IGD TOC-750S-CO User manual

Doc Ref: SL-065 v1.2 pg 1

2-WIRE SYSTEMS

SAMPLER MODULES

Addressable

2-Wire

Document Ref: SL-065 v1.2

Operation Manual

Sampler Module

FS646773 EMS696504

Triton House

Crosby Street

Stockport

SK2 6SH

internationalgasdetectors.com

+44 (0)161 483 1415

/international-gas-detectors-ltd

@

2

Doc Ref: SL-065 v1.2 pg 2

Standard Specifications

Standard Features

Power

Construction

Outputs

Comms

Temperature

Humidity

Pressure

Sealing

Mounting

Weight

24V DC

ABS Enclosure

4 off SSR Outputs (Switched Neg 24V DC, Common

200mA load shared across all O/P’s)

OP1 Dedicated to Low Flow

IGD Sentinel+ 2-Wire Protocol

-5 to 55 Deg C Full Specification.

0-95% RH Non-Condensing

Samples From Ambient Pressure to 10mBar

Depression, Low Flow Indication at 23mBar Depression

IP54

Wall Mount

TOC-750S-CO2 (typical) 0.85Kg

Auto Zero / Cal

Constant Flow Monitoring With Low Flow

Protocols

1.0 to 1.5L/Min Sample Rate

4 off SSR Outputs

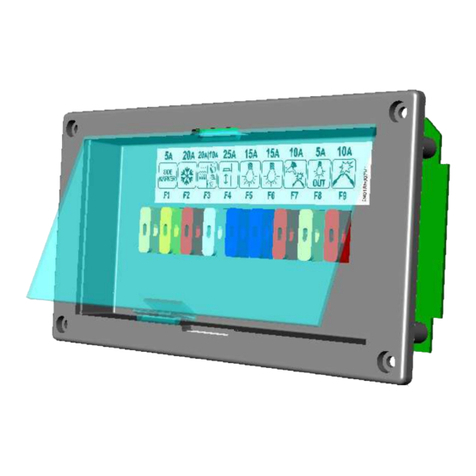

Sample Module Order Codes

Order Code

TOC-750S-CO

TOC-750S-CO2

TOC-750S-FIL

TOC-750S-H2

TOC-750S-IRF

TOC-750S-N20

TOC-750S-NH3

TOC-750S-O2

TOC-750S-PN1

TOC-750S-TBE

TOC-750S-PN2

TOC-750S-CBF

TOC-750S-SLF

TOC-750S-PCF

TOC-750S-INF

Description

Carbon Monoxide Sampler Standard range 0-100ppm

Carbon Dioxide Sampler Standard Range 0-5000 ppm

Standard End Of Line Filter Assy

Hydrogen Gas Sampler Standard Range 0-2000ppm

Flammable Gas Sampler Standard Range 0-100% LEL

Nitrous Oxide Sampler Standard Range 0-1000ppm

Ammonia Gas Sampler Standard Range 0-500ppm

Oxygen Sampler Standard Range 0-25% Vol

Luer Lock Thro' Wall Sample Point M20

20m Reel Sample Tube 6mm X 4mm Polyurethane

Low Maintenance End of Line Filter Assy

Replacement Carbon Zero Filter

Replacement Soda Lime Filter

Replacement Standard Particulate Filter

Replacement Internal Protection Filter (Pack of 5)

Addressable

2-Wire

Doc Ref: SL-065 v1.2 pg 3

202 mm

188mm

Mounting Holes

90 mm

90 mm

Mounting Holes

122 mm

2 off 20mm

Cable Entries

Sample

Exhaust

Sample

Port

Active

Zero

Filter

Physical Details

Sample and exhaust ports suit 6mm OD x 4mm ID Soft tubing. IGD Part Number TOC-750S-TBE

supplied as 20M coils.

Samplers are designed for ambient sampling only

Only use conduit/cable entries provided, drilling the enclosure will void any warranty

It may be necessary to vent spill gases to a safe area

4

Doc Ref: SL-065 v1.2 pg 4

Installation Requirements for Samplers

TOCSIN

650 OR

750 Series

Controller

L1

L2

Port 1 to 4

Drain Wires to Earth

Interconnecting Highway Cabling

For 2-Wire Addressable Systems:

For Safe Area Detectors Use 2

Core Cable 1.0 to 2.5mmSQ

Cable Depending on Distance.

Ensure Cable Screens are

Correctly Terminated and cables

are stripped to the enclosed

guide.

See Cable Calculator for Cable

Core Size vs Distance VS

Number of Devices

Cable Screen or

Drain Wire

Tubing 6 x 4 Polyurethane

Other Tube Options Available

Do Not Exceed 20M

A variety of End of Line Termination

Points Are Available Contact IGD For

Further Details

Tube work should not allow condensing liquids to trap in the

pipework. Where a large amount of condensation may occur

consider fitting line traps. Contact IGD for further advice.

Ensure screened cable is utilised

Doc Ref: SL-065 v1.2 pg 5

TOCSIN 750 Sampler End of Line Filter Assembly

Deployment

Tocsin 750 Series Addressable Sample Modules are designed to sample using 6mm OD x

4mm ID tubing from locations up to 20M distant from the module. IGD provide EOL (End

Of Line) filter modules to prevent dirt and debris from being drawn into the system.

Part Number TOC-750S-FIL

There are two methods to deploy the EOL assembly. Under ideal circumstances the

assembly should be fitted as indicated in fig 1 at the very end of the sample tube. This

provides best protection.

In some circumstances this option may not be possible, for example access to the filter

may be limited or the nature of the environment may prohibit. In this case the filter can be

fitted at a convenient position in the tube run as close to the end of the sample line as

possible to protect as much of the tubing as possible. This is indicated in fig 2

Note that the stainless steel housing is designed to be mounted to a suitable surface. The

cover then provides mechanical protection for the filter whilst still being able to view its

condition. Note correct orientation of the filter.

Fig 1. Filter Installed End of Sample Line

Picture Shows Cover Fitted

Fig 2. Filter Installed ‘into’ The Sample Line

Run. Note Picture Shown Cover

Removed.

Note Correct

Orientation of

Filter. In this

orientation dirt

collects on the

outside of the

filter and will be

visible through

the cover window

Direction

of

Flow

Replacement Filter

Part Number

TOC-750S-PCF

6

Doc Ref: SL-065 v1.2 pg 6

TOCSIN 750 Sampler End of Line Filter Assembly

Deployment

Part Number TOC-750S-PN1

TOCSIN 750 Sampler End of Line Filter Assembly

Deployment

Part Number TOC-750S-PN3

Up to 50mm

6mm x 4mm Tubing

This style EOL module is designed to terminate through

composite walls or ceilings. The bulkhead will clamp up to

50mm to provide a thro’ wall termination. The bulkhead can

be fitted with an optional luer lock style disk filter. If this is a

requirement contact IGD for advise for suitable filters to

match the environmental condition.

Optional Protection Filter

Note these are advised to

suit the application,

consult IGD for further

details

Where termination is required through into cold stores or wet environments IGD advise use of this

part number. The rigid tube assembly passes through the wall of the process at an angle. The

diameter and angle are chosen to ensure condensed liquids cannot be drawn up into the sampler

assembly. A cartridge filter is provided for further protection.

Typically 120+ Degrees

End of Line

Filter

Sample velocity is low

enough such that

condensed liquids can’t be

drawn up the sample tube

Replacement Filter

Part Number

TOC-750S-PCF

Doc Ref: SL-065 v1.2 pg 7

Overview

SSR 1 Dedicated Fault

SSR 2

SSR 3

SSR 4

Vent Port, Do Not Block

Note depending on the nature of the sample it may be

necessary to vent the spill gases to a safe location.

Sample Port

Zero port and protection filter.

Note the sampler can be set to

periodically zero itself by drawing a

clean air sample through its zero port.

Depending an the gas to be sampled

the zero port can be fitted with air

scrubbers to remove any traces of the

target gas from the zero air stream.

For example :

Ammonia, LPG Fit activated Carbon

Filter PN TOC-750S-CBF

CO2 fit Soda Lime Filter Part Number

TOC-750S-SLF

For Oxygen detectors that will auto

calibrate through this port fit particulate

filter TOC-750S-PCF (as picture)

Typical flow rate is 1L/Min with clean filters. Each 1M

length of sample tubing will add an approximate 1s

delay to the sample time.

Note filters should be changed at each service interval

Internal Hydrophobic

protection filter

Replacement Part Number

TOC-750S-INF

Sample modules

should be fitted

vertically

UP DOWN

1 2 3 4 5

Function Buttons and LED’s

8

Doc Ref: SL-065 v1.2 pg 8

Addressing the Assembly Using the Function Buttons and LED’s

The TOC-750 Module PCB is an Addressable Device and

Comes Equipped With a Simple Interface to Allow the Base

Address to be Set. To Set The Set Address,

Press and hold the Down button for >2s

Release Button the Light Pattern Will Now Indicate the set Address as Shown in the Table Below.

With the Set Address Lit, the UP and DOWN buttons can now be used to alter the address if required

With the Required Address lit, Press and Hold the DOWN Button Until the LED’s go out. Release the

DOWN button and the new Base Address is Now Set.

Note That with the base address set the LED’s revert to showing what options are active and which of

those options are communicating, see previous section on ‘Module Indications’.

00

08

16

24

01

09

17

25

02

10

18

26

03

11

19

27

04

12

20

28

05

13

21

29

06

14

22

30

07

15

23

31

Setting the base address using the button interface sets the address for all other active options on the

module as follows:

For a Base Address Set of 01:

NOTE: WHEN SETTING ADDRESSES YOU CANNOT HAVE TWO DEVICE ADDRESSES SET THE

SAME ON THE SAME ADDRESSABLE HIGHWAY or DEVICE.

Pellistor Input = Base Address = 01

02 = IR/PID/Toxic or Oxygen Sensor

03 = T102 Port 2

05 = E-Stop

06 = Key Switch

101 = SSR 2

102 = Display Sounder

103 = SSR 3

104 = SSR 4

S YSTEM S TAT U S

EDIT

19

Note when editing if an

Annunciator Display is

fitted the base address

display will also update

UP DOWN

1 2 3 4 5

UP DOWN

1 2 3 4 5

Anything turned off is ignored. Addresses are allocated in the sequence shown above.

1 2 3 4 5 1 2 3 4 5

Doc Ref: SL-065 v1.2 pg 9

Setup and Service Using IGD Android Apps

IGD provide a range of Android based Apps for use with suitable tablets and mobile phones. For control

panels these connect directly using bluetooth. For addressable devices it is necessary to make a direct

USB cable connection using IGD’s interface cable as indicated below. Apps can be downloaded from the

App store.

Interface Cable

PN TOC-CBL-SET

NOTE:

When undertaking work with a

connected tablet ensure the system

controller is placed in INHIBIT mode.

Failure to do so may result in system

errors.

Use the highway options

to view devices on the

same highway. Sort by

address or volt drop

To Edit Channels, Settings or

Addresses on the sampler the

Android unit must be directly

connected to the sampler in

question.

10

Doc Ref: SL-065 v1.2 pg 10

Setup Channels Option

This menu selection gives access to pump settings as follows:

Ideal Typical Flowrate 0.8 to 1.2L/Min

Use the pressure

indication to:

1. Check pump suction

performance by blocking

the inlet line. Minimum

should be a 25mBar

pressure drop.

2.Use to observe the

system running

pressure, typically

10mBar Pressure drop

with new filters.

Sampler low flow threshold. Set this to be 5mBar below maximum pump suction

pressure with the sample line blocked. For example with new internal and EOL filters

fitted the running pressure is 990mBar. With filters removed the running pressure is

1002 mBar. So the filters and sample line impose a 12mBar pressure drop. The

maximum pump suction performance with the line blocked is 967mBar indicating a

25mBar max suction pressure. In this case set the low flow threshold to 20mBar.

Use to turn pump on/off

Use to view pump running

pressure difference on to off

and to ensure pump starts

correctly after tuning

Tune function will

automatically set the pump

optimum operating

frequency.

Manual pump adjustment to

fine tune using attached

flowmeter. Use test or On/Off

buttons to ensure pump reliably

starts after tuning.

Doc Ref: SL-065 v1.2 pg 11

Sample time is the period in seconds that the system runs for before either:

1

Running an auto zero

2

Running an auto calibration (Oxygen samplers)

Turning pump off for 10s for the system to check ambient pressure **

Protect Mode

Gas reading is withing Min to Max Protection

Concentration.

Sample pump is turned off and the zero air

pump is turned on for the sample time

seconds set for the zero pump.

At the end of that period the zero pump is

turned off and the sample pump turned back

on. The system does not start updating the

gas readings until the sample pump purge

time expires.

Note 1.

Most detectors can be set to auto zero.

Ensure either an appropriate scrubber is

fitted to the zero port or the zero port is

tubed away to a ‘clean air’ location. Do

not exceed 20M of tubing.

Note 2.

Oxygen detectors are normally expected

to read 20.9% and so in their case the

sampler can be set to auto-calibrate on

air drawn from a ‘safe’ location. This

could be the sampler location if the

sampler is drawing for example from

another room via its sample tubing.

Alternately the zero port could be tubed

away to a ‘clean air’ location

Note there are selections mentioned

against both the sample and zero

pumps, ensure correct pump is

selected.

Setup Auto Zero/Calibration and Purge Settings

Note:

Any changes to Settings

Must be Stored

12

Doc Ref: SL-065 v1.2 pg 12

Calibration

Zero

Gas

Gas

Zero and Calibration

The following diagram shows the preferred method to

introduce zero and calibration gases to the sampler.

The sampler must not be over or under pressurised

during the zero or calibration process.

With this arrangement set the flow rate from the gas

cylinder such that the flowmeter shows 0.5L/Min of gas

flow spilling off.

This arrangement allows the sampler to take its required

flow rate at close to atmospheric conditions allowing

excess gas to spill off.

Always zero first and then calibrate.

With the Android device

connected to the sampler

comm port as previously

indicated select the Zero/Cal

option

Doc Ref: SL-065 v1.2 pg 13

Zero and Calibration

Flow a suitable zero gas (usually

Nitrogen) allow the graph/reading to

settle (usually 60-90 seconds) and

select ZERO to zero the detector

Now apply calibration gas as

indicated.

The graph should show the signal rise

as the detector responds to gas and

gives a visual indication to show when

the reading has stabilised.

Once the graph shows a flat line and

the reading is stable.

1. Check and enter the calibration gas

value.

2. Select to calibrate

3. Observe the result is within

tolerance

This manual suits for next models

14