Cinetech Albatross Dolly User manual

ALBATROSS DOLLY

©2019 Cinetech Italiana Srl

User Manual

INDEX

USER GUIDE

• Albatros Dolly - pg.6

• Steering system - pg.9

• Small arms - pg.14

• Small arms positions - pg.16

• Hydraulic system - pg.20

• Oil ow regulator - pg25

• Lifting arm - pg.26

• Accessories - pg.28

©2019 Cinetech Italiana Srl

User Guide

pag. 6

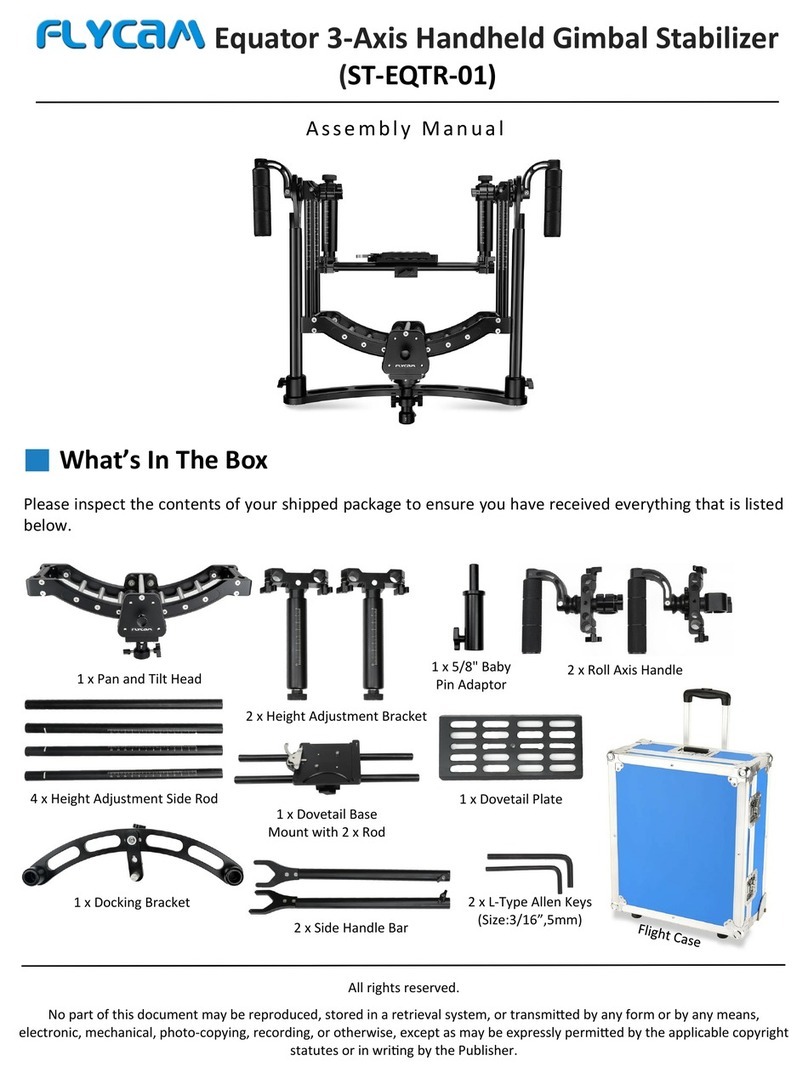

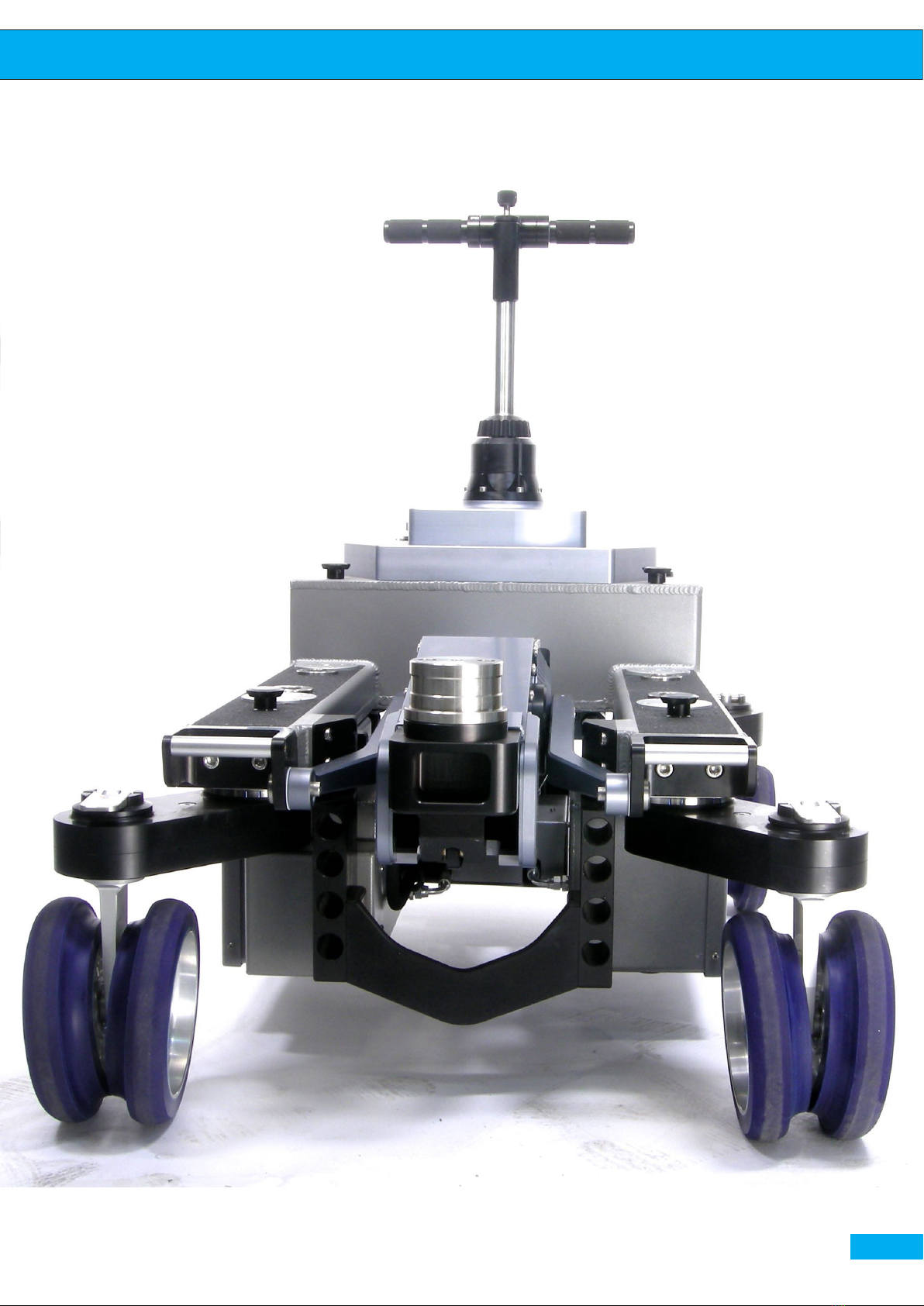

Albatros is a dolly engineered and desi-

gned using the latest modern technology

in structural materials and surface ni-

shes built to meet all the needs of profes-

sionals in the world of cinema.

All parts of the Albatross dolly are made

of stainless steel and light aluminum al-

loy. Vertical movements as well as starts

and stops are uid and repeatable.

The Albatross design is extremely robust

and guarantees excellent performance

in all weather conditions. All the com-

ponents are designed and manufactured

in the Cinetech Italiana factory based in

Rome.

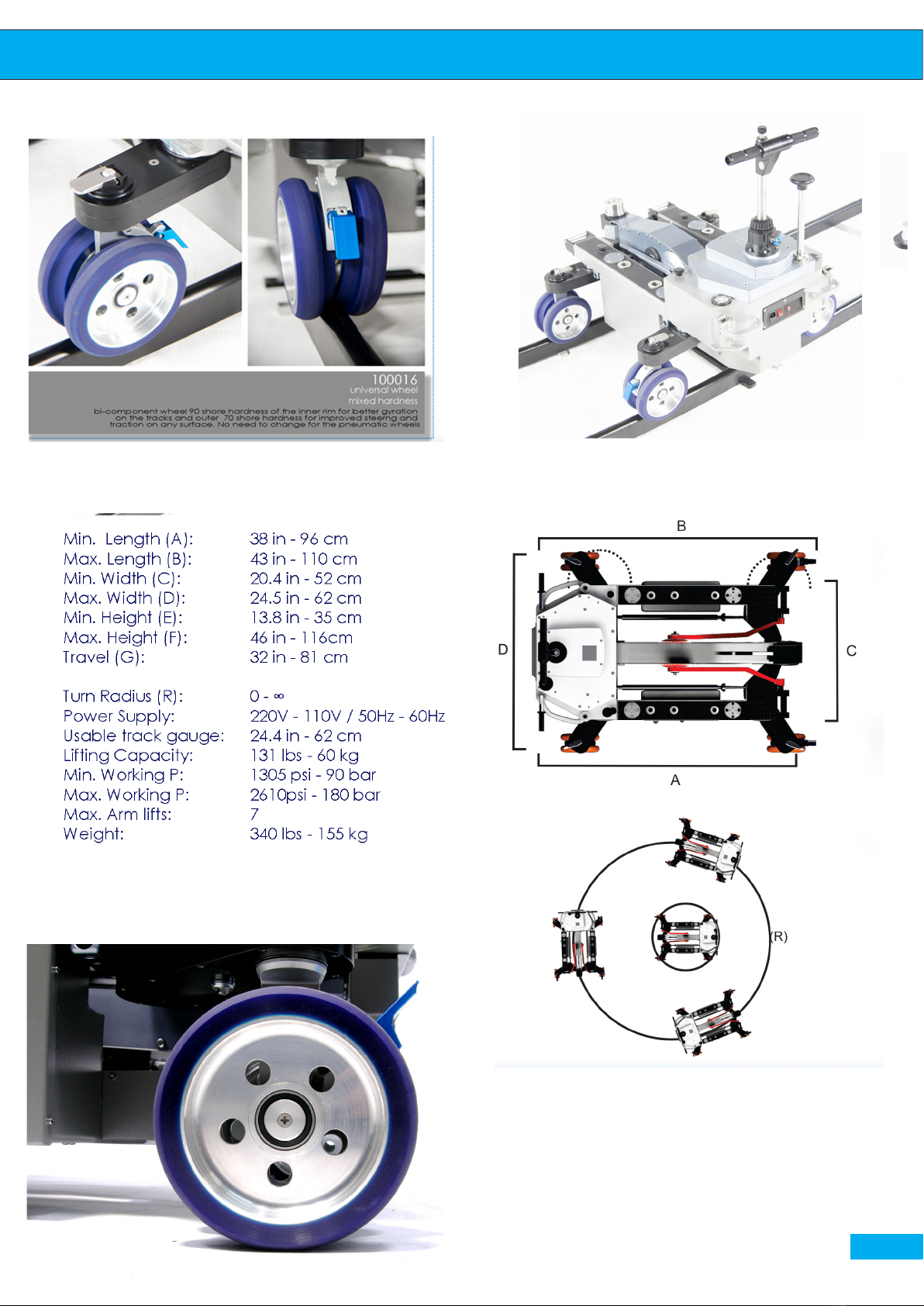

It is possible to choose the following stee-

ring modes:

CRAB: all the wheels are turning at the

same angle, allowing the dolly to have

the longitudinal, transversal and oblique

movements without turning;

ROUND: all the whells are positioned

at dierent angles, thus allowing the

dolly to make the round 360° movement

around its own axis or make the precise

turnaround with an established radius

without the use of the track;

CONV: conventional mode with two rear

wheels steering, so the operator makes a

turn while tracking.

Steering mode change can be made by

simply twisting the steering handle.

Steering system is composed by the hi-

ghly-precise gears and is based between

the rear wheels to facilitate the guidance,

thus avoiding friction.

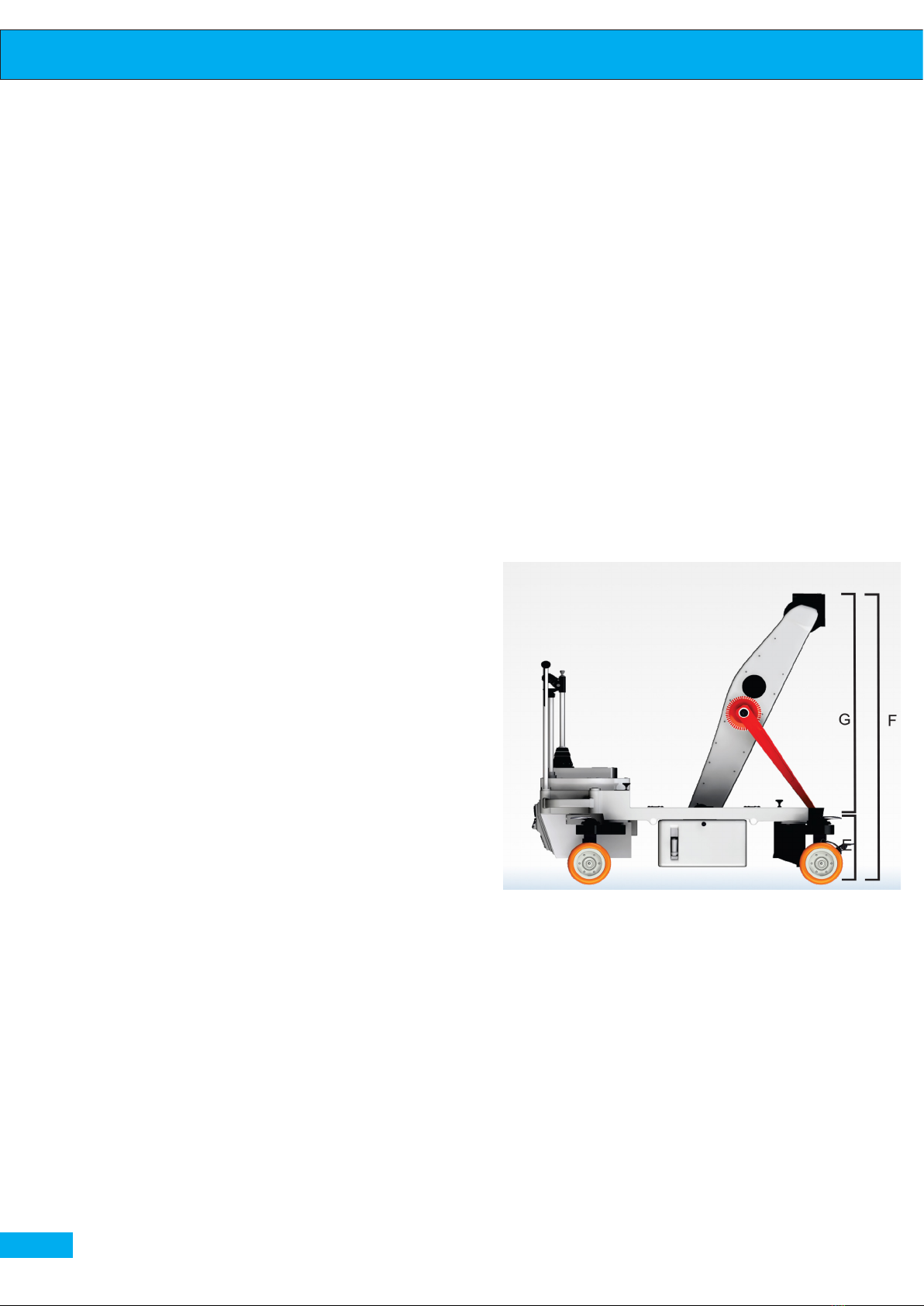

Dolly is equipped with premiere bi-com-

ponent wheels, where the inner rim has

a 90 shore hardness for beer gyration

on tracks, incredible stability and smo-

othness, while the outer rim has 70 sho-

re hardness for improved steering and

traction on any surface. This feature me-

ans more elasticity and crush-proofness,

a concept aiming to eliminate traditional

pneumatic wheels that frequently do

not maintain a proper ination pressure

and consequently stress the entire dolly

structure. Dolly can be equipped with

pneumatic wheels on demand.

A new ow regulation valve allows the

arm to go faster and without vibrations.

The dolly is equipped with a new piston

that inbodies an end run “dashpot”

A new steering lock allows the dolly

grip to make precise straight moves wi-

thout any extraneous movement of the

wheels, even without using the tracks.

User Guide

pag. 7

New bi-component wheel. 70 Shore External Rim - 90 Shore

internal rim

User Guide

pag. 8

The maximum payload on the Albatros arm is 60 Kg on the head and the height from the

ground is 116 cm. Albatros dolly can work both on the track and on the ground allowing

to the grip and a camera assistant to work owlessly carrying the above mentioned wei-

ght on the head.

The Dolly is composed of several main systems, each of those has a specic function, so

the dolly can go on the ground, on the track and the hydraulic arm can be moved.

Albatross Dolly on track with standard accessories mounted. Levelling head maxi and camera mounted on the head

User Guide

pag. 9

Steering system

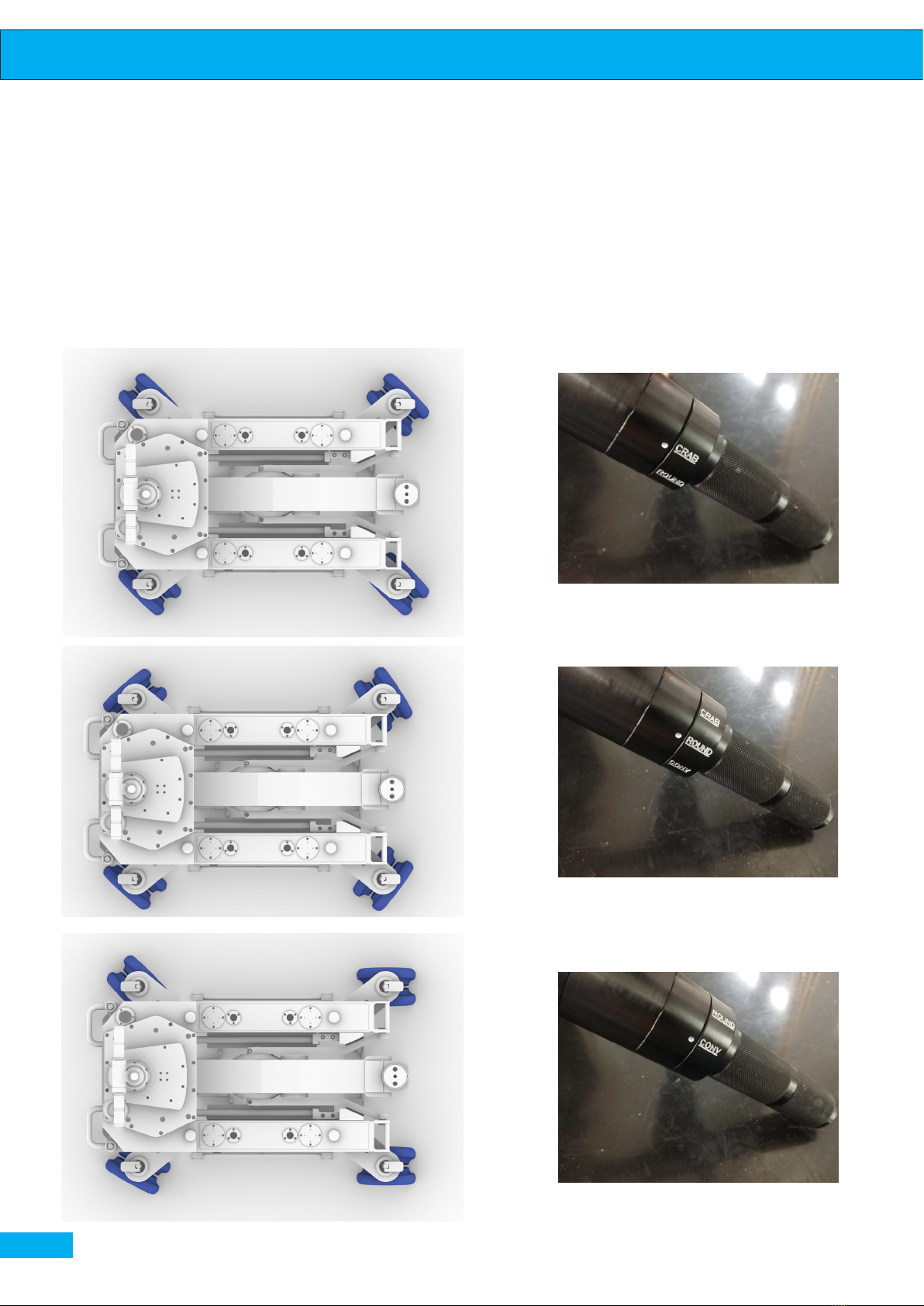

Steering wheel with CRAB, ROUND and CONV steering modes

User Guide

pag. 10

Albatross dolly has the innovative gearbox which is able to transmit the move-

ment to the wheels through a complex gear system. Steering system doesn’t requi-

re a lot of maintenance as it is a synchronized system, always in phase for all three

movements (CONV, ROUND, CRAB), guaranteeing reliability over time.

CONV. STEERING MODE CRAB STEERING MODEROUND STEERING MODE

User Guide

pag. 11

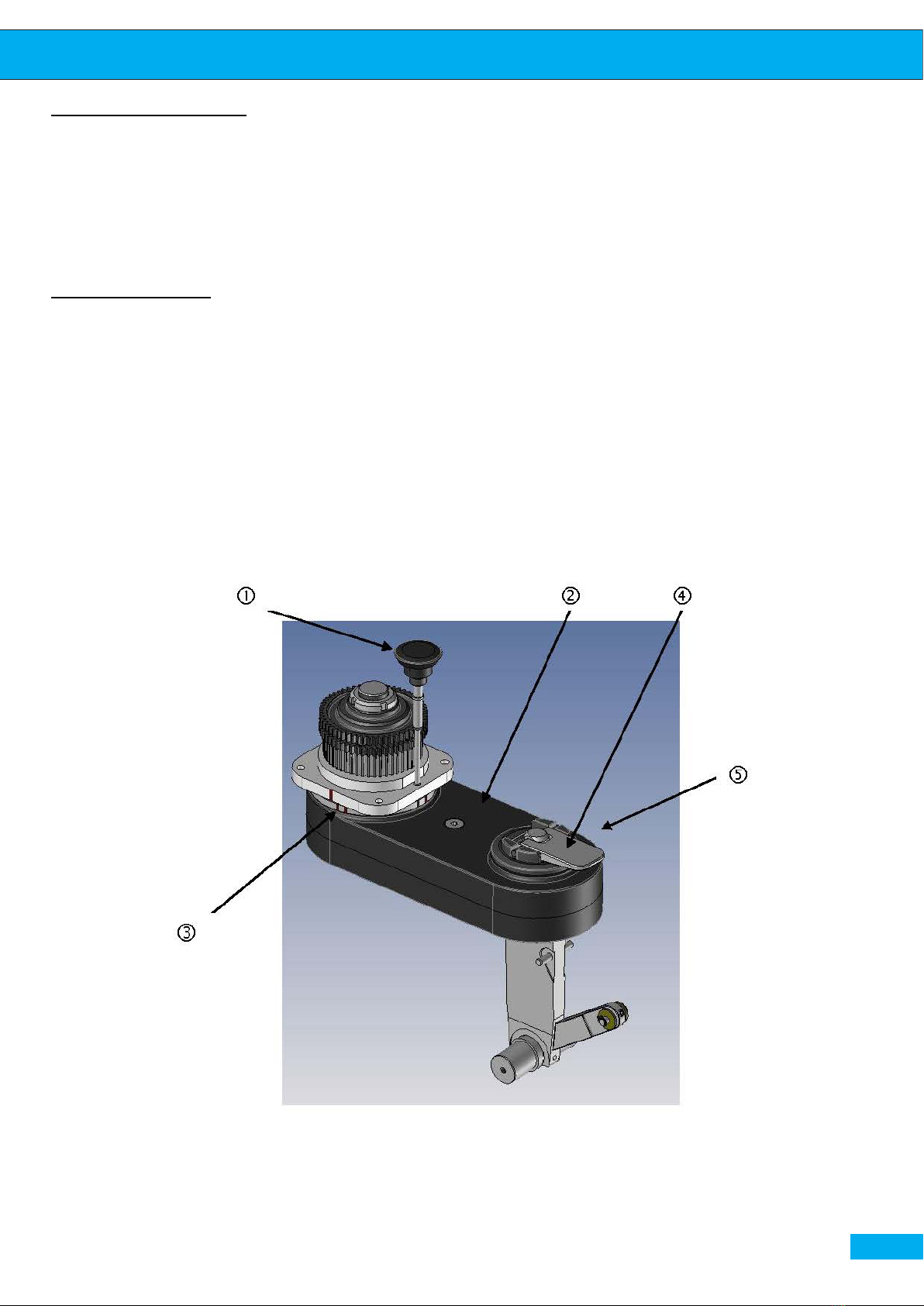

The removable steering column allows simultaneous control of the three synchro-

nized steering modes, changing from CONV to ROUND to CRAB.

Insertion / Extraction

Position the steering column in its compartment on the Dolly, tighten the upper

nut -2- until it stops to connect the column to the steering system. Lock the colu-

mn by tightening the knurled knob -3-

To extract the column execute the inverse operation.

Locking of the steering wheel

It is possible to block the steering wheel in central position by locking the lever -1-

Choosing the steering mode

Change of the steering modes can be made by twisting two handles -4- of the ste-

ering wheel, thus choosing the steering mode between CRAB, CONV or ROUND.

In order to change the steering mode it is necessery to bring back the steering to

the initial point i.e. with the steering handles set in the position parallel with the

rear side of the dolly and start twisting the handles. Any change of the steering

mode must be made only when the steering wheel is perfectly centered.

The steering has to be smooth and in case the operator doesn’t manage to steer,

it’s not advisable to force the steering.

Steering column. Column lock, gear change rings and knurled fixing ring nut

User Guide

pag. 12

Use on the track --> pg.17

User Guide

Albatross dolly can be placed on the track both in the longitudinal and tran-

sversal positions.

Albatross on the track placed transversely

pag. 13

User Guide

pag. 14

User Guide

Small arms

The small arms are an integral part of the dolly that serve to increase or

decrease the wheelbase length depending on the width of the track and the

stability when working on the oor. The dolly is equipped with 4 lateral

rotating on 180° arms that can be set in 5 positions, allowing a wide range

of use and easy transportation.

Lifting the grip (A) one can unlock the small arm allowing it to freely turn

around, when the reference marks are aligned it is possible to repress the

grip in order to block the small arm in the desired position. Various posi-

tions are available, such as the transport position with the wheels positio-

ned under the dolly, one position for use on the ground and on the track

signed with the mark between two dots, position for shots in narrow envi-

ronments with the wheels aligned outside (pages 16,19), etc

IMPORTANT: While working on the ground, make sure the small arms

remain in the position signed with the mark between two red dots on the

ring nut which correspond to the ideal calculation of the steering mecha-

nism and that allows the dolly to work at its best.

The lever (C) locks or unlocks only the wheel axis, in fact when the Dolly

has to make a turn on the track it is required to keep all four axis free by

unlocking the four wheels eccentrics, lifting the appropriate levers (C), and

it is also advisable to unlock two arms diagonally (for example front right

and rear left) as explained above.

In the case of the wheel impact, the small arm has a friction system that al-

lows to the wheel to turn freely without damaging the internal parts. In the

case when one or more wheels are turned, or not perfectly straight, when

the steering is in the change position, it is sucient to lift the appropriate

levers (C), realign the wheels and re-tighten.

When the dolly has to work on the curves, one should check that four of

the small arms are in the correct position, i.e. that the four levers (C) are ful-

ly released and two pins (for example A1 e B or opposite combination) are

released diagonally.

The rear wheels are equipped with brakes that must be unlocked in order

to start moving the dolly.

pag. 15

User Guide

Left and right side footboards and front footboard.

Locking arm positions

pag. 16

User Guide

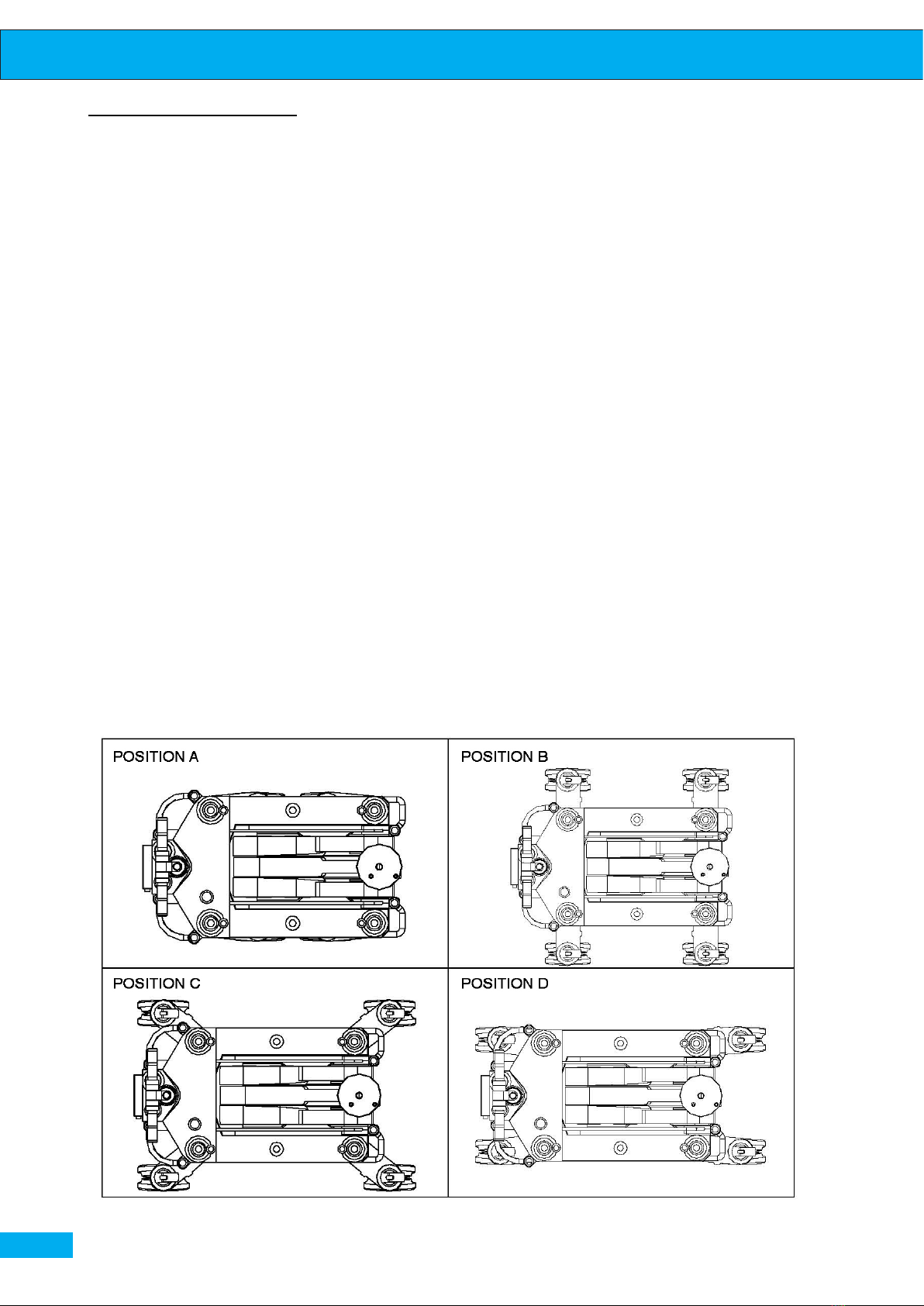

Small arms positions

The default positions are:

1. Position A for transportation: the arms are folded under the Dolly for a mini-

mum footprint.

2. Position B is the ideal position for the maximum stability of the dolly, even if

this position is not ideal to work with the steering system. In this position the

dolly can work on the 620mm track transversally (photo pg.12).

3. Position C when the rear and front small arms are in this position, the dolly

works at its maximum eciency with the steering, allowing the extreme uidi-

ty and smoothness of the movement while working on the ground and also on

the 620 mm track.

4. Position D is created to work in the narrow spaces. Dolly can work on the

450mm track in this position.

Diagram of positions of the arms on the dolly structure

pag. 17

User Guide

Small arms rotation

1. Lift the xing pin -1-

2. Rotate the small arm -2- until the desired reference mark -3-.

3. Insert the xing pin -1- again.

4. Repeat the operation on all four arms.

Use on the track

1. Put the small arms into the Position C.

2. Lift the front right and rear left pins 1.

3. Loosen the levers (4) of the four wheel axis.

4. Lock the steering column.

5. Before moving the dolly on the ground, insert the pins 1, lock four levers (4) and

release the steering column. Now the dolly is ready to work on the ground.

pag. 18

User Guide

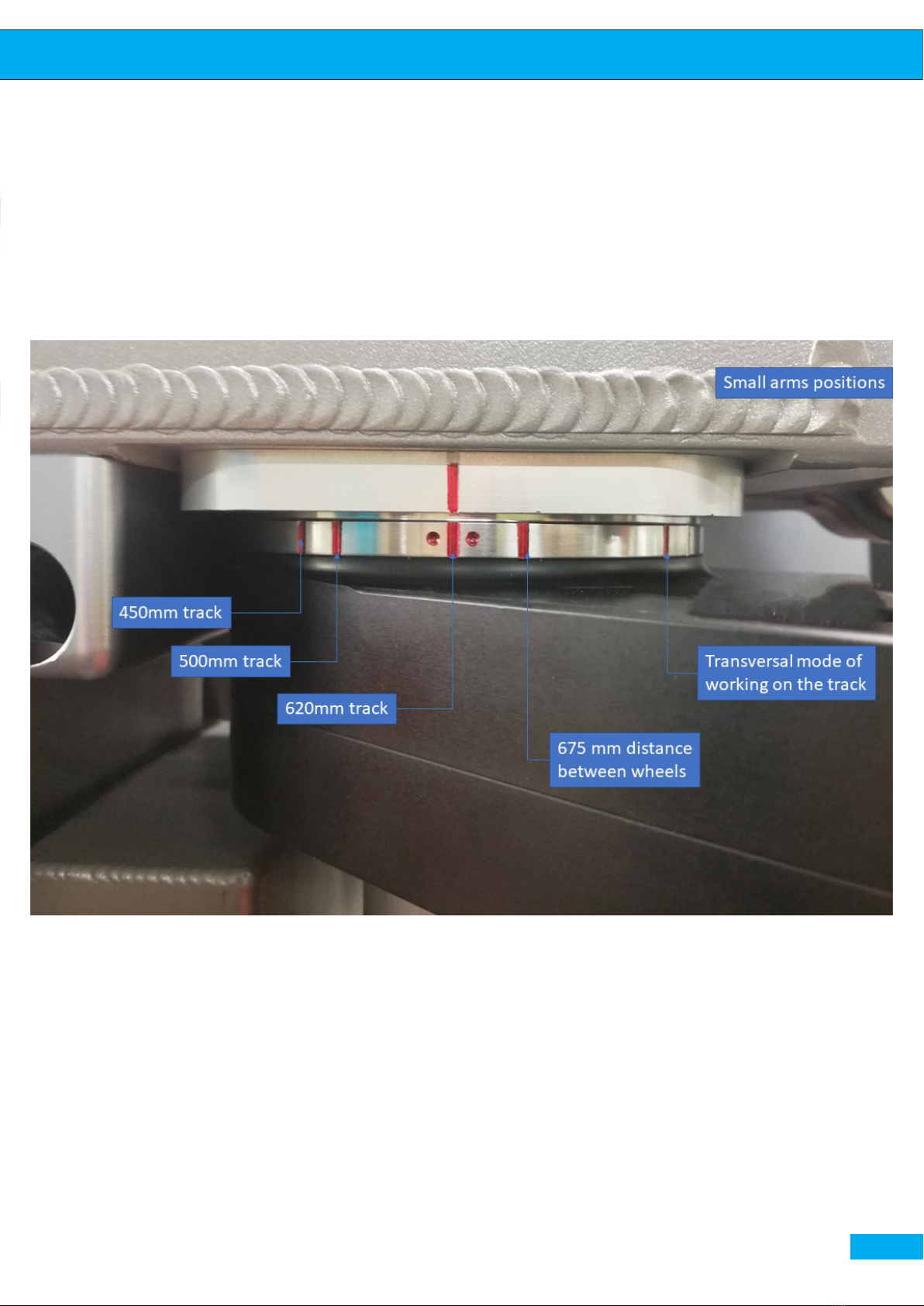

Work on the 620mm track transversely

620mm track. Dolly mounted with the longitudinal axis

pag. 19

User Guide

Work on the 620mm track transversely

Alignment of the ring nut in the 5 available positions. From left to right, 450mm track, 500mm track, 620mm standard track, 675mm

distance between the wheels, and the final position with the small arms perpendicular to the longitudinal axis of the dolly (transversal

placement of the dolly on 620mm track)

pag. 20

User Guide

Hydraulic system

Hydraulic system allows the Dolly to perform up to six lifts. The charging

time is approximately 60 seconds. The proportional control valve allows the

arm to have a speed range from 0 to 2 seconds.

Charging of the dolly can be made in two ways:

• Electrical (depending on the preset voltage): Connect the power cable

supplied, switch on the main switch (1) and press the charging buon (2).

Charging will stop automatically once you reach the maximum pressure

of 180 Bar set by the manufacturer to avoid the damage to the Dolly. In

case of anomalous currents or voltages the electrical box is equipped with

a fuse (3) that protects the system, easily replaceable;

• The second way of charging is through a manual pump that is used only

in places where there is no electricity (as shown in image A). Insert the

control rod (g. B) into the special housing and pump it up and down

until it reaches the desired pressure.

fig.A - manual charge pump handle (configuration)

Fig. B manual pump-rod

Table of contents

Popular Professional Video Accessories manuals by other brands

PROAIM

PROAIM DL-SPIN-01 instruction manual

Autoscript

Autoscript LED8TFT-ME user guide

Prompter People

Prompter People Flex Series setup sheet

MOVOFILMS

MOVOFILMS MF-RIG-120 instruction manual

Square Perfect

Square Perfect Table Top Deluxe 24" Assembly and user's manual

EyeDirect

EyeDirect Mark II Assembly manual