IHNE & TESCH HAK User manual

INSTRUCTIONS FOR USE OF HAK HEAT-COOL COMBINATIONS

IMPORTANT: READ THROUGH THE INSTRUCTIONS CAREFULLY BEFORE USE AND KEEP IN A SAFE

www.electricalheat.com

ITE-KIT-HCC-001 09/2020

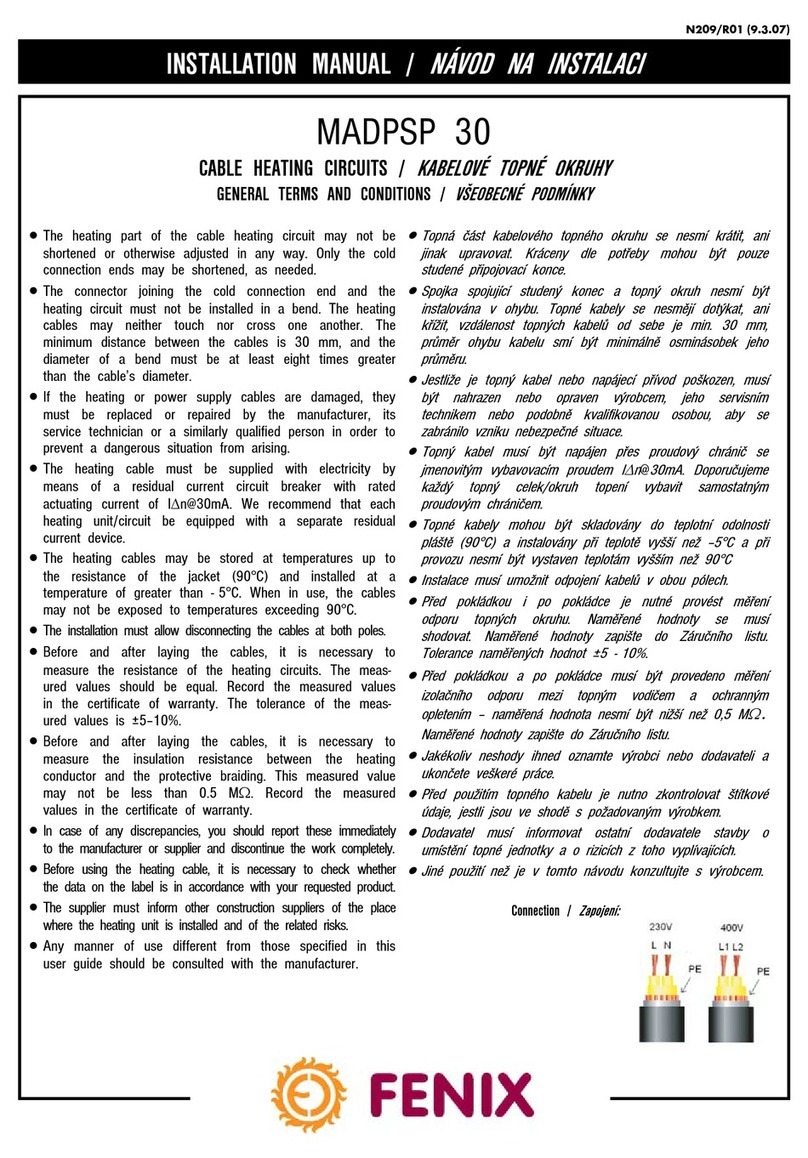

4. Connection

Caution: Electrical connections !

The electrical connection must only be performed

by qualified electricians or persons trained in elec-

trical safety. Work on equipment must be carried

out with the equipment disconnected from the

mains. It must also be ensured that the equipment

cannot unintentionally be made live again.

Note the connection voltage!

Standards and specifications for electrical work

must be observed. Particular attention must be paid

here to conformity of the operating voltage (as em-

bossed on the equipment) with the supply voltage.

4.1 Protective conductor

It is imperative that the protective conductor is con-

nected, where available. Otherwise the connection

of the protective conductor of the heating system

must be checked as part of the mechanical connec-

tion to the machine.

4.2 Ex area

Operation of the heating systems in an Ex area is

not permissible.

4.3 Connecting line

To avoid short circuits, the connecting lines must

be routed such that they cannot come into contact

with sharp edges or objects. It must be ensured that

the terminal area is protected against the penetrati-

on of materials (e.g. oils, plastics, moisture, greases

and gases).

Note:

The appropriate connection variant for the terminal area

(e.g. cables, stranded wires, connectors, busbars etc.) must

be chosen depending on the ambient temperatures.

5. Technical data

5.1 Surface temperature

The specifications given below are maximum values for the

heating side and must not be exceeded:

HAK type: 450 °C max.

6. Disassembly + assembly

The heat-cool combinations are delivered fully assembled

for transport and insurance reasons. Disassembly and as-

sembly must be carried out as described below to achieve

the positive-locking fit required for operation.

6.1 Disassembly

Step 1: Open and remove the upper half of the cooling

jacket.

Step 2: Loosen clamping screws of cup spring caps on

the top heat-cool segments and then open these

segments.

Step 3: Loosen the retaining straps on the lower half of

the cooling jacket and remove the screws and

transport ring.

Ready for installation !

Dear customer,

Thank you very much for placing your trust in heating ele-

ments from Keller Ihne + Tesch, part of the IHNE & TESCH

Group. We have been developing and producing high-

quality electrical heating technology of the kind you have

opted for since 1932.

1. General

Our heating elements are high-quality products made in

Germany that have be subjected to rigorous quality checks

throughout all stages of development and production. A

high degree of vertical integration and the many years of

experience of our employees ensure that our high level of

performance can be maintained.

This quality standard will give you a guarantee of continued

reliable use of the heating elements over long periods of

time, provided that the technical information set out below

is observed.

If you have any other questions on installing and using the

heating elements or any of our other products not covered

in the information below, our field service sta and sales

engineers will be happy to help.

Our heating systems conform to the applicable provisions

of relevant EU directives and Equipment and Product Safe-

ty Act and bear the CE mark.

2. Applications

Our heat-cool combinations are ideal for heating and coo-

ling solids (extruder and injection moulding applications).

The heating elements are components, not operational

devices. They are intended for use in industrial electrical

heating systems.

3. Safety information

The instructions for use must be read carefully and under-

stood prior to commissioning the heating systems. Incor-

rect assembly, selecting the wrong heating system and

regulating a heating system incorrectly will cause defects

and accidents.

For safety reasons, the heating systems may only be used

for the applications described in these instructions for use.

General operating instructions and safety information must

be observed. When assembling the system, the safety ins-

tructions relevant to the installation location and generally

accepted technical rules and standards must be observed.

Heating systems must not under any circumstances be

commissioned if there are visible signs of (transport) dama-

ge.

Heating systems must not be commissioned until it has

been ensured that the insulation resistance is ≥1 MOhm.

The surface temperature of the heating systems must not

cause the temperature of the material to be heated to rise

to a critical level that could, for example, trigger a fire, ex-

plosion, the emission of smoke or gas, etc.

The heating systems must not be commissioned until they

have been mounted such the entire contact surface cannot

move.

Operating conditions other than those described in the

instructions for use will cause heating systems to malfunc-

tion or fail. Special applications must be approved by IHNE

& TESCH, Keller Ihne + Tesch.

Caution: Risk of combustion!

High temperatures occur during operation. All sur-

faces must be cold (≤40°C) when performing work

on heating systems.

INSTRUCTIONS FOR USE OF HAK HEAT-COOL COMBINATIONS

IMPORTANT: READ THROUGH THE INSTRUCTIONS CAREFULLY BEFORE USE AND KEEP IN A SAFE

www.electricalheat.com

ITE-KIT-HCC-001 09/2020

6.2 Assembly

Step 1: Mount the open system across the diameter of

the machine and provisionally fix in place with

side mounting braces. Close the heat-cool

segments and screw the clamping screws of the

cup spring caps on these segments to the lower

heat-cool segments.

CAUTION: Ensure a positive-locking construction and an

even clamping gap on the heat-cool segments!

Step 2: Tighten the clamping screws to a torque of

8.5 Nm and the clamping screws with cup

springs to 20 Nm (when cold). The expansion

compensation required at operating state tem-

perature to maintain functionality must be ensu-

red. In the case of heater bands with clamping

screws, the heating systems must be retigh-

tened during the first heating-up period to ensu-

re that the heating systems are sitting correctly

in relation to the metal insert to be heated.

Step 3: Place outer shell of cooling jacket in place and

screw down.

Ready for connection!

Heating systems may be destroyed by overheating if they

are not connected with a positive-locking fit.

It must be generally ensured that no mechanical damage

can be caused by external impacts, such as moving parts.

7. Operating conditions

7.1 Temperatures

The connecting lines must be protected against tempera-

ture eects or be designed to withstand them.

7.1.1 Temperature control

Heating systems can absorb moisture during storage or

storage in the wrong conditions, so they must be fitted with

temperature control with start-up circuitry.

7.2 Protection against accidental contact, dust and

moisture

The heating systems must be protected against contact,

dust and moisture according to the ambient conditions.

During operation, it is particularly important to prevent the

ingress of any foreign matter such as oil, water, plastic etc.

7.3 Storage

If storing for a prolonged period of time (several months), it

must be ensured through measures within the system that

the insulation resistance will drop.

Heating systems must not be commissioned until it has

been ensured that the insulation resistance is ≥1 MOhm.

Note:

We recommend that heating systems are stored in a dry

environment and that a suitable desiccant is added as

appropriate.

7.4 Disposal

Disposal must be carried out in accordance with statutory

regulations.

8. Troubleshooting and remedy of faults

Fault Possible cause Remedy

Not heating No mains voltage

present

Loose mains

connection

Torn connection

Heater band

faulty

Check/replace fuse,

switch on the switch

Tighten the mains con-

nection

Replace the heating

system

Replace the heater band

Insucient

heating

Incorrect heater

band, loose hea-

ter band

Incorrect opera-

ting voltage

Replace the heater band

Tighten the heater band

so that a positive-locking

fit is created

Connect the prescribed

supply voltage

Excessive

heating

Incorrect opera-

ting voltage

Construction of

heating elements

Connect the prescribed

supply voltage

Retighten the heater band

Heater

bands

cannot be

mounted

Diameter not

correct

Transport/sto-

rage damage

Readjust the heater band

diameter

Replace the heater band

Publisher:

Ihne & Tesch GmbH

Am Drostenstueck 18

D-58507 Luedenscheid

Phone: +49 2351 666 0

Fax: +49 2351 666 24

www.electricalheat.com

ITE-KIT-HCC-001 09/2020

Subject to changes

Popular Heating System manuals by other brands

flowair

flowair EX LITE Technical documentation operation manual

Viessmann

Viessmann AC-Box Installation and service instructions for contractors

HEATIZON SYSTEMS

HEATIZON SYSTEMS Gutter Melt SR Design & Installation Manual

Innova

Innova EF40 Series Installation, instruction and service manual

DEVI

DEVI DEVIcomfort 10T installation guide

Armcor

Armcor 0AP900 Installation and operation manual

Juwent

Juwent TROPIC-1 Original instruction manual

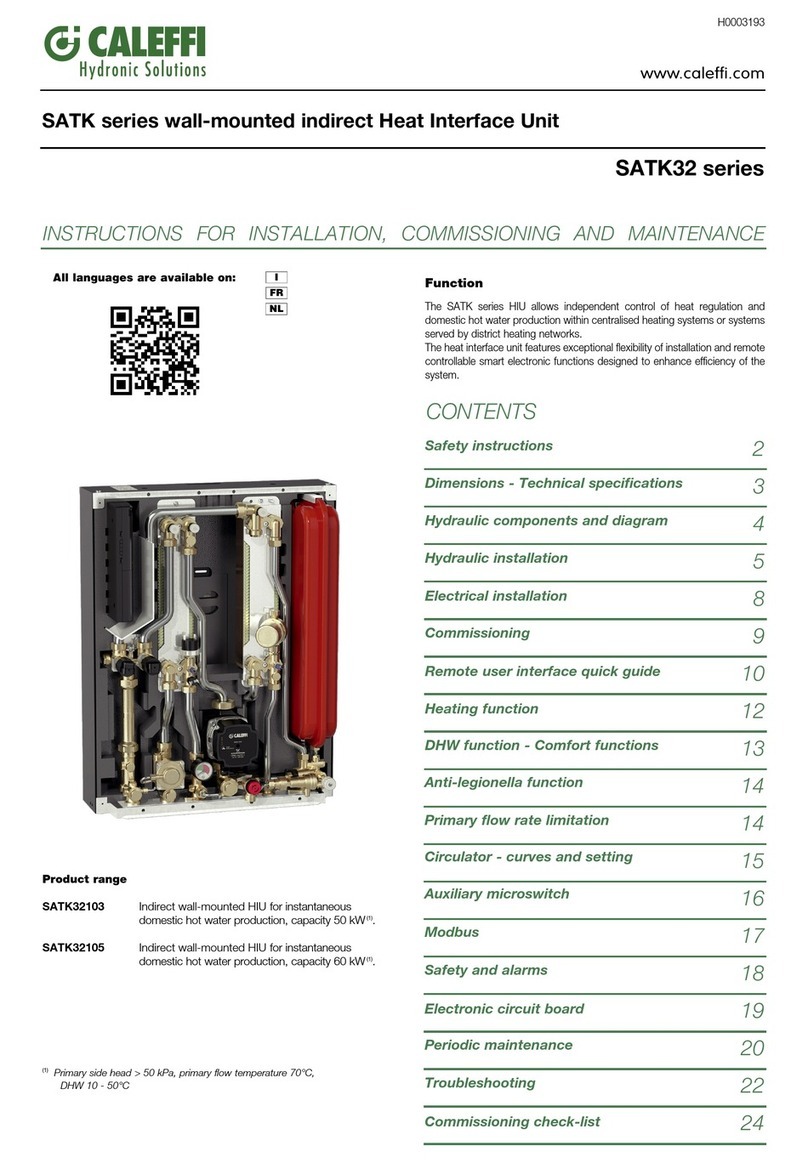

CALEFFI

CALEFFI SATK32105 INSTRUCTIONS FOR INSTALLATION, COMMISSIONING AND MAINTENANCE

Vortice

Vortice VORT HR 350 AVEL Instruction booklet

Titon

Titon HRV1 Q Plus product manual

General Pipe Cleaners

General Pipe Cleaners Hot-Shot 320 operating instructions

TEHNISCHE ALTERNATIVE

TEHNISCHE ALTERNATIVE ATON EHS-R user manual