7

5.3 Auxiliary function setting mode 1

Character

(PV display) Name, Description, Setting range Default value

(SV display)

Set value lock selection Unlock

• Locks the set value to prevent setting errors.

The setting item to be locked depends on the selection.

•If Lock 1 or Lock 2 is selected, PID auto-tuning or auto-reset cannot be carried out.

• (Unlock): All set values can be changed.

(Lock 1): None of set values can be changed.

(Lock 2): Only main setting mode can be changed.

(Lock 3): All set values exceptinput type and Controller/Converter function

can be changed. However, they return to their previous value after power is

turned off because they are not saved in the non-volatile memory. Be sure to

select Lock 3 when changing the set values frequently via communication

function, (If the value set by the communication function is the same as the

value before the setting, the value will not be written in the non-volatile memory.)

Do not change anysetting item in Auxiliary function settingmode 2. If any item in

themode is changed, it will affect other setting itemssuchas SV and Alarm value.

Sensor correction setting 0.0

• Sets the sensor correction value for the sensor.

• Thermocouple, RTD input: –100.0 to 100.0 ( )

DC voltage, current input: –1000 to 1000 (The placement of the decimal

point follows the selection)

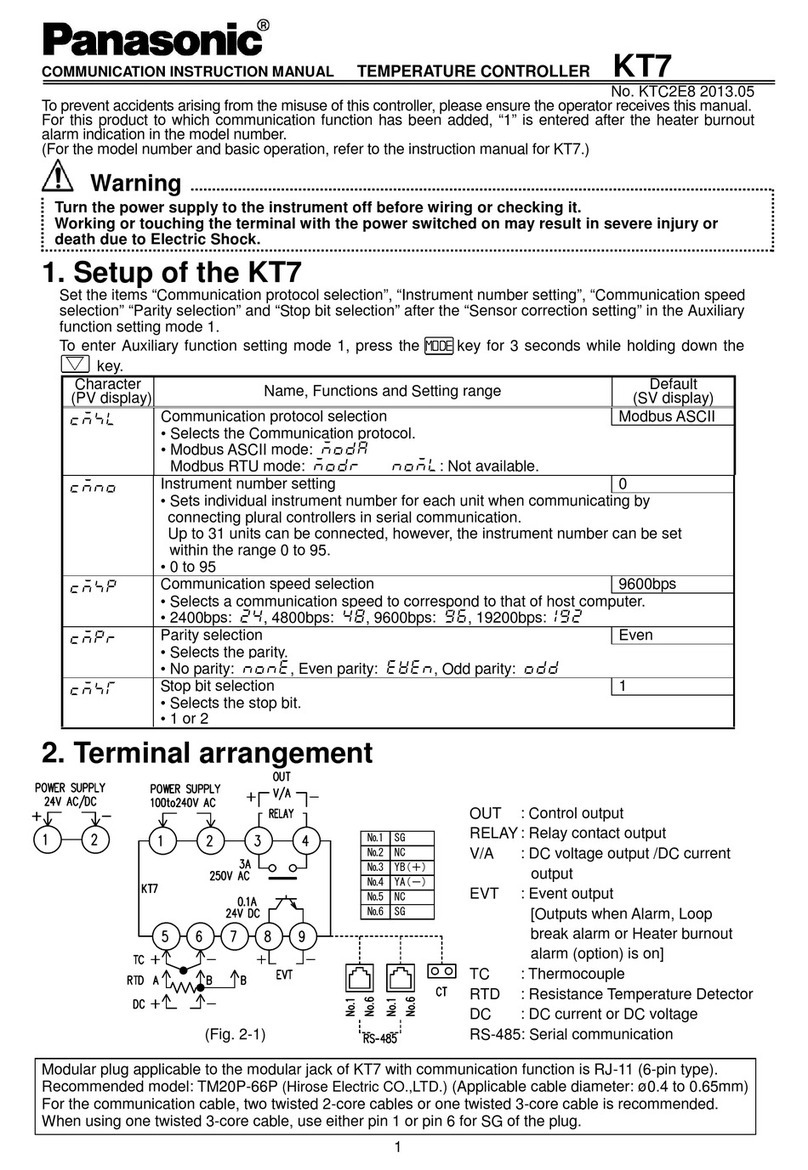

Communication protocol selection

• Selects the communication protocol.

• Available only when Serial communication (option) is applied.

• Not available if is indicated

• Modbus ASCII mode: , Modbus RTU mode:

Instrument number setting 0

• Sets the instrument number. (Communication cannot be carried out unless an

instrument number is individually set when communicating by connecting plural

instruments in serial communication.)

• Available only when Serial communication (option) is added.

• 0 to 95

Communication speed selection 9600bps

• Selects a speed to be equal to the speed of the host computer.

• Available only when Serial communication (option) is added.

• 2400bps: , 4800bps: , 9600bps: , 19200bps:

Parity selection Even parity

• Selects the parity.

• Not available if Serial communication (option) is not added or if

is selected during the Communication protocol selection.

• No parity: , Even parity: , Odd parity:

Stop bit selection 1

• Selects the stop bit.

• Not available if Serial communication (option) is not added or if

is selected during the Communication protocol selection.

• 1 or 2

5.4 Auxiliary function setting mode 2

Character

(PV display) Name, Description, Setting range Default value

(SV display)

Input type selection

• Theinput type can be selected from thermocouple (10 types),RTD K

(–200 to 1370 )

(2 types), DC current(2 types) and DC voltage(4 types), and the unit / can be selected.

K –200 to 1370 : K –320 to 2500 :

–199.9 to 400.0 : –199.9 to 750.0 :

J –200 to 1000 : J –320 to 1800 :

R 0 to 1760 : R 0 to 3200 :

S 0 to 1760 : S 0 to 3200 :

B 0 to 1820 : B 0 to 3300 :

E –200 to 800 : E –320 to 1500 :

T –199.9 to 400.0 : T –199.9 to 750.0 :

N –200 to 1300 : N –320 to 2300 :

PL- 0 to 1390 : PL- 0 to 2500 :

C (W/Re5-26) 0 to 2315 : C (W/Re5-26) 0 to 4200 :

Pt100 –199.9 to 850.0 : Pt100 –199.9 to 999.9 :