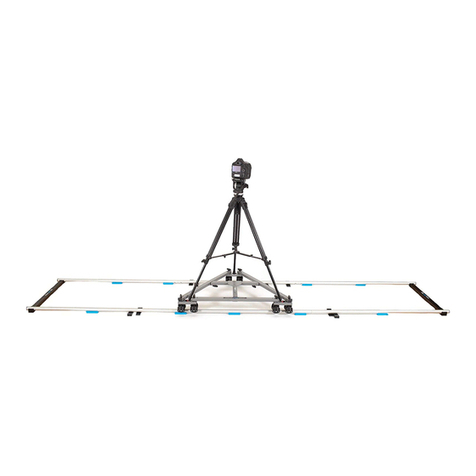

iFootage Shark Slider Mini Series User manual

INSTRUCTION MANUAL

FOR THE SHARK SLIDER MINI SERIES

DK0801001

Thank you for purchasing this iFootage product, The Shark Slider Mini is compact,

lightweight, easy to carry and is ideal for all types of studio and location camera

movement.

To get the most from your Shark Slider Mini, please read the following instructions

carefully before operating the equipment. Please keep the manual safe for future

reference.

This instruction manual supports the following:

TECHNICAL INFORMATION

FEATURES

PRECAUTIONS

COMPONENT DESCRIPTION

STATE INDICATORS

INSTALLATION GUIDE

SET UP AND SCENARIOS

MAINTENANCE

Whilst every care has been taken to ensure that this manual supports the product and our

customers, some ambiguity or description omissions may exist. We always welcome

customer feedback on how we can improve the product manual.

Contents

Notes: Please read the following information:

Please note that customers who have purchased the following will need to download the

iFootage App which currently supports iPhone IOS8.3 and above and will soon support

iPad and Android: Mini 2 Axis Module, Mini 3 Axis Module, Shark Slider Mini Complete and

Shark Slider Mini Premium.

Please check all components and packaging for any damage. In the case of missing or

defective parts, please contact your distributor as soon as possible.

When the motion module is switched off but still connected to power via a USB port, power

will still be supplied to the battery. When the motion module is switched on, power is supplied

directly to the motion module. If the battery inside the motion module is in power off mode the

battery will not charge .

1.Shark Slider Mini Track

2.Shark Slider Mini Standard

3.Shark Slider Mini Bundle

4.Mini 2 Axis Module

5.Mini 3 Axis Module

6.Shark Slider Mini Complete

7.Shark Slider Mini Premium

Technical Information

Shark Slider Mini Track Length

Track SpecificationsWeight

Material Aluminum magnesium alloys + SUS304 Stainless steel

Shark Slider Mini Standard Length

Useable Length

Weight

Material

Max load

with pulley

Shark Slider Mini Bundle

Track Specifications

Weight

Material

Track Specifications

Length

Max load

Mini 3 Axis Module

Module slider

Location accuracy of Module

Load of Slider tilt 45°

Slider motor power

Slider endurance time

Radio frequency Bluetooth and 2.4GHz

Operating voltage

Spin speed

Location accuracy of Pan Head

Max Load of Pan Head

Pan Head motor power

Pan Head endurance time

Pan Head self-weight

Radio Signal Range

Battery model

0.68Kg/1.5Lb

2.2Kg(with pulley)/4.85Lb

Aluminum magnesium alloys + SUS304 Stainless steel

Aluminum magnesium alloys + SUS304 Stainless steel

Useable Length

1.

.

3.

4.

8.

13.

14.

Features (depending on package purchased)

Lightweight, compact, portable and easy to deploy.

Seamless track locking design with track extensions available as an accessory.

High quality design, engineering, durable materials (hard anodized technology)

and components.

Unique, quick release, original design flywheel and motion module.

Agile and adjustable angle of carriage plate, allows for fast adjustment of camera

position.

Modular design allows for future additions and updates to mini slider including

moving from manual operation to automated motion control of up to 3 axis.

Highest location accuracy for motion control slider is 0.00325mm and for the Pan

and Tilt Head it is 0.001°.

Starting point detection avoids repetition of manual reset with multiple recordings.

USB power charge and power supply to motors.

Reliable, wireless control using Bluetooth BLE 4.0 and 2.4 GHz.

Instant automatic connectivity via Smartphone Bluetooth BLE 4.0.

Multiple key frame Bezier curve preset timeline function allowing you to accurately

programme all three axis. Perfect for sophisticated time-lapse recording.

iFootage motion control App with free firmware updates.

The Shark Slider Mini connects via Bluetooth BLE 4.0 technology. Prior to opening

App ensure that your Smartphone's Bluetooth is activated.

Please use only FW50 batteries. Alternative batteries may damage the unit.

As a result of lithium battery discharge characteristics and the overall power

requirement for the Shark Slider Mini to operate, should the battery power be 10%

or less, the operation time may be reduced to less than 10 minutes. Please ensure

that batteries are fully charged so that there is sufficient power for sustained

operation.

Once activated, Motion X2 automatically moves to the initial status/zero point.

Please ensure that the track is clear of obstacles prior to starting. It is recommended

that users keep their hands clear of the tracks also to avoid damage or injury.

Always protect the equipment when working in dusty, damp or wet environments.

Failure to ensure adequate protection from elements may result in equipment failure.

Do not use this motion control unit in environments above 50°C and below-20°C

degrees.

Precautions

Any disassembly or modification without authorization or improper use of the equipment

may result in damage and affect the warranty.

Automatic target control (focal point detection)-ideal for interviews.

Preset, repeatable camera movement.

Slider can be utilized both vertically and horizontally.

Panoramic function.

Photostitching function.

Toolless and beltless assembly for super smooth movement.

5.

6.

7.

9.

10.

11.

12.

15.

16.

17.

18.

19.

1.

3.

4.

5.

6.

7.

2.

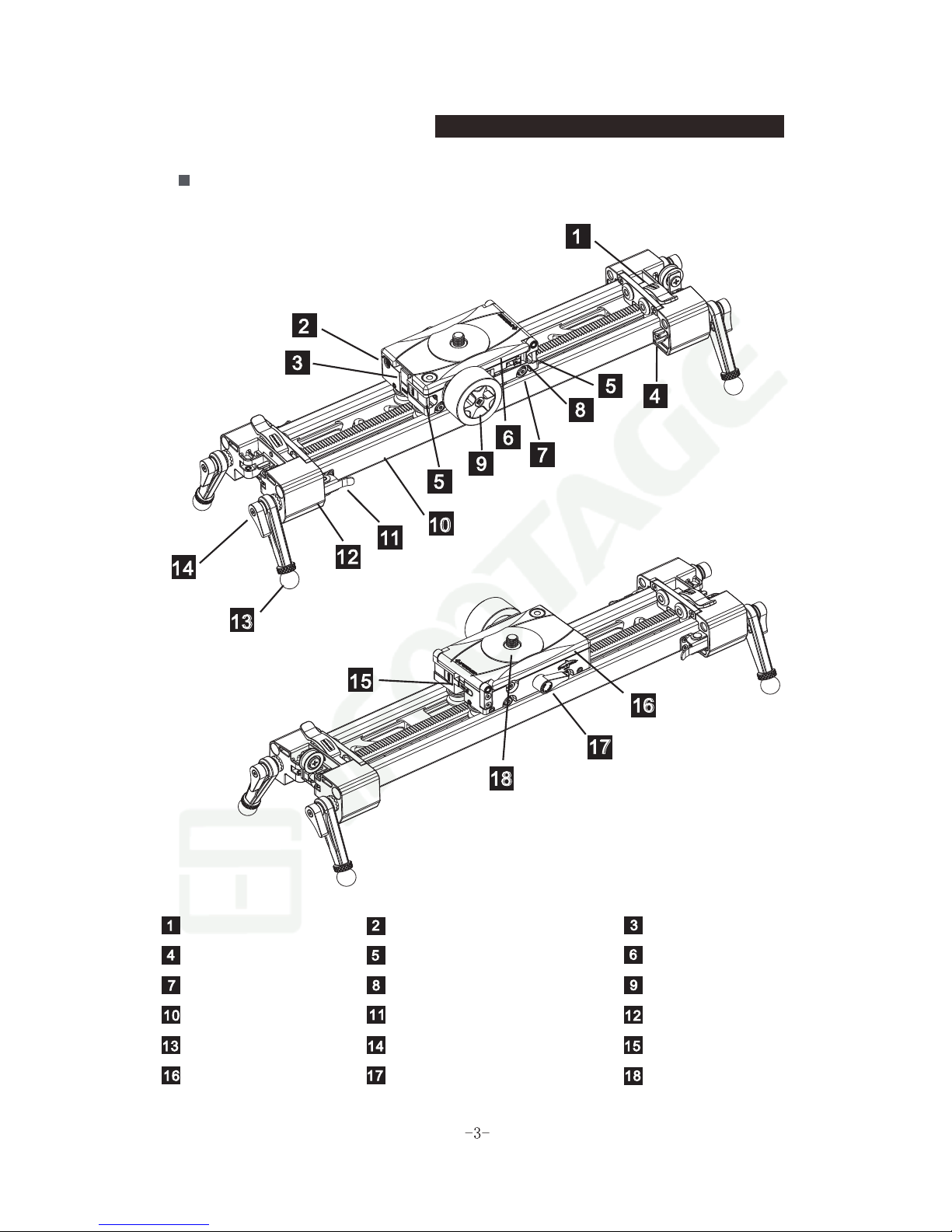

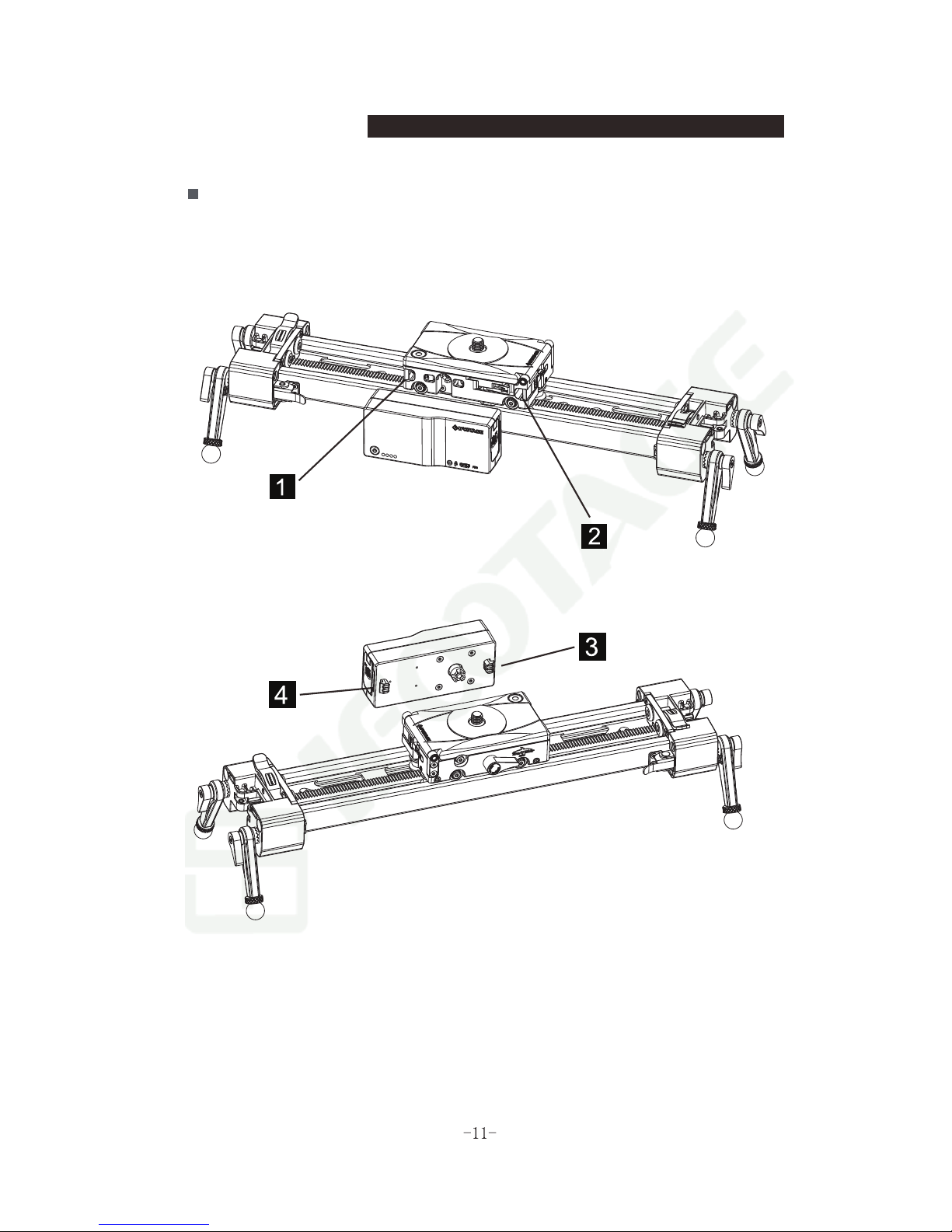

Component description

Shark Slider Mini Standard

Foot stand lock buckle 1/4'' hole Angle plate buckle

Clamp-A Lock buckle of 1-Axis module Carriage

Flat pulley Carriage locking control Flywheel

Track Clamp-B Foot stand

Adjustable legs Locking control Hanging buckle

Angle plate Angle locking control 3/8'' screw

864

53 2 1

8

12

7

5

4

9

10

11

LED1 LED2 LED3 LED4

LED1

LED2

LED3

LED4

7

7

Shark Slider Mini Motion Control Version

Hanging pulley Battery cable cover Battery cover

Micro USB port 2.5 inch shutter interface Slider module

Indicator light Power switch Locking button for X2 Mini

1/4'' screw 1/4'' Screw / 3/8'' Screw Locking control

*Micro USB port supplies power to Pan and Tilt Head and Slider or can be used

to charge battery.

*To reset to factory settings, press and hold the On/Off switch, then insert the

battery and wait 10 seconds until the red light flashes to indicate the reset is

complete.

Component description

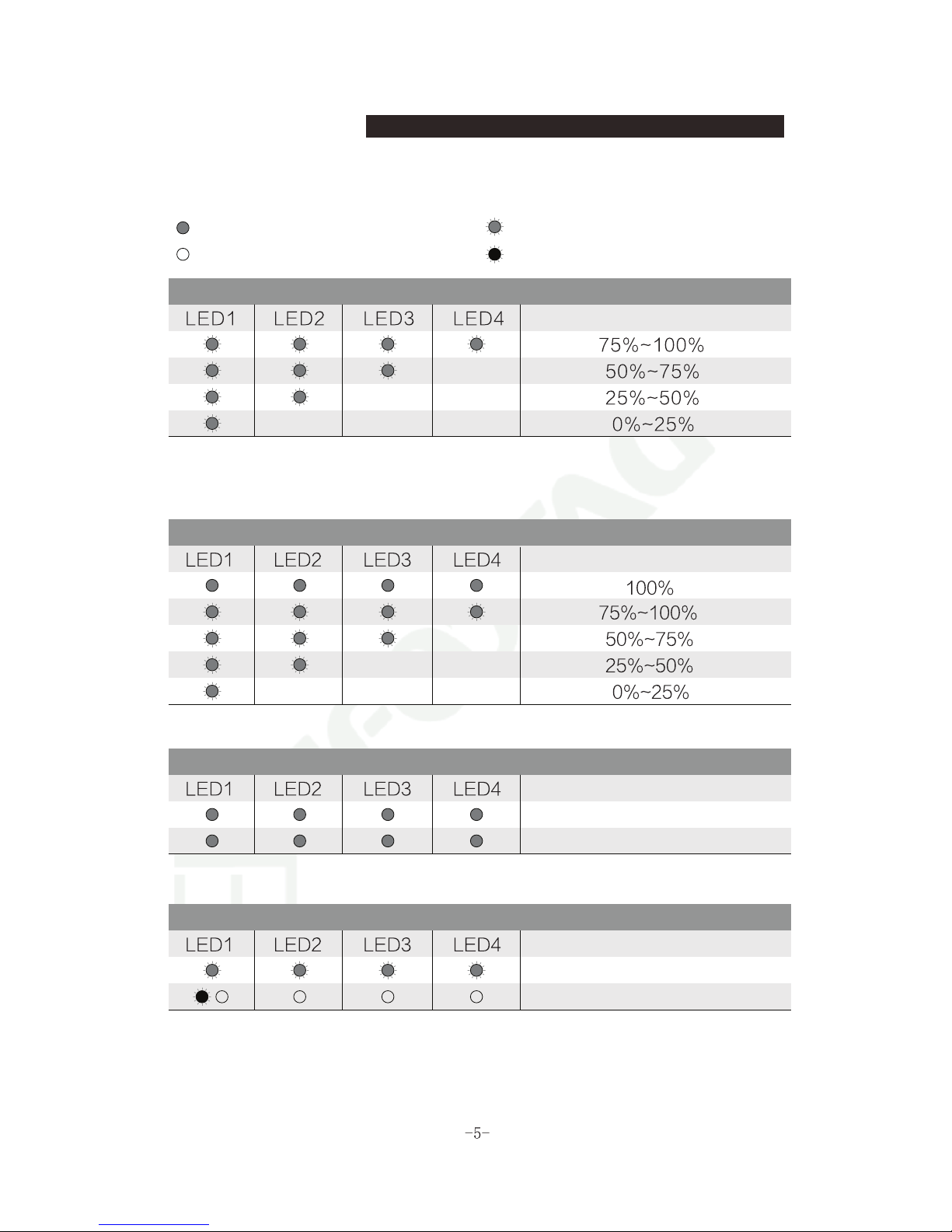

Status indicators

LED status explained:

LED green LED flashes green

LED off LED flashes red

Battery level

Current battery level

* Quick press the On/Off switch to check the battery level while the unit is

powered off.In standby mode the LED will flash every two seconds to indicate

the battery level.

Battery charging level

* Insert 5V USB to charge the unit during powered off mode.

Shutter status

Current state

Shutter ready to fire

Shutter fire after 0.3s

On/Off status

Current state

LED flashes from 1 to 4 and all 4 LED flash 3 times.

* To switch ON or Off, press and hold the On/Off switch for 2 seconds.

Current battery level

LED lights off from 4 to 1 and all 4 LED red lights flash 4 times.

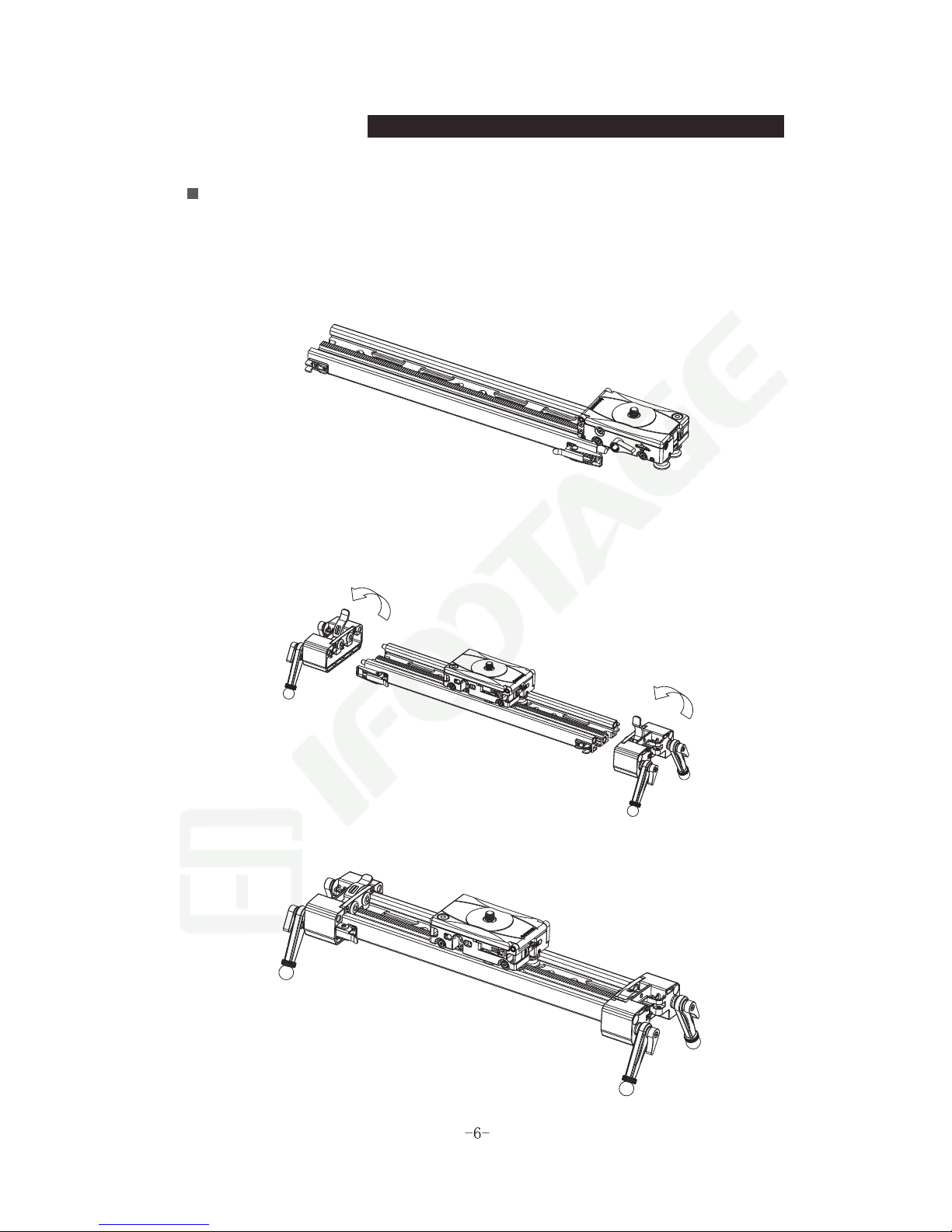

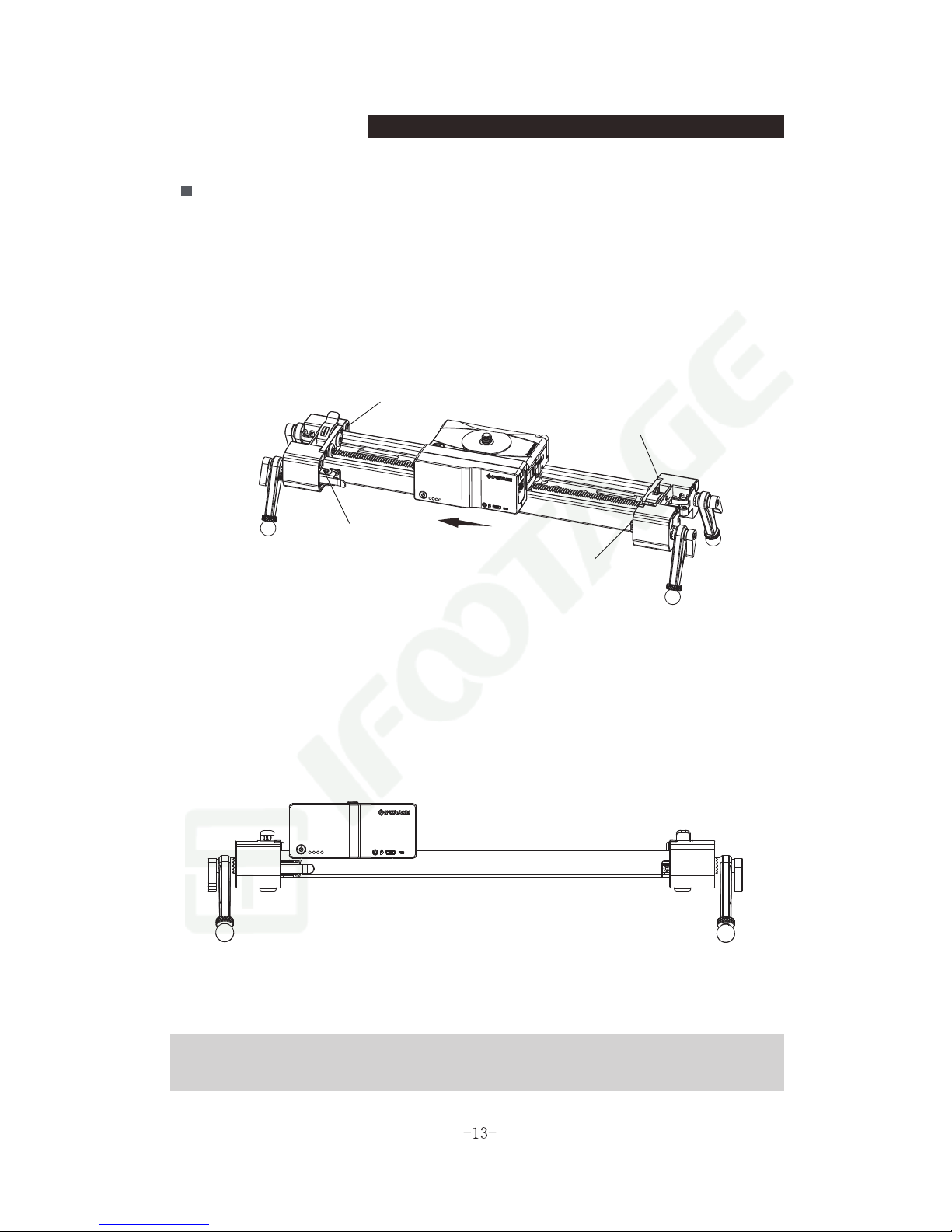

Installation guide

How to install the carriage

Step 1: Attach carriage by carefully sliding carriage onto the track at one end.

Gently push carriage along length of track to ensure correct contact

and smooth operation.

Step 2: Attach both track end/feet by opening buckle connection on track, pushing

into place and locking using buckle system. You may wish to attach one end

prior to attaching carriage, then fit the other end.

Completed installed diagram for reference:

How to install the flywheel

Step : Press the flywheel into the receiving port on the side of the carriage.

You will audibly hear it click as it locks into place. Move carriage or turn

flywheel to check it is installed correctly.

Completed installed diagram for reference:

Installation guide

How to remove the flywheel

Firmly hold the flywheel and gently pull to the left, then do the same, but to the

right followed by pulling the flywheel away from the carriage at 90 degrees. This

will ensure safe removal of the flywheel from the carriage.

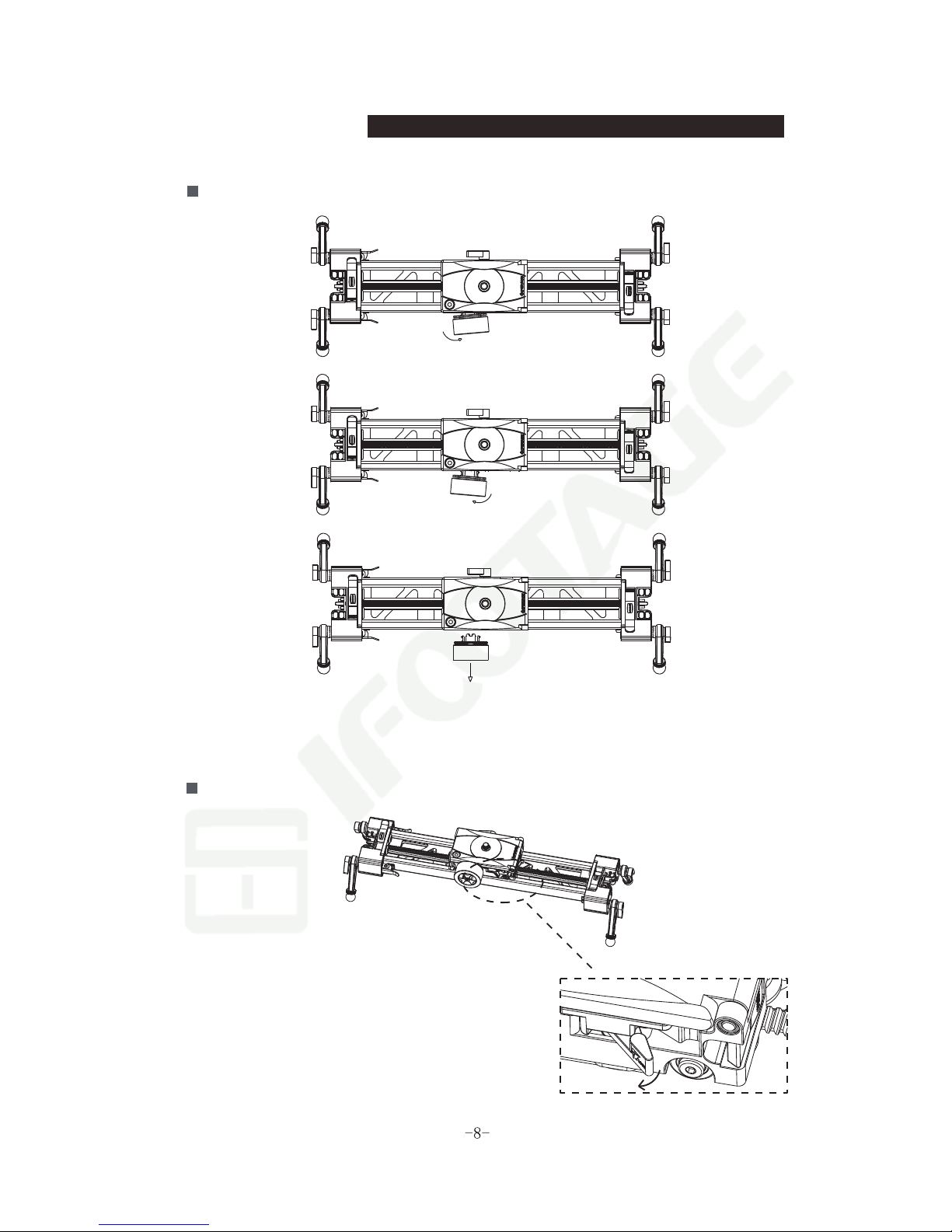

Locking the module

In order to prevent the carriage from moving,

rotate the carriage locking control, following

the direction of the arrow direction.

(Note: Locking is not intended to lock the unit

completely in position, it is designed to assist

stability during 2 axis operation with the X2 Mini)

Installation guide

Mounting the Shark Slider Mini onto a tripod with a hemisphere base

Step 1: Attach the hemisphere base onto the slider using the central screw

hole on the track underside. Screw the hemisphere base in a clockwise

direction until fully tightened.

Hemisphere base

Step 2: Mount the hemisphere base on the tripod and adjust the slider until the

carriage's spirit level shows the slider is horizontal, Lock into position.

Spirit level

Bowl

Locking handle

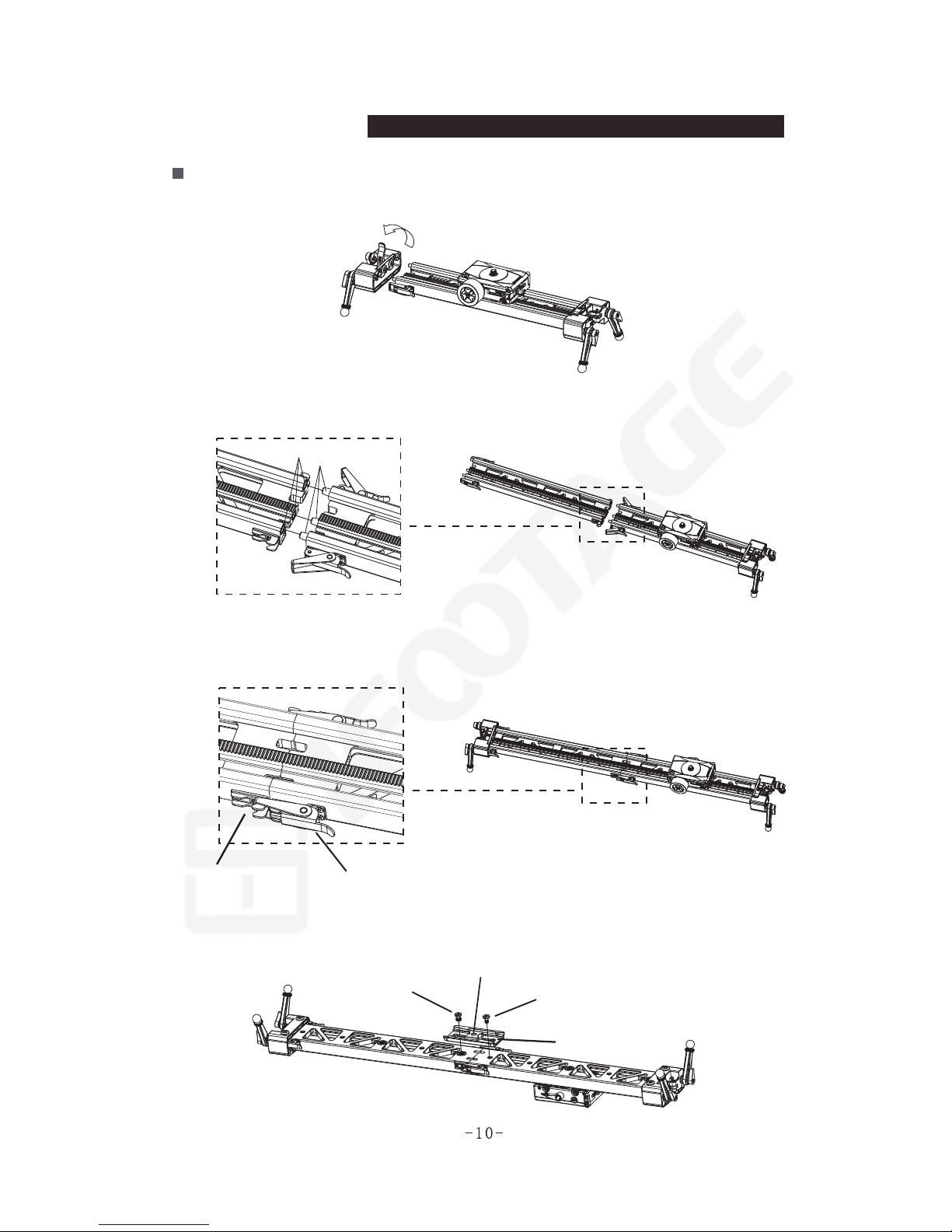

Installation guide

Extending the track

Step 1:Remove the foot stand from one end of the slider.

Step 2: Attach the track extension to existing track using the male and female

connecting nodes. (see diagram).

Step 3: Use the buckle locking system to lock the two tracks together. Check

buckles are closed and tracks are secured together successfully prior to

replacing and locking in place the foot stand.

Joint-A(female track)

Joint-B(male track)

Clamp-A(Female lock) Clamp-B(Male lock)

Step 4: Place the track connection plate on the underside of the joined track and

secure with screws provided. Check that the plate is secure and is adequately

supporting the track joint.

3/8 ''hole

3/8'' screw 1/4''screw

Connection plate

Installation guide

How to install the single-axis module

Installation guide

Step 1:Remove the flywheel as per instructions.

Step 2:Attach the single-axis module onto the carriage as shown in the figure.

Step 3:Check that the single-axis module is securely attached to the carriage.

Step 4:Check track is clear of obstruction.

Step 5:install battery and switch on unit.

How to install the battery

Step :To open up the battery cover move the switch to 'OPEN'.

Battery Type: FW50

Battery curved side

*Insert the battery in the 1 -axis module, pay attention to the direction,

DO NOT insert it in opposite direction.

Installation guide

Step 2:Carefully install battery ensuring positive

end is connected correctly.

Step 3:Close battery compartment

Battery curved side

Automatic starting point function

Step :Insert the battery and close the battery cover. Press and hold “On”

switch for at least two seconds until the four indicator lights flash three

times (green light), after which the pan head will begin to move to the

direction as shown in the chart.

*The carriage will stop automatically 10mm from the left foot stand.(The 1 axis

slide module is equipped with a sensor which will move to the starting point

and stop automatically)

*For maximum run time, please ensure that you run the single axis module on

a fully charged battery.

Installation guide

Automatic Sensor

Automatic Sensor

Automatic Sensor

Automatic Sensor

How to disassemble the single axis module

Step 1:Press the locking latches on both sides of the unit simultaneously.

Step 2:Gently remove the single axis module from the carriage at a 90 degree

angle to the carriage.

Installation guide

Carriage Angle Plate

Step :Turn the angle plate anti-clockwise. Press to release the angle plate latch,

lift the angle plate and adjust to desired angle.

Spirit Level

Angle Plate

Angle plate latch

Angle Plate Lock

How to use the loading function

Step 1:Install the pulley cord (Push the pulley pins through the groove at the end).

Pulley Mounting Groove

Pulley Pin Installation Diagram

*The carriage and camera may slip if the rake or slider set up angle is too

steep. This can be prevented by using the pulley and correct counterweight.

These should be removed when not in use.

Installation guide

How to use the loading function

Step 2:Attach the counterweight and secure the cord to the hanging buckle.

Step 3:Set up fully loaded slider at the angle you wish to use it and carefully

test out counterweight. Increase or reduce weight accordingly.The

pulley must be installed using an appropriate counterweight for the

set up and weight of the camera and head.

*Care must be taken to ensure that user's fingers and hands are not 'pinched'

or trapped within moving the parts.

Installation guide

Using the remote control App

How to mount the X2 Mini on a tripod

3/8'' screw

3/8'' thread hole

Rotate

to mount

Rotate

to mount

Step 1:Please ensure that the tripod camera plate has a 3/8'' screw and therefore

matches the X2 mini pan head 3/8'' screw thread.

Step 2:Carefully place the X2 Mini onto the tripod camera plate and screw the two

together ensuring the thread is not crossed.

Step 3:Tighten and lock plate onto tripod.

Step 4:Check items are secure prior to use.Carry out reverse procedure when

removing X2 Mini from a tripod.

Installing the X2 mini onto the shark slider mini

3/8'' screw 3/8'' thread hole

Using the remote control App

Step 1:Carefully place the thread 3/8'' hole of the X2 Mini pan head onto the 3/8''

screw on top of the Shark Slider carriage. Rotate clockwise.

Step 2:Press the pan locking button and rotate the pan head at the same time to

lock the pan head tighter. You will also need to press the locking button

when removing the pan head from the slider carriage.

Step 3:Please mount the camera as shown in the diagram when using the target

control feature.

Rotate

to mount

Rotate

to mount

This manual suits for next models

7