8 FD151 Gas Compressor

2.1 LOCATION

Corken compressors are designed and

manufactured for outdoor duty. For applications in

which the compressor will be subjected to extreme

conditions for extended periods, such as hot boiler

rooms, corrosive environments, arctic or desert

conditions, etc., consult Corken. Check local safety

regulations and building codes to assure installation

will meet local safety standards.

Corken recommends that machines compressing toxic

or flammable gases be placed outdoors. If such units

are placed indoors, make sure the area is well

ventilated. Vent the distance piece to the outdoors or

purge the distance piece with an inert gas and vent to

a safe disposal area.

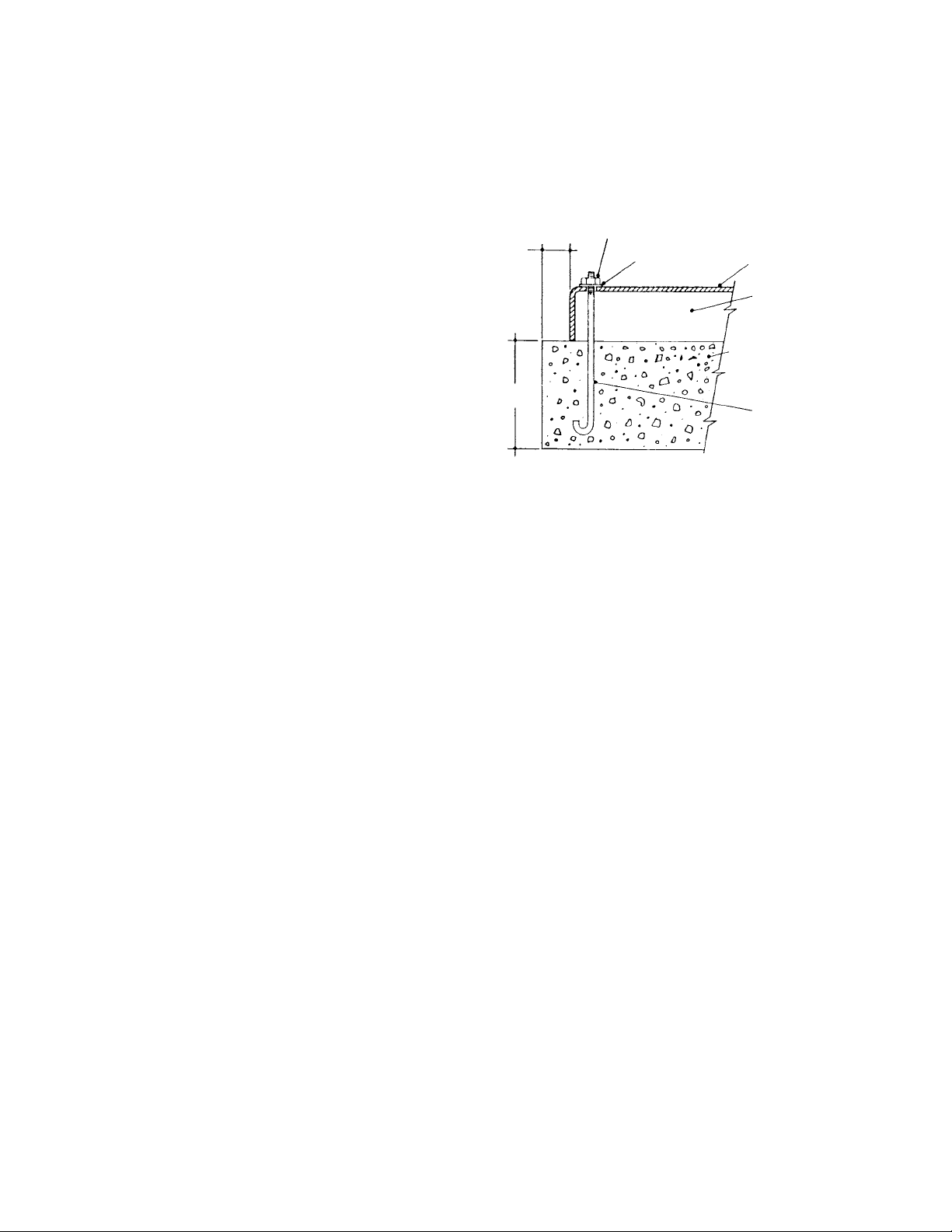

2.2 FOUNDATION

Proper foundations are essential for a smooth running

compression system. Corken recommends the

compressor be attached to a concrete slab at least 8"

thick, with a 2" skirt around the circumference of the

baseplate. The baseplate should be securely

anchored into the foundation by 1/2"diameter "J" bolts

12" long. The total mass of the foundation should be

approximately twice the weight of the compressor

system (compressor, baseplate, motor, etc.). After

leveling and bolting down the baseplate, the volume

beneath the channel must be grouted iron baseplate

to prevent flexing of the top portion of the "J" bolt that

extends beyond the foundation. The grout also

improves the dampening capabilities of the

foundation by creating a solid interface between the

compressor and foundation.

On models mounted on a longer baseplate a hole

can be cut in the baseplate for filling the middle

section of the channel-iron base with grout. See

additional foundation design aids in appendix H.

2.3 PIPING

Proper piping design and installation is as important

as the foundation is for smooth operation of the

compressor. Improper piping installation will result

in undesirable transmission of compressor vibration

to the piping.

DO NOT SUPPORT PIPING WITH THE

COMPRESSOR.

Unsupported piping is the most frequent cause of

pipe vibration. The best method to assure

transmission of vibration from the compressor to the

piping is minimized by using flexible connectors (see

Figure 2.3A).

Pipe must be adequately sized to prevent excessive

pressure drop between the suction source and the

compressor, as well as between the compressor and

the final discharge point. In most cases, piping should

be at least the same diameter as the suction nozzle

on the compressor.

Care must be taken if a restriction device such as a

valve, pressure regulator, or back-check valve is to

be installed in the compressor's suction line. The

suction line volume between the restrictive device

and the compressor suction nozzle must be at least

ten times the swept cylinder volume.

Piping must be installed to prevent condensate from

draining into the compressor. This is especially

important on applications where gas is being handled

at or near its saturation point.

Figure 2.2A

2” Min.

All Sides

8” Min.

Hex Nut

Washer Compressor

Baseplate

Grout Beneath

Base

Concrete Foundation

With Reinforcements

Should be Used on

All Models

1/2” “J” Bolts

12” Long

Recommended Foundation Details

for Corken Compressors

Note:

Locate “J” Bolts Per

Compressor Outline

Dimension Drawings

CHAPTER TWO

INSTALLING YOUR CORKEN COMPRESSOR