iFlow iFLH-14000W User manual

iFLOW HVAC INC. www.iflowhvac.com

iNTELLIGENT SMART IoT TECHNOLOGIES

iFLOW HYDRONIC AIR HANDLER

NEW GENERATION OF HEATING &COOLING

iFLOW AHU MANUAL

WiFi & ZONING

Model

iFLH-14000W

iFLH-16000W

iFLH-18000W

iFLH-16000D

iFLH-18000D

iFLH-18000Q

iFLOW HVAC INC.

www.iflowhvac.com

iFLOW HVAC INC. www.iflowhvac.com

2

Introduction

1. Introduction Safety ………………………………………………………………………………………………………………………………………………………… 3

2. Summary of Air Handler Components …………………………………………………………………………………………………………………………… 3

3. Installer’s checklist ………………………………………………………………………………………………………………………………………………………… 3

Product Description

1. Components ………………………………………………………………………………………………………………………………………………………………… 4

2. Standard features and benefits ……………………………………………………………………………………………………………………………………… 5

3. Equipment selection and sizing ……………………………………………………………………………………………………………………………………… 6

4. Suitable applications (choosing the right heat source) …………………………………………………………………………………………………… 9

Installation

1. Location requirements and clearances ………………………………………………………………………………………………………………………… 10

2.Dimensions ………………………………………………………………………………………………………………………………………………………………… 10

3. Installation examples …………………………………………………………………………………………………………………………………………………… 11

4. Water heater/ boiler piping …………………………………………………………………………………………………………………………………… 11

5. Domestic piping ……………………………………………………………………………………………………………………………………………………… 11

6. Installing the iFLOW air handler with a tankless/tank water heater ……………………………………………………………………… 12

7. Electrical requirements and making connections ……………………………………………………………………………………………………… 12

8. Temperature sensors ……………………………………………………………………………………………………………………………………………… 12

9. Installing the iFLOW air handler with a Navien tankless water heater …………………………………………………… 13

10. Zone damper ……………………………………………………………………………………………………………………………………………………………… 13

11. WiFi Module connect to iFLOW control boards ………………………………………………………………………………………………………… 13

Start-Up

1. Procedure ……………………………………………………………………………………………………………………………………………………………………… 14

2. Flushing the heat exchanger ………………………………………………………………………………………………………………………………………… 14

3. Sequence of operation ………………………………………………………………………………………………………………………………………………… 14

Service and Maintenance

1. Maintenance …………………………………………………………………………………………………………………………………………………………… 20

2. Checking temperature sensors …………………………………………………………………………………………………………………………………… 20

3. Wiring diagrams ………………………………………………………………………………………………………………………………………………………… 21

4. Ladder diagram …………………………………………………………………………………………………………………………………………………………… 28

Troubleshooting

1. Fault codes and explanations …………………………………………………………………………………………………………………………………… 29

2. Problems and solutions …………………………………………………………………………………………………………………………………………… 31

3. Component assembly diagram and parts list …………………………………………………………………………………………………………… 32

4. Installation diagram …………………………………………………………………………………………………………………………………………………… 40

Warranty and Contact Information

1. Warranty ……………………………………………………………………………………………………………………………………………………………………… 48

2. Contact information …………………………………………………………………………………………………………………………………………………… 48

Table of Contents

iFLOW HVAC INC. www.iflowhvac.com

WARNING

This Air Handler Unit (AHU) is not intended for installation in a

unconditioned space where the potential may exist for the water

and/or drain lines to freeze.

3

1. Introduction Safety

Ensure the instructions and requirements provided in this manual are

read and understood before installation. Failure to comply with these

instructions can cause product and property damage, serious injury

or death.

Pay attention to the following safety symbols and words:

DANGER

Indicates an imminently hazardous situation, which if not

avoided, will result in death or serious injury.

WARNING

This product can expose you to chemicals including lead,

lead compounds, and carbon bisulfide which are known to the

State of California to cause cancer and birth defects or other

reproductive harm. For more information, go to

www.P65Warnings.ca.gov.

CAUTION

Indicated a potentially hazardous situation, which if not

avoided, may result in minor or moderate injury. It is also used

to alert against unsafe practices and hazards involving property

damage.

• Be sure to bleed all air from all system components and piping prior

to start-up.

• It is recommended to install purge valves between the air handler

and water heater’s isolation valves.

• If connected to domestic piping creating an open system, make

sure all piping, components, and solder are lead-free and approved

for potable-use.

CAUTION

Return air openning shall not be installed

on the back side of unit.

IMPORTANT

The maximum ambient temperature must

not exceed 122℉ (50℃)

• Ensure fan assembly is clear of any obstruction

• Check that air filter is installed upstream of air conditioning coil.

• If the appliance is installed with air conditioning,the A/C refrigerant

charge and system operation must be verified by a certified/ licensed

mechanic prior to commissioning.

2. Summary of air handler

The iFLOW hydronic air handlers are designed to deliver the highest

performance rating of any air handler regardless of the hot water

source. This unique hydronic furnace is built for use in residential and

commercial applications.

CAUTION

The air handler must be installed such that electrical components

are away from water (spraying, splashing, etc.) during operation and

service.

IMPORTANT

A field fabricated auxiliary drain pan with a drain pipe connection is

recommended in all configurations.

Introduction

3. Installer’s checklist

iFLOW HVAC INC. www.iflowhvac.com

4

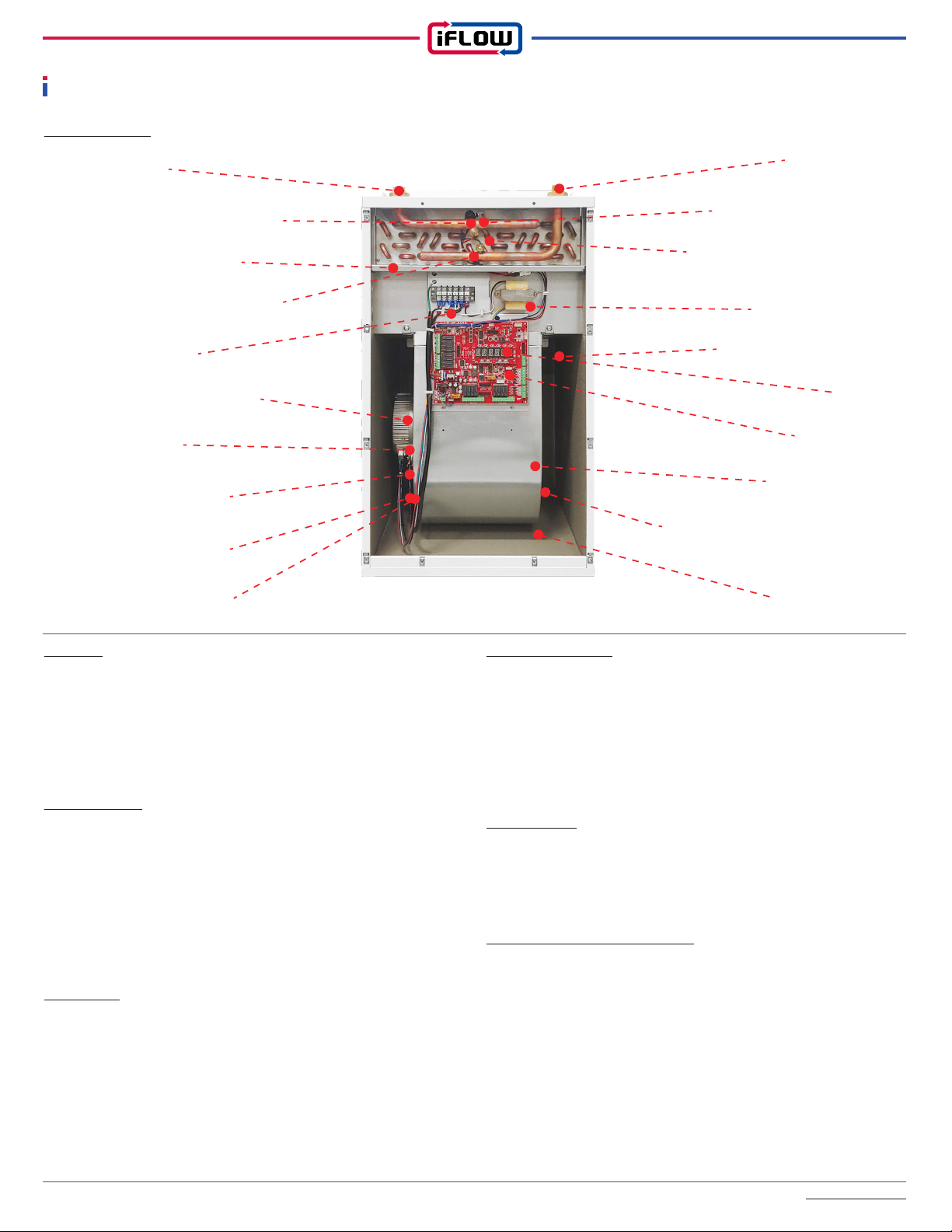

1) Components

Cabinet:

All cabinets are made of high quality, and durable heavy gauge

galvanized steel. The inside of the cabinet is fully insulated with ½”

polyethylene sheets. This prevents moisture and mold growth, as well

as unwanted heat loss due to an R-Value. The smaller cabinet size

and shape is designed to maximize installation flexibility.

Heating Coils:

All iFLOW heating coils are constructed of potable, water-grade

copper for use in plumbing systems. Lead-Free solder has been used

for assembly on all components. All coils and internal piping conform

to ASTM B-68, ASTM B-88 and/or B-743 standards. Carefully

engineered, high-density aluminium fins allow for maximum heat

transfer across smaller coils. This provides warmer, more comfortable

heating with lower air flow for minimal operating noise.

Fan Motor:

All iFLOW air handlers are equipped with variable speed ECM

motors. This allows for separate heating, cooling, and continuous run

speeds. They reduce electrical-use and are dynamically balanced

for extra quiet operation. Blowers are mounted with four screws on

rails for easy removal and service. Multi-directional motors allow for

mounting in any direction.

Circulating Pump:

All air handlers require a field supplied single speed or 3-speed pump,

to be controlled by the iFLOW circulator control. This the speed of the

pump increases or decreases depending on the information provided

by the temperature sensors. The pump also provides maximum

performance when used in conjunction with an instantaneous water

heater or a storage-type water heater.

Check Valve:

A spring-loaded check valve must be installed either with the field-

supplied pump or externally to prevent the by passing of water to the

appliance.

Multi-Function Control Board:

This intelligent control board comes factory installed. No dip

switches are required or included with the iFLOW control board.

Easy programming allows for user-friendly startup and service/

maintenance. Some of the parameters the user is able to configure

are: heating output, CFM for heating, cooling and continuous low-

speed fan, outdoor design temperature and circulating pump speed.

Product Description

Water Inlet Water Outlet

Supply Air Temp. Sensor

Supply Water Temp. Sensor

Transformer AC24V

Blower Assembly Bracket

Display

Main Control

Blower Assemble

Dehumidier Eva. Temp. Sensor

(Option)

Humidity Sensor

A/C Evap. Air Temp. Sensor

Heat Exchanger Ass'y

(Hydronic Coil)

Return Water Temp. Sensor

Power Terminal

Return Air Temp. Sensor

Blower Motor

Blower Arm & Band

Motor Power Cable

Motor Control Cable

iFLOW HVAC INC. www.iflowhvac.com

2) Standard Features and Benefits:

• Highest performance at 98% efficiency (CAN/CAS P.9-11

Performance Ratings: TPF 0.98)

• Ultra-efficient heat-exchanger design with high-density aluminum

fins

• Offers installation flexibility allowing for up-flow, down-flow or

horizontal applications

• Cost effective and extremely quiet variable speed ECM fan motor /

constant CFM

• Slide-out blower rail assembly for easy maintenance & removal with

4 screws

• 6 fully modulating models: 3 ‘standard duct’ models (S, M, L) & 3

high-static pressure models (S, M, L)

• Easy installation: Lightweight, “one-man job” with Optional EZEE

Plumbing Kit

• Approved for potable water (‘open’) systems with buit-in anti-

stagnation and DHW priority included in the control board

• Air and water supply and return temperature sensors included

• Humidity sensor included for cooling fan speed modulation

• Freeze Protection/ Evaporator Temperature Sensor

• Outdoor temperture sensor included

• Intelligent iFLOW control board

• All models are compatible with mercury or digital thermostats

• Supports the use of two stage and inverter-driven variable speed

cooling equipment

• Accessories are controlled by AC24V power

• LED light indicates alarm, test mode and normal operation

• Auxiliary contacts (dry contact) for boiler or water heater activation

• Bottom or left or right side return air supply

• 0” clearance to combustibles

• Cabinet lined with 1/2” Polyethylene High-Density Insulation

• Cabinet manufactured with heavy gauge galvanized steel and

powder-coated to prevent corrosion

iNTELLIGENT PUMP CONTROL:

• Pump modulation control

• Low flow pump exercise function (Water Circulation / Seize

Protection)

• Low ambient freeze protection

iNTELLIGENT CONTROL:

• Boiler demand control

• Installer & user-friendly interface

• Informative display: error code, temperture, humidity, fan & pump

speed

• Easily configure all parameters smartphone App.

• 22 segment LED indicator / all input & output signals: built-in

programmable and diagnostic control display

• Outdoor reset function / outdoor temperature sensor

• Full modulation a single or two stage settings for heating & cooling

• Humidity control / humidity sensor

• ΔT auto-adjustment air and water (air and water flow control)

• Fan "ON" delay & Fan "OFF" heat purge control

5

• DHW priority & dual mode (heating and DHW)

• High & low limit safety control: air temperature sensor

• Home freeze protection: low ambient temperature sensor

• Evaporator freeze protection: compressor protection

• Virtual termostat mode with the smartphone app

• Smart zoning control (saving gas & hydro)

• Maximize heat pump performance / (AVOID) Peak Time AVOID

Electricity Function

• Hybrid heating system switching control and backup with heat pump

• Communication with NAVIEN Tankless Water Heater

OPTIONS:

• Multi-system central control for building HVAC systems

• Wi-Fi connection with a smartphone (Free app available on iOS and

Android)

• Remotely adjust and monitor operation through web integrated plug-

in control, or directly via a smartphone connection

• All-in-one package (EZEE plumbing kit and stand) for easy

Installation: iFLOW AHU with any TLWH/TWH

Freeze Protection:

iFLOW Air handlers include a freeze protection sensor that will

temporarily disable the outdoor condenser for 5 minutes if the

evaporator coil outlet temperature drops below 40°F/4°C. This will

allow the system to warm up and return back to normal operating

conditions.

To protect the hydronic heating coil from freezing, the pump will

operate for a minimum of 30 seconds. Dirty air filters, oversizing of A/

C equipment, improper A/C installation or poor duct design will also

play a role in the evaporator coil freezing.

Water Circulation / Pump Exercise:

In section 4.2.5.1 Prevention of Stagnation of the 'CAN/CSA-B214-12

Installation Code for Hydronic Heating Systems', it states: "a means

shall be provided to prevent the stagnation of potable water in a

hydronic system by recycling or flushing the contents not less than

once every 24 hours."

The iFLOW controller is defaultset to turn on the circulating pump to

cycle the total volume of potable water in the system, once every 24

hours. This will prevent stagnation and protect the pump from seizing.

There is a test button to verify that this operation is working. The

setting can be adjusted to circulate more frequently if desired.

Alarms:

In the event of a service problem (i.e. temperature sensor failure, low

ambient temperature, cooling lockout, etc.), the iFLOW air handler

will notify the user/owner with an audible alarm and red light. The

alarm on the control board can be silenced by turning the power off

for 5 seconds and then back on.

iFLOW HVAC INC. www.iflowhvac.com

6

Set Back Recovery:

If a programmable thermostat with setback is used or a sudden

increase in temperature is required, the iFLOW intelligent control

board will modulate the air handler to its maximum output to speed

temperature delivery. The next cycle will return to normal operation.

See "Heat Boost Delay" Parameter.

Test Mode:

Entering ‘test mode’ on the controller will allow the technician to test

the iFLOW air handler heating and cooling mode parameters. Once

completed, push the test button again to return to normal operation.

Heating:

The iFLOW air handler will automatically change the fan and pump

speeds to control the temperature output of the unit and cycle-time

length. This will allow the heat output of the air handler to match the

current heat loss of the home. Maximum ‘matching’ performance is

achieved when used in conjunction with the outdoor sensor. This

leads to a longer runtime, providing superior warmth and comfort.

Cooling/Dehumidifying:

The iFLOW air handler uses a modulating blower fan to regulate

humidity levels. The blower fan speed decreases in high humidity

to remove moisture quicker. The blower fan speed increases under

normal conditions to provide optimal cooling. The balance of the two

is always met. Optimal humidity levels result in increased comfort

for the homeowner, and at the same time reduces cooling loads and

operating costs.

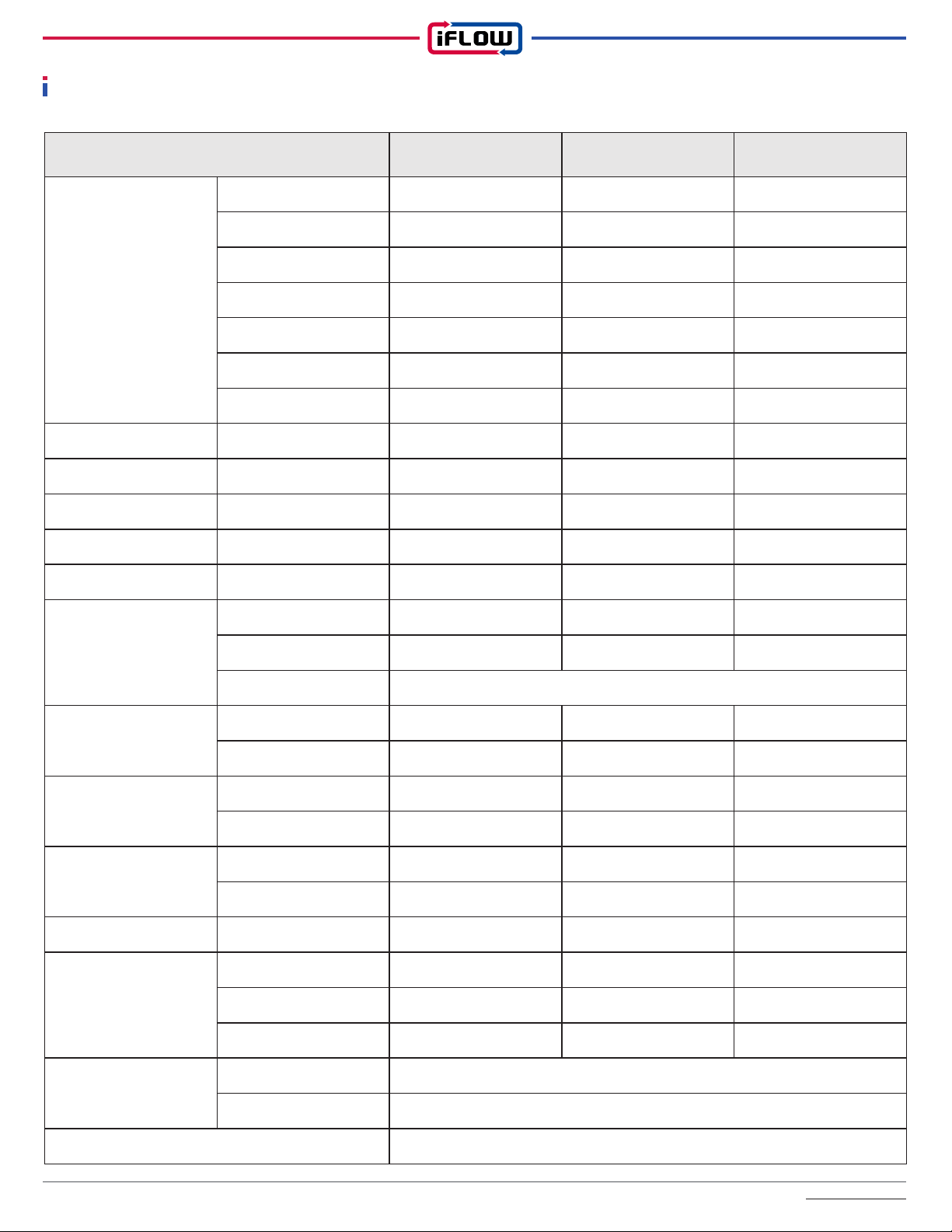

3. Equipment selection and sizing

iFLOW air handlers are available in 3 models. Please use the

following charts to determine which best suits the application:

1. Obtain/calculate/determine a proper heat load for the home

2. Determine the inlet water temperature from water heater(or boilder)

3. Determine the duct layout/ available duct size

4. Be sure the system air flow rate matches the air flow rate of the

selected air handler

System Design Resource Note:

From the CAN/CSA-B214-12 Installation Code for Hydronic Heating

Systems, section 4.2.2.1 Heat-source output, it states: "the heat-

source output shall be not less than the heat load indicated in the

system design."

4.2.2.2 Dual-purpose water heater

Model No. Description

Model No. Description WiFi @ IoT Zoning Temperature

Control

iFLH-140000

iSmart

Control No No Room

Thermostat

iFLH-160000

iFLH-180000

iFLH-14000W

iSmart

Control

WiFi

@

Internet/

Paring Mode

No

Room

Thermostat

or

Smart Mode

with

Smartphone

iFLH-16000W

iFLH-18000W

iFLH-16000D

iSmart

Control

WiFi

@

Internet/

Paring Mode

2 Supply

Zone

2 Return

Zone

Room

Thermostat

or

Smart Mode

with

Smartphone

iFLH-18000Q

4 Supply

Zone

4 Return

Zone

Model No. Description

Model No. Format

▶

i F L H - 1 4 0 0 0 0

Function / B: basic, W: WiFi,

D: 2 zone, Q: 4 zone

▶

▶Cabinet Size / 14 : 14", 16 : 16", 18 : 18" Width

Static Pressure / L : Low Static Pressure,

H: High Static Pressure, LH : Universal

▶Company Initial

Model No. Initial Size Function Initial

i F L H 14, 16, 18 B, W, D, Q, 0

iFLOW HVAC INC. www.iflowhvac.com

7

Description iFLH-140000 iFLH-160000 iFLH-180000

Heating

Capacity

@

Entering

Water

Temperature

120℉ 27,834 BTUH 34,211 BTUH 42,376 BTUH

130℉ 33,478 BTUH 41,357 BTUH 50,966 BTUH

140℉ 37,729 BTUH 48,379 BTUH 59,632 BTUH

150℉ 44,998 BTUH 55,485 BTUH 68,334 BTUH

160℉ 50,869 BTUH 62,632 BTUH 77,065 BTUH

170℉ 56,941 BTUH 69,769 BTUH 85,648 BTUH

180℉ 62,786 BTUH 76,982 BTUH 94,633 BTUH

Flow Rating LPM / GPM 11.4 / 3 11 / 2.9 10.6 / 2.8

Return Air Temp. ℃ / ℉ 22 / 72 22 / 72 22 / 72

E. S. P. inWC 0.6 / 1.2 0.6 / 1.6 0.6 / 1.6

Airflow SCFM 941 / 824 1222 / 1009 1423 / 1093

Cooling Capacity Ton 1 - 2 1.5 - 3 2 - 4

Cabinet Size

(W x D x H)

in 14 x 18 3/4 x 27 1/8 16 x 20 3/4 x 27 1/8 18 x 25 3/4 x 29 1/8

mm 356 x 476 x 689 406 x 527 x 689 457 x 654 x 740

Material Cold Roll Steel Sheet Metal / Powder Coated

Weight

kg 28.6 32 42

lb 63 71 92.5

Supply Air Opening

(W x D)

in 13 x 14 14 x 16 16 x 20

mm 330 x 356 356 x 406 406 x 508

Return Air Opening

(H x D)

in 12 x 16 13 x 18 14 x 23

mm 406 x 304 457 x 330 584 x 355

Electrical ACV/Hz/Ph AC 120V 60Hz 1Ph AC 120V 60Hz 1Ph AC 120V 60Hz 1Ph

Motor

HP 1 / 2 1 / 2 3 / 4

Type ECM Eon ECM Eon ECM Eon

W431 / 393 519 / 516 592

Piping Connection

Supply 3/4" Male NPT Thread / 1/2" Soldering Connection

Return 3/4" Male NPT Thread / 1/2" Soldering Connection

Hydronic Heating Coil Aluminum Ultra Efficiency Fins, Copper Tubing

Specification

iFLOW HVAC INC. www.iflowhvac.com

8

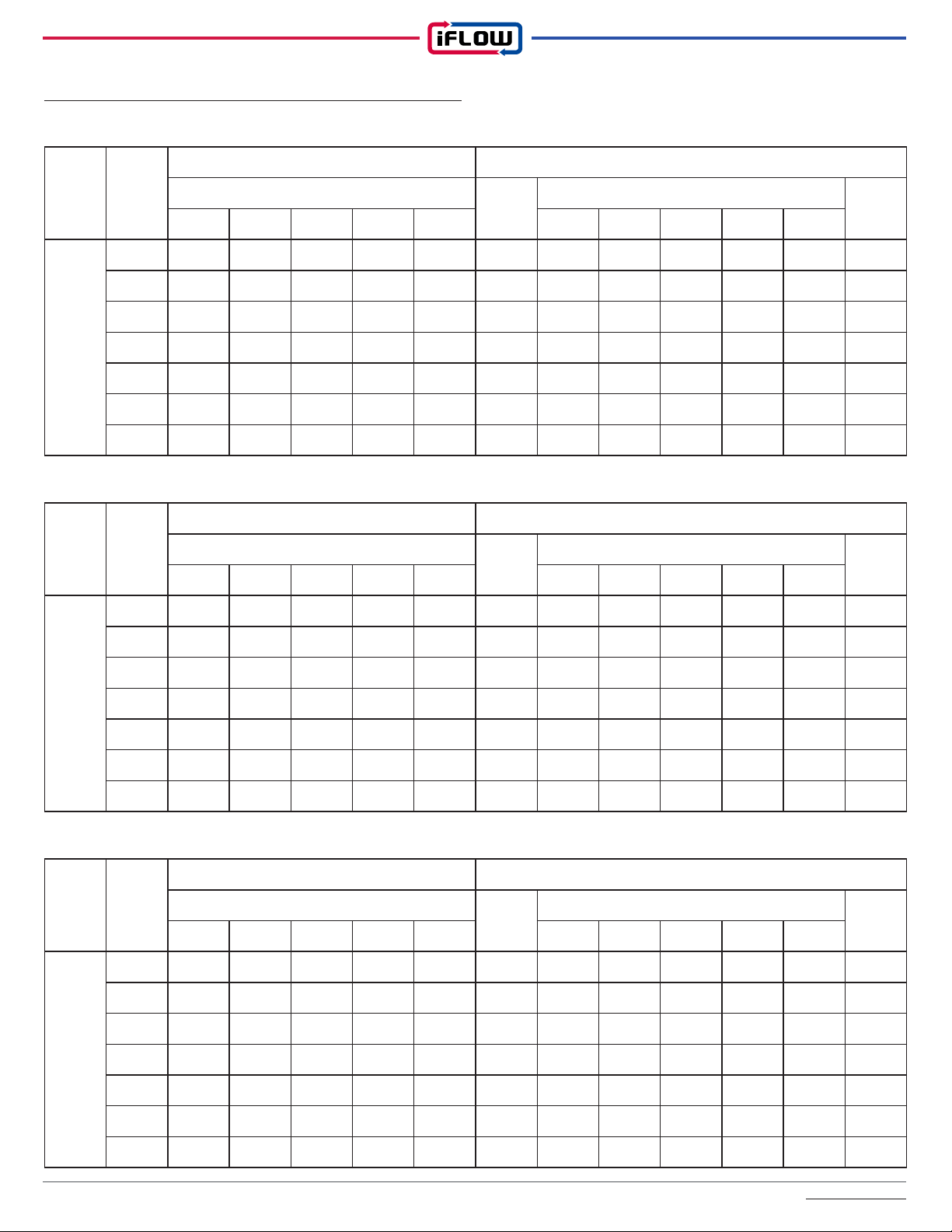

Water Heating Capacity (BTUH) / Water Pressure Drop (Feet)

iFLH-140000

H.Ex.

Rows

Entering

Water

Temp.

3 GPM 4 GPM

CFM

W.P.D

CFM

W.P.D

400 600 700 800 950 400 600 700 800 950

4

120℉ 17,365 21,756 23,654 25,347 27,834 2.9 18,425 23,097 25,653 27,246 29,906 4.3

130℉ 20,756 26,235 28,105 30,632 33,478 2.9 21,365 27,743 30,014 32,954 36,183 4.3

140℉ 24,142 30,754 33,521 36,065 37,729 2.8 24,845 32,469 35,478 38,549 42,376 4.2

150℉ 27,587 35,329 38,013 41,365 44,998 2.8 28,326 37,254 40,024 44,287 48,598 4.2

160℉ 30,965 39,865 43,247 46,759 50,869 2.8 31,824 41,987 45,726 49,976 54,843 4.1

170℉ 34,329 44,432 48,628 52,125 56,941 2.7 35,327 46,743 51,214 55,643 61,176 4.1

180℉ 37,734 49,032 54,573 57,683 62,786 2.7 39,836 51,458 56,429 61,398 67,497 4.0

iFLH-160000

H.Ex.

Rows

Entering

Water

Temp.

3 GPM 4 GPM

CFM

W.P.D

CFM

W.P.D

600 800 900 1000 1250 600 800 900 1000 1250

4

120℉ 24,625 27,865 29,865 31,087 34,211 3.7 28,268 30,042 31,986 34,109 38,287 5.7

130℉ 28,218 33,572 35,724 37,429 41,357 3.7 33,625 36,256 38,524 41,162 46,456 5.7

140℉ 32,865 39,218 41,625 43,843 48,379 3.7 38,245 42,367 45,412 48,235 53,971 5.5

150℉ 37,536 45,075 47,536 50,327 55,485 3.6 42,765 48,559 52,369 55,149 61,864 5.5

160℉ 42,125 50,732 53,425 56,798 62,632 3.6 47,325 54,632 58,489 62,268 69,832 5.4

170℉ 46,852 56,579 59,425 63,266 69,769 3.5 51,869 60,861 64,542 69,345 77,846 5.4

180℉ 51,425 62,329 65,325 69,747 76,982 3.5 56,465 67,054 72,369 76,486 85,742 5.3

iFLH-180000

H.Ex.

Rows

Entering

Water

Temp.

3 GPM 4 GPM

CFM

W.P.D

CFM

W.P.D

600 800 1000 1200 1450 600 800 1000 1200 1450

4

120℉ 28,963 34,245 35,648 38,946 42,376 5.6 30,125 36,203 38,224 42,376 46,638 6.9

130℉ 33,412 39,632 42,820 46,981 50,966 5.5 34,845 41,952 45,996 50,996 56,173 6.8

140℉ 37,954 45,126 50,157 54,844 59,632 5.5 39,652 47,623 53,756 59,465 65,789 6.7

150℉ 42,503 50,520 57,489 62,529 68,334 5.4 44,321 53,304 61,533 68,255 75,223 6.7

160℉ 47,127 55,963 64,732 70,931 77,065 5.3 49,032 59,123 69,325 76,905 84,896 6.6

170℉ 51,608 61,412 72,078 78,842 85,648 5.3 53,741 64,745 77,199 85,627 94,441 6.5

180℉ 56,129 66,846 79,354 87,055 94,633 5.2 58,429 70,487 84,923 94,336 104,056 6.4

iFLOW HVAC INC. www.iflowhvac.com

9

4. Suitable applications: Choosing the right heat source

The iFLOW air handler can be installed with various types of

heat sources and heating systems. The following are its primary

applications:

1. Air handler with tankless water heater

2. Air handler with conventional thank-type water heater

3. Air handler with heating boiler

4. Air handler with combi boiler

5. Air handler with heat pump + tankless water heater

6. Air handler with heat pump + tank-type water heater

7. Air handler with heat pump + boiler

8. Air handler with heat pump + combi boiler

Refer to the installation manual for diagrams of each type of installati-

on.

Hybrid Heating System

Definition:

A hybrid heating system is a dual-energy system using gas OR

electricity. The most common hybrid systems use a combination of

a furnace and heat pump to heat and cool a home. They can be a

fuel-saving alternative to traditional heating systems using only a

gas furnace. Hybrid systems use outdoor conditions to automatically

adjust to the most efficient method of heating, gas OR electricity.

Heat pump systems operate on electricity and are significantly more

energy efficient when compared to gas-operated furnaces. The heat

pump is effective alone at low temperatures close to 20 degrees

Fahrenheit. At that point, a gas furnace will kick in and help heat the

home.

You can save money with a heat pump. Heat pumps are an excellent

source of energy-efficient heat for your home, with the added benefit

of cooling your home in the summer months. With significant savings

over electric heat, heat pumps can reduce your energy bill without

changing the comfort level in your home.

Defrost cycle:

When the ambient temperature outside gets very cold (close to 0°C

or below) the moisture in the air freezes on the outdoor unit's heat

exchanger as the fan blows the air across it. A heat pump has a cycle

called a “defrost cycle,” which removes the frost from the outdoor coil.

A heat pump unit will defrost regularly when frost conditions occur.

The defrost cycle should be long enough to melt the ice, and short

enough to be energy-efficient. When a heat pump goes into defrost

mode, the heat pump shifts temporarily into the cooling mode to

reverse the flow of refrigerant through the coils. The reversing valve

activates and runs the refrigerant backward. Instead of extracting

heat from the outdoor air and putting it into the house, it extracts heat

from the house and sends it into the cold outdoor air.

iFLOW Hybrid heating System:

Definition:

The iFLOW Hybrid Heating System Control uses a dual-energy

system that uses gas AND electricity at the same time. This heating

system combines an iFLOW Hydronic Air Handler, using any water

heat source and a heat pump. It has the capability of running both at

the same time. The air heated as it passes across the hydronic coil

and the heat pump evaporator coil. The evaporator coils sit on top of

the iFLOW hydronic air handler.

Benefit:

The main benefit of the iFLOW Hybrid Heating System is its ability to

provide variable capacity heat, which is sufficient to provide the total

heat loss of a house regardless of the heat pump capacity. Therefore,

the defrost cycle will be long enough to melt the ice, and short

enough to be energy-efficient.

SMART MODE / SMART TEMPERATURE CONTROL MODE

In the General Parameters Setting Mode, the SMART MODE/SMART

TEMPERATURE CONTROL MODE can be selected to provide the

functions of the Smart Temperature Control without a thermostat.

When the SMART MODE/SMART TEMPERATURE CONTROL is

selected, the return air temperature sensor in the air handler will

sense an average air temperature from the space NOT the room air

temperature where the thermostat is located. This will provide better

control and comfort.

When the SMART MODE/SMART TEMPERATURE CONTROL is

selected the blower is always active while using this function. The

blower will run at the continuous blower speed setting selected.

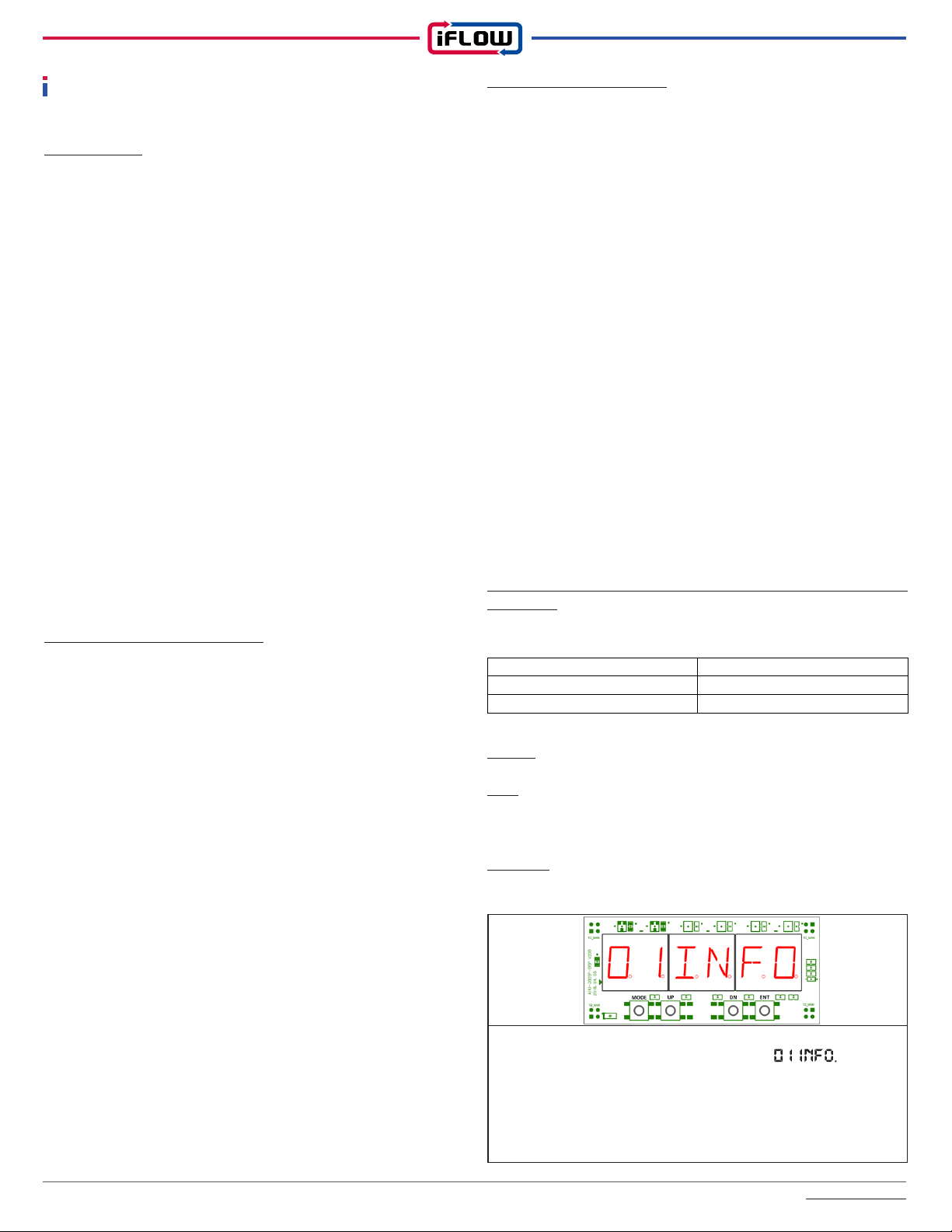

*The DH Evap Defrost Sensor must be installed on

the suction pipe to operate for H/P.

DH Evap Defrost Sensor

A / C Evap T. Sensor

iFLOW HVAC INC. www.iflowhvac.com

Model Unit Width Depth Height a b c d

14" Cabinet

in 14 18 3/4 27 1/8 13 14 16 12

mm 355.6 476.3 689 330.2 355.6 406.4 304.8

16" Cabinet

in 16 20 3/4 27 1/8 14 16 18 13

mm 406.4 527.1 689 355.6 406.4 457.2 330.2

18" Cabinet

in 18 25 3/4 29 1/8 16 20 23 14

mm 457.2 654.1 739.8 406.4 508 584.2 355.6

10

AIR CONDITIONING AND HEAT PUMPS USED WITH ZONING

SYSTEMS

It is recommended that when zoning, air conditioning and heat pump

units used (with iFLOW air handler models iFLH-16000D, iFLH-

18000D and iFLH-18000Q with zoning) shall be variable speed

inverter type models. These units can ramp up or down in small

increments depending on the load.

Refer to Cooling Parameter Mode to set the blower speed

requirements for each zone and the minimum and maximum blower

speeds for cooling mode.

EXAMPLE ONLY

1) Location requirements and clearances:

• The installer shall comply with all local, state/provincial and national

code requirements that apply to the installation of this equipment.

• The air handler must be installed in such a way that electrical

components are protected from water during operation and service.

• If installed in an unconditioned space, sealant should be applied

around where the electrical wires, refrigerant tubing, and condensate

lines enter the cabinet. This appliance shall not be installed in a non-

conditioned space where the potential may exist for the appliance,

water lines and/or drain lines to freeze.

• If installed with air conditioning in a suspended application, ensure a

drain pan with a proper slope is installed.

Recommended Clearances:

Be sure to provide a minimum of 24” clearance to the front panel

of the iFLOW air handler. 0” clearance is allowed for all other sides

of the cabinet and for the first 36” of ductwork. Ensure adequate

clearance is left for the installation of ductwork, plumbing, and

electrical connections.

LEFT SIDE

0 inch

RIGHT SIDE

0 inch

BACK

0 inch

PLENUM

0 inch

BOTTOM

0 inch

FRONT

SERVICING

2) Dimensions

Installation

iFLOW HVAC INC. www.iflowhvac.com

11

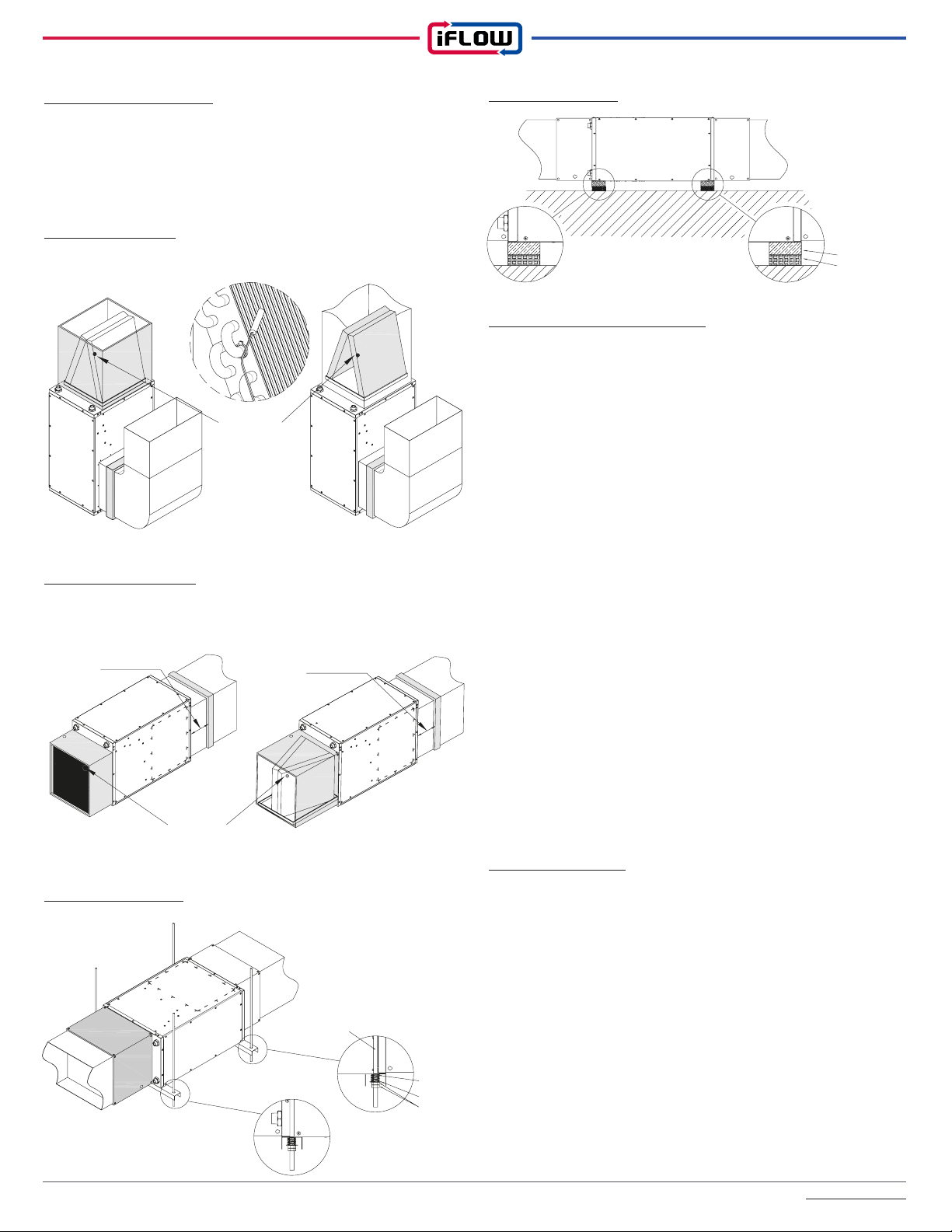

3) Installation examples:

The iFLOW air handler is multi-positional and therefore can be

mounted in any position. If installed with air conditioning, proper

positioning of the evaporator coil and drain line must be considered to

install correctly.

Vertical Installation

Horizontal Installation

The evaporator coil must be installed on the supply side of the air

handler.

Hanging Installation

Ceiling Installation

4) Water Heater / Boiler Piping:

When installing the iFLOW air handler with a heating boiler or combi-

boiler in a closed loop system, refer to the boiler manufacturer’s

instructions for proper installation with an air handler. Depending on

the boiler selected and system design, it may be required to use a

primary/secondary piping arrangement to de-couple the flow through

the boiler from the flow through the air handler.

Air-removal device:

Provisions shall be made for the removal of air in the heat-distribution

piping system. The air-removal device shall be located in the area

of the heat-distribution piping system where the air is likely to

accumulate (often the highest point in the system).

Required Components:

Expansion tank, isolation valves, air eliminator, dirt collector/filter/

strainer (if other heating loads are being heated by the same boiler),

make-up water and low loss header (optional).

Sensor Installation

A/C Evaporator Temperature Sensor: Air outlet on the Evaporator

coil (See Installation Illustration: Page 12)

Zone Air Temperature Sensor:

Zone supply side: Air outlet of the damper

Zone return side: Air inlet of the damper (if there is a dedicated return

duct with the damper)

5) Domestic Piping:

Notes: When installing the iFLOW air handler with a water heater,

refer to the manufacturer’s guidelines on coupling the water heater

with an air handler. Use components and piping that are allowable

with potable use. Lead-free solder must be used on all joints.

When both top and side connections are present on the water heater,

the side connections should be used for the space-heating loop.

The heating loop connections should be positioned horizontally in a

vertical section of the domestic water line for both the inlet and outlet.

Refer to the piping diagram for details. Minimize the distance and

piping between the water heater and the iFLOW air handler.

If the main water line has an installed check valve, a potable

expansion tank must be installed to provide room for the expansion

of water.

AHU with

Case Coil or A Coil

Evaporator

Temperature

Sensor position

Filter Rack Filter Rack

Minimum 6inch

Filter Rack Filter Rack

Minimum 6inch

Evaporator

Temperature

Sensor position

AHU with

Slab Coil

AHU with

Case Coil or A Coil

Support

Anti-Vibration Pad

The Threaded Rod

Spring

Flat washer

Nut

iFLOW HVAC INC. www.iflowhvac.com

12

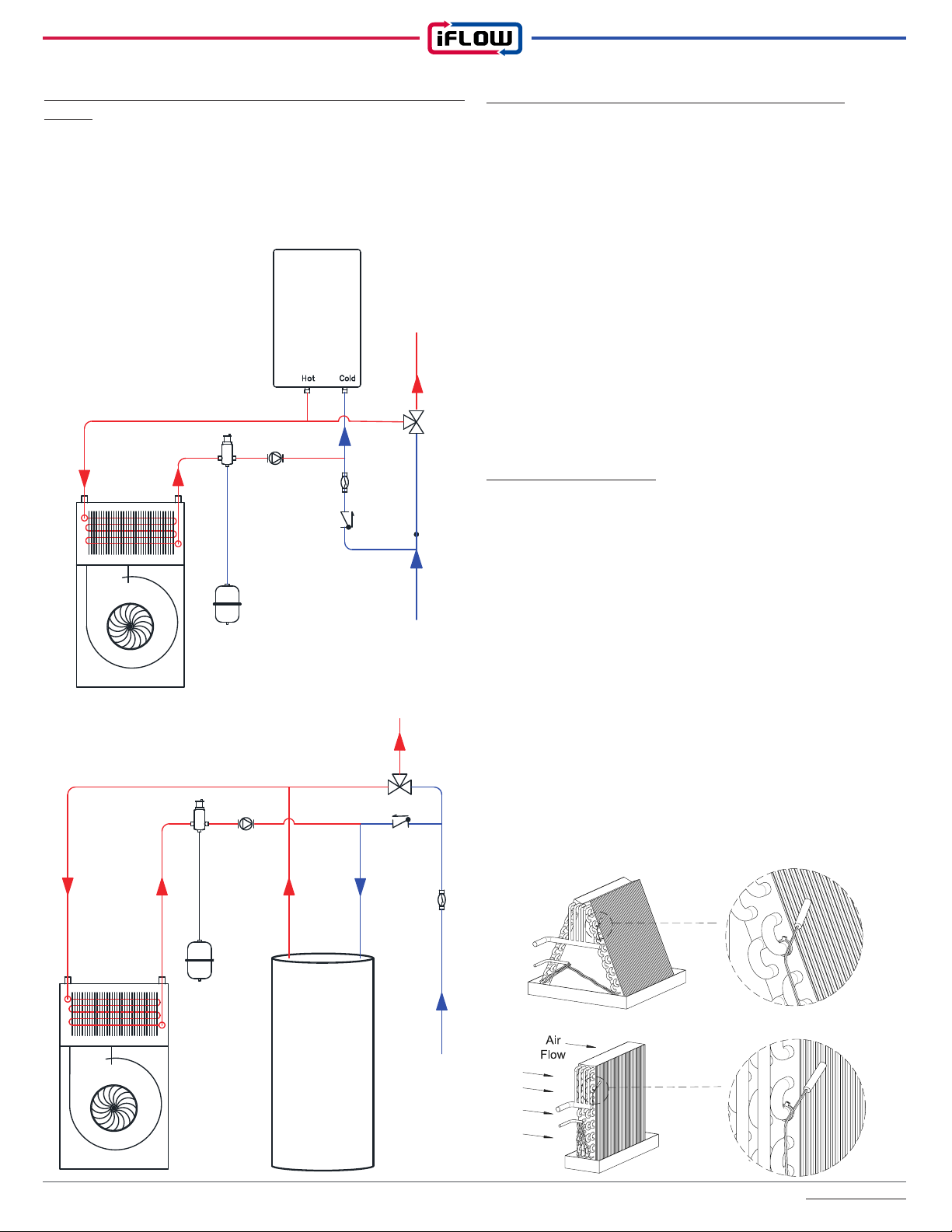

6) Installing the iFLOW air handler with a tankless/tank water

heater:

Check with the tankless water heater manufacturer prior to installation

to ensure it can be used for combo space heating applications. Make

sure to check that the valves, including but not limited to the purge

and isolation valves are properly installed. If connecting to a tankless

water heater, the circulating pump needs to be sized correctly.

7) Electrical requirements and making connections:

This unit requires single phase AC 120V power to operate and must

be hardwired. To connect, follow these directions:

1. To avoid electrical shock, turn off electrical power at the breaker

dedicated to the air handler. Ensure the power remains off while any

wiring connections are being made.

2. Remove the iFLOW front access panel.

3. Route the field supplied line voltage wiring to the iFLOW air

handler.

4. Using CSA & UL listed wire nuts, connect the field supplied wires

to the air handler (black to black and white to white).

5. Connect ground wire to GND terminal.

6. Repeat the process for the circulating pump (connect to terminal

block).

7. Route low voltage thermostat wire to the unit; connect to

thermostat terminal on control board.

8. Re-secure the front access panel.

8) Temperature sensors:

The iFLOW air handlers come equipped with 5 wire sensors that plug

into connectors on the control board for easy servicing.

1. Supply water sensor: mounted on the supply end of the water

heating coil.

2. Return water sensor: mounted on the return end of the water

heating coil.

3. Supply air sensor: mounted above the water heating coil exchanger

to detect supply air temperature and freezing temperatures.

4. Outdoor temperature sensor: modulates air handler operation

based on outdoor temperature. Provides outdoor reset function.

5. Return air sensor: factory installed in return air path blower. If you

install a slab coil on the return air side, you must install the return air

sensor before(or upstream of) the slab coil.

6. A/C Evap sensor: mount on the A coil, or on the slab coil. It should

be installed on the surface of the cold air outlet on the evaporator or

the U-bend pipe. Refer to the figure below.

Air

Elliminator

Expansion

Tank

Circulator

with

Check Valve

Flow

Switch

Check

Valve

Tank

Water Heater

D H W

An�Scald

Valve

Cold

Water

An�Scald

Valve

Tankless

Water

Heater

Circulator

Expansion

Tank

Flow

Switch

Check

Valve

D H W

Cold

Water

Air

Elliminator

iFLOW HVAC INC. www.iflowhvac.com

10) Zone Damper

Zone Temperature Sensor Installation and Control Wiring

11) Wi-Fi Module connect to iFLOW control boards

WiFi Module sold separately.

Refer to set up manual, how to use with smartphone

13

9) Installing the iFLOW air handler with a Navien tankless

water heater:

Use the optional communication cable between the iFLOW AHU

and the Navien tankless water heater. Connect the thermostat to the

iFLOW AHU at the thermostat connector. Connect the communication

cable from the iFLOW AHU to the cascade communication port on

the Navien Water Heater Panel. The parameter P28 of the NAVIEN

TL WH should be set to ON ( Refer to Navien Tankless Water

Heater Installation Manual)

No Description Part # Model Remark

1iFLOW Communication Cable 30NWCC05 Length: 5m

2iFLOW Communication Cable 30NWCC10 Length: 10m

No Description Part # Model Remark

1 6" Damper 2000D06A

AC24V 5W

2 7" Damper 2000D07A

3 8" Damper 2000D08A

Supply Air Temp. Sensor

Hole " Diameter

Return Air Temp. Sensor

Hole " Diameter

No Description Part # Model Remark

1WiFi Module 30WFA00A Option

iFLOW HVAC INC. www.iflowhvac.com

14

1) Procedure:

Do not start the boiler or water heater until ALL air has been purged

from the water lines and air handler pump.

1. Fill the boiler loop or water heater with water. Do not start it.

2. Purge all air from the heating boiler or domestic hot water system

(Hold the UP & ENTER button for 10 seconds and then the circulator

will alternate power ON and OFF for about 10 minutes to purge air).

3. Purge all air from the space heating loop by closing the isolation

valve on the return leg of the loop and open the drain to purge the air.

Open the return leg isolation valve and then close the drain valve.

4. If a bleed screw is not present, it is recommended to run the pump

on speed #3 for 1 minute. If air is still present, switch from speed #1

to #3 every 10 seconds for a minute.

5. Start the boiler or water heater according to the manufacturer’s

instructions. Set the design water temperature and wait for the

system to satisfy and shut off.

6. Turn on the power to the iFLOW air handler and set the room

thermostat to ‘heat’ to energize the fan and pump. If noise is still

present after one minute, repeat step #3 to purge air.

7. Check supply and return pipes for temperature differences to

make sure there is flow. There should be a noticeable difference in

temperature. Use caution when supply water temperature is above

120˚ F.

2) Flushing the heat exchanger:

Flushing the hot water coil prior to startup is required to remove any

residual material from the installation or manufacturing processes as

well as to remove any air from the system. Take precautions while

flushing the air handler to prevent the multi-function control board and

other electrical components from getting wet.

The iFLOW air handler requires an external circulating pump to be

installed and should be installed with an external purge valve.

Flushing is a 3-step process:

1) Use a bucket or hose to dispose of water during the flushing

process. First, flush the return line by closing the inlet valve (supply)

and opening the outlet valve (return). Open the purge valve. Close

the purge valve once flushing is complete.

2) Second, flush the supply line and coil by closing the outlet valve

(return) and opening the inlet valve (supply). Open the purge valve.

Close the purge valve once flushing is complete.

3) Third, apply power to the air handler. Open inlet and outlet valves.

Engage the pump and open the purge valve. Verify proper flow

direction - inlet valve should become warm before the outlet. Close

the purge valve once flushing is complete. Operate the pump for 5

minutes immediately after flushing the system to purge remaining air

from the pump bearing chamber.

3) Sequence of operation:

Cooling: When the thermostat calls for cooling, the circuit between

R and G is completed. The normally open contacts close and the air

handler blower motor operates. The circuit between R and Y is also

completed; this closes the contact on the outdoor condenser unit.

The air handler fan turns off 45 seconds after the call for cooling is

completed.

Heating: When the thermostat calls for heat, the circuit between R

and W is completed, activating the hot water circulating pump. A dry

switching relay labeled “T T” can be used to activate a boiler or combi

boiler. After the circuit between R and W is completed, a time delay

follows before the circuit between R and G is completed, which will

then activate the air handler blower motor.

Freeze protection: If the temperature of the water in the hot water

coil drops below 40°F/4°C, the circuit between R and W is completed.

This will activate the circulating pump until the water temperature

reaches 70°F.

Pump timer/ exercise function: The iFLOW control is equipped to

turn on the circulating pump to cycle the total volume of potable water

in the system if the pump has not been turned on within the past

24 hours. This function is skipped while the A/C condensing unit is

operating.

How to Access and Configure the iFLOW Intelligent

Controller

The controller has 6 modes:

The controller has 4 buttons used to navigate those modes:

MODE: Press the ‘MODE’ button to scroll between the different

modes, numbered 1-6 (see above).

ENT: Press the ‘ENT’ (enter) button to confirm the mode you wish to

enter. Press ‘enter’ to also confirm any changes or commands that

you selected using the ‘up’ and ‘down’ buttons (see below) while in

each mode.

UP & DN: Once you are in a ‘mode’, press the ‘UP’ and ‘DN’ (down)

buttons to scroll all menu lists of the various information.

Information Mode

How to access Information display:

Push the ‘MODE’ button until the screen reads

Press ‘ENT’ (enter) to confirm you wish to enter the information

mode. Use the ‘UP’ and ‘DN’ (down) buttons to scroll through the

menu of information available. The information available varies

depending on the model of air handler. The 4 characters on the right

indicate the value.

START-UP

1. Information

2. Error Codes

3. General Parameters

4. Heating Parameters

5. Cooling Parameters

6. Test Mode

iFLOW HVAC INC. www.iflowhvac.com

15

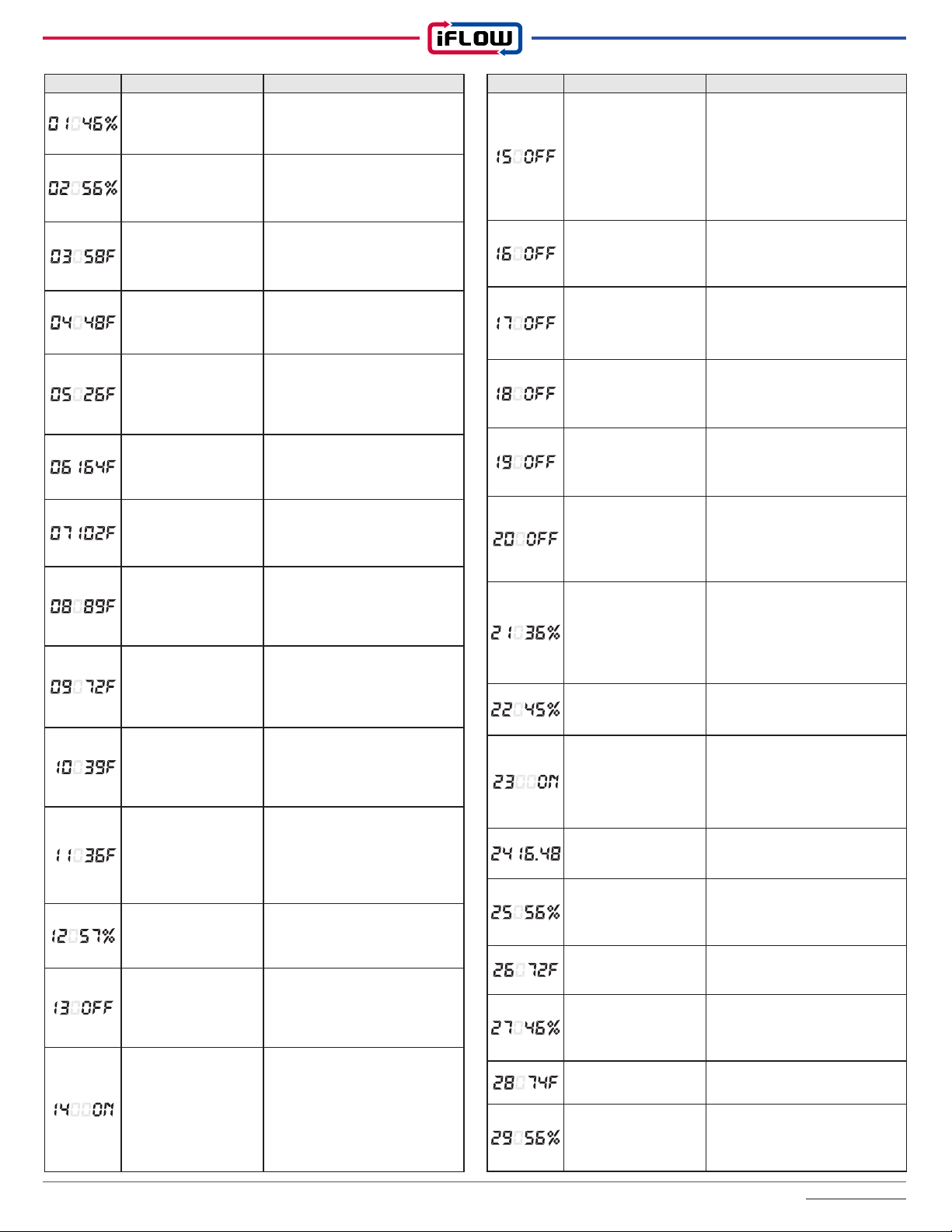

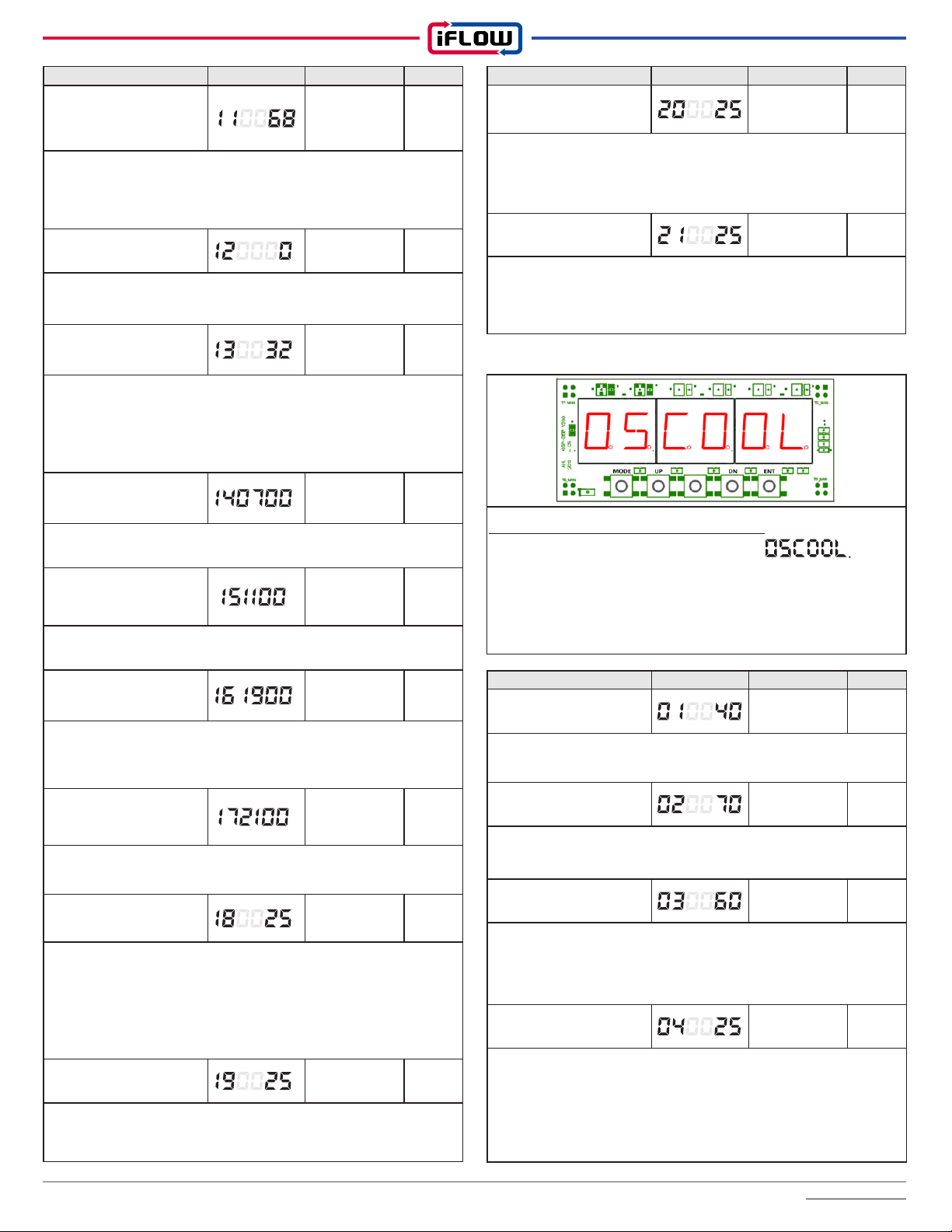

Display Description Explanation

Boiler TT State

Indicates whether the air

handler is currently sending a

dry contact call for heat to the

connected boiler

(ON = calling boiler on;

OFF= not calling boiler on)

A/C Y1 Relay State

Indicates whether the air handler

is sending an AC 24V cooling

call to the A/C condensing unit

A/C Y2 Relay State

Indicates whether the air handler

is sending an AC 24V cooling

call to the A/C condensing unit

H/P W1 Relay State

Indicates whether the air handler

is sending an AC 24V heating

call to the H/P condensing unit

H/P W2 Relay State

Indicates whether the air handler

is sending an AC 24V heating

call to the H/P condensing unit

Dehumidifier Relay

State

Indicates whether the humidifier

is in the ‘on’ or ‘off’ state (is relay

supplying 24V or not?)

Humidifier Relay

State

Indicates whether the external

humidifier, which is wired to the

control board, is in the ‘on’ or ‘off’

state (is relay supplying 24V or

not?)

Water Adjustment

Valve

Reserved for future cool

functionality

Communication

Connection Status

RS485 Communication Cable

State with Navien Tankless

Water Heater (ON/OFF)

Time

(24 hr HH:MM)

Current time display

(24 hour clock = HH:MM)

Zone 1 Supply

Damper State

Zone 1 Supply Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 1 Supply

Temperature

Zone 1 Supply Air Temperature,

in °F

Zone 1 Return

Damper State

Zone 1 Return Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 1 Return

Temperature

Zone 1 Return Air Temperature,

in °F

Zone 2 Supply

Damper State

Zone 2 Supply Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Display Description Explanation

Blower Motor Speed

Indicates present operation as

a percentage of the total fan

motor capacity

Pump Speed

Indicates present pump

operation as a percentage of

the total capacity of the pump

Water Temperature ∆t

(Delta T)

Indicates the difference between

the supply and return water

temperature in °F

Air Temperature ∆t

(Delta T)

Indicates the difference between

the supply and return air

temperature in °F

Outdoor

Temperature

Displays the outdoor air

temperature in °F. (If outdoor

sensor is not installed, 999 will

be displayed)

Supply Water

Temperature

Displays the temperature of the

water entering the hydronic coil

heat exchanger, in °F

Return Water

Temperature

Displays the temperature of the

water exiting the hydronic coil

heat exchanger, in °F

Supply Air

Temperature

Displays the temperature of the

air exiting the air handler into

the plenum, in °F

Return Air

Temperature

Displays the temperature of the

air entering the air handler from

the return duct, in °F

A/C Evaporator

Temperature

Displays the current temperature

of the air sensor attached

downstream of, but near the

evaporator coil in °F

Dehumidifier

Evaporator

Temperature

Displays the current temperature

of the sensor located in the

dehumidifier evaporator, in °F

(If d.h. sensor is not installed,

999 will be displayed)

Humidity Value

Measured value of the current

humidity in the return section of

the unit

Flow Switch On/Off

State

Indicates whether the external

flow switch, which is wired to the

control board, is activated or not

(ON = flow; OFF= no flow)

Pump Relay State

Indicates whether the external

pump (field supplied) should be

in operation (is power supplied

by relay to pump?)

(ON = should be operating;

OFF= should not be operating)

iFLOW HVAC INC. www.iflowhvac.com

16

Display Description Explanation

EXAMPLE OF LAST 10 ERROR CODES

Display Description Explanation

EXAMPLE OF LAST 10 ERROR CODES

Item Display Range Default

Temperature Unit of

Measure Set 0=℃, 1=℉ 1

Select the temperature units of measure you wish to display:

Celsius or Fahrenheit

Humidifier 35 – 65% 45%

Select the rate of humidity, below which, the humidifier will operate.

General Parameter Settings Mode

Push the mode button until the screen reads

Press ‘ENT’ (enter) to confirm you wish to enter the General

Parameters Mode. Use the ‘UP’ and ‘DN’ (down) buttons to scroll

through the menu of General Parameters, numbered 01-20 and

press enter to select. The 1-3 characters on the right indicate the

value. Use the up and down buttons to change the range of the

value and press ‘ENT’ (enter) to confirm and ‘MODE’ to exit.

How to access Error codes:

Display Description Explanation

Zone 2 Supply

Temperature

Zone 2 Supply Air Temperature,

in °F

Zone 2 Return

Damper State

Zone 2 Return Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 2 Return

Temperature

Zone 2 Return Air Temperature,

in °F

Zone 3 Supply

Damper State

Zone 3 Supply Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 3 Supply

Temperature

Zone 3 Supply Air Temperature,

in °F

Zone 3 Return

Damper State

Zone 3 Return Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 3 Return

Temperature

Zone 3 Return Air Temperature,

in °F

Zone 4 Supply

Damper State

Zone 4 Supply Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 4 Supply

Temperature

Zone 4 Supply Air Temperature,

in °F

Zone 4 Return

Damper State

Zone 4 Return Damper Opening

Ratio (0%= Fully Closed ~

100%=Fully Opened)

Zone 4 Return

Temperature

Zone 4 Return Air Temperature,

in °F

Error Codes

Push the mode button until the screen reads

Press ‘ENT’ (enter) to confirm you wish to enter the Error code

mode. Use the ‘UP’ and ‘DN’ (down) to scroll through the last 10

errors which will be numbered 01 to 10, with 01 being the most

recent. The 3 numbers on the right will indicate which error code is

present. If more than 10 errors occur, the oldest error will be deleted

from the memory.

How to access Error codes:

iFLOW HVAC INC. www.iflowhvac.com

17

Item Display Range Default

‘Maximum Heating ON’

Coldest Outdoor

temperature

0 – 32 °F 5

Enter the coldest outdoor temperature, below which, you expect the

heating to run a maximum.

‘Heating OFF’ Warm

Outdoor temperature 59 – 80 °F 70

Enter the outdoor temperature, above which, the heating will not

operate.

Building’s Total Heat Loss

15 – 60/75/95K

BTU (de-

pending on

model)

Enter the home’s estimated heat loss. Identifies the target maximum

BTUH output required for the AHU.

Number of Supply Zones

Range: 1 ~ 4

SZ=1, DZ=2,

QZ= 3 or 4

SZ=1,

DZ=2,

QZ=4

Sets the number of supply zones for the controller to expect.

Reserved Future Cool

Function

Zone Air Mix Function 0=OFF, 1= ON 0

The Zone Air Mix Function is used to measure the temperature of

each zone when heating or cooling is requested. Any stratified air

is mixed before operating the heat / AC source (i.e.: in summer,

circulate hot air from upper floors with cold air in basement).

Zone Air Mix

Temperature Differential 0 – 10 °F 3

When the Zone Air Mix Function (above) is selected and once the

stratified zone mixing has been completed, the iFLOW AHU will

operate the heat / A/C source only if the mixed temperature of any

zone differs by more than the differential (set using this function)

from the zone setpoint temperature.

Damper Opening Duration 1 – 60 Second 7

Enter the time (in seconds) that it takes for the zone dampers to

initialize and fully open. iFLOW will ensure the AHU blower does not

come on until the dampers are fully open and that power supplied to

the dampers does not exceed that time. The iFLOW dampers have a

7 second ‘closed to open’ duration so that is default. Other damper

manufacturers are typically slower so adjust 7 to a higher number.

Item Display Range Default

‘Heating OFF’ Indoor

Temperature Limit 74 – 90 °F 85°F

Select the indoor temperature, above which, the heating will

automatically stop.

‘A/C Cooling OFF’ Indoor

Temperature Limit 60 – 70 °F 65°F

Select the indoor temperature, below which, the cooling will

automatically stop.

Pump Exercise Frequency

Set Up (Anti-Stagnation) 0 – 24 Hours 24

CSA B214 requires pump circulation once every 24 hours (default).

Some jurisdictions may require a shorter time interval based upon

local codes (ex.: if the pump must cycle once every 8 hours, set at

060008).

Pump Exercise

Duration Set Up 30 – 600 sec 30

Determines the duration the pump runs for during the Exercise cycle

(above). The circulation time should be adjusted according to the

pipe length between the heat source and the iFLOW AHU to ensure

full circulation.

Pump Duty ON 0.0 – 5.0 sec 1.0

When the heat source selected is a tankless water heater (except

Navien), use this setting to circulate but without triggering a burner

‘on’ condition. To do that, maintain the flow rate low enough and/or

the duration short enough so the burner does not ignite. With the

Pump Duty ON (this function) and Pump Duty OFF function (below),

set up a pulse sequence to achieve this objective. The pump will

turn on for a short period of time (Pump Duty ON) and then turn off

for a period of time. (Pump Duty OFF).

The default length of time the pump operates is 1 second, however

depending on the tankless water heater, this duration may need to

be adjusted.

Pump Duty OFF 0.0 – 5.0 sec 3.0

When the heat source selected is a tankless water heater (except

Navien), during the “Pump Duty OFF” function, the pump will turn off

for a short period of time. Depending on the tankless water heater,

this duration may need to be adjusted, however the duration of the

“Pump Duty OFF” must always be longer than “Pump Duty ON.”

If the burner does light, it will not harm the equipment at all; it just

means the heating and cooling will be running simultaneously for the

Pump Exercise Duration (30 seconds once every 24 hours if using

default settings).

Heat Boost Delay 0 – 60 min 30

Use this function to quickly increase the heat delivery. If the room

temperature does not rise more than 2˚F within the set time, the

Heat Boost function will engage and run at maximum until the room

thermostat is satisfied. Set the parameter above for the duration the

heating will operate at normal before boosting.

Continuous Circulation

(‘G’ Call) Blower Speed 5 – 50 % 10

Set the blower speed when running on ‘G’ / Fan On / Continuous

Circulation

45/55/65

(depending

on

model)

iFLOW HVAC INC. www.iflowhvac.com

18

Item Display Range Default

Minimum Pump Speed 35 ~ 100 % 45 %

Used for advanced adjustment & troubleshooting only. Sets the

pump speed when a W1 heating call is received.

Minimum Blower Motor

Speed Control 10 ~ 100 % 20 %

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a W1 heating call is received.

Reserved

Future

Cool

Function

Maximum Pump Speed 35 ~ 100 % 80 %

Used for advanced adjustment & troubleshooting only. Sets the

pump speed when a W2 heating call is received.

Maximum Blower Motor

Speed Control 10 ~ 100 % 60 %

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a W2 heating call is received.

Blower ON Delay Time 10 ~ 120

Seconds

30

Seconds

Used for advanced adjustment & troubleshooting only. On a call for

heat, iFLOW delays blower motor operation until the hydronic coil

receives heat from the heat source (avoids blowing any cold air).

Blower OFF Delay Time 0 ~ 180

Seconds

90

Seconds

Used for advanced adjustment & troubleshooting only. Delays

blower motor shut off once a call for heat is completed to maximize

efficiency. iFLOW continues to circulate the blower to deliver any

residual coil heat to the home. Use this function in combination with

Setting #8 ‘Post Purge Function’ below. Set #8 to “1”

Post Purge Function 0: OFF 1: ON 1

Used for advanced adjustment & troubleshooting only. Sets

the pump to continue to run after a heat demand to maximize

efficiency by extracting all residual heat from the heat source.

iFLOW continues to circulate the pump to deliver any residual heat

to the hydronic coil, instead of the heat source post-purging its

residual waste heat through the exhaust vent. Use this function in

combination with Setting #7 ‘Blower Off Delay Time’ above.

DHW Priority 0 = ON, 1=OFF 1

Used for advanced adjustment & troubleshooting only. When a flow

switch on the cold water supply is installed and wired to the iFLOW

AHU, iFLOW offers DHW Priority. Set whether or not the air handler

should shut down during periods where there is a demand for

domestic hot water.

For cool

future

function

Heating Parameter Mode

How to access Heating Parameter:

Push the mode button until the screen reads

Press ‘ENT’ (enter) to confirm Heating Parameter Mode. Use the

‘UP’ and ‘DN’ (down) buttons to scroll through the menu of heating

parameters, numbered 01-16. The 1-3 characters on the right

indicate the value. Use the up and down buttons to change the

range of the value and press ‘ENT’ to confirm and ‘MODE’ to exit.

Item Display Range Default

Smart Mode 0= OFF, 1=ON 0

There are 2 way to deliver temperature to the home: 1) Thermostat

Mode and 2) Smart Mode. Thermostat mode relies on the room

thermostat to provide a signal for the air handler to come on and

turn off. Smart Mode by-passes the room thermostat and instead

circulates air continuously through the home and relies on the return

air temperature to indicate if more or less heating/cooling required.

The ECM blower is default set at 10% but can be set as low as 5%

to minimize energy consumption. See ‘General’ parameter #11

(Continuous Circulation (‘G’ Call) Blower Speed) to adjust. WiFi

mode must be set to ‘internet’. Also use this function when zoning

but do not have a thermostat for every zone (i.e.: in a retrofit, when

you cannot run new wire).

Wi-Fi Mode 0=Internet,

1=Paring 1

There are 2 ways to connect to, and communicate with the iFLOW

Air Handler using the iFLOW App: through the internet or by pairing.

Through the internet requires the contractor or homeowner to

connect the iFLOW Air Handler to the homeowner’s local home Wi-

Fi network. Pairing connects your smartphone to the air handler

without a local network (similar to pairing a phone to a car’s stereo).

In pairing mode, the phone must be in close proximity of the iFLOW

unit.

Emergency Mode

0=OFF,

1=Heat,

2=Cool

0

Use this setting to override the thermostat and run the heating or

cooling automatically in an emergency. Provides emergency heating

or cooling should there be a thermostat failure.

Schedule Mode 0=OFF, 1=ON 0

Use this mode to select whether you want to use the iFLOW

scheduling function.

Day

1:SUN 2:MON

3:TUE 4:WED

5:THU 6:FRI

7:SAT

SUN

Set current day of the week

Time HH:0~24,

MM:0~59

Current

Time

Set current time (24 hour clock)

iFLOW HVAC INC. www.iflowhvac.com

19

Item Display Range Default

Coldest Indoor

‘Maximum Heating ON’

Temperature

60 ~ 80 °F 68˚F

Set a base temperature such that if the return air temperature

goes below that temperature (default is 68˚F), the unit will run at

maximum capacity. This temperature should be below any daytime

or nighttime ‘setback’.

Heat Source Type(s) 0, 1 0

0 : Hot Water Only (water heater, boiler or combi-boiler)

1: Hot Water + heat pump (Hybrid)

Outdoor Temperature for

‘H/P Heating OFF’

23 ~ 41˚F

(-5˚ ~ 5˚C) 32˚F

Set the lowest temperature at which you wish the heat pump

to operate (Balance Point Consideration: H/P COP and cost of

electricity at that temperature vs. gas efficiency and cost of gas).

Below that temperature, iFLOW will switch to the gas hot water

source.

‘Peak Rate Period 1 Start ’

- H/P Stop 00:00~24:00 07:00

Electricity Off-peak On time Set

‘Peak Rate Period 1

Finish’

- H/P Start

00:00~24:00 11:00

Use this function to start operating the heat pump again at end of

the ‘peak’ period 1 (started above).

‘Peak Rate Period 2 Start ’

- H/P Stop 00:00~24:00 19:00

If the electric utility has peak rates, use this function to stop operating

the heat pump at the beginning of the ‘peak’ period 2. (Refer to your

electric utility’s Time-of-Use Pricing and Schedule)

‘Peak Rate Period 2

Finish’

- H/P Start

00:00~24:00 21:00

Use this function to start operating the heat pump again at end of

the ‘peak’ period 2 (started above).

Zone 1 Blower Speed

(Heating Mode) 0 ~ 100 % 25%

Set the blower motor speed for zone 1 as a percentage of the

home’s total heat loss or CFM requirement. For example, if the

home’s total heat loss is 60MBH and Zone 1 accounts for 20MBH

(1/3) of that loss, the percentage would be 33%. If the home’s total

CFM requirement is 1200 CFM and Zone 1 accounts for 400 CFM

(1/3) of that loss, the percentage would be 33%.

Zone 2 Blower Speed

(Heating Mode) 0 ~100 % 25%

Set the blower motor speed for zone 2 as a percentage of the

home’s total heat loss or CFM requirement (see Zone 1 above for

details).

Item Display Range Default

Zone 3 Blower Speed

(Heating Mode) 0 ~ 100 % 25%

Set the blower motor speed for zone 3 as a percentage of the

home’s total heat loss or CFM requirement (see Zone 1 above for

details).

Zone 4 Blower Speed

(Heating Mode) 0 ~ 100 % 25%

Set the blower motor speed for zone 4 as a percentage of the

home’s total heat loss or CFM requirement (see Zone 1 above for

details).

Cooling Parameter Mode

Push the mode button until the screen reads

Press ‘ENT’ (enter) to confirm Heating Parameter Mode. Use the

‘UP’ and ‘DN’ (down) buttons to scroll through the menu of heating

parameters, numbered 01-16. The 1-3 characters on the right

indicate the value. Use the up and down buttons to change the

range of the value and press ‘ENT’ to confirm and ‘MODE’ to exit.

Item Display Range Default

Minimum Blower Motor

Speed Setting 10 ~ 50 % 40 %

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a Y1 cooling call is received.

Maximum Blower Motor

Speed Setting 10 ~80% 70%

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a Y2 cooling call is received.

Blower OFF Delay Time 0 ~ 300 sec 60 Sec

Used for advanced adjustment & troubleshooting only. Sets a delay

of the blower motor shutting off after a call for cooling is completed.

To maximize efficiency, iFLOW continues to circulate the blower to

deliver any residual coil cooling to the home.

Zone 1 Blower Motor

Speed (Cooling Mode) 0 ~ 100 % 25%

Set the blower motor speed for zone 1 as a percentage of the

home’s total cooling load or CFM requirement. For example, if the

home’s total cooling load is 30MBH and Zone 1 accounts for 10MBH

(1/3) of that loss, the percentage would be 33%. If the home’s total

CFM requirement is 1200 CFM and Zone 1 accounts for 400 CFM

(1/3) of that loss, the percentage would be 33%.

How to access Cooling Parameter:

iFLOW HVAC INC. www.iflowhvac.com

20

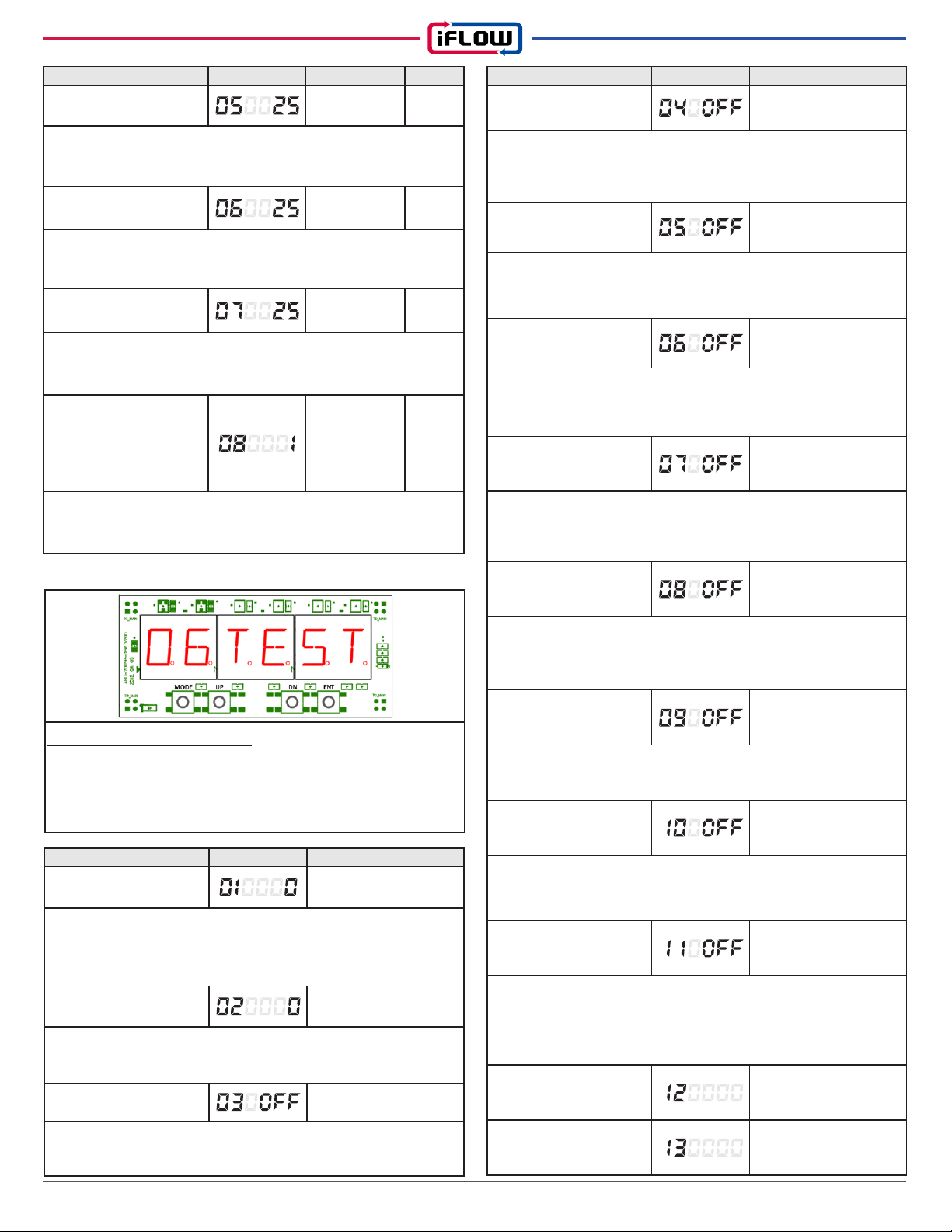

Test Mode

How to access Test codes:

Push the mode button until the screen reads 06TEST. Press

‘ENT’ (enter) to confirm the test mode. Use the ‘UP’ and ‘DN’ (down)

buttons to scroll through the menu of tests, numbered 01-20. Use the

up and down buttons to change the values. Press ‘MODE’ to exit.

Item Display Test Operation

Boiler T T Relay Test

Press enter while 04 is flashing. Display will show OFF. Use ‘UP’ or

‘DN’ button to turn on. Boiler TT Relay will start immediately. Press

enter to exit.

H / P Relay W1 Test

Press enter while 05 is flashing. Display will show OFF. Use ‘UP’

or ‘DN’ button to turn on. H/P Relay W1 Test will start immediately.

Press enter to exit.

H / P Relay W2 Test

Press enter while 06 is flashing. Display will show OFF. Use ‘UP’

or ‘DN’ button to turn on. H/P Relay W2 Test will start immediately.

Press enter to exit.

A / C Relay Y1 Test

Press enter while 07 is flashing. Display will show OFF. Use ‘UP’

or ‘DN’ button to turn on. A/C Relay Y1 Test will start immediately.

Press enter to exit.

A / C Relay Y2 Test

Press enter while 08 is flashing. Display will show OFF. Use ‘UP’

or ‘DN’ button to turn on. A/C Relay Y2 Test will start immediately.

Press enter to exit.

Dehumidifier Relay Test

Press enter while 09 is flashing. Display will show OFF. Use ‘UP’ or

‘DN’ button to turn on. Dehumidifier Relay Test will start immediately.

Press enter to exit.

Humidity Relay Test

Press enter while 10 is flashing. Display will show OFF. Use ‘UP’ or

‘DN’ button to turn on. Humidifier Relay Test will start immediately.

Press enter to exit.

Flow Switch Test

Press enter while 11 is flashing. Jumper terminals FS on the right

side of the control board. The display will flash ON if it is working

correctly. You can also open a hot water faucet; this should trip the

switch to ON.

Reserved Future cool function

Reserved Future cool function

Item Display Test Operation

Blow Motor Speed Control 0 ~ 100%

Press enter while 01 is flashing. Display will flash 0. Use ‘UP’ or

‘DN’ buttons to change blower speed value from 0-100%. Blower

will speed up and down as you increase or decrease the value,

respectively.

Pump Speed Control 0 ~ 100 %

Press enter while 02 is flashing. Display will flash 0. Use ‘UP’ or ‘DN’

buttons to change value from 0-100% pump speed. Pump will speed

up and down as you increase or decrease the value, respectively.

Pump Relay

Press enter while 03 is flashing. Display will show OFF. Use ‘UP’ or

‘DN’ button to turn on. Relay test will start immediately. Press enter

to exit.

Item Display Range Default

Zone 2 Blower Motor

Speed 0 ~ 100 % 25%

Set the blower motor speed for zone 2 as a percentage of the

home’s total cooling load or CFM requirement (see Zone 1 above for

details).

Zone 3 Blower Motor

Speed 0 ~ 100 % 25%

Set the blower motor speed for zone 3 as a percentage of the

home’s total cooling load or CFM requirement (see Zone 1 above for

details).

Zone 4 Blower Motor

Speed 0 ~ 100 % 25%

Set the blower motor speed for zone 4 as a percentage of the

home’s total cooling load or CFM requirement (see Zone 1 above for

details).

A/C Type Selection

(when Zoning)

0=single stage

A/C

1= inverter A/C

or HP

2=Inverter 2 A/

C or HP

1

0=Single stage A/C: all zone dampers will open. 1=inverter A/C:

1 zone will open at a time. 2=Inverter 2 A/C: multiple zones open

simultaneously

This manual suits for next models

8

Table of contents

Other iFlow Air Handler manuals

Popular Air Handler manuals by other brands

Mars

Mars Comfort-Aire Century VCD18 SA Series owner's manual

BLAUBERG

BLAUBERG VUT 270 V5B EC user manual

Trox Technik

Trox Technik FK2-EU Additional manual

Lennox

Lennox LNINVE052 Service manual

Trane Technologies

Trane Technologies THERMO KING UT-1290 installation manual

Armstrong Air

Armstrong Air BCE7S Series installation instructions

Mars

Mars Century Comfort-Aire HRG18 S1P Series Service manual

Midea

Midea 40MBAA installation instructions

ECR International

ECR International EMI DHMZ218DA Installation, operation and maintenance manual

Vents

Vents VUT 160 V EC user manual

Nortek

Nortek B6VM Series installation instructions

Verano

Verano freshAIR+ VST Installer manual