idomus IDO-HOME User manual

USER MANUAL / DOOR PASSPORT

2

3

TABLE OF CONTENT

USER MANUAL

NO

1. INTRODUCTION

2. LIST OF TERMS

3. GENERAL PART

3.1 Scope of use

3.2 Prohibitions

3.3 Environmental conditions

3.4 Control

3.5 Remote control

4. SAFETY

4.1 Hazards

4.1 Safety

4.1 Precautions

5. EXPLANATION OF SYMBOLS

6. OPERATING TIME AND FAULTS

6.1.1 COMPACT, COMPACT+ models

6.1.2 IDO-HOME, IDO-PRO models

6.2 Minor disturbances

7. INSPECTION, MAINTENANCE AND REPAIR

8. DOOR PASSPORT

9. WARRANTY

4

USER MANUAL

1. INTRODUCTION

This user manual is intended for users using the following types of garage doors (or a combination of the following types of

doors):

• IDO-HOME;

• IDO-COMPACT;

• IDO-COMPACT+;

• IDO-PRO.

This manual is part of the technical documentation for sectional garage door, as required by LSTEN 12635: 2003 + A1: 2009

standard “Industrial, commercial and garage doors and gates - Installation and use”.

This manual is designed to dene the safety, operation, maintenance and dismantling of garage doors.

This manual contains references described below:

- DANGEROUS

- IMPORTANT

2. LIST OF TERMS

RESPONSIBLE PERSON

The responsible person must be at least 16 years old, familiar with the user manual and able to use the garage door.

QUALIFIED SPECIALIST

A qualied specialist is one who has technical knowledge and experience to work with garage doors. This person has to be aware

of the potential hazards.

DOOR PLANE

The plane of the door consists of sections that are mounted horizontally on top of each other. The door sections consist of two

sheets of metal lled with insulating foam. In case of panoramic door, sections are made of aluminium proles and organic glass

units.

GARAGE DOOR

The garage door construction consists of a segment plane and steel parts thanks to which the plane of the door moves up and down

and opens or closes the door opening.

IDO-HOME, IDO-COMPACT, IDO-COMPACT+, IDO-PRO (sound and thermally insulated metal door)

The door section is of a “sandwich” construction: two steel sheets with polyurethane foam ller between them. The section is 40

mm thick.

- MAY CATCH / CRUSH

- FALLING PARTS

5

USER MANUAL

3. GENERAL PART

3.1. SCOPE OF USE

The garage door is designed to close the opening of the building, for cars to drive in and/or for people to enter. Using the garage

door for other purposes is prohibited.

Read installation and user manuals carefully before using the garage door. The manufacturer is not liable for faults caused by

improper use and maintenance.

3.2. PROHIBITED

Do not lift objects, animals or persons by door mechanisms.

Do not replace door parts with door parts supplied by other manufacturers.

Acceleration or deceleration of the operation of the door controlled by an automatic drive is not permitted.

3.3. ENVIRONMENTAL CONDITIONS

• Ensure proper drying or ventilation of the building, otherwise there is a risk of corrosion;

• Provide proper protection of the door before starting plastering, painting works since cement, gypsum and other building

materials can damage the surface of the door;

• Protect the door from aggressive and corrosive substances as this may cause corrosion;

• The protective lm must be peeled off the door within 30 days of the installation of the door (this instruction does not apply to

painted door).

• Optimal climatic conditions for the use of the door:

- the outdoor temperature should be ≤ -20°C and ≤ +50°C*.

- relative air humidity from 20% to 90%.

- wind speed shall not exceed 30 m/s.

The water resistance class is IP65 (the door is watertight, there is no leakage of liquids sprayed on the door surface). Large

temperature fluctuations inside and outside the premises can cause surface deflections of the segments (i.e. bimetallic effect may

occur). This is especially typical in dark-coloured doors installed on south / southwest side.

Surface must be maintained using the following instruction:

When the ambient temperature is below 0°C, spraying the side sealing rubber with liquid silicone is recommended. Lubricate castor,

hinge shafts and springs.

Corrosion and aggressive environment may adversely affect the operation of the door.

3.4. CONTROL

Use the door only when there are no obstacles on its path of operation, avoid standing or walking under moving door;

TWO METHODS OF CONTROL ARE POSSIBLE:

MANUAL – when the door is lifted by means of a handle, rope or manual chain drive;

AUTOMATIC – when the door is opened and closed by an automatic electric drive. The door lock must not be used if the door is

controlled by means of an automatic drive.

REMOTE CONTROL

An automatic electric drive can be controlled with help of remote control. The same button on the remote control opens and closes

the door. Pressing the button once will fully open the door and will stop it. If the button is pressed while the door is rising, the door

stops. Pressing the button once again closes the door. The drive has an automatic reverse function. It means that if there is an

obstacle in the path of operation of the door, the door will stop and will automatically rise to the open position. In the event of a

power failure, the drive may be disconnected and the door may be opened manually.

The automatic drive cover may only be removed by a qualied professional.

6

USER MANUAL

4. SAFETY

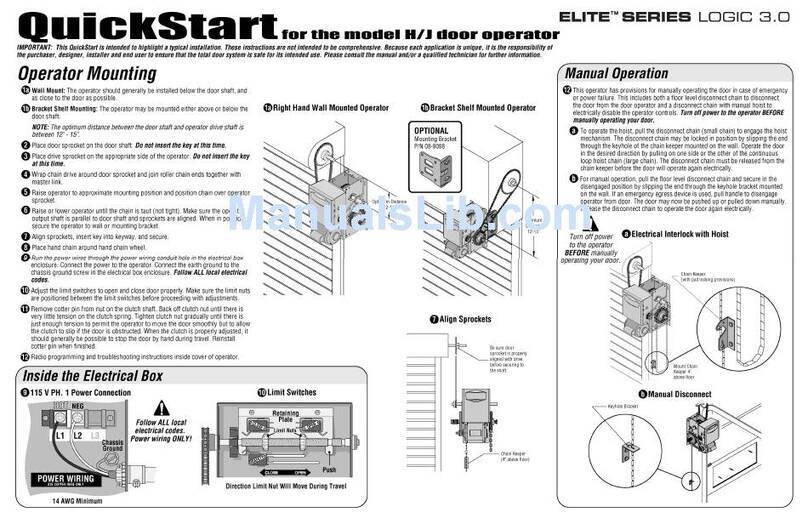

4.1. POSSIBLE HAZARDS (see pages 12-13)

• There is a risk of being crushed by the door plane while it is moving.

• The automatic drive needs to be disconnected from power supply when being repaired. This can only be done by a qualied

professional.

• Only a responsible person may use the door.

• The door can only be used when it is in your eld of vision and cannot endanger anyone. Make sure there are no obstacles

in the door opening or under the door (D) before opening it.

• When opening the door, keep your ngers away from moving parts, do not lean on the rail system (A),

door plane (E) or access door (F + G).

• Always use a lifting rope, handle or a chain drive for the manually opened door.

• Torsion / tension springs (B), ropes and lower castor holders (C) are subject to signicant tension. For this reason, keep

yourself away from them. Contact a qualied professional only for their repair, adjustment or replacement.

• Assembly, maintenance, disassembly and inspection must be carried out by a qualied professional.

• Corrosion and aggressive environments may affect the safe use of the door.

• Entering the garage by car is only possible when the door is fully opened.

Do not operate the door if obvious damage is visible, as well as damage to the ropes, springs and guards. If defects in

individual parts of the door, such as windings of the lifting ropes began to crack, weakened spring tension, the door is difcult to lift,

extraneous sounds are heard during lifting/lowering, and the like, became evident during the operation, contact the company that

has installed the door for warranty or post-warranty service.

If protection is triggered by rope rupture or spring breakage, immediately contact the company that has installed the door;

Never modify the door construction or remove the door parts by yourself.

4.2. SAFETY

All doors of IDO-HOME, IDO-PRO models have spring break guards. In the event of a spring breakage, these guards prevent the door

from falling. 4 springs are used in the doors of IDO-COMPACT AND IDO-COMPACT + models. If one spring breaks, the increase in load

on the other springs is within the limits allowed by the legislation (does not exceed 20 kg). All doors are equipped with lifting ropes

with strength and thickness calculated using a coverage factor of 6. This means that each rope can support a weight of 6 doors.

The buyer can additionally order the following safety measures:

• Automatic drives;

• Door protection sensor (SK-MS);

• Rope breakage guards;

• Latch protection switch;

• Pressure guard sensor in the lower gasket.

AUTOMATIC DRIVE

The door with an automatic drive has built-in guards that protect in case of spring or cable failure. The drive prevents the door from

moving uncontrollably.

4.1. PRECAUTIONS

Please note the following clauses:

• Carefully read the manual before using the door.

• Removing protective parts, pictograms and manufacturer’s marks or adapting the door constructions for another purpose

are prohibited.

• Repair and maintenance must be done by a qualied professional.

• The owner of the door is also fully responsible for the correct operation of the door when it is used by a third party.

• Do not use the door when it is faulty.

• Only a responsible person may use the door.

7

USER MANUAL

5. EXPLANATION OF SYMBOLS

The following symbols can be found on the door:

6. OPERATING TIME AND FAULTS

6.1.1. COMAPCT, COMPACT+ MODELS

The durability of the door parts is 100,000 cycles (1 cycle - one door lifting and lowering). The average durability of the faster-

wearing parts (springs, ropes) is 15,000 cycles.

DOOR NUMBER

„CE - MARKING” - IT INDICATES THAT THE DOOR MEETS

ALL THE REQUIREMENTS OF THE EU STANDARDS

6.1.2. IDO-HOME, IDO-PRO MODELS

The durability of the door parts is 100,000 cycles (1 cycle - one door lifting and lowering). The average durability of the faster-

wearing parts (springs, ropes) is 20,000 cycles for IDO-HOME doors, and 25,000 cycles for IDO-PRO doors.

6.2. MINOR DISTURBANCES

DISTURBANCE POSSIBLE REASON SOLUTION

Spontaneous door movement Improperly tightened springs /

Spring relaxation has occurred after

use

Contact the door servicing company

The door squeaks when opened,

closed

Dry castor or hinge axles Clean and lubricate the castors,

hinges

The remote control does not work Automatic drive defect or low

battery

Check the remote control battery

and/or contact your dealer

The plane of the door is tilted Rope, drum or shaft failure Contact the door servicing company

In all cases, contact a qualied professional to eliminate door faults. Door maintenance reduces risk of door failure.

The operating time depends on the intensity of use. When the door is used intensively (parking lots with more than 6 users), the

following formula is used to calculate the spring warranty period: 20,000 cycles / (number of parking spaces X 4 times) = warranty

period in days.

8

USER MANUAL

7. INSPECTION, MAINTENANCE AND REPAIR

7.1. OVERALL INSPECTION

• Maintenance of the door must be carried out by a qualied professional or company.

• According to EU standards, the door must be regularly maintained and inspected starting from the rst use. A qualied

professional, having installed the door, according to the instructions contained in the installation instructions for that door

model, must lubricate the door immediately after its installation.

The door should be inspected annually (or more frequently if specied so in the installation instructions for that door model) by

entering into a contract with a service company approved by the manufacturer. The wear of the moving parts and the condition of

an automatic drive are inspected.

The door owner can only lubricate the castors, hinges and sealing after disconnecting an automatic drive from power supply.

7.2. INDIVIDUAL PARTS

A worn or defective door part must only be replaced by a part of the same manufacturer.

7.3. DISASSEMBLY OF THE DOOR

Do not disassemble the worn door by yourself. Disassembly of a spring is a dangerous process and can only be performed by

qualied gate professionals.

Metal and plastic parts must be separated and disposed of in the appropriate place. Automatic drives contain oil. This

can lead to chemical contamination.

In all cases of doubt, consult the dealer.

9

DOOR PASSPORT

TECHNICAL ASSISTANCE

Name

Ad

d

ress

Tele

phone No

This door passport contains technical references to the

installed product and records of its maintenance, repairs

and modifications, which must be available to

authorized persons during any inspections

CLIENT:

Name, address, responsible person

PRODUCT TYPE:

PRODUCT NUMBER:PLACE OF INSTAL.

Address

LEAF:

Number of panels, material, measurements of the opening, door panel weight

VOLTAGE USED:CONTROL METHOD:

Voltage and power Manual, automatic

INSTALLER:DATE OF INSTALLATION:

Name, surname, signature

Dat

e

LIST OF INSTALLED COMPONENTS

The technical characteristics and performance of the components listed below are described in the relevant

installation instructions and / or on the identification label of the component itself.

DRIVE AND

CONTROL UNIT

CONTROL METHOD

Works until is released / pulse / automatic

PHOTOCELLS:

(Model)

SAFETY DEVICES:

(Model)

RADIO RECEIVER:

(Model)

OTHER CONTROL

MECHANISMS

Warnings about places that could become dangerous due to improper use of the equipment:

The door user or responsible person has been made familiar with potential risks and intended misuse.

I have made myself familiar with the warranty

conditions and the user manual. name, surname, signature of the customer

WORKS UNTIL IS RELEASED

(Model,

power

)

AUTOMATIC

PULSE

IDO-COMPACT+

AUTOMATIC

10

DATE:

WORKS PERFORMED

(INSTALLATION, COMMISSIONING,

ADJUSTMENT, INSPECTION, REPAIR,

REPLACEMENT OF SAFETY DEVICES)

TECHNICIAN

SIGNATURE

CLIENT

SIGNATURE

11

WARRANTY TERMS

During the warranty period, we (or our authorized technicians) will repair any defects of the products or goods resulting from the manufacturing or

material quality, free of charge. The guarantee does not include reimbursement of expenses for:

Disassembly and/or installation of a product or an item

Travel expenses incurred when dismantling and/or assembling the product or an item

Losses resulting from an inspection of the product or an item, disassembly or assembly work

Possible lost/not received prots.

10 YEAR WARRANTY IS GRANTED TO:

• Anti-corrosion coating of gate segments and peeling of insulation ller from the tin sheet*

• Door guides, hinges, brackets and drums *

2 YEAR WARRANTY IS GRANTED TO:

• Other gate parts

• Automatic gate opening equipment

• Installation works;

The warranty period is calculated from the date of sale indicated in the VAT invoice and/or product warranty card.

* The warranty period does not apply when the gate is operated in aggressive environments and/or in case of incorrect operation thereof.

WARRANTY SERVICE RULES:

• After receiving the products and/or goods and noticing any damage or non-conformities thereof, the Customer must submit a written claim

within ve days of receipt. If the Customer does not submit a claim within the specied term, the Customer shall be deemed to acknowledge that “Idomus”,

UAB has properly performed its obligations.

• The Customer must submit the purchase document (invoice or warranty card) when submitting equipment for warranty repairs.

• When submitting equipment for warranty repair, the Customer must deliver it to “Idomus”, UAB headquarters at V. Krėvės Ave. 129, Kaunas (in

individual cases, if the equipment cannot be dismantled, e.g. if such equipment is gates, doors, etc., authorized service representatives of “Idomus”, UAB

may arrive at the equipment installation site by mutual agreement). All costs related to transportation of the item shall be borne by the Customer.

• Where a part/component has been replaced for the warranty product or item, the warranty for the replaced part will be the same as the original

warranty for the product or the item.

• In the event that the fault has not been conrmed and/or in the event of the faults not covered by the warranty, the Customer shall bear all

expenses related to the transportation costs, the identication and repair of the fault at his own expense.

• ; Equipment must be delivered to “Idomus”, UAB in a package that ensures safe transportation. If the equipment is delivered without packaging,

“Idomus”, UAB shall not be liable for mechanical damage caused during transportation.

• If after 6 months after the repair of equipment, the Customer does not take it back, “Idomus”, UAB shall have the right to no longer store the

equipment.

• The duration of the warranty repair of the item depends on the nature and complexity of the fault. The duration may vary if ordering parts/

components/goods is required.

We reserve the right to refuse to apply the warranty if the following warranty conditions and/or instructions for use of the equipment listed below

are violated.

WARRANTY OBLIGATIONS DO NOT APPLY IN THE FOLLOWING CASES:

• In the event of any mechanical damage resulting from the Customer’s fault (e.g., the equipment has been disassembled without assistance,

damaged, etc.)

• For naturally worn parts of the equipment (compensation springs, gate wheels, ropes, engine carbons, worm bars, gear pinions, accumulators,

batteries, bulbs, fuses, etc.)

• Faults resulting from improper use in the mains or malfunctions in the mains

• Operation of the equipment in aggressive environments (car wash, salt storage, acid or alkaline environment, seacoast)

• Performance (by the user or third party) of equipment repair without assistance, modication or structural changes

• Equipment malfunctions are caused by external mechanical influences, due to improper operation, as well as when the equipment is not used

for its intended purpose

• Equipment faults are caused due to the use of consumables, accessories not recommended by “Idomus”, UAB

• Equipment faults result from increased friction when the units of the equipment and related machinery are not properly lubricated

• Equipment is not installed by “Idomus”, UAB technicians or its authorized personnel. “Idomus”, UAB shall not be liable for any loss or damage

resulting from improper installation of the products

• Damage occurred due to transportation when transportation is performed not by the “Idomus”, UAB

• The customer has not fully paid for the equipment or installation works

• The activities of “Idomus”, UAB will be damaged due to unforeseen circumstances such as war, social upheaval, catastrophes, natural disasters,

border and information blocking, import restrictions

• Claims for technical parameters, if they meet the manufacturer’s instructions, shall not be accepted

• Equipment not covered by this warranty will be repaired by “Idomus”, UAB at Customer’s expense. If the equipment can no longer be repaired,

“Idomus”, UAB will, in its sole discretion and at the Customer’s expense, replace it with a new one.

12

B

D

A A

E

C

C

B

D

A A

E

C

C

FRONT SPRINGS

BACK SPRINGS

13

B

D

B

C

C

E

A A

F FG

SIDE SPRINGS

WICKET DOOR

12

13

This manual suits for next models

2

Table of contents

Other idomus Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Chamberlain

Chamberlain Power Drive Security+ 248735S owner's manual

CAME

CAME C-BX installation manual

Guardian

Guardian 21230L Installation instructions and owner's manual

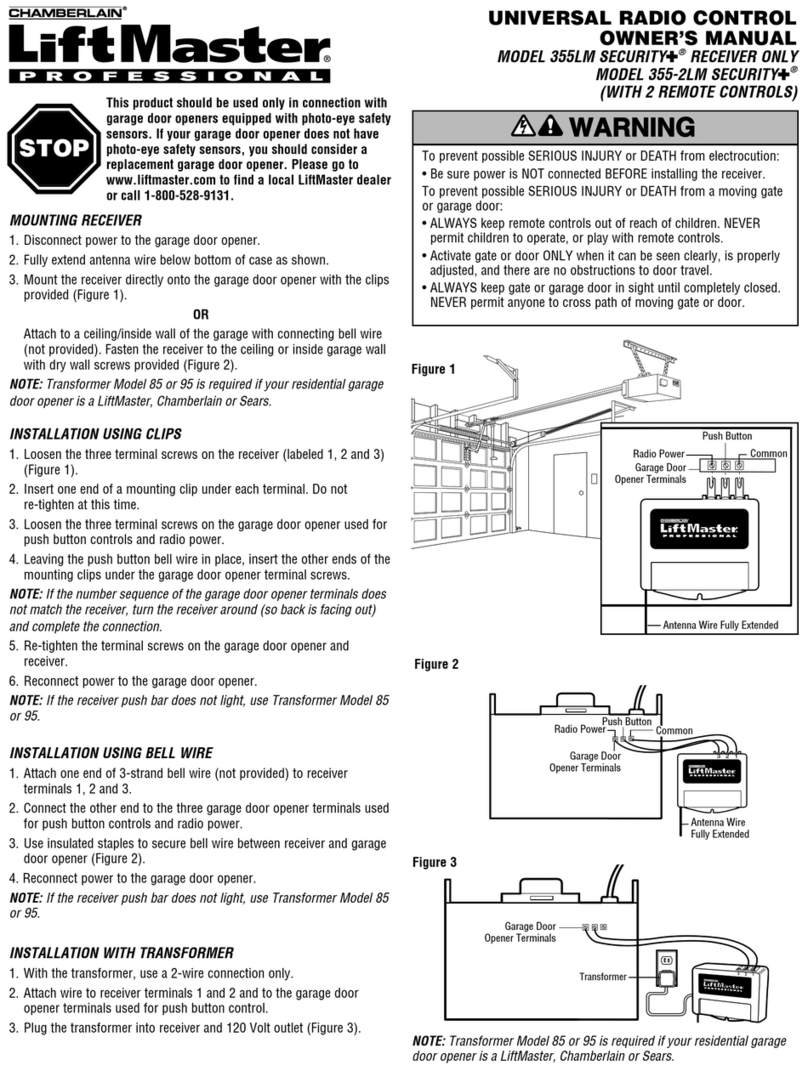

Chamberlain

Chamberlain LiftMaster 355LM Security+ owner's manual

Craftsman

Craftsman 139.54930 owner's manual

Raynor

Raynor 2220RGD 1/2 HP owner's manual