iET SRL Series User manual

¨PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ¨

Email: inf[email protected]

TEL: (516) 334-5959 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

SRL Series

Resistance Standard

Operation Manual

Copyright © 2022 IET Labs, Inc.

Visit www.ietlabs.com for manual revision updates

SRL im/Oct 2022

¨PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ¨

Email: inf[email protected]

TEL: (516) 334-5959 • FAX: (516) 334-5988

www.ietlabs.com

IET LABS, INC.

WARRANTY

We warrant that this product is free from defects in material and workmanship and, when properly used,

will perform in accordance with applicable IET speci•cations. If within one year after original shipment,

it is found not to meet this standard, it will be repaired or, at the option of IET, replaced at no charge when

returned to IET. Changes in this product not approved by IET or application of voltages or currents greater

than those allowed by the speci•cations shall void this warranty. IET shall not be liable for any indirect,

special, or consequential damages, even if notice has been given to the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

i

ii

SRL Series

Safety Symbols

General de•nitions of safety symbols used on the instrument or in manuals are listed below.

Caution symbol: the product is marked with this symbol when it is necessary for the user to

refer to the instruction manual.

Hazardous voltage symbol: the product is marked with this symbol when high voltage maybe

present on the product and an electrical shock hazard can exist.

Indicates the grounding protect terminal, which is used to prevent electric shock from the

leakage on chassis. The ground terminal must connect to earth before using the product

Direct current.

Alternating current.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment which

normally includes all exposed metal structures.

On supply.

O• supply.

Hot surface. Avoid contact. Surfaces are hot and may cause personal injury if touched.

Disposal

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirements.

The a!xed label indicates that you must not discard this electrical/ electronic product in domestic

household waste.

Product Category: With reference to the equipment types in the WEEE directive Annex 1, this product

is classi•ed as a “Monitoring and Control instrumentation” product.

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available. If electrical

appliances are disposed of in land•lls or dumps, hazardous substances can leak into the groundwater

and get into the food chain, damaging your health and well-being.

When replacing old appliances with new one, the retailer is legally obligated to take back your old ap-

pliances for disposal.

Proposition 65 Warning for California Residents

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

This product may contain chemicals known to the State of California to cause cancer, birth defects, or

other reproductive harm

iii

SRL Series

SAFETY PRECAUTIONS

The following general safety precautions must be observed during all phases of operation, service,

and repair of this instrument. Failure to comply with these precautions or with speci•c WARNINGS

elsewhere in this manual may impair the protection provided by the equipment. Such noncompliance

would also violate safety standards of design, manufacture, and intended use of the instrument.

IET Labs assumes no liability for the customer’s failure to comply with these precautions.

The SRL is an indoor use product.

DANGEROUS PROCEDURE WARNINGS

Comply with all WARNINGS - Procedures throughout in this manual and instructions on the

instrument prevent you from potential hazard. These instructions contained in the warnings must

be followed.

BEFORE APPLYING POWER

Verify that all safety precautions are taken. Make all connections to the instrument before applying

power. Note the instrument’s external markings described under “Safety Symbols”.

• DO NOT Operate in an Explosive Atmosphere

• Do not operate the instrument in the presence of in•ammable gasses or fumes

• Operation of any electrical instrument in such an environment clearly constitutes a safety

hazard

• Use Caution around live circuits and whenever hazardous voltages > 45 V are present

• Operators must not remove instrument covers

• Component replacement and internal adjustments must be made by quali•ed maintenance

personnel only

• DO NOT substitute parts or modify the instrument

• When working with high voltages; post warning signs, train personnel and keep unauthorized

personnel away.

To avoid the danger of introducing additional hazards, do not install substitute parts or perform

unauthorized modi•cations to the instrument.

Return the instrument to an IET Labs for service and repair to ensure that safety features are maintained

in operational condition.

WARNING

OBSERVE ALL SAFETY RULES

WHEN WORKING WITH HIGH VOLTAGES OR LINE VOLTAGES.

Dangerous voltages may be present inside this instrument. Do not open the case

Refer servicing to quali•ed personnel

HIGH VOLTAGES MAY BE PRESENT AT THE TERMINALS OF THIS INSTRUMENT

WHENEVER HAZARDOUS VOLTAGES (> 45 V) ARE USED, TAKE ALL MEASURES TO

AVOID ACCIDENTAL CONTACT WITH ANY LIVE COMPONENTS.

USE MAXIMUM INSULATION AND MINIMIZE THE USE OF BARE

CONDUCTORS WHEN USING THIS INSTRUMENT.

Use extreme caution when working with bare conductors or bus bars.

WHEN WORKING WITH HIGH VOLTAGES, POST WARNING SIGNS AND

KEEP UNREQUIRED PERSONNEL SAFELY AWAY.

CAUTION

DO NOT APPLY ANY VOLTAGES OR CURRENTS TO THE TERMINALS OF THIS

INSTRUMENT IN EXCESS OF THE MAXIMUM LIMITS INDICATED ON

THE FRONT PANEL OR THE OPERATING GUIDE LABEL.

iv

Contents

Chapter 1 Introduction ..............................................................................1

1.1 Introduction........................................................................................................... 1

Chapter 2 Specifications ...........................................................................2

Speci!cations ................................................................................................................ 2

Chapter 3 Operation ..................................................................................4

3.1 Initial Inspection and Setup .................................................................................. 4

3.2 Connections........................................................................................................... 4

3.2.1 Connections for values "190 k# ................................................................ 4

3.2.2 Connections for values $ 1 M# and >100 M# .......................................... 4

3.2.3 Connections for values $100 M#............................................................... 5

3.3 Thermal emf Considerations................................................................................. 5

3.4 Temperature Coe%cient Constants ....................................................................... 6

3.5 Environmental Conditions .................................................................................... 6

3.5.1 Operating Temperature ............................................................................... 6

3.5.2 Storage Temperature ................................................................................... 6

3.6 Shipping and Handling ......................................................................................... 6

Chapter 4 Maintenance..............................................................................7

4.1 Maintainability and Reliability ............................................................................. 7

4.2 Preventive Maintenance........................................................................................ 7

4.3 Calibration............................................................................................................. 7

4.3.1 Calibration Interval..................................................................................... 7

4.3.2 General Considerations............................................................................... 7

4.3.3 Required Equipment ................................................................................... 8

4.3.4 Calibration Procedure ................................................................................. 8

4.4 Replaceable Parts List........................................................................................... 8

v

Figures and Tables

Figure 1-1: SRL Series Resistance Standard .............................................1

Figure 2-1: OPERATION GUIDE affixed to unit...........................................2

Figure 2-2: Temperature Calibration Chart..................................................2

Table 2-1: SRL Specifications .....................................................................3

Figure 3-1: Connections for values £190 kW...............................................4

Table 3-1: Connections for values £190 kW................................................4

Figure 3-2: Connections for values ³1 MWand >100 MW..........................4

Table 3-2: Connections for values ³1 MWand >100 MW............................4

Figure 3-3: Connections for values ³100 MW..............................................5

Table 3-3: Connections for values ³100 MW................................................5

Figure 3-4: Resistance vs. temperature relationship ...................................6

Figure 3-5: Temperature Calibration Chart..................................................6

Table 4-1: Replaceable Parts List................................................................8

Figure 4-1: SRL Replaceable Parts.............................................................8

vi

1

SRL Series

1Introduction

Chapter 1

INTRODUCTION

1.1 Introduction

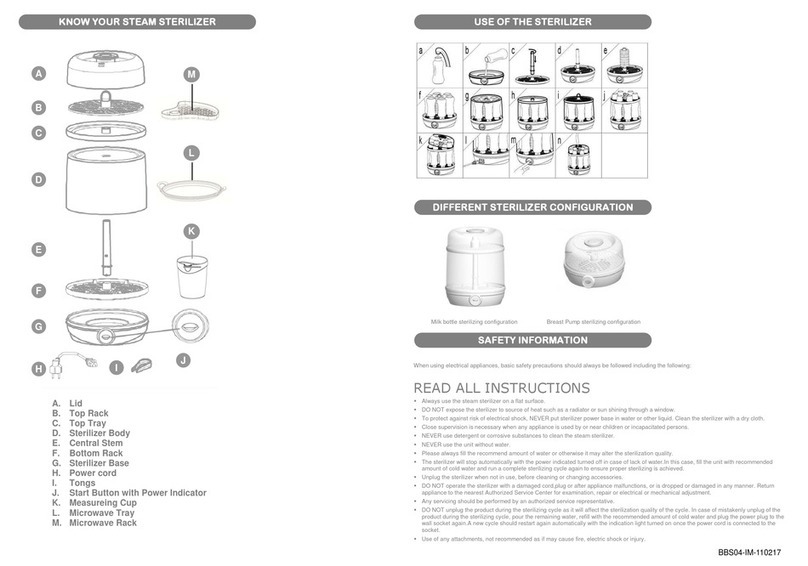

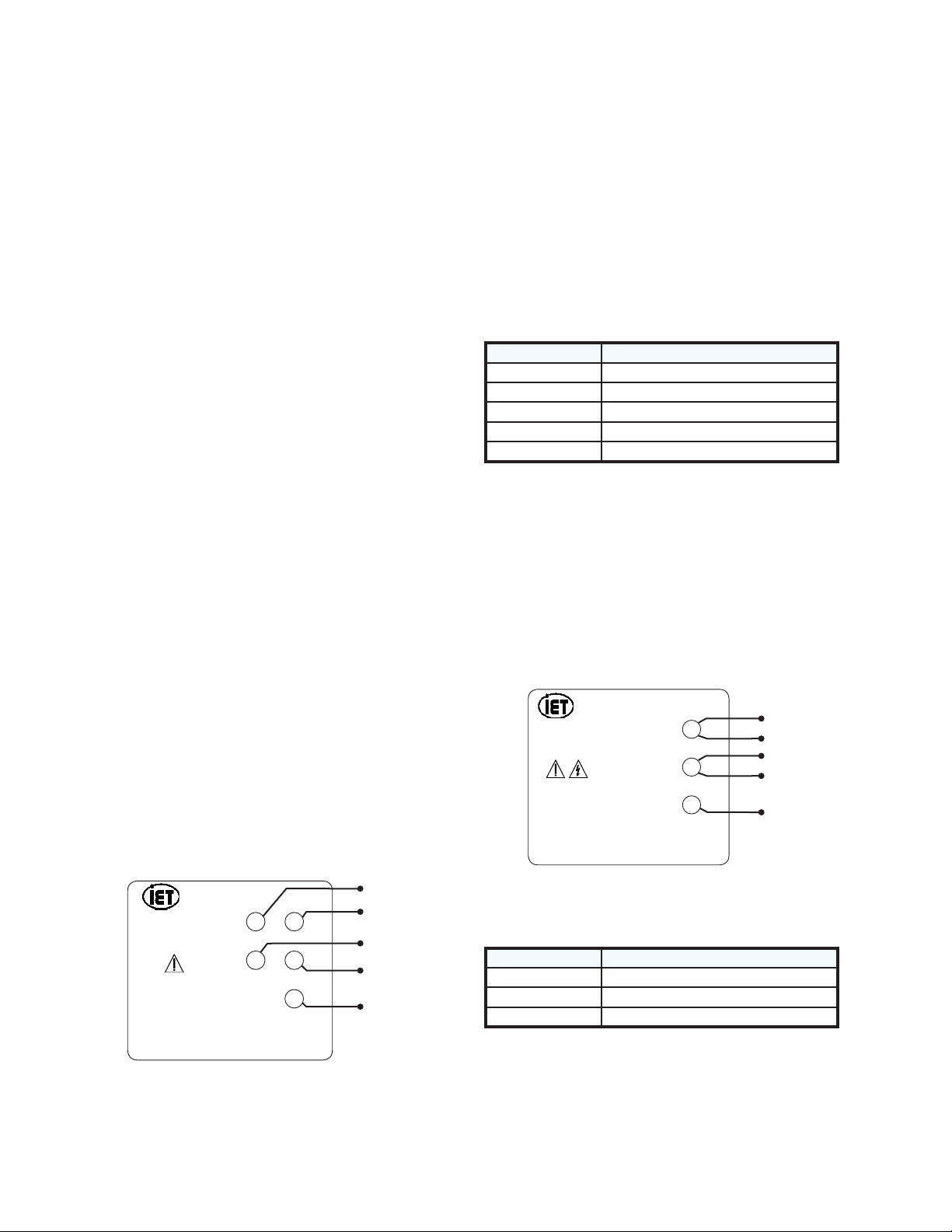

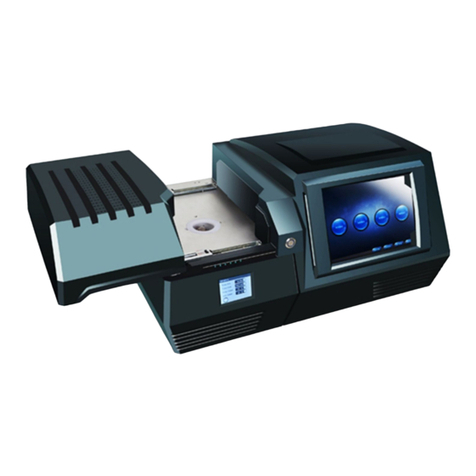

The SRL Series (Figure 1.1) are extremely stable,

precise, laboratory or portable resistance standards.

Their ruggedness and small size plus their virtually

zero temperature coe•cient makes the SRL Series

ideal for any applications outside of laboratory en-

vironment within the temperature range of 18°C to

28°C. The temperature chart provided with each unit

enhances the accuracy by indicating the deviation

from nominal for the operating temperature range in

0.5°C increments. Because of the low temperature

coe•cient, they require no oil-or-temperature bath.

The SRL series units are available in values ranging

from 1 m• to 2 T•, with custom values available,

to satisfy any need. They are built with precision

resistors and use no adjustable resistors of any kind.

To further reduce errors caused by temperature

changes, the SRL units are built with a temperature

coe•cient of near zero at 23°C. The binding posts

are constructed of low-thermal emf material.

Figure 1-1: SRL Series Resistance Standard

2

SRL Series

2 Specifications

Chapter 2

SPECIFICATIONS

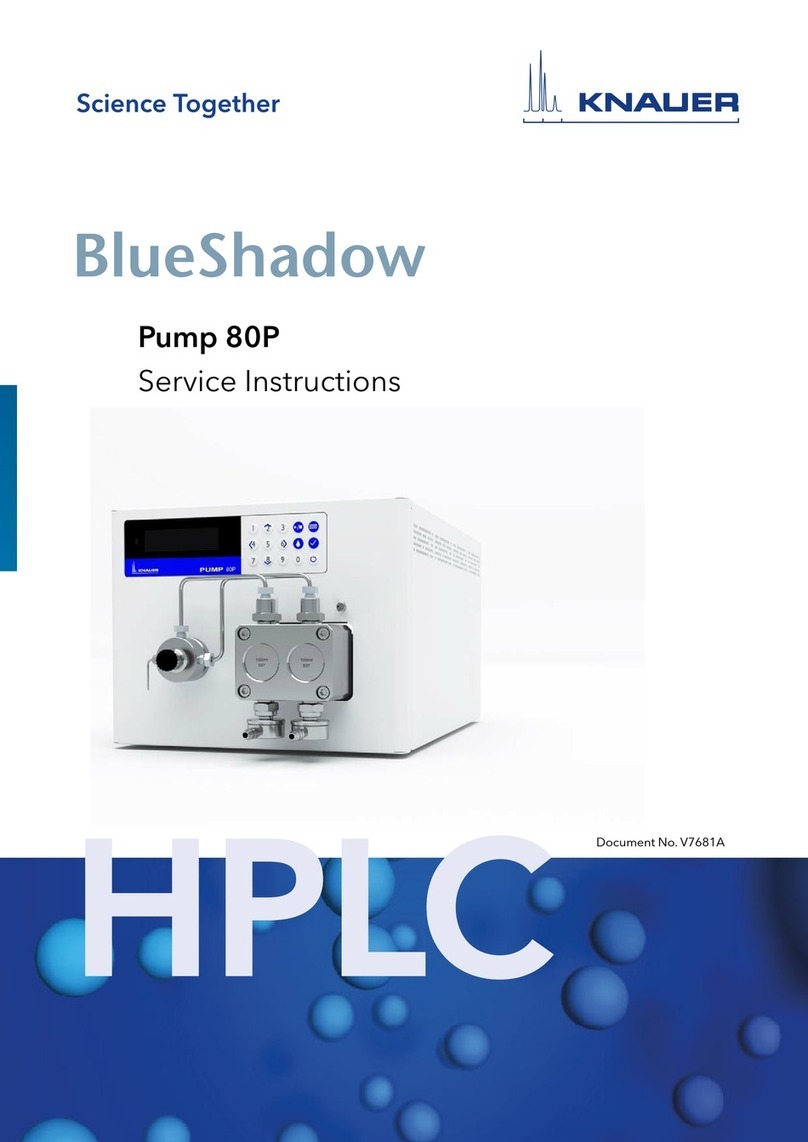

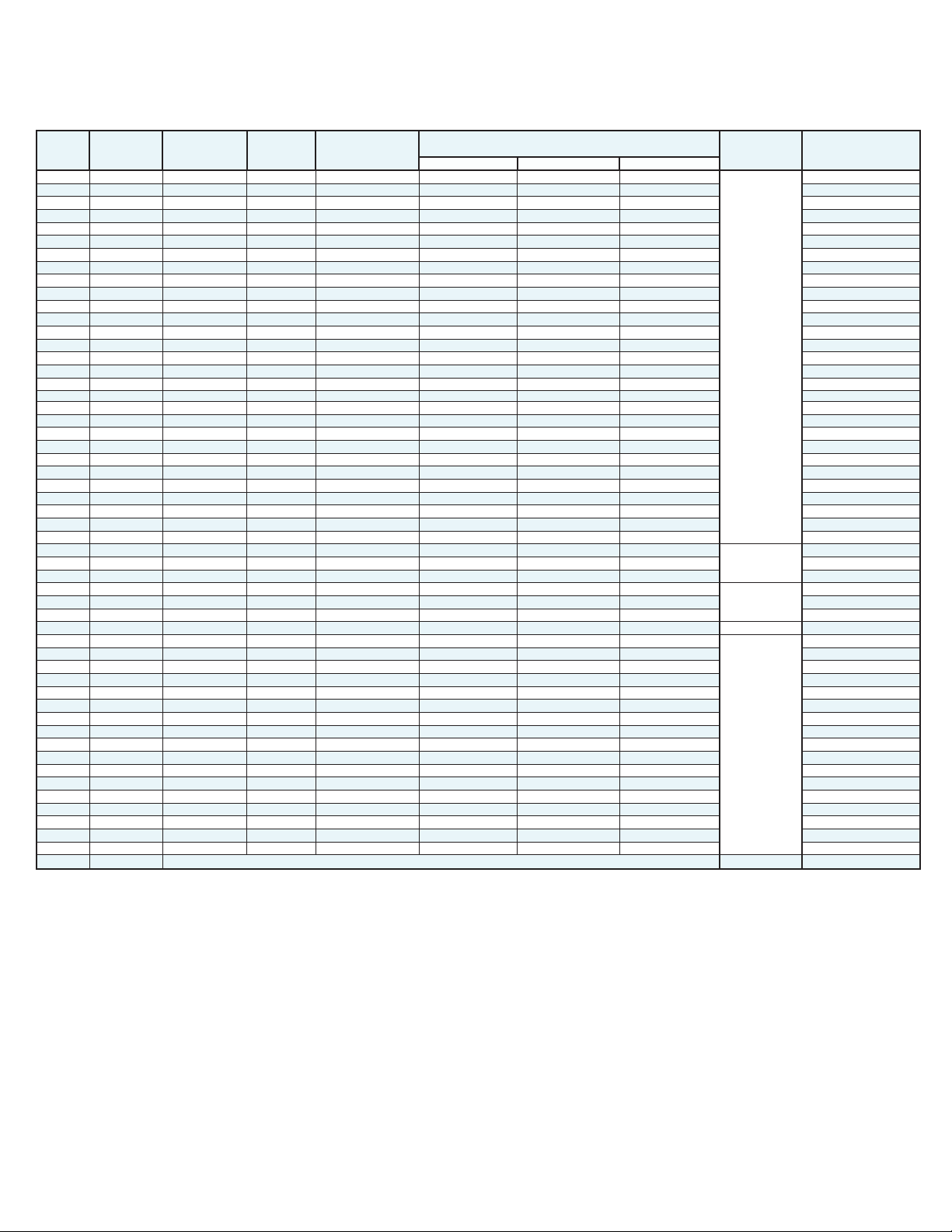

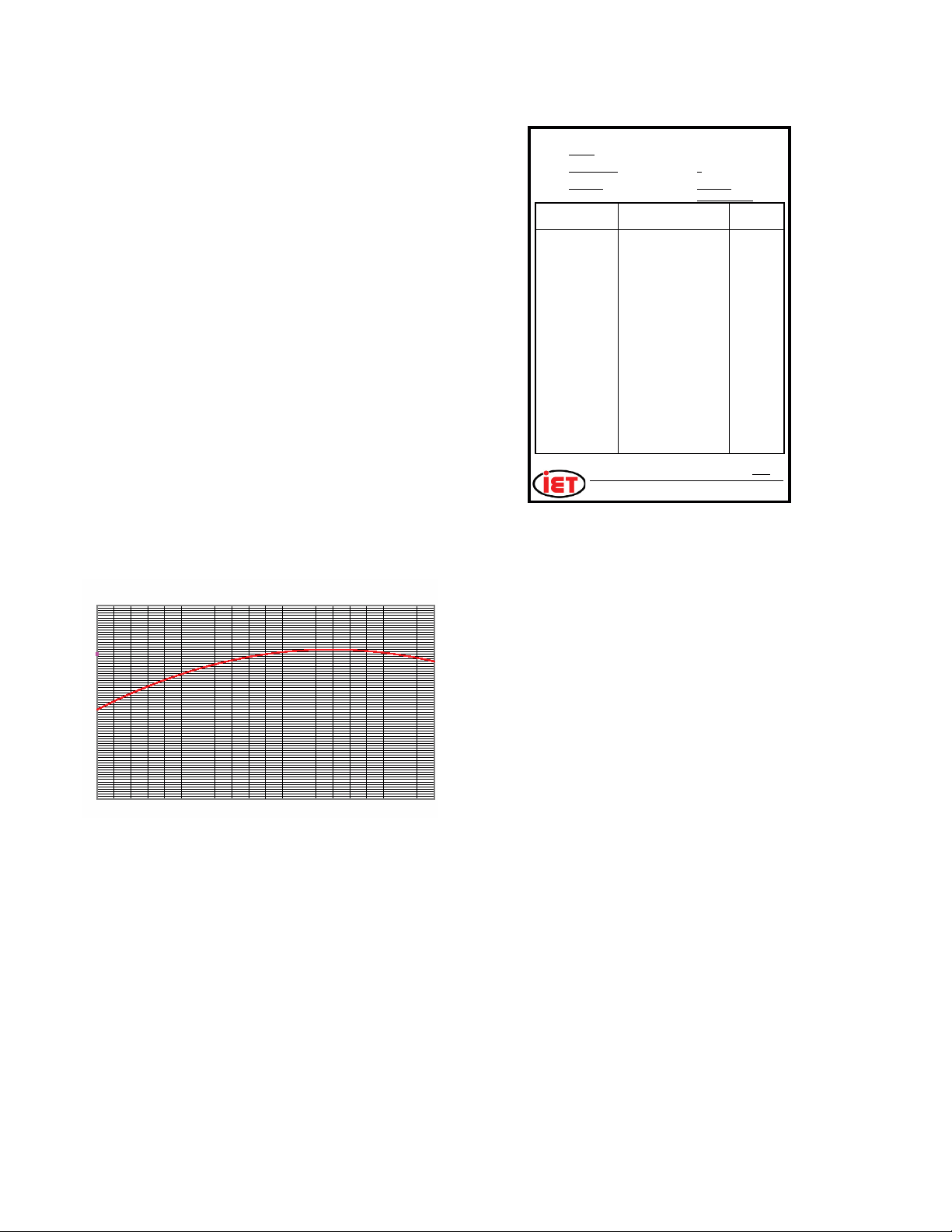

For convenience to the user, the pertinent speci•cations are given in an OPERATION GUIDE, shown in Figures

2-1 and 2-2, a!xed to the case of the instrument.

SPECIFICATIONS

Accuracy and other speci!cations:

See Table 2-1.

Retrace:

1 " to 19 M#: Permanent shift in resistance value

is <2 ppm for 23°C to 0°C to 23°C cycle, and 23°C

to 40°C to 23°C cycle

Calibration Report:

Initial SI traceable calibration data provided in

0.5°C increments for temperature range of 18°C to

28°C as shown in Figure 2-2.

Calibration Conditions:

Three of four-wire Kelvin measurements, low

power, at 23°C; two wire for 1 M" and over.

Traceable to SI

Terminals:

Gold-plated, tellurium-copper, low-thermal-emf binding

posts on standard 3/4 inch spacing. A GROUND terminal

is provided on all units.

#190 k$: four 5-way binding posts for 4-terminal

measurement

<190 k$: two 5-way binding posts

%100 M$: two 5-way binding posts with GUARD

Other available terminals:

• DMM direct input compatibles

• bnc, Triax, and custom connectors

Transit Case:

Optional Model SRC-100 lightweight transit case

with handle, suitable for transporting and storing

two units. The case provides mechanical protection

and insulation from temperature changes during

transportation or shipping.

Dimensions:

8.6 cm H x 10.5 cm W x 12.7 cm D (3.4” x 4.15” x 5”)

Weight:

0.73 kg (1.6 lb)

Figure 2-1: OPERATION GUIDE affixed to unit

Figure 2-2: Temperature Calibration Chart

JOS

19-Jun-2002

SRL-1 B2-9240246

N/A

1.000 003 3

N/A

N/A

SRL-1 STANDARD RESISTOR

±2 ppm

±3 ppm

18°C to 28°C

0.5 V

500 mA

8 ppm per year max; 2

ppm typical.

<2 ppm for for max.

temp. cycles.

-1.6E-07 -2.4E-08

19-Jun-2001

23.0°C

Adjustment to Nominal:

Max. Change from 23°C

value (18°C to 28°C):

Operating Temperature

Range:

Max. Voltage:

Max. Current:

Stability:

Retrace:

Date Calibrated

Temperature (°C)

Relative Humidity

Resistance R

Test Conditions

Meas. Uncertainty

By

Recommended Due

www.ietlabs.com

IET LABS, INC.

534 Main Street, Westbury, NY 11590

800-899-8438 • 516-334-5959

(FAX) 516-334-5988

Model: SN:

R

t

= R

23

[1 + α ( t - 23 ) + β( t - 23 )

2

]; α=β=

23

JOS

19-Jun-2001

1.000 003 3

SRL-1

B2-9240246 0

-1.6E-07 -2.4E-08

3.0

2.9

2.1

1.9

2.7

2.6

2.4

2.3

3.4

3.3

3.2

3.1

3.5

3.5

3.6

3.6

3.6

3.6

3.5

1.000 002 1

1.000 003 5

1.000 003 5

1.000 003 4

1.000 003 4

3.5

3.4

1.000 001 9

1.000 003 3

1.000 003 2

1.000 003 1

1.000 003 0

1.000 002 9

1.000 002 7

1.000 002 6

1.000 002 4

1.000 002 3

1.000 003 5

1.000 003 5

1.000 003 6

1.000 003 6

1.000 003 6

1.000 003 6

28.0

26.0

26.5

27.0

27.5

24.0

24.5

25.0

25.5

22.0

22.5

23.0

23.5

20.0

20.5

21.0

21.5

18.0

18.5

19.0

19.5

Temperature Calibration Chart

Model:

SN:

Alpha:

Report No:

Beta:

Temperature

(°C)

Deviation from

Nominal

(ppm)

Measured value at 23°C:

Date:

By:

IET LABS, INC.

• (516) 334-5959

• (800) 899-8438

• 534 Main Street, Westbury, NY 11590

Traceable to NIST

Resistance

3

SRL Series

3Specifications

Nominal

Value

Model

Number

Adjustment to

Nominal

Stability per

year (max

change)

Max Resistance

Change 18-28°C

from 23 °C

Max Applied Power Typical change

at 1 kHz Terminals

0 ppm change* 1 ppm change** 3 ppm change**

1 mΩ SRL-0.001 ±100 ppm ±50 ppm 25 ppm/°C

<100 ppm

4 bp's + gnd

10 mΩ SRL-0.01 ±5 ppm ±15 ppm 5 ppm/°C 25 mW 50 mW 200 mW 4 bp's + gnd

19 mΩ SRL-0.019 ±5 ppm ±15 ppm 5 ppm/°C 25 mW 50 mW 200 mW 4 bp's + gnd

20 mΩ SRL-0.02 ±5 ppm ±15 ppm 5 ppm/°C 25 mW 50 mW 200 mW 4 bp's + gnd

100 mΩ SRL-0.1 ±5 ppm ±12 ppm 2 ppm/°C 50 mW 100 mW 250 mW 4 bp's + gnd

190 mΩ SRL-0.19 ±5 ppm ±12 ppm 2 ppm/°C 50 mW 100 mW 250 mW 4 bp's + gnd

200 mΩ SRL-0.2 ±5 ppm ±12 ppm 2 ppm/°C 50 mW 100 mW 250 mW 4 bp's + gnd

1 Ω SRL-1 ±2 ppm ±8 ppm 3 ppm tot 175 mW 350 mW 850 mW 4 bp's + gnd

1.9 Ω SRL-1.9 ±2 ppm ±8 ppm 3 ppm tot 175 mW 350 mW 850 mW 4 bp's + gnd

2 Ω SRL-2 ±2 ppm ±8 ppm 3 ppm tot 175 mW 350 mW 850 mW 4 bp's + gnd

10 Ω SRL-10 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

19 Ω SRL-19 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

20 Ω SRL-20 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

25 Ω SRL-25 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

30 Ω SRL-30 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

50 Ω SRL-50 ±2 ppm ±8 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

100 Ω SRL-100 ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

190 Ω SRL-190 ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

200 Ω SRL-200 ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

350 Ω SRL-350 ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

400 Ω SRL-400 ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

1 kΩ SRL-1K ±2 ppm ±6 ppm 3 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

1 kΩ SRL-1K-TC ±2 ppm ±6 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

1.9 kΩ SRL-1.9K ±2 ppm ±6 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

2 kΩ SRL-2K ±2 ppm ±6 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

4 kΩ SRL-4K ±2 ppm ±4 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

10 kΩ SRL-10K ±2 ppm ±4 ppm 1.5 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

19 kΩ SRL-19K ±2 ppm ±4 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

20 kΩ SRL-20K ±2 ppm ±4 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

100 kΩ SRL-100K ±2 ppm ±6 ppm 2 ppm tot 100 mW 200 mW 500 mW

<200 ppm

4 bp's + gnd

190 kΩ SRL-190K ±2 ppm ±8 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

200 kΩ SRL-200K ±2 ppm ±8 ppm 2 ppm tot 100 mW 200 mW 500 mW 4 bp's + gnd

1 MΩ SRL-1M ±2 ppm ±8 ppm 2 ppm tot 100 mW 200 mW 500 mW

<1000 ppm

2 bp's + gnd

1.9 MΩ SRL-1.9M ±2 ppm ±9 ppm 3 ppm tot 100 mW 200 mW 500 mW 2 bp's + gnd

2 MΩ SRL-2M ±2 ppm ±9 ppm 3 ppm tot 100 mW 200 mW 500 mW 2 bp's + gnd

10 MΩ SRL-10M ±2 ppm ±9 ppm 3 ppm tot 500 V 1000 V 2500 V <2 % 2 bp's + gnd

19 MΩ SRL-19M ±2 ppm ±10 ppm 4 ppm tot 1000 V 2000 V 5000 V

NA

2 bp's + gnd

20 MΩ SRL-20M ±2 ppm ±10 ppm 4 ppm tot 1000 V 2000 V 5000 V 2 bp's + gnd

100 MΩ SRL-100M ±10 ppm ±20 ppm 5 ppm/°C 2000 V 4000 V 5000 V 2 bp's + gnd + guard

190 MΩ SRL-190M ±10 ppm ±20 ppm 5 ppm/°C 2000 V 5000 V 2 bp's + gnd + guard

200 MΩ SRL-200M ±10 ppm ±20 ppm 5 ppm/°C 5000 V 2 bp's + gnd + guard

1 GΩ SRL-1G ±0.1% ±200 ppm 23 ppm/°C 5000 V 2 bp's + gnd + guard

1.9 GΩ SRL-1.9G ±0.1% ±200 ppm 23 ppm/°C 5000 V 2 bp's + gnd + guard

2 GΩ SRL-2G ±0.1% ±200 ppm 23 ppm/°C 5000 V 2 bp's + gnd + guard

10 GΩ SRL-10G ±0.1% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

19 GΩ SRL-19G ±0.1% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

20 GΩ SRL-20G ±0.1% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

100 GΩ SRL-100G ±0.3% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

190 GΩ SRL-190G ±0.3% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

200 GΩ SRL-200G ±0.3% ±500 ppm 25 ppm/°C 5000 V 2 bp's + gnd + guard

1 TΩ SRL-1T ±0.5% ±500 ppm 50 ppm/°C 5000 V 2 bp's + gnd + guard

1.9 TΩ SRL-1.9T ±0.7% ±1000 ppm 100 ppm/°C 5000 V 2 bp's + gnd + guard

2 TΩ SRL-2T ±0.7% ±1000 ppm 100 ppm/°C 5000 V 2 bp's + gnd + guard

XXX Ω SRL-XXX customer-selected value and power specifications

* negligible effect of self-heating; do not exceed voltage limits where given.

** non-permanent self-heating change; exceeding power given for 3 ppm change may cause a permanent change in the resistance.

Table 2-1: SRL Specifications

4

SRL Series

4 Operation

Chapter 3

OPERATION

3.1 Initial Inspection and Setup

This instrument was carefully inspected before ship-

ment. It should be in proper electrical and mechanical

order upon receipt.

An OPERATION GUIDE is attached to the case

of the instrument to provide ready reference to

speci!cations.

3.2 Connections

The SRL series has three di"erent types of connec-

tions listed below.

3.2.1 Connections for values

£190 kW

Values #190 k$ have four insulated low thermal

emf binding posts for four-terminal measurements as

shown in Figure 3-1. The !fth binding post is con-

nected to the case. For high-resistance models (e.g.

>10 k%) two-terminal measurements may be made

by shorting HI to HI and LO to LO, preferably with

shorting links or other substantial means.

Figure 3-1: Connections for values £190 kW

1 W

RESISTANCE STANDARD

MODEL SRL-1

Maximum Resistance Change (18°C to 28°C): ±3 ppm

Maximum Voltage: 0.5 V

Maximum Current: 0.5 A

LO

HI

LO

HI

SENSE

CURRENT

GND

HI INPUT

HI SENSE

LO INPUT

LO SENSE

GROUND

Binding Post Function

CURRENT HI Current input from source (e.g. ohmmeter)

CURRENT LO Current return to source (e.g. ohmmeter)

SENSE HI Measurement point for a four-wire ohmmeter

SENSE LO Measurement point for a four-wire ohmmeter

GND Guard or shield

Table 3-1: Connections for values £190 kW

3.2.2 Connections for values

> 190 kWand <100 MW

Values > 190 k$ and <100 M$ have two insulated,

low thermal emf binding posts for two-terminal mea-

surements as shown in Figure 3-2. The third binding

post is connected to the case.

Figure 3-2: Connections for values > 190 kW

and <100 MW

Binding Post Function

HI Input from source (e.g. ohmmeter)

SENSE LO Measurement point

GND Guard or shield

Table 3-2: Connections for values > 190 kW

and <100 MW

HI INPUT

HI SENSE

1 MW

LO

HI

GND

RESISTANCE STANDARD

MODEL SRL-1M

Maximum Resistance Change (18°C to 28°C): ±2 ppm

Maximum Voltage: 100 V

Maximum Current: 0.1 mA

LO SENSE

LO INPUT

GROUND

5

SRL Series

5Operation

3.2.3 Connections for values

³100 MW

Values ≥100 MΩ have two insulated, low thermal

emf binding posts for two-terminal measurements as

shown in Figure 3-3. The third binding post, labeled

GROUND, is connected to the case. The fourth

binding post, labeled GUARD, is connected to an

internal case that contains the resistor.

Figure 3-3: Connections for values ³100 MW

Binding Post Function

HI Input from source (e.g. ohmmeter)

SENSE LO Measurement point

GROUND Shield

GUARD Interrupts leakage from the internal resistor to

the case and other components of the unit

Table 3-3: Connections for values ³100 MW

RESISTANCE STANDARD

MODEL SRL-100M

Temperature Coefficient: 5 ppm/°C

Maximum Voltage: 1000 V

100 MW

LO

HI

GROUND

GUARD

HI INPUT

HI SENSE

LO SENSE

LO INPUT

GROUND

GUARD*

*If no GUARD point exists on the measuring instrument,

it may be connected to GROUND.

3.3 Thermal emf Considerations

High-quality, gold-plated, tellurium-copper binding

posts serve to minimize the thermal emf effects which

would artificially reflect a change in dc resistance

measurements. All other conductors within the

instrument, as well as the solder used, contain no

metals or junctions that could contribute to thermal

emf problems.

There nevertheless may be some minute thermal emf

generated at the test leads where they contact the gold

banana jacks. This voltage will also be eliminated if

a meter with so called “True Ohm” capability is used.

Otherwise the generated emf may represent itself as a

false component of the dc resistance measurement.

Always use low emf test leads when working with

SRL models. In particular, avoid brass or steel

conductors.

6

SRL Series

6 Operation

3.4 Temperature Coefficient Constants

The change of resistance with temperature for each

standard is accurately expressed by the equation:

Rt=R23[1+a(t-23)+ß(t-23)2]

Rt=Resistance at (°C)

R23 = Resistance at 23°C

a = Slope of the curve (ppm/°C) at 23°C

ß = Rate of change of slope of the curve (ppm/°C2)

The values of

aand ß are given with each unit.

Experience shows that these values do not change

appreciably with time and hence need to be deter-

mined only once.

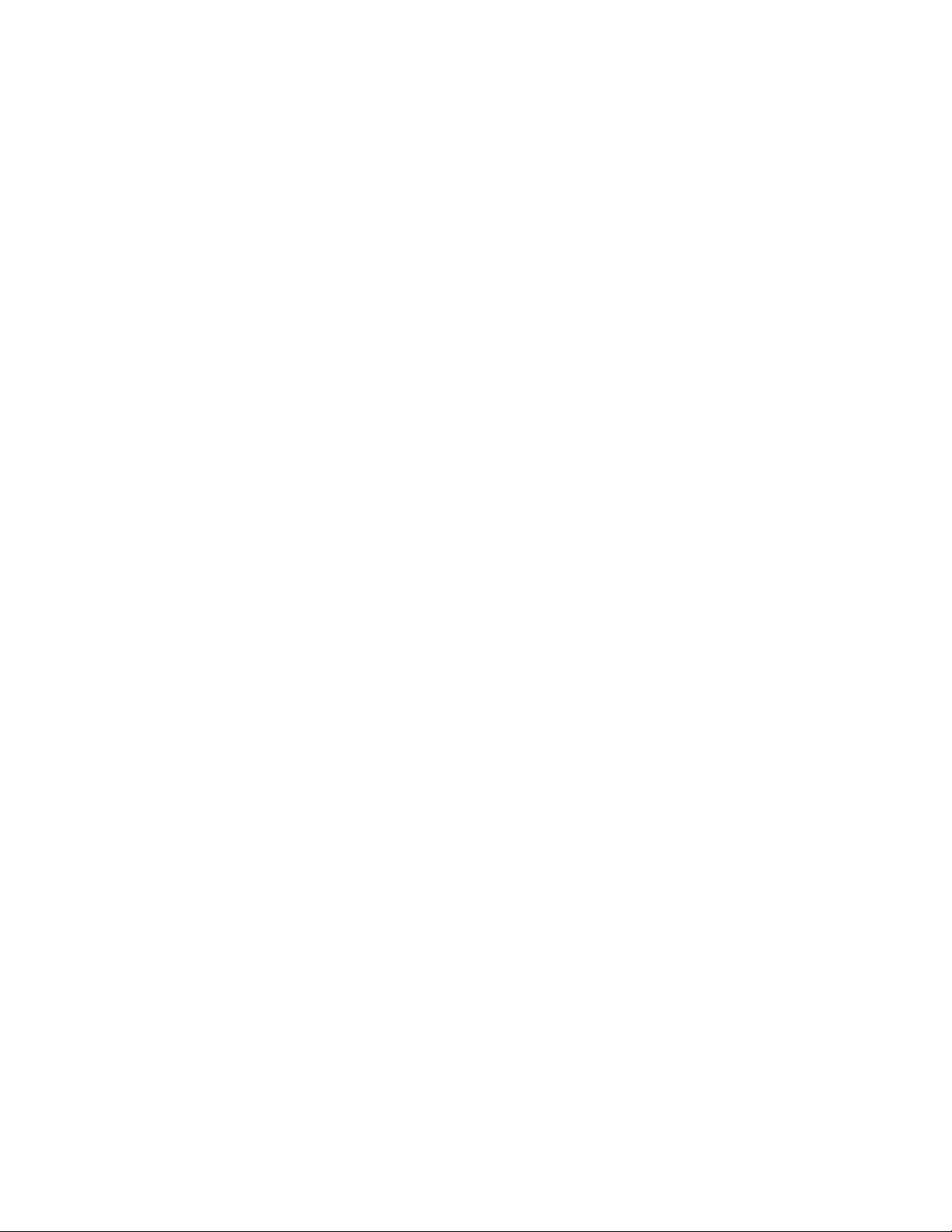

The resistance vs. temperature relationship is shown

in Figure 3-4. The value at any temperature may be

obtained from the above formula, or the temperature

calibration chart shown in Figure 3-5.

Figure 3-4: Resistance vs. temperature

relationship

Approximate Temperature (°C)

-3

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

-0.5% -0.4% -0.3% -0.2% -0.1% 0.0% 0.1% 0.2% 0.3% 0.4% 0.5%

Figure 3-5: Temperature Calibration Chart

3.5 Environmental Conditions

3.5.1 Operating Temperature

For optimal accuracy, SRL Models should be used

in an environment of 23°C ±5°C. They should be

allowed to stabilize at those temperatures after any

signi!cant temperature variation. For determina-

tion of accuracy for other temperatures consult the

Temperature Calibration Chart provided with each

unit. The calculated resistance value is provided be-

tween 18°C and 28°C in 0.5°C increments. Figure

2-2 shows an example of this table.

3.5.2 Storage Temperature

The SRL Series should be maintained within the

storage temperature range of 0°C to 40°C to retain

its accuracy within the speci!ed limits.

3.6 Shipping and Handling

The SRL Series should not be exposed to any excessive

shock or temperature extremes. The option SRC-100, a

lightweight transit case capable of storing two SRL units,

is recommended for shipping or transporting the models.

JOS

19-Jun-2001

1.000 003 3

SRL-1

B2-9240246 0

-1.6E-07 -2.4E-08

3.0

2.9

2.1

1.9

2.7

2.6

2.4

2.3

3.4

3.3

3.2

3.1

3.5

3.5

3.6

3.6

3.6

3.6

3.5

1.000 002 1

1.000 003 5

1.000 003 5

1.000 003 4

1.000 003 4

3.5

3.4

1.000 001 9

1.000 003 3

1.000 003 2

1.000 003 1

1.000 003 0

1.000 002 9

1.000 002 7

1.000 002 6

1.000 002 4

1.000 002 3

1.000 003 5

1.000 003 5

1.000 003 6

1.000 003 6

1.000 003 6

1.000 003 6

28.0

26.0

26.5

27.0

27.5

24.0

24.5

25.0

25.5

22.0

22.5

23.0

23.5

20.0

20.5

21.0

21.5

18.0

18.5

19.0

19.5

Temperature Calibration Chart

Model:

SN:

Alpha:

Report No:

Beta:

Temperature

(°C)

Deviation from

Nominal

(ppm)

Measured value at 23°C:

Date:

By:

IET LABS, INC.

• (516) 334-5959

• (800) 899-8438

• 534 Main Street, Westbury, NY 11590

Traceable to NIST

Resistance

7

SRL Series

7Maintenance

Chapter 4

MAINTENANCE

4.1 Maintainability and Reliability

It is possible to maintain SRL units inde•nitely. They

are reliable due to their closed, rugged design and

sealed resistors. The units are resistant to electro-

magnetic interference (EMI) because of their metal

enclosure.

4.2 Preventive Maintenance

Keep the SRL units in a clean environment. This will

help prevent possible contamination.

The front panel may be cleaned to eliminate any leak-

age paths from near or around the binding posts. To

clean the front panel:

Wipe the front panel clean using alcohol and a

lint-free cloth.

4.3 Calibration

The SRL units may be employed as stand-alone in-

struments or as an integral components of a system.

If used as part of a system, they should be calibrated

as part of the overall system to provide an optimum

system calibration.

If an SRL model is employed as a stand-alone device,

the following should be observed:

• Calibration Interval

• General Considerations

• Required Equipment

• Calibration Procedure

4.3.1 Calibration Interval

The recommended SRL Series calibration interval is

twelve (12) months.

If the instrument is used to transfer resistance values

only, recalibration is not required, assuming that there

has been no drastic change of value.

4.3.2 General Considerations

Before starting the calibration procedure, you need

to consider the following:

• Calibration environment should be 23°C and

less than 50% relative humidity.

• Test instruments should be su!ciently more

accurate than the SRL unit, and/or the uncer-

tainty of the measurement instrumentation

has to be considered in the calibration Test

Uncertainty Ratio (TUR).

• The testing equipment and the SRL unit

should stabilize at laboratory conditions for

at least 24 hours.

• Kelvin type 4-wire test leads should be

used to obtain accurate low resistance

measurements.

• Steps should be taken to minimize thermal

emf e"ects, such as using a meter with “True

Ohm” capacity.

• Accepted metrology practices should be

followed.

8

SRL Series

8 Maintenance

4.3.3 Required Equipment

Many combinations of standards, transfer stan-

dards, meters, and bridges may be used to calibrate

this instrument. The following are some possible

choices:

• Resistance Standards or Transfer Standards

for the required values with traceable cali-

brations, such as the following standards

available from IET Labs

• SR-102 100 Ω

• SR-103 1 kΩ

• SR-104 10 kΩ

• SRL series

• Precision resistance measurement bridge

or multimeter, with a transfer accuracy

of ±l ppm. Options include:

• Measurements International Model

6010C, 6000B

• ESI model 242, 242A, 242C, or

242D

• A high-precision, high-stability digi-

tal multimeter (e.g. Fluke 8508A)

along with a set of resistance stan-

dards for ratio mode.

4.3.4 Calibration Procedure

To calibrate an SRL unit, proceed as follows:

1. Set up the calibration equipment in the resis-

tance measurement mode.

2. Confirm the resistance of the unit.

Allow a confidence band for the uncer-

tainty of the measuring instrument and

setup.

3. Confirm that the resistance is consistent with

historical measurements.

4.4 Replaceable Parts List

Reference IET Pt No Description

1BP-1000-RD Binding Post, Red

2BP-1000-BK Binding Post, Black

3BP-1000-GN Binding Post, Green

3BP-1000-BL Binding Post, Blue

Not Shown SRL-*-Res SRL resistor assembly

Replace * with nominal resistance value

Table 4-1: Replaceable Parts List

Figure 4-1: SRL Replaceable Parts

12

3

4

This manual suits for next models

49

Table of contents

Other iET Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

NAPCO

NAPCO NAP9600 user manual

Pasco Scientific

Pasco Scientific CI-6689A instruction sheet

ThermoFisher Scientific

ThermoFisher Scientific HyPerforma S.U.F. user guide

Fisher Scientific

Fisher Scientific Fisherbrand accuSpin Micro Series instruction manual

THORLABS

THORLABS KURIOS-WB1 user guide

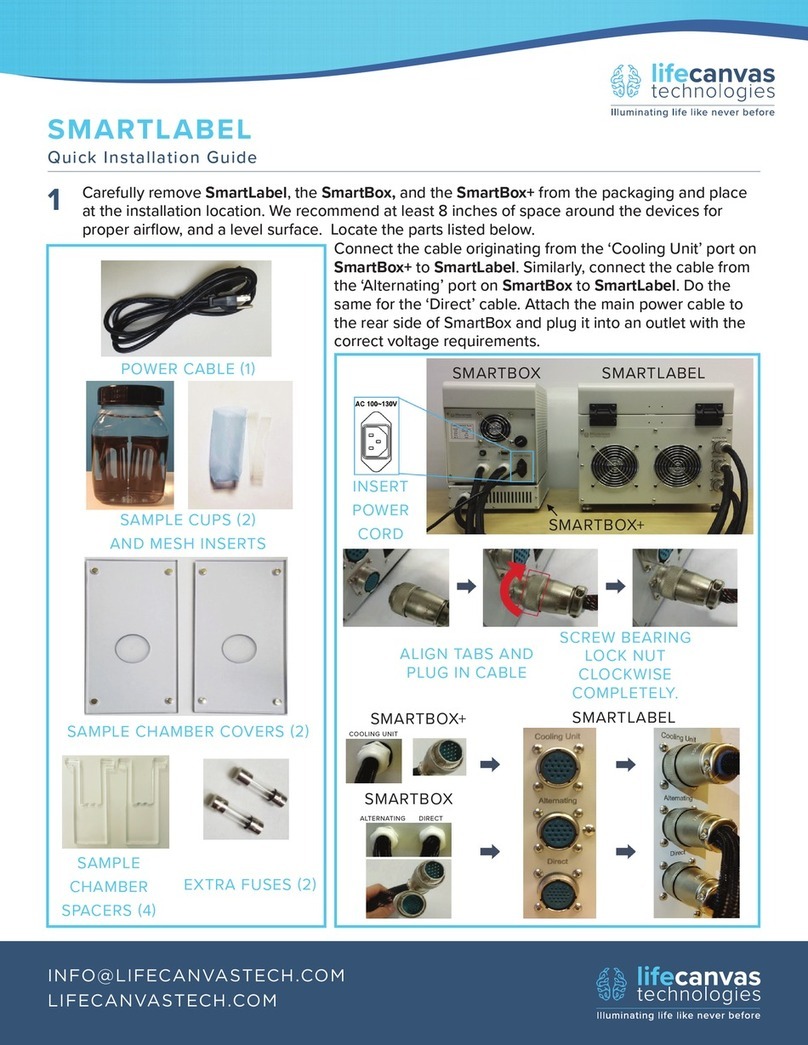

Lifecanvas Technologies

Lifecanvas Technologies SMARTLABEL Quick installation guide