IDROBASE Adi User manual

Use and maintenance manual

EN

LIB. 0143

Rev.01

Ed.03.2020

Arch for sanitizing people

IMPORTANT!

Before installing and using

the machine it is compul-

sory that the installer and

users read and understand

all of the information in this

manual.

This manual is an integral

part of the machine; it must

always be available during

the normal operation of

the machine and it is impe-

rative that it is retained for

future reference until the

disposal of the machine.

2

CONGRATULATIONS ON CHOOSING ONE OF OUR PRODUCTS,

THE RESULT OF TECHNOLOGICAL EXPERIENCE AND CONTINUOUS RESEARCH

GOOD JOB!

3

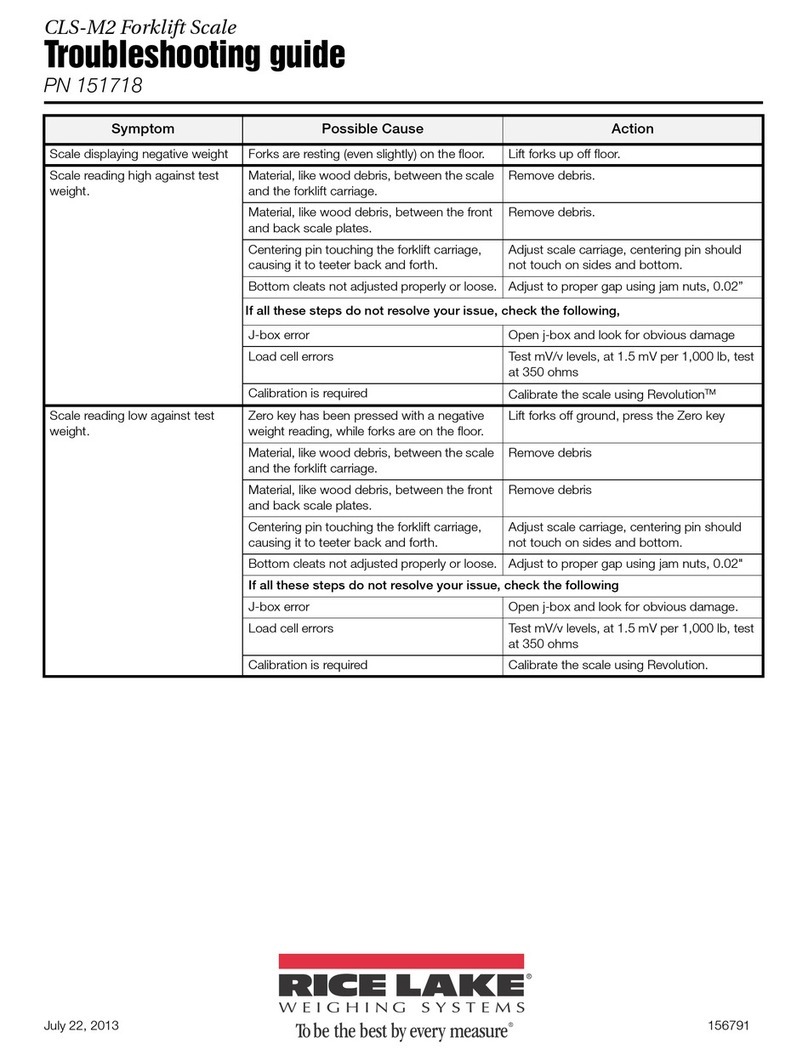

Prog. Descrizione

Pag.

1 Organization of the manual

1.1 Advice 4

2 Application elds

2.1 General warnings 5

2.2 Machine identication 5

2.3 Warranty 6

2.4 Return procedure 6

2.5 Cases that release from liability

the builder 6

2.6 Safety 7

2.7 Symbology 7

2.8 Glossary 8

2.9 Notes on graphic display 9

3 Product presentation

3.1 Finality 10

3.2 Composition 10

4 Data and technical characteristics

4.1 Tecnical data 11

5 Unpacking and installation 12

6 Cleaning

6.1 Cleaning and disinfection 22

6.2 Reinstallation and reuse 22

6.3 Demolition and disposal 23

7 Operation and use

7.1 Description of the operation 25

7.2 Intended use 25

7.3 Operating limits and environmental limits 25

7.4 Positioning of the operator and dangerous areas 25

7.5 Safety equipment for the operator 26

7.6 Training 26

8 Instructions for the operator 27

9 Methods of intervention 27

10 Demolition and disposal 28

11 Declaration of Conformity 29

INDICE

4

This manual has the function of guaranteeing the correct use and maintenance of the machine.

1.1 ADVICE

The manual is an essential document for the safe use of the machine. It must be kept in a safe place and

must be accessible by the user / repairer to ensure the correct use of the machine and therefore avoid any

risk through incorrect installation, improper use or negligence.

It is advisable to scrupulously follow the instructions given here, as the manufacturer is not liable for da-

mage caused to people or things, or suered by the machine if used in a manner inconsistent with what is

described or if the maintenance and safety requirements are not respected.

This manual must always be available to the user and / or maintenance technician, who must be informed

of the correct use of the machine and any residual risks. The instructions in this manual do not replace

the safety provisions and technical data, for installation and operation, applied directly on the machine.

The user must comply with the safety standards in force in the country of installation in addition to the

rules dictated by common sense.

The machine must not be used if any defects or deteriorations are found that could compromise its origi-

nal safety; The installer, the user or the maintenance technician have the obligation to report any anoma-

lies to the manufacturer.

The machine is built for specic applications. It must not be modied and / or used for applications other

than those foreseen in the eld of use.

The instructions, drawings, tables and everything contained in the following le are of a technical, con-

dential nature and for this reason any information cannot be disclosed to third parties without the written

authorization of IDROBASE GROUP SRL which is the exclusive owner.

The descriptions and illustrations contained in this publication are not binding; IDROBASE GROUP SRL

therefore reserves the right to make changes to organs, details, accessories supplies at any time, which it

deems convenient for improvement or for any construction or commercial requirement.

In case of dispute, the valid reference text remains Italian.

Competent court of Padua.

1 ORGANIZATION OF THE MANUAL

5

2 APPLICATIONS

2.1 GENERAL WARNINGS

BEFORE INSTALLING AND USING THE MACHINE IT IS COMPULSORY THAT THE INSTALLER AND THE

USERS READ AND UNDERSTAND ALL OF THE INFORMATION IN THIS MANUAL.

THIS MANUAL IS AN INTEGRAL PART OF THE MACHINE; IT MUST ALWAYS BE VAILABLE DURING THE

NORMAL OPERATION OF THE MACHINE AND IT IS IMPERATIVE THAT IT IS RETAINED FOR FUTURE

REFERENCE UNTIL THE DISPOSAL OF THE MACHINE.

THE COPYRIGHT OF THIS MANUAL “INSTRUCTION FOR INSTALLATION AND USE” IS THE PROPERTY

OF IDROBASE GROUP SRL. ALL OF THE INFORMATION TEXT, DRAWINGS, DIAGRAMS, ETC. CON

TAINED IN THIS MANUAL IS CONFIDENTIAL. NO PART OF THIS MANUAL CAN BE REPRODUCED AND

DISTRIBUTED EITHER IN PART OR COMPLETE BY ANY MEANS OF REPRODUCTION, PHOTOCOPIES,

MICROFILM, OR OTHER WITHOUT WRITTEN AUTHORIZATION FROM IDROBASE GROUP SRL.

2.2 MACHINE IDENTIFICATION

The machine is distinguished by a manufacturer’s plate

Idrobase Group S.r.l.

35010 Borgoricco (PD) ITALY - Via dell’Industria, 25

Tel. +39 049 9335903 r.a. - Fax +39 049 9335922

Modello

Model

Matricola

Production nr.

Anno

Year

Kg V Hz A Kw Temperatura

Temperature

Pressione max

Max pressure

lt/min Pressione nominale

Nominal pressure

MODEL

WEIGHT

MAX PRESSURE

MANUFACTURER

NAME

PRODUCTION

NUMBER

YEAR OF PRODUCTION

FREQUENCY

CURRENT ABSORBED

VOLTAGE

POWER ABSORBED

FLOW RATE

PROTECTION DEGREE

TEMPERATURE

NOMINAL PRESSURE

GUARANTEED SOUND

POWER LEVEL

6

2 APPLICATIONS

2.3 WARRANTY

All of our equipments are subjected to accurate and rigorous tests and are covered under warranty in

accordance with statutory law from manufacturing defects.

THE WARRANTY IS INVALIDATED IF THE USE OF THE MACHINE DOES NOT CONFORM TO THE IN

STRUCTIONS FOR USE CONTAINED IN THIS MANUAL, AND IF THE ORIGINAL COMPONENTS, ACCES

SORIES, SPARE PARTS AND CONTROL SYSTEMS ARE NOT USED.

The warranty starts from the date of purchase within the meaning of the act concerning warranty in the

country of sale. IDROBASE GROUP SRL undertakes to repair or replace free of charge any parts that have

manufacturing faults within the warranty period. Faults not clearly due to materials or manufacturing shall

be examined at one of our Technical Assistance Centres or at our headquarters and charged according to

the results. The following are excluded from the warranty: accidental damage due to transport, negligence

or inappropriate treatment, incorrect or improper use or installation, i.e. not complying to the instruction

manual, and any situations that do not depend on machine standards and operation, or on electrical and

equipment use. The warranty is invalidated if the equipment is repaired or tampered with by unauthorized

third parties. The equipment shall not be replaced nor the warranty extended after it has been repaired for

faults. The warranty does not cover cleaning the working parts or replacing consumable components such

as pump oil, nozzle, lances, etc. IDROBASE GROUP SRL is not liable for any damage to persons or objects

due to incorrect installation or improper use of the equipment.

2.4 CONDITIONS FOR RETURNS

It will be the responsibility of the end user to return the product to the retailer; or telephone for further

information to the number

+39 049 9335903

2.5 CASES IN WHICH THE MANUFACTURER IS NOT LIABLE

The manufacturer is not liable for damage caused by the following:

•Improper use of the machine or use by untrained personal.

•Use of non genuine spare parts.

•Non-compliance with maintenance.

•Unauthorized modications or operation.

•Non-observance, in total or part, of the instruction manual.

•Non-observance, in total or part, of the safety regulation in force in the country where the machine is

used.

7

2 APPLICATIONS

2.6 SAFETY

The ADI disinfection system is technically advanced and for correct installation, proper operation, correct

use and maintenance, the sta in charge needs to be responsible and observe the following safety and

behavior rules:.

- DO NOT run the pump without water or circulate liquids with sand and other solid particles that aect the

eciency of the system. If necessary, install auxiliary lters in the water supply circuit.

The electrical system to which the appliance is connected MUST be made in accordance with the laws in

force in the country of installation.

We RECOMMEND the presence of a dierential thermal magnetic circuit breaker, with sensitivity equal to

30mA, upstream of the power socket or in the system.

- DO NOT use extension cords and / or ying pins.

The integrity and insulation of the electrical cable must be checked as well as the equipment as the work

environment is forcibly exposed to water and humidity which preclude the natural insulation conditions of

the system.

- DO NOT use the appliance if damage or deterioration is found to it; disconnect the machine from the

mains and contact an authorized service center.

- You MUST comply with the regulations imposed by the Fire Brigade or by the bodies in charge of the

installation site.

- DO NOT touch the plug with wet hands or feet! Avoid accidental ignition.

- You MUST set the switch to OFF before inserting or removing the plug from the socket.

- DO NOT pull on the cable to pull out the plug.

- DO NOT install the machine near ammable products (pay attention to environments with particles su-

spended in the air: plastic materials, resins, acids, inks, etc.).

- DO NOT use paints, acids, solvents, oily or very thick liquids, etc.

The machine MUST be used by a properly trained operator.

- NEVER leave the machine unattended, especially in the presence of children. Once turned on and able to

work, the machine must be supervised by the operator.

- DO NOT use the machine in the presence of unauthorized persons without protective clothing.

The machine MUST be used with chemicals recommended by the manufacturer. The use of chemicals

otherthan those specied can compromise the safety of the machine.

It is strictly forbidden to cross the disinfection arch while it is running.

If the system is set up (for installation, see paragraph 5) outside,

- MUST take the appropriate precautions (roofs, etc.) against weather phenomena (rain, snow, etc.) that

couldcompromise its functionality.

2.7 SYMBOLS

In this manual the symbols depicted describe important functions of the machine for the installation, and

for the use and disposal. For correct and safe use of the machine the operator must read carefully all parts

of this manual paying special attention to the warning symbols and manufacturer’s plate.

PAY ATTENTION TO SAFETY IN THE WORKPLACE!

FOLLOW THE INSTRUCTIONS DISPLAYED ON THE WARNING SIGNS. FAILURE TO DO SO MAY CAUSE SEVERE

INJURY OR ENDANGER PERSONAL SAFETY. ENSURE THAT THE SIGNS ARE PRESENT AND LEGIBLE.

8

2 APPLICATIONS FIELDS

2.8 GLOSSARY

The following symbols advise the operator of dangerous situations or the important operations for the

correct running of the machine.

WARNINGS SIGNS!

THIS MANUAL MUST BE READ BEFORE USING OR CARRYING OUT MAINTENANCE OR OTHER OPERA

TIONS ON THE MACHINE.

INFORMATION!

THE INFORMATION CONTAINED IN THIS MANUAL SHOW THE RIGHT PROCEDURES FOR THE COR

RECT MAINTENANCE AND USE OF THE MACHINE

WARNING!

THE CAUTION INDICATES SPECIAL PROCEDURES THAT IF NOT OBSERVED CAN CAUSE DAMAGE TO

PERSONS OR PROPERTY.

WARNING!

MAINTENANCE OR REPAIRS MUST NEVER BE CARRIED OUT WHILE THE MACHINE IS LIVE/SWITCHED

ON. ALWAYS DISCONNECT FROM THE ELECTRICAL SUPPLY BEFORE CARRYING OUT REPAIRS OR RE

MOVING THE COVER.

CAUTION!!!

AVOID EXPOSING THE MACHINE TO COLD TEMPERATURES, THE FORMATION OF ICE

CAN CREATE SERIOUS DAMAGE TO THE PUMP. IT IS THEREFORE RECOMMENDED THAT

THE TANK BE EMPTYED.

9

2 APPLICATIONS FIELDS

2.9 NOTES ON GRAPHIC DISPLAY

Never remove labels from the machine. If these have deteriorated, request them from your dealer or

directly from the manufacturer in order to replace them.

THE MANUFACTURER IS RELIEVED FROM ANY LIABILITY IN THE EVENT OF INCIDENTS OR BREAKS

DUE TO FAILURE TO COMPLY WITH THE WARNINGS.

IN THE EVENT OF LOSS OF THIS BOOKLET OR MISUNDERSTANDINGS, CONTACT THE DEALER IM

MEDIATELY.

THE LABEL SHOWING THE METHODS OF USE AND RESTRICTIONS MUST NEVER BE REMOVED FROM

THE PLACE IN WHICH IT IS LOCATED.

10

3 PRODUCT PRESENTATION

3.1 FINALITY

The ADI modular system is a system designed for the sanitization / disinfection of people in places where neces-

sary, in compliance with the rules and regulations on safety and sanitation.

At the passage, the system starts automatically and the person who passes between the two half arches is af-

fected by spraying from head to toe without being wet.

3.2 COMPOSITION

As shown below, it is composed of: (1) half arc (2) xing plate (3) pumping module (4) switchboard + timer and

photocell control (5) Drafting kit (6) 50 L tank (7) tube kit (8 ) photocell kit with 9m cable (9) plastic platform.

1

6

5

4

3

11

4 DATI E CARATTERISTICHE TECNICHE

4.1 TECNICAL DATA

The table below shows the models and characteristics of the machine.

Code Model No. nozzle Max pression

[bar]

Drop size Flow rate

[L/min]

Power

KW

Wight

[Kg]

ZX.2198 ADI 26 60 10 mcr 1,0 200W (220V-

50Hz) 40

DIMENSIONS L [mm] W [mm] H [mm]

MISTING LINE 2000 450 2900

H

L

W

12

5.1 UNPACKING

The machine is packed in a simple cardboard wrapper to protect it. The cardboard wrapping must be re-

moved with appropriate means; the use of cellophane, staples and adhesive tape, in the packaging itself,

can cut or injure if not handled with care. To free the machine from its wrapping, settle on a at surface

near the drain, the water connection and the use. Then proceed to a check of the integrity of the compo-

nents.

WARNING!

USE PERSONAL PROTECTIVE EQUIPMENT AND TAKE THE UTMOST CARE IN RELEASING THE CASING.

STRAPS OR STAPLES IF NOT HANDLED WITH CARE CAN INJURE OR INJURE EXPOSED PARTS.

The disposal of the packaging components must be carried out in compliance with the local regulations

in force. After unpacking the machine, make sure that the system is intact and complete with any required

accessories.

5.2 INACTIVITY

During periods of machine inactivity (machine in use or new machine still packed), keep it in a at, clean

and dry place with a temperature of not less than 5 ° C and more than 40 ° C.

WARNING!

THE APPLIANCE CAN STAND THE FROST. DO NOT ALLOW TO STAND IN HARSH ENVIRONMENTS

WHERE THE TEMPERATURE COULD GO BELOW 0 ° C, WITH CONSEQUENT FORMATION OF ICE.

WARNING!

DO NOT FEED THE MACHINE WITH WATER AT TEMPERATURES ABOVE 40 ° C 104 ° F OR BELOW 5

° C 41 ° F.

WARNING!

THE PRESSURE OF THE FEED WATER MUST BE GREATER THAN 1.5 AND LESS THAN 2.5 BAR.

WARNING!

DO NOT FEED THE MACHINE WITH BRACKISH WATER OR CONTAINING IMPURITIES. USING NON

DRINKING WATER COULD SPREAD BACTERIA IN THE ENVIRONMENT, CREATING SERIOUS DAMAGE

TO PEOPLE, ANIMALS AND THE ENVIRONMENT ITSELF.

5 UNPACKING AND INSTALLATION

13

IMPORTANT!

IT IS RECOMMENDED TO APPLY A FILTER SUITABLE FOR THE PUMP WATER FLOW ON THE WATER

SUPPLY CIRCUIT, WITH A LARGE FILTER SURFACE AND LOW PRESSURE DROP.

5.3 CHECKS AND CONNECTION TO THE ELECTRICITY NETWORK

Have a qualied technician check that the power supply of the electrical system complies with the data

shown in the technical data table. Furthermore, the power outlet to which the system is connected must

be equipped with an earth conductor, an adequate fuse and must be protected by a dierential magne-

tothermic switch.

WARNING!

DO NOT TOUCH THE ELECTRIC PLUG WITH WET HANDS AND FEET!

5.4 TRASPORT

The machine is placed on a wooden pallet and covered with a cardboard wrapper, held in place by plastic

straps and staples. The machine is generally transported by truck. Unloading from the truck is carried out

by forklifts with appropriate brackets or manually respecting the current safety standards.

5.5 HANDLING

Always use the forklift truck to move or move the product.

5.6 STANDARD EQUIPMENT

•Make sure that the following elements are contained in the packaging of the purchased product:

•ADI - Arco sanitation system for people with required kits;

•User manual;

5 UNPACKING AND INSTALLATION

14

D

5.7 INSTALLATION AND CONNECTION

The rst operation to be done is to identify the environment where to install the PUMPING MODULE KIT, which

must be installed in a well-ventilated and suciently spacious place, positioning it 30 cm from the walls and which

complies with current regulations. In addition, the following supplies are required:

ELECTRIC CURRENT

•served by a socket connected to a general switch that can supply the Kilowatts and the voltage required by the chosen model,

protected by a dierential switch (circuit breaker) and relative earth connection.

A

Switch

general

CURRENT

ELECTRIC

5.8 PUMPING MODULE INSTALLATION

1. Place the pumping module (C) in a well-ventilated and suciently spacious place, positioning it on the

oor, on the basis of the standards in force, taking care to prevent unauthorized persons from accessing it.

2. Connect the water supply kit (draft) (B) to the pumping module (C).

3. Connect the polyamide tube kit to the disinfection arch (A).

4. Connect the photocell kit (E) to the electrical panel of the pumping module.

5. Connect the pumping module (C) to the main switch of the electric current (D).

Switch

ON / OFF

plant start

C

B

Water supply kit

5 UNPACKING AND INSTALLATION

15

PRELIMINARY ACTIVITIES

Make sure that the tank 50 L(E) is loaded (please note that 380 drives are guaranteed with the 50 liter tank)

1. Give power to the main switch (D) by setting it to ON.

2. Act on the pump module switch (C) and turn it to the ON position, at this point the pump module starts.

3. System in operation with timer and photocell sensor active.

4. To turn o the system, act on the control panel of the pumping module by pressing the ON / OFF switch.

OUTPUT AP

(SLIP LOCK connection 3/8 “pipe)

ARC LINE

WARNINGS!

- The system performed for 10 seconds after activation.

- The system is equipped with a tank level monitoring system.

- In case of lack of product the pump stops automatically.

D

ON

C

E

Prog.Descrizione

1FRAME

2WATER SUPPLY KIT

3AP OUTLET WITH AP WATER FILTER

4CONTROL PANEL

5SWITCH ON/OFF

6COVER

7PHOTOCELL KIT CONNECTOR

4

5

2

3

7

1

6

5 UNPACKING AND INSTALLATION

16

transmitter receiving

1 - Fill the tank.

2 - Remove the highest nozzles of the arc (A)

3 - Operate the system by pressing the ON/OFF switch on the control panel.

4 - Occlude the photocells in order to keep the system running.

5 - Operate the system until the system has been emptied of all air present in the circuit.

6 - Stop the plant.

7 - Ret the nozzles (A).

8 - Remove the occlusion from the photocells.

9 - Check the correct nebulization.

FIRST START INSTRUCTIONS

A A

5 UNPACKING AND INSTALLATION

17

The device is equipped with supports that must be anchored to the pavement in a stable and safe way (de-

tail of supports image A, B); the supports have the function of supporting the high pressure pipe.

For correct ground xing, the user must:

- Make use of a professional such as to be able to correctly dene the type and method of fastening accor-

ding to the NTC 2008 European and/or US UBC regulations, as well as the reference legislation in force in the

country of destination if dierent from what is mentioned above.

Image A

Image B

B

SALDATURA SU DUE LATI

CONTINUOS BUTT WELDS

SALDATURE CONTINUE DI TESTA

GIUNZIONI SALDATE TESTA

MINIMUN S1 VALUE = 2,5 mm

BxB

SALDATURA SU UN LATO

BS1

A

S1 MINIMO = 2,5 mm

S1

BS1

A

A = 0.7 x S1

BS2

B = S1

S1 < S2

TIPICI PER SALDATURE D'ANGOLO

BxB

A = 0.5 x S1

B = 0.7 x S1

S1 < S2

S2 B

TOLLERANZE DI FABBRICAZIONE IN ACCORDO A: UNI EN 13920 Classe C

Il presente disegno è di proprietà esclusiva di IDROBASE GROUP S.r.l. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, è vietata secondo i termini di legge.

This drawing is the exclusive property of IDROBASE GROUP S.r.l. Reproduction in whole and/or partial disclosure to third parties, without our express written permission, is prohibited according to the terms of the law.

Codice / Code

Scala / Scale

Verificato / Checked

Rev.

ID documento / ID document

TESTO 1:5

R

PASSIO N FOR WATER

Disegnato / Drawn

Rev. Descrizione

Description Data

Date

Descrizione / Description

Disegnatore

Designer

TESTO

Verificatore

Checked

TESTO TESTO

TESTO

00

00

01

FIRST EDITION 00/00/0000 --

-00/00/0000 --

02 -00/00/0000 --

03 -00/00/0000 --

Errore: Nessun riferimento

Peso:

65

330,83

65

65 65

A

A

SEZIONE A-A

302,16

60

60

61,08 57,16 322,99 57,16 61,08

56,08294,3256,08

559,48

406,49

5

IT.1550 Lamiera supporto arco/palma

nebulizzatrice AISI 304

Image of the photocell kit

(for a correct installation see page 18)

B

SALDATURA SU DUE LATI

CONTINUOS BUTT WELDS

SALDATURE CONTINUE DI TESTA

GIUNZIONI SALDATE TESTA

MINIMUN S1 VALUE = 2,5 mm

BxB

SALDATURA SU UN LATO

BS1

A

S1 MINIMO = 2,5 mm

S1

BS1

A

A = 0.7 x S1

BS2

B = S1

S1 < S2

TIPICI PER SALDATURE D'ANGOLO

BxB

A = 0.5 x S1

B = 0.7 x S1

S1 < S2

S2 B

TOLLERANZE DI FABBRICAZIONE IN ACCORDO A: UNI EN 13920 Classe C

Il presente disegno è di proprietà esclusiva di IDROBASE GROUP S.r.l. La riproduzione totale e/o parziale e la divulgazione a terzi, senza nostro esplicito consenso scritto, è vietata secondo i termini di legge.

This drawing is the exclusive property of IDROBASE GROUP S.r.l. Reproduction in whole and/or partial disclosure to third parties, without our express written permission, is prohibited according to the terms of the law.

Codice / Code

Scala / Scale

Verificato / Checked

Rev.

ID documento / ID document

TESTO 1:5

R

PASSIO N FOR WATER

Disegnato / Drawn

Rev. Descrizione

Description Data

Date

Descrizione / Description

Disegnatore

Designer

TESTO

Verificatore

Checked

TESTO TESTO

TESTO

00

00

01

FIRST EDITION 00/00/0000 --

-00/00/0000 --

02 -00/00/0000 --

03 -00/00/0000 --

Errore: Nessun riferimento

Peso:

65

330,83

65

65 65

A

A

SEZIONE A-A

302,16

60

60

61,08 57,16 322,99 57,16 61,08

56,08294,3256,08

559,48

406,49

5

IT.1550 Lamiera supporto arco/palma

nebulizzatrice AISI 304

cavo di collegamento

al pannello elettrico del

modulo pompante L= 9 m

stae di ssaggio

5 UNPACKING AND INSTALLATION

transmitter receiving

transmitter receiving

18

DOC-L / DOC-LN / CSS

CSSN / CLM / CLMN

www.came.com

120

120

X

70 70

DOC-L

DOC-LN

DELTA-I

DELTA-SI

DOC-I

CSS

CSSN

SET-I

SET-K

TSP00

TSP01

S6000

S9000

CLM

CLMN

SEM-2

❶❷ ❸ ❹

❺

24h

❻ ❼

❾

3

5

7

6

1

2

4

X = 458 (DOC-L/DOC-LN)

X = 958 (CSS/CSSN - CLM/CLMN)

⓫ ⓬❿

❼

❼

❽

Italiano

IT

English

EN

Français

FR

Русский

RU

FA00591M4A

FA00591M 4 A - ver. 2 - 03/ 2 017

5 UNPACKING AND INSTALLATION

ENGLISH

Description

Natural-finish (DOC-L) or black (DOC-LN) 0.5 meter anodi-

zed aluminum post;

Natural-finish (CSS) or black (CSSN) 1.0 meter anodized

aluminum post;

Natural-finish (CLM) or black (CLMN) 1.0 meter anodized

aluminum post with tamper-proof brace;

Components

1. Fastening plate with braces

2. Brace-counter base-plate fastening screw UNI 5739

M8X18

3. Base-plate for post

4. Base-plate to post fastening screw UNI 6949 6,3X25

5. Small post

6. Device casing

7. Screw for case UNI 6954 3.9x25

Mounting

- Set up the fastening base-plate, fit the screws and tighten then

by using the supplied nuts and washers. ❶

- Extract the perforated braces by using a screwdriver or pliers. ❷

- Set up a framework box that is larger than the fastening base-

plate and fit it into the foundation pit. ❸

- Fill the framework box with cement. Sink the braces into the

cement, being careful that the cable-threading corrugated tube

fits through the hole. ❹

- Wait at least 24 hours for the cement to dry. ❺

- Remove the framework box and fill with earth the pit around

the cement slab. ❻❼

- Loosen the nuts and washers from the screws. The fastening

plate must be clean, perfectly level and with the threads

completely above surface. ❽

- Thread the cables through the tube. ❾

- Assemble the post to the base-plate by using the four supplied

self-threading screws. ❿

- Fasten the post to the plate by using the supplied nuts and

washers.

⓫

- Fit the container, turned as shown in the figure, and fasten it

using the supplied screws.⓬

19

5 UNPACKING AND INSTALLATION

Raccomandazioni per il corretto funzionamento delle fotocellule

Recommendations for the correct functioning of the photocells

• Assicurarsi che le fotocellule siano allineate.

Se non viene rispettato l’allineamento delle due fotocellule (emittente e ricevente), l’impianto non

viene arrestato dopo 10 secondi, ma lavora in modalità continua.

• Make sure that the photocells are aligned.

If the alignment of the two photocells (transmitter and receiver) is not respected, the system is not

stopped after 10 seconds, but works in continuous mode.

emittente

issuer

ricevente

receiving

allineamento/alignment

20

1 - Fasten the arch support to the relative

steel plate using the 4 four screws provi-

ded. Position the connection of the polya-

mide tubing according to the direction as

indicated by the arrow.

Arch support assembly instructions

3- Check the fastening of the screws befo-

re positioning the arch vertically.

Finally, proceed with the connection of the

polyamide tube according to the diagram

on page 19

2- Make sure that the screws are positio-

ned correctly in the respective slots (as

shown in the gure).

5 UNPACKING AND INSTALLATION

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

urmet domus

urmet domus Grothe CALIMA 400 Series Installation and operating instructions

Intelbras

Intelbras XAS 4010 SMART user manual

Balluff

Balluff BES M18MH2-GNX50B-S04G-EXC user guide

G-Homa

G-Homa EMW302WF quick start guide

Rice Lake

Rice Lake CLS-M2 troubleshooting guide

Byron

Byron SX-6 Installation and operation instruction

OBH Nordica

OBH Nordica 9966 manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS CADMIUM EPOXY instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 640B72 Installation and operating manual

Sunx

Sunx FX-100-Z Series instruction manual

Bushnell

Bushnell Night Vision 26-1020 instruction manual

ECOWITT

ECOWITT WH51 manual