2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

1�2 Warnings used�����������������������������������������������������������������������������������������������5

2 Safety instructions �����������������������������������������������������������������������������������������������5

2�1 General requirements on the safety-related functions�����������������������������������6

3 Functions and features ����������������������������������������������������������������������������������������7

3�1 General function description��������������������������������������������������������������������������7

3�2 Safe state of the output relays (failsafe state) �����������������������������������������������7

3�3 Switching function "underspeed" �������������������������������������������������������������������8

3�4 Hysteresis������������������������������������������������������������������������������������������������������8

3�5 Initialisation����������������������������������������������������������������������������������������������������8

3�6 Start-up delay ������������������������������������������������������������������������������������������������9

3�7 Fault output (Y7)������������������������������������������������������������������������������������������10

3�8 Underspeed output (Y8) ������������������������������������������������������������������������������10

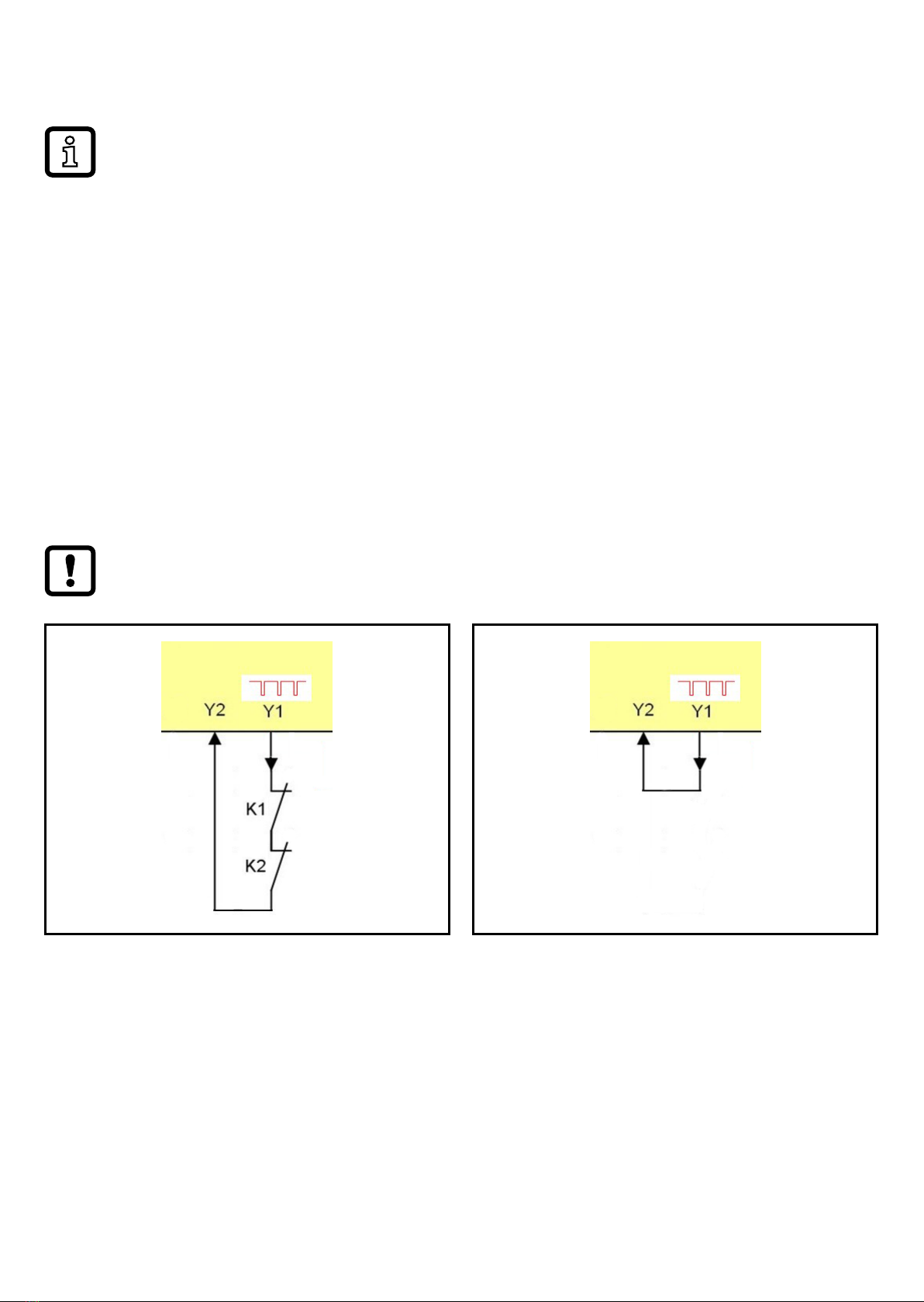

3�9 Feedback circuit for external device monitoring (Y1-Y2)�����������������������������10

4 Installation���������������������������������������������������������������������������������������������������������� 11

4�1 Mechanical installation of the device ����������������������������������������������������������� 11

4�2 Remove the device�������������������������������������������������������������������������������������� 11

5 Electrical connection������������������������������������������������������������������������������������������12

5�1 Terminals �����������������������������������������������������������������������������������������������������12

5�2 Automatic/manual mode selection���������������������������������������������������������������14

5�2�1 Automatic operation����������������������������������������������������������������������������14

5�2�2 Manual operation��������������������������������������������������������������������������������16

5�3 Enable inputs�����������������������������������������������������������������������������������������������18

6 Indicators and operating elements���������������������������������������������������������������������19

6�1 LEDs������������������������������������������������������������������������������������������������������������19

6�2 Switches ������������������������������������������������������������������������������������������������������20

7 Set-up ����������������������������������������������������������������������������������������������������������������21

7�1 Configuration position (factory setting) ��������������������������������������������������������21

7�2 Setting the switch point��������������������������������������������������������������������������������22

7�3 Examples of switch point settings����������������������������������������������������������������23

7�4 Checklist after installation and set-up����������������������������������������������������������23

7�5 Notes on the positioning of the sensors / damping elements ����������������������24