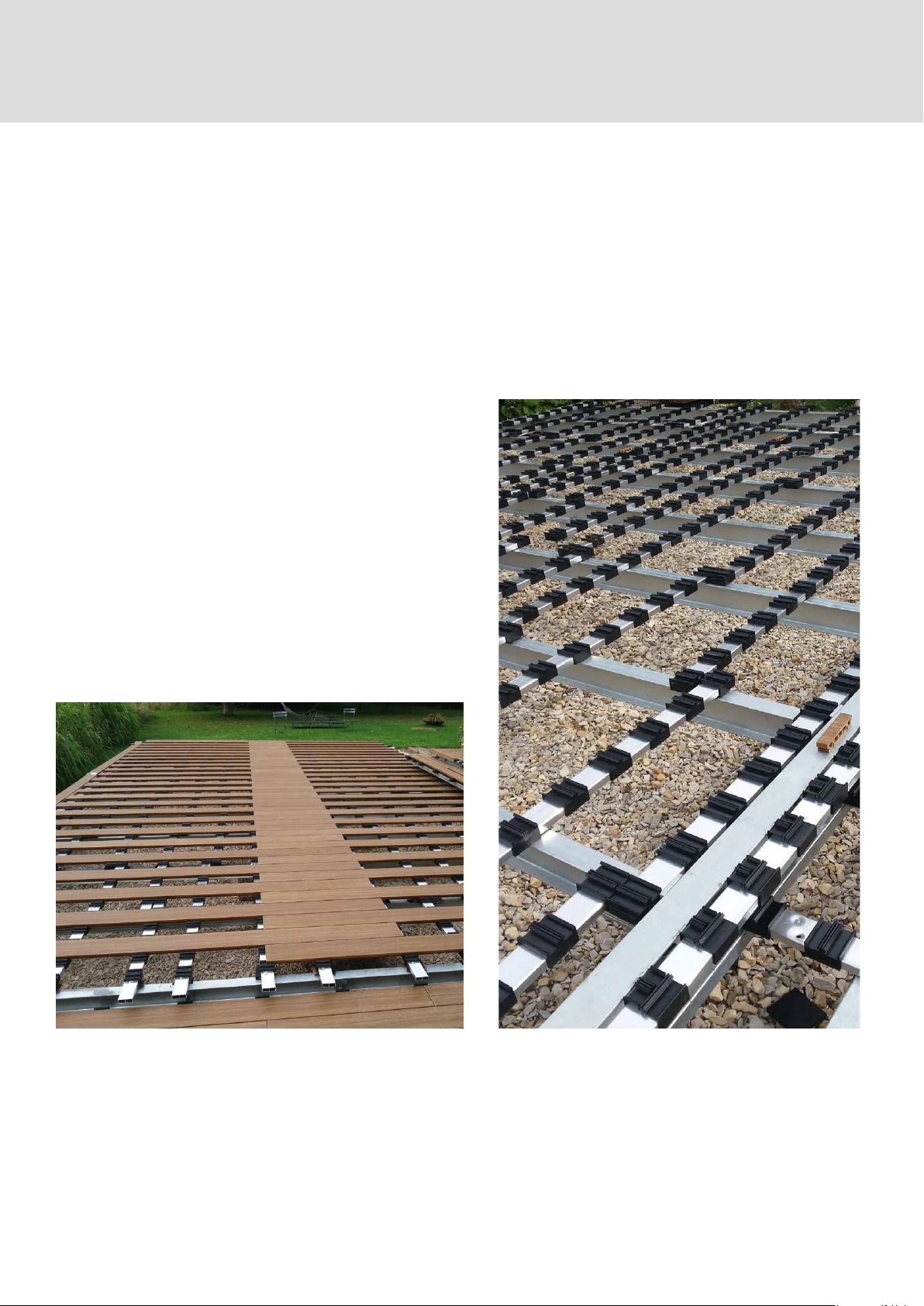

SCENARIO A :

Installaons on concrete or exisng paving using rubber pads or adjustable pedestals bonded or xed to understructure.

Leveling with rubber pads

● Posion the rubber pads or adjustable pedestals following max

of 600 mm interval from one another in the intended direcon of

the rails.

● Make adjustments to them in order to be all roughly the same

level.

● Place the EasyClick rails onto the pedestals.

Placing the EasyClick Understructure

- The interval between the aluminium rails depends on the kind

of board chosen for the deck.

- Align the aluminium rails following the suggested interval:

• Duro: interval 35cm (public areas) 40cm (private areas)

• Etherno Bamboo: interval 46cm

- Stagger the joints between the rails to ensure a more stable

structure.

Fixing the pedestals / supports to the ground

● It is now me to x the pedestals to the ground.

● In order to x the supports to the ground, li the support

from the side and inject the necessary amount of glue to x it

on the ground.

● Wait for the glue to sck to avoid support movements.

NO

YES

● Lay the board over the aligned rail.

● Click it by pressing down with your foot, rst on one side (1)

then the other side (2) onto the clips below.

● Repeat the operaon over each intersecon between board

and rail.

● When the height doesn’t allow the use of your foot, use a

rubber mallet to click the boards in place.

● It is now me to x the rails to the pedestals. Slightly li the

rails and apply a sucient amount of glue to the head of the

pedestal before replacing the rail in the centre of the pedestal

head.

● Don’t wait for the glue to completely dry. This allows a certain

degree of movement needed to square the whole structure.

● Click in every 4th or 5th board in order to square the whole

deck structure. This allows alignment of the rails that will then be

ready to be xed to the ground.

IMPORTANT: the posion of each board has to be judged with

care, paying close aenon on alternang the board edges

meeng point.

● Remember to t iJack expansion control bracket to each board

if present.

● When installing large decks, we suggest installing smaller areas

at a me and connecng the separate areas together.

ground

● To x the understructure to the ground, Drill and x the

aluminium rails to the ground.

● Complete the deck by clicking the rest of the boards.

posa del sistema EasyClickInstallation: EasyClick system

ATTENTION:

- in case you need to pull your deck close to a x point (ie. house, wall) you will have cut half of the rst

clip as shown in CASE 1 - page 13

posa del sistema EasyClick

Scenario B:

installaons on sensive roong membranes where xing down of iDecking is not possible, an addional

“blank rail” is required for this method of installaon

● Posion the rubber pads or adjustable pedestals following max of

600 mm distance from one another in the intended direcon of the

deck boards.

● Adjust the height of the pedestals to create a level under surface.

● Place the “blank rails” at intervals of 600mm for domesc decks and

500mm for public areas allowing for a 1-2% fall.

Placing the iDecking Rails

● Cross the iDecking “A” or “B” Rails over the “blank rail” placing them

at the advised intervals (Duro Excellence at 400mm for domesc use

or 350mm for public use • Etherno Bamboo at 450mm intervals)

Installing the remaining boards

● Click in every 4th or 5th board in order to square the whole deck

structure. This allows alignment of the rails that will be then ready to

be xed to the ground. IMPORTANT: the posion of each board should

be judged with care, paying close aenon on alternang the board

edges meeng point.

● Remember to t iJack expansion control bracket to each board if

available.

● At this point you will need to x the two rails together with self

drilling screws on the rails underneath.

● When installing large decks, we suggest installing smaller areas at a

me and connecng the separate areas together.

● Complete the Deck by clicking the rest of the boards.

Weight plates

● When installaon is on inverted roofs (insulaon above membrane) weight plates

will be needed. They are hung between the rails to add ballast to the deck area.

Installation: EasyClick system

● Lay the board over the aligned rail.

● Click it by pressing down with your foot, rst on one side (1) then the

other side (2) onto the clips below.

● Repeat the operaon over each intersecon between board and rail.

● When the height doesn’t allow the use of your foot, use a rubber

mallet to click the boards in place.

ATTENTION:

- in case you need to pull your deck close to a x point (ie. house, wall) you will have cut half of the rst

clip as shown in CASE 1 - page 13

posa del sistema EasyClickInstallation: EasyClick system

posts concreted into the ground

● Build a bearer framework in the chosen area with posts concreted

into the ground.

● For best results use Galvanised steel frame with bearers posioned

at intervals of 600mm for domesc applicaons and 500mm for public

areas

Placing the iDecking Rails

● Cross the iDecking Rails over the bearer framework placing them at

the advised intervals (Duro Excellence 400mm for domesc use or

350mm for public use • Etherno Bamboo: interval 450mm)

Installing the remaining boards

● Click in every 4th or 5th board in order to square the whole deck

structure. This allows alignment of the rails that will be then ready to

be xed to the ground. IMPORTANT: the posion of each board should

be judged with care, paying close aenon on alternang the board

edges meeng point.

● Remember to t iJack expansion control bracket to each board if

available.

● At this point you will need to x the two rails together with self

drilling screws on the rails underneath.

● When installing large decks, we suggest installing smaller areas at a

me and connecng the separate areas together.

● Complete the Deck by clicking the rest of the boards.

● Lay the board over the aligned rail.

● Click it by pressing down with your foot, rst on one side (1) then the

other side (2) onto the clips below.

● Repeat the operaon over each intersecon between board and rail.

● When the height doesn’t allow the use of your foot, use a rubber

mallet to click the boards in place.

ATTENTION:

- in case you need to pull your deck close to a x point (ie. house, wall) you will have cut half of the rst

clip as shown in CASE 1 - page 13

● Repeat the operaon over each intersecon between board and

understructure.

Installation: EasyClick system

Placing the iDecking Rails

- Cross the iDecking Rails over the Primary understructure

placing them at the advised intervals as shown in CASE A & B

(Duro: interval 35cm public use / 40cm private use • Etherno

Bamboo: interval 46cm) and x them with self drilling screws on

the rails underneath.

necessary when it’s impossible to x the rails on the ground

- Place the Primary Aluminum Rails with an interval range of

65/70 cm one from the other. The section of the Aluminum rails

used for Primary Understructure is: 30 x 50 x 3 mm. – 1200gr/m

- Complete the Deck by following the guidelines of the chosen

iDecking System: EasyClick or EasyChange and place the rest

of the boards

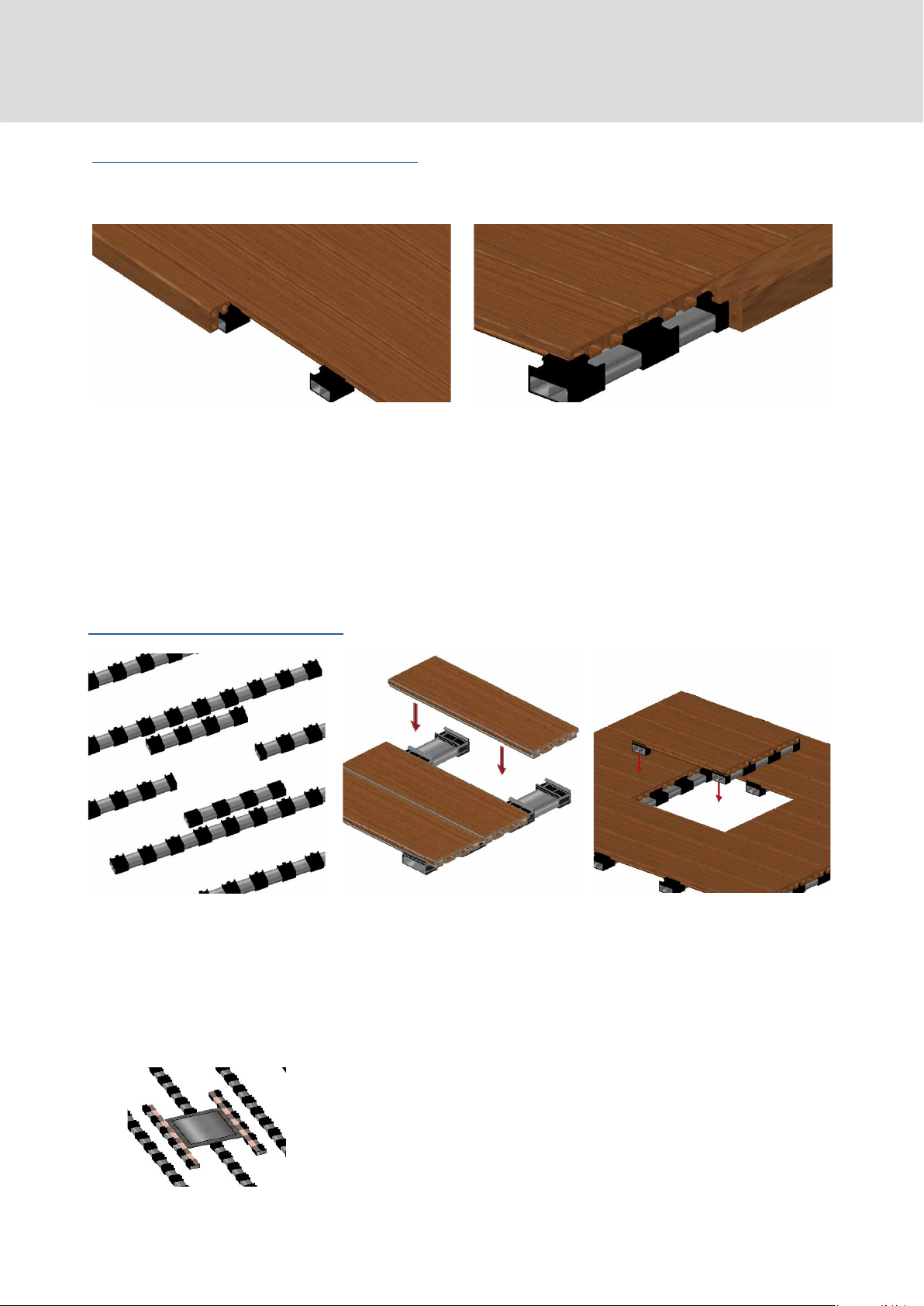

Modules: EasyClick system

EasyClick MODULES deck building

The Clip B lets you pre-build the modules of your future

deck. This soluon is even quicker in installaon me

and it is highly suggested in case of big areas to cover or

temporary decks that will have to be removed and re-

installed.

Create the module understructure

- Place the aluminum rails at the right interval:

Internals clip A rails,

Externals clip B rails

Complete the module

- Complete the Module assembling by clicking the rest of the

boards.

SUGGESTION: create the module with a maximum of 7 boards

and with understructures cut half in order to handle them

easier.

- Aer preparing the Modules and having veried the ground

level, place the modules over the desired area. Distance them in

order to let the connecng board be clicked correctly.

- The Clips B present on the short external sides of the single

modules will let you connect the modules even in longitudinal

sense.

- Insert the connecng boards (highlighted in red) both in

latudinal and longitudinal sense.

posa del sistema EasyClickframes and finishes EasyClick system

EasyClick system allows a clickable framing/nosing prole called Step Prole, to be easily and

quickly installed.

- Click the Step Prole onto the remaining

half clip at the end of each “A” rail.

- Use the Clip B understructure at the end

- Click the Step Prole in the remaining half

clip at the end of each understructure

Placing the alu rails

- Cut small secons of “A”

rail to the size of the manhole.

- Insert two pieces of aluminum

understructure as reinforcement

of the manhole.

- Remove a part of the clips to

create the manhole support.

- Cut boards to the length of

the manhole.

- Click boards into the clips

on the “A” rails to create a

small secon of decking.

- Ensure that the rails are

set back from the end of

the boards.

- Place the manhole over the

opening: the projecons of

board then lie on the

surrounding understructure

proles.

posa del sistema EasyClickframes and finishings EasyClick system

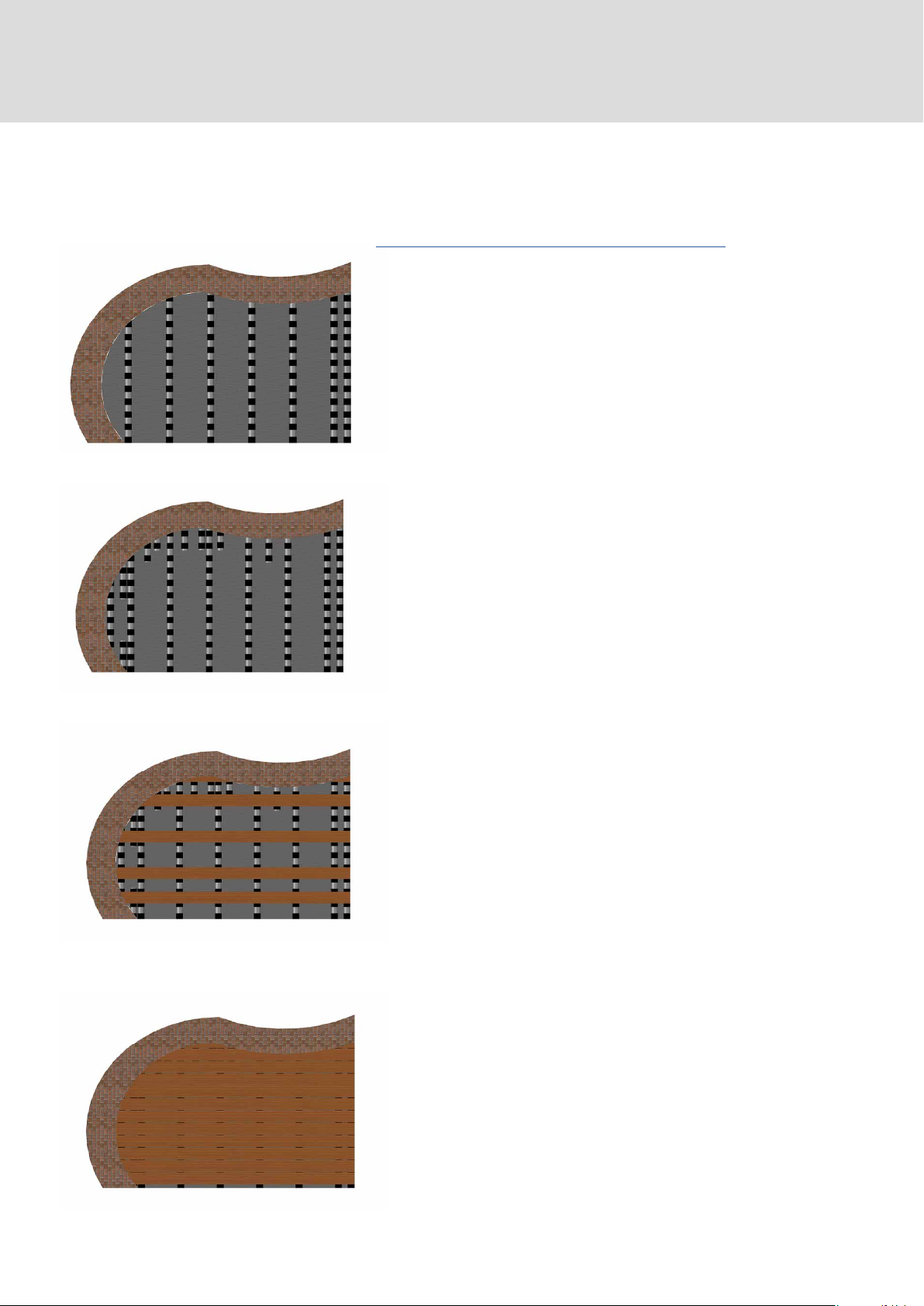

Diagonal cuts

- Cut the nal part of the understructures following the desired

angle.

- Add porons of understructure “A” among the principal ones,

to ensure correct support for the boards to click to.

Complete the deck

- Cut the boards according to the desired size and complete the

deck.

SUGGESTION: if a board ends up to be over an understructure

the rail and gluing the boards down.

Rounded cuts

- Create the deck normally and let the boards protrude over the

area that will have to be round cut.

- Perform the cut with the right tools

- Make sure the understructure has a support clickable point at

the end of each board.

● Once cut, it is possible to install the special 10x95mm

framing prole.

● Heat the prole with a hot air gun and bend the framing

prole around the shape of the curve.

● Fix it with screws while bending it.

● Once the prole cools down, it will maintain the given bent

shape.

on the diagonal with the parallel clip pins removed.

posa del sistema EasyClickframes and finishings EasyClick system

Rounded cuts - placing the understructure

- Cut the nal part of the understructures following the desired

angle.

- Add porons of understructure among the principal ones,

otherwise the boards would not be supported in the nal part

- Cut the boards according to the desired size and complete the

deck.

Complete the deck

SUGGESTION: if a board ends up to be over an understructure

posa del sistema EasyClickframes and finishings EasyClick system

Optionals EasyClickposa del sistema EasyClickframes and finishes EasyClick system

How to pull the boards close to a wall

- Cut the nal part of the clip as shown in the picture.

- Cut the board according to the needed size

- put a rubber riser as shown (in red) in the picture to

ensure the board is properly supported underneath.

- Click the board and for best results screw the outer

edge of the board down in order to secure it rmly.

together to the gap stays constant.

- Duro Excellence boards are already drilled on the underside in

preparaon of taking the iJack

Optionals EasyClick

- Turn the Duro board and click the iJack into the pre-drilled

hole, pay aenon to leave the at sides of the iJack out.

- Turn the board and click it to the understructure. Go on with

the rest of the boards if necessary.

at 17mm from the edge with a 10mm drill bit.

Counterweight plates

Useful accessory to use when

it’s not possible to drill the

soil. Counterweight plates are

50x30x2cm and 24kg each.

ClickOUT

the CLIP B understructure.

We suggest to place the plates around the perimeter of the deck at a

spacing of 1 metre one from each other. In the case of much larger areas

- ATTENTION: EasyClick system is the only in the world to block each board

posa del sistema EasyClickframes and finishes EasyClick system

IDECK SRL

EasyClick system

Professional Deck builders will be extremely happy to know that

iDecking EasyClick system won’t force them on their knees all day long

and will also drascally reduce installaon me!

Say good bye to wasng your me aligning each decking board

since ourEasyClicksystemautomacallyalignsioryou! EasyClick

understructure “rails” are placed every 40 cm, locking each decking

board on four dierent points increasing the strength of the enre

oor/wall structure.

Special EasyClick clips are also available to serve any decking design.

zone

EasyClick system

www.idecksystems.com

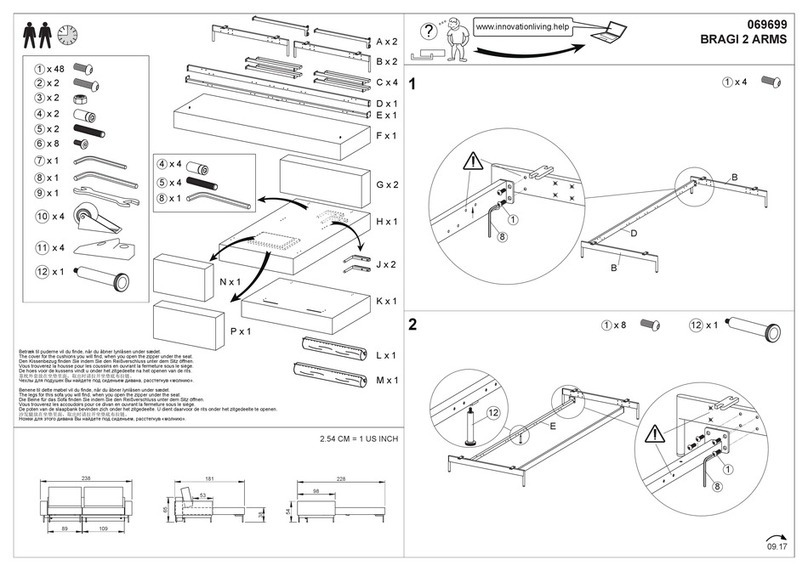

Popular Indoor Furnishing manuals by other brands

Innovation Living

Innovation Living BRAGI 2 ARMS Assembly instuctions

VIBO

VIBO Galaxy 041-VGSBO Series Assembling instructions

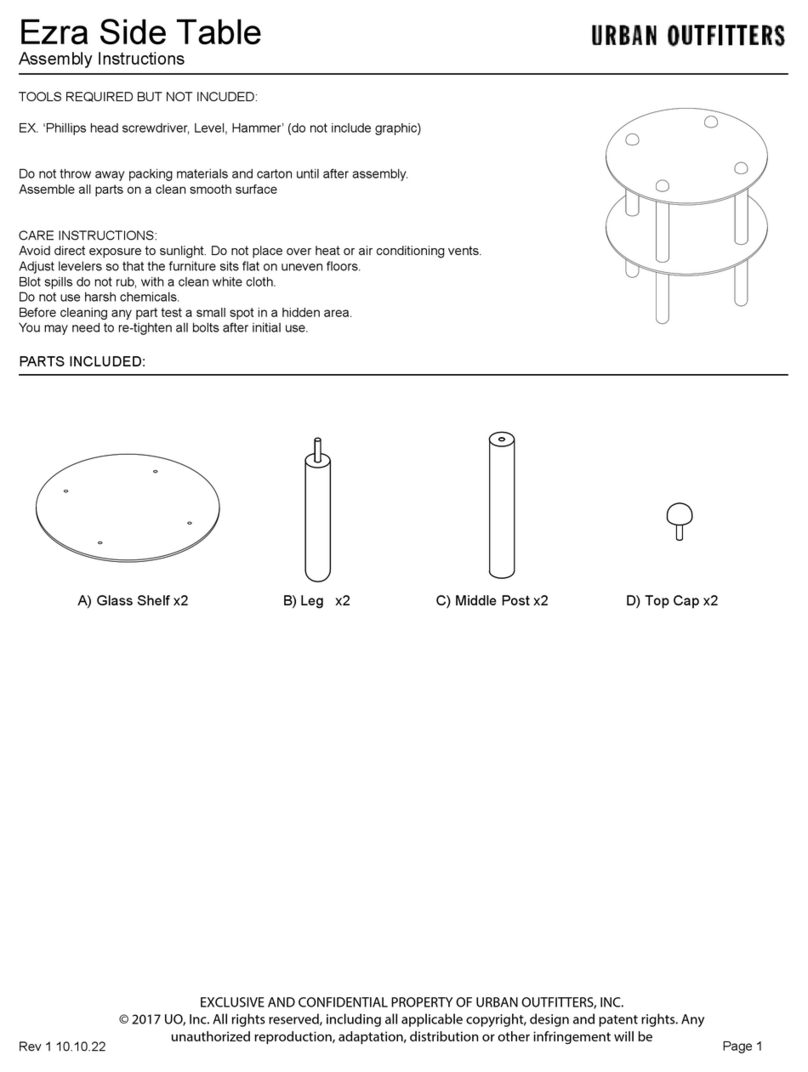

URBAN OUTFITTERS

URBAN OUTFITTERS Ezra Side Table Assembly instructions

Sauder

Sauder 408951 Assembly instructions

Ty Pennington

Ty Pennington Style KEY LARGO SECTIONAL SOFA SET Use and care guide

ZEITRAUM

ZEITRAUM SILENT Assembly instructions

OfficeSource

OfficeSource PBTR66 Assembly instructions

Fusion

Fusion 2K Series Operation manual

L.L.Bean

L.L.Bean OTNQ9 quick start guide

convenience concepts

convenience concepts 7104090 Assembly instructions

Okay

Okay STELLA D30 Assembly instruction

Furniture Solutions

Furniture Solutions CAESAR 17CAEC02CX2 instruction manual