Ignis gamma v 2.15 User manual

1 2

IGNIS gamma v 2.15

TMK Września

Ignis gamma v2.15 is a microprocessor temperature regulator to control the central heating boiler with a solid fuel

feeding screw. The Ignis gamma v2.15 controller with room sensor supports the preset room temperatures

according to established time programs.

APPLICATION

The purpose of Ignis gamma v2.15 is automatic control of feeding screw, blower, central heating pump (CH pump)

and feeding pump for tap water container (TW container).

FRONT PANEL

Controls:

feeding pump for TW container

CH pump

blower

feeding

parameter setting MENU ON/OFF MENU navigation and parameter setting

MAIN DISPLAYS

controller

operation status

current

boiler temperature

current

tap water temperature

current

room temperature

boiler

temperature setting current day/hour

controller

daytime

room temperature

for daytime

The main displays operate changing in cyclic mode. The boiler temperature can be set on Display 1 using

buttons and . The arrow we can use to change displays in manual mode. In 30 seconds the controller

returns to its cyclic operation of changing displays.

Mo 12:35

Daily & 21,5*

- day

- day edition

- day selection - copy to other day - daytime

- hour selection

- enter the copy

- reset the day for introduced copy

Mo@ EDIT@

COPY#

Mo (! 7@ &21,0*

^^^^^^& &&&& @

Mo@ COPY

TO )Tu @

)Mo@^^^^^^&&&&&&

&&&&&&&&====

OPERATION

The boiler is fired up in MANUAL MODE (f). To start MANUAL MODE press MENU and next use and .

When the feeder is started wait till coal is delivered to retort then stop the feeder and fire up the coal. The blower can

be used during this operation with its whole range of power.

If there is fire in the whole retort, you can change operation mode into automatic. For this purpose press MENU and

next - START. Operation status changes from STOP to FIRE UP. The blower is working with its maximum

power and the feeder delivers coal regularly.

When the BURNING OUT TEMPERATURE (M) is exceeded controller starts HEAT.

If maximum and minimum power of the blower are different the quantity of delivered air and fuel decreases (feeder

operation time is automatically reduced) as the temperature is drawing near the value preset by user and increases as

the temperature is drawing away.

When the preset temperature is exceeded, the controller changes to HOLD mode. The feeder and blower begin

periodical operation to keep fire on. Whereas, there is possibility to stop blower as in case of using the sawdust as

solid fuel.

If the boiler temperature decreases, controller changes over to HEAT. If the boiler temperature drops below the

value of BURNING OUT TEMPERATURE controller changes to STOP status. However controller cannot

change to STOP, if the FIRE UP (F) time has not been completed since pressing START, that is setting of 1 hour -

made by producer.

The controller operation can be stopped at any time by pressing - STOP. In STOP status the blower and feeder

are stopped.

ROOM TEMPERATURES ROOM TEMPERATURES parameter (a) see page 3.

Controller keeps up the room temperature in three daytimes accordingly;

day period, night period, economy period.

The operator can set different room temperature for each of these periods. If the preset room temperature

is exceeded the CH pump stops and controller changes to HOLD status.

Each day and hour can have any of those period set.

DAYTIME PROGRAM EDITION DAYTIME PROGRAM parameter(b) see page 3

& ^ =

display informs:

Monday

00:00 - 05:59 night period

06:00 - 19:59 day period

20:00 - 23:59 economic period

holding or changes between

copy daytime and an hour selection

!a@ ROOM TEMP.

EDIT#

!b@TIME PROGRAMS

EDIT#

Blower [$ ! 30@%

Feeding [#

!c@ WARM WATER

TEMP: 45)*

!d@ TIME DAY

12:30$ Fr#

HOUR:MINUTES

12:30

TEMP:!&@ &)21,0*

^ 18,0* = 17,0*

!e@ SEASON

WINTER)

!f@ MANUAL

$START$

TAP WATER PUMP (TW PUMP) OPERATION

TW pump starts when the boiler reaches TW PUMP START (H) temperature and keeps working till the container

reaches WARM WATER (c) temperature. The following TW pump start occurs when the container temperature

decrease is equal to TW HYSTERESIS (I). The pump will not start again if the boiler temperature is not

at least 5°C higher than temperature of container (protection for the container against cooling due to over-cooled

boiler).

RESETTING

The flickery arrows ! @ $, # and ) inform which button must be used to operate MENU and make any

resetting.

and are for parameter changing and MENU navigation

and are for MENU navigation

Button enables the following returns to each previous displays till you are back on the MAIN DISPLAY.

If the operator makes any modifications the controller will ask if those modifications are to be entered to memory.

If there is no reaction during 1 minute, controller returns to MAIN DISPLAY and does not introduce any new data.

The other settings can be change after pressing MENU:

, ,

a) room temperature for each daytime

& -day period

^ -night period

= -economic period

b) time programs

daytime for each day and hour daytime - hour , day (see

page 2)

c) tap water container temperature

d) hour setting display

day edition

and hour and minute setting

and active parameter selection

e) the season edition

WINTER - central heating and tap water pumps control

SUMMER - tap water pump control only

f) manual mode on

blower ON( )/OFF( )

feeder ON( )/OFF( )

and blower power increasing and decreasing

] [

] [

MANUAL MODE

Manual mode enables the blower and feeding screw start and stop at any time. Manual mode is very useful

at the firing up process if the feeding screw is empty.

Having the container filled with coal the feeding screw must be started and kept on till the coal appears in the retort.

Next the feeding screw must be stopped and the coal in retort partly fired up. Then the blower must be started

on and its power set accordingly ( percent figure is given on the display). If the coal in retort is completely fired up

the MANUAL mode must be stopped by pushing MENU and next - START.

SEQUENCE OF WIRES CONNECTION

TAP WATER FEEDING PUMP

CENTRAL HEATING PUMP

FEEDING SCREEW

BLOWER

EMERGENCY BLOWER BREAKER

POWER

ROOM TEMPERATURE SENSOR

BOILER TEMPERATURE SENSOR

FEEDER TEMPERATURE SENSOR

TAP WATER CONTAINER

TEMPERATURE SENSOR

WARRANTY

TMK (registered partnership) warrants 3 year product warranty for IGNIS gamma v2.15 controller. Warranty

starts in the day of purchase and cannot be longer than 4 years since production date.

WARANTY CONDITIONS

The warranty is given under condition of the unit application in accordance with this instruction literally and

general rules of the electronic units operation. TMK guarantees correct workmanship, high quality and reliability of

the IGNIS gamma v2.15 controller. In case of any malfunction or defect due to the fault of manufacturer, TMK

undertakes to repair it or replace the controller for a new one in term of 14 days since the fault product return to

producer (personally or by post).

Warranty does not include any damage caused by fault of the user, especially due to mechanical failure, incorrect

assembling, humidity or if the user fails to comply with general rules of electronic units operation.

DATE OF SALE …………………………

…………………………

Stamp and salesman signature

…………………………

MANUFACTURER ADDRESS

TMK sp.j. (registered partnership)

Szosa Witkowska 105

62-300 Września, Poland

Tel./fax +48 61 437 97 60

mail: [email protected]

www.tmk.com.pl

MANUFACTURE DATE

!C@ OPER. TIME

HOLD: 10)s

!D@ BRAKE TIME

FOR HOLD: 30)m

!F@ FIRE UP

TIME: 60)m

!G@ CH PUMP ON

TEMP: 35)*

!H@ TW PUMP ON

TEMP: 30)*

!J@TW PUMP ON

NO )

!I@TW HYSTERESIS

TEMP: 3)*

!L@ BLOWER POWER

MAX: 100)%

!A@ OPER. TIME

HEAT: 10)s

!B@ BREAK TIME

HEAT: 30)s

!E@ BLOW TIME

MULTIPL: 2)

!K@TW HEATING

BOILER>TW C +10)*

OPERATING SETTINGS

To enter the OPERATING MENU press MENU on MAIN DISPLAY and hold it 2 seconds.

A) Feeder operation time for HEAT - the boiler temperature

value.

below the setting

B) Feeder operation break time for HEAT

C) Feeder and blower operation time for HOLD - boiler temperature above the

setting value. The blower operation time can be increased by the blowing

time multiplier (E)

D) Feeder and blower operation break time for HOLD

E) Information how many times the blower operation time

is longer than feeder operation time at HOLD. It informs about the time

necessary for blowing the fire after boiler operation break.

F) Time since the controller operation START during which

the boiler is not OFF in spite of temperature decrease below the value

of BURNING OUT TEMPERATURE .

G) CH pump start temperature

H) TW (tap water) feeding pump starting temperature

I) TW (tap water) container temperature decrease necessary to start the TW

pump.

J) TW (tap water) feeding pump priority towards CH (central heating) pump

K) Increasing the boiler temperature value while TW container is heating up if

this temperature is too low. The higher temperature setting the shorter

heating up time.

L) Blower maximum power.

The blower power upper limit.

IGNIS gamma v 2.15

TMK Września

!M@ BLOWER POWER

MIN: 30)%

!T@ FACTORY SET

$RETURN$

!N@ BOILER OFF

TEMP: 35)*

!O@ FEEDER ALARM

TIME: 5)m

!P@ FEEDER ALARM

TEMP:100)*

!R@CH PUMP START

SUMMER: 80)*

!S@KEEPING BOILER

TEMP NO)

M) Blower minimum power.

The blower power lower limit.

N) The temperature limit below which controller makes the boiler OFF when

the FIRE UP TIME is completed.

O) The coal pushing time when the feeder alarm temperature is exceeded. (To

prevent the flashback from the boiler to coal container).

P) Feeder alarm temperature value. Exceeding this temperature the feeder

starts its operation to withdraw fire from feeder to the boiler. (To prevent

the flashback from the boiler to coal container).

R) CH pump alarm temperature to start CH pump in SUMMER mode. When

this temperature value is exceeded CH pump starts working to cool down

boiler. (To avoid boiling water in the boiler).

S) Parameter informing if in case of CH pump stop due to obtaining the preset

room temperature value,

i) boiler will obtain the preset boiler temperature and keep it ( on

display)

ii) boiler will be in HOLD status till CH pump start (NO on display)

YES

T) Return to the factory settings. Controller makes possible the return to

factory settings. After pressing the question concerning confirmation

of your decision will appear.

Table of contents

Popular Temperature Controllers manuals by other brands

Honeywell

Honeywell FIRE-LITE ALARMS W-H355 Installation and maintenance instructions

Aegis

Aegis ECS-180neo user manual

S+S Regeltechnik

S+S Regeltechnik THERMASGARD RGTF1 Series Operating Instructions, Mounting & Installation

Intertec Data Systems

Intertec Data Systems TC D operating instructions

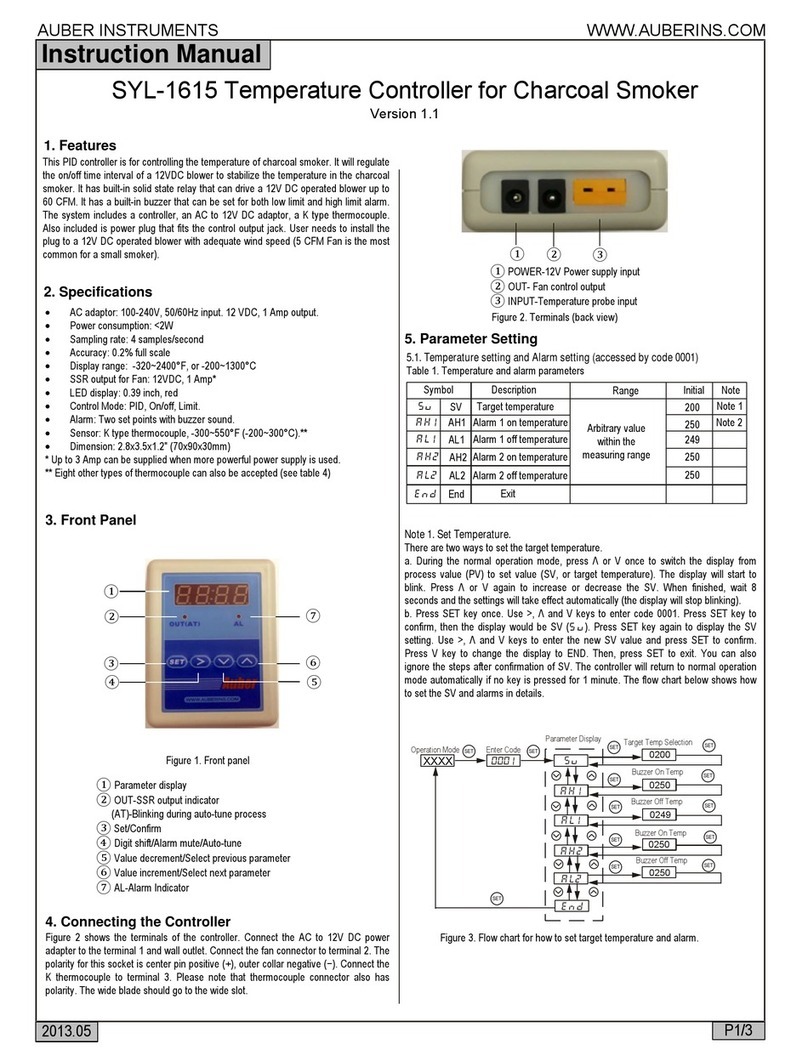

Auber

Auber SYL-1615 instruction manual

Temptek

Temptek Veteran VT LXG Series instruction manual