HEATIZON SYSTEMS Gutter Melt SR User manual

www.heatizon.com

© 2017 Heatizon Systems

HEATIZON SYSTEMS

RADIANT HEATING AND SNOW MELTING SYSTEMS

GutterMelt® SR is a registered trademark of Heatizon Systems.

®

07-17

2

3

Table Of Contents:

Product Overview………………………………………………………………..…………………….………….4

Cable Specifications…………………………………………………………..……………….………………...5

Warnings and Reminders………………………………………………………………….…………………….6

GutterMelt®SR Cable Layout Design Guidelines …………………………………………………………..7

GutterMelt®Accessories………………………………………………………………………………………...9

GutterMelt®Activation ...……………………………………………………………………………………….11

Design and Installation………………………………………..……………………………….....……………13

Resistance Recording Page ..……………………………………………………….………………………..18

Warranty…………………………………………………………………..……………………………..………..19

Note: Before proceeding with the installation of GutterMelt SR Cable, be sure to read the entire manual.

4

Heatizon Systems GutterMelt®SR rain gutter, eaves trough, downspout, and eave

deicing systems provide heat to maintain water flow paths on eaves, and in gutters,

downspouts and drains. This heating cable is placed directly on top of the roofing

material and/or in the rain gutter, downspouts and drains of a building. Heatizon

Systems products can be activated by a large variety of activation alternatives ranging

from a simple switch to an automatic temperature moisture sensor.

ADVANTAGES

•Prevents costly damage to roofs, gutters and downspout drains by providing a path for water to exit

•May be applied anywhere snow or ice can accumulate

•May be used on all types of standard roof covering material

•May be installed in rain gutters and downspouts made of metal, plastic, etc

•Industry leading warranty - designed for reliability

•GutterMelt®SR is available in 5, 9, and 12 Watts/ft. Special orders deliver up to 24 Watts per foot at 32°F in iced water

•Field cut to length

• Many activation options including temperature/moisture sensors

• Finest quality SR cable available

FAST & EASY INSTALLATION

Heatizon Systems GutterMelt®SR system utilizes easy to install

SR cable to provide reliable freeze protection of roofs, gutters,

downspouts and roof drains. Simply run the cable in gutters

using foil tape with pressure sensitive adhesive to secure cable

placement, or Heatizon roof clips (Heatizon Part #HT386530 or

#HT386530R). Roof clips attach the cable to standard roof

covering material. The cable can also be inserted in downspouts

using downspout hangers or brackets (Heatizon Part #HT38411

or #HT386412) to support the heating cable. GutterMelt® SR

cable may be cut to length in the field making installation easy

and convenient.

VALUE

Winter has many freeze thaw cycles that can cause millions of dollars

of damage to roofs, gutters, downspouts, and drains every year. As

winter progresses buildings experience ice buildup which can lead to

roof damage, or damage caused by snow and ice falling from the roof.

These cycles can cause ice to accumulate and back up under

shingles, resulting in ice dams. In some cases, damage appears in the

form of soaked insulation, stained, cracked and damaged sheet rock,

damp, smelly, rotting wall cavities and stained, blistered and peeling

paint. Heatizon Systems has the products and expertise to effectively

solve potential winter issues and protect your investment by

managing ice dams, minimizing icicles, and keeping ice from

accumulating in gutters and downspouts.

What GutterMelt won’t do?

• Prevent snow movement on/off the roof

• Remove accumulated snow and ice from roofs, gutters and

downspouts

•

••

•Gutters •

••

•Downspouts •

••

•Roof Eaves

ENERGY EFFICIENT AND COST EFFECTIVE

GutterMelt®SR is 100% efficient and automatically adjusts its heat output and energy consumption as the temperature conditions

change. When precipitation is expected, simply energize the cable. The cable provides maximum melting power when snow or

ice is present, but will automatically regulate its output and save energy when the roof and gutters are clear of snow and ice.

5

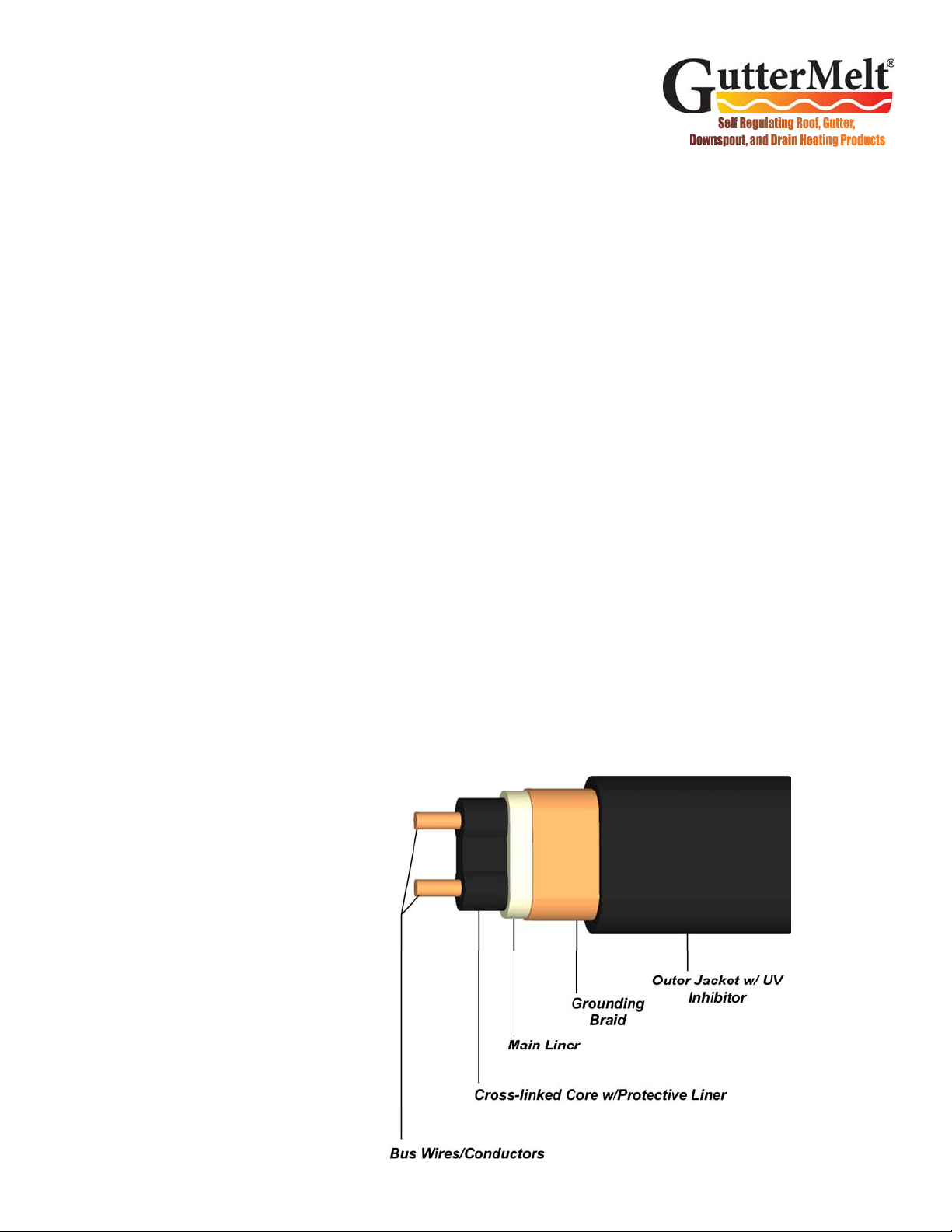

Self-Regulating Cable

Phase Conductor

Neutral Conductor

Ground Shield

120VAC, 277VAC

Connection

Phase Conductor

Phase Conductor

Ground Shield

208VAC, 240VAC

Connection

Electrical Connection Wiring

Note: GutterMelt®SR should be stored in a cool,

dry location.

Note: It is important that GutterMelt®SR be

installed only by qualified persons who are familiar

with the proper sizing, installation, construction and

operation of snow melting systems and the hazards

involved. GutterMelt®SR products are designed for

on roof, in rain gutter, and in downspout drain

applications.

Note: GutterMelt®SR must be installed in

accordance with the manufacturer’s installation

instructions, as well as with the National Electric

Code (NEC) and Canadian Electrical Code (CEC),

part 1, and local codes and regulations.

Note: Ground fault protection must be used when

installing all GutterMelt®SR products. Refer to the

NEC or CEC for specific requirements.

Note: Do not bend GutterMelt® SR Cable within

1.6” (40mm) of a termination or connection

between the GutterMelt®SR Heating Element and

the cold lead or power connection.

Required Tools:

2500VDC Megohmmeter

Digital Multimeter (DMM)

Screwdrivers

Wire Stripper

Crimping Tool

Utility Knife

Heatshrink Heating Device

GutterMelt® SR Cable Specifications

Watts per linear foot at

32°in iced water 5 9 12

Cable type Self Regulating (SR)

Copper bus wire 22 AWG Min

Maximum maintenance

temperature 185ºF (85ºC)

Maximum intermittent

exposure temperature

212ºF (100ºC)

T rating: T5

Voltage AC 120, 208, 240, 277

Maximum length Refer to product label

Approximate thickness/

width 0.25” x 0.50”

Bending radius 1”

Minimum spacing 2”

Standard spacing along

eave 18” to 24”

6

Warnings

•Failure to follow this Design and Installation Manual and/or

incorrect design, installation, handling or maintenance of

product may cause electrical shock, injury, damage or fire

•Disconnect all power to GutterMelt®SR and its activators prior

to handling, replacing or servicing

•Read this entire Design and Installation Manual prior to installing

GutterMelt®SR

•Do not twist, kink, or spiral GutterMelt®SR

•Always test GutterMelt®SR with a Megohmmeter Tester prior

to installing, once installation is complete, and prior to

energizing. All Megohmmeter tests must be performed at the

power termination of the GutterMelt®SR cable, between the

braided shield and the core wire(s)

•The minimum installation temperature is 40°F (5ºC)

•Use only copper wire from the distribution panel to the

GutterMelt®SR cable

•Do not allow the GutterMelt®SR Heating Element to touch or

cross other electrical conductors or gas lines

•GutterMelt®SR’s braid shield must be grounded to a suitable

earth ground

•Do not exceed the maximum circuit lengths listed in this Design

and Installation Manual

Always remember to test the insulation

resitance using a 2500 VDC Megohmmeter,

verify and record the actual results at specific

points throughout the installation process. A

resistance recording page is included in this

manual for this purpose. If the taken readings

are at anytime less than 20 megohms

replace or repair the damaged cable. Do not

energize the damaged GutterMelt®SR, and

call Heatizon Systems.

Roll the GutterMelt®SR spool to unreel the

heating element. Do not pull GutterMelt® SR

from the spool.

Verify that the supply voltage matches the

design voltage of the GutterMelt®SR product

you have purchased.

To avoid the hazard of electric shock,

disconnect all power prior to beginning

installation of GutterMelt®SR. Effectively

ground all installations prior to installing the

GutterMelt®SR Heating Element in

accordance with CSA Standard C22.1,

Section 10, and with the NEC.

Contact Heatizon Systems at 888-239-1232

with any additional questions you may have.

Reminders

Heatizon

GutterMelt®SR Cable

Available in 5W/ft, 9W/ft, & 12W/ft

7

GutterMelt®SR Cable Layout Design Guidelines

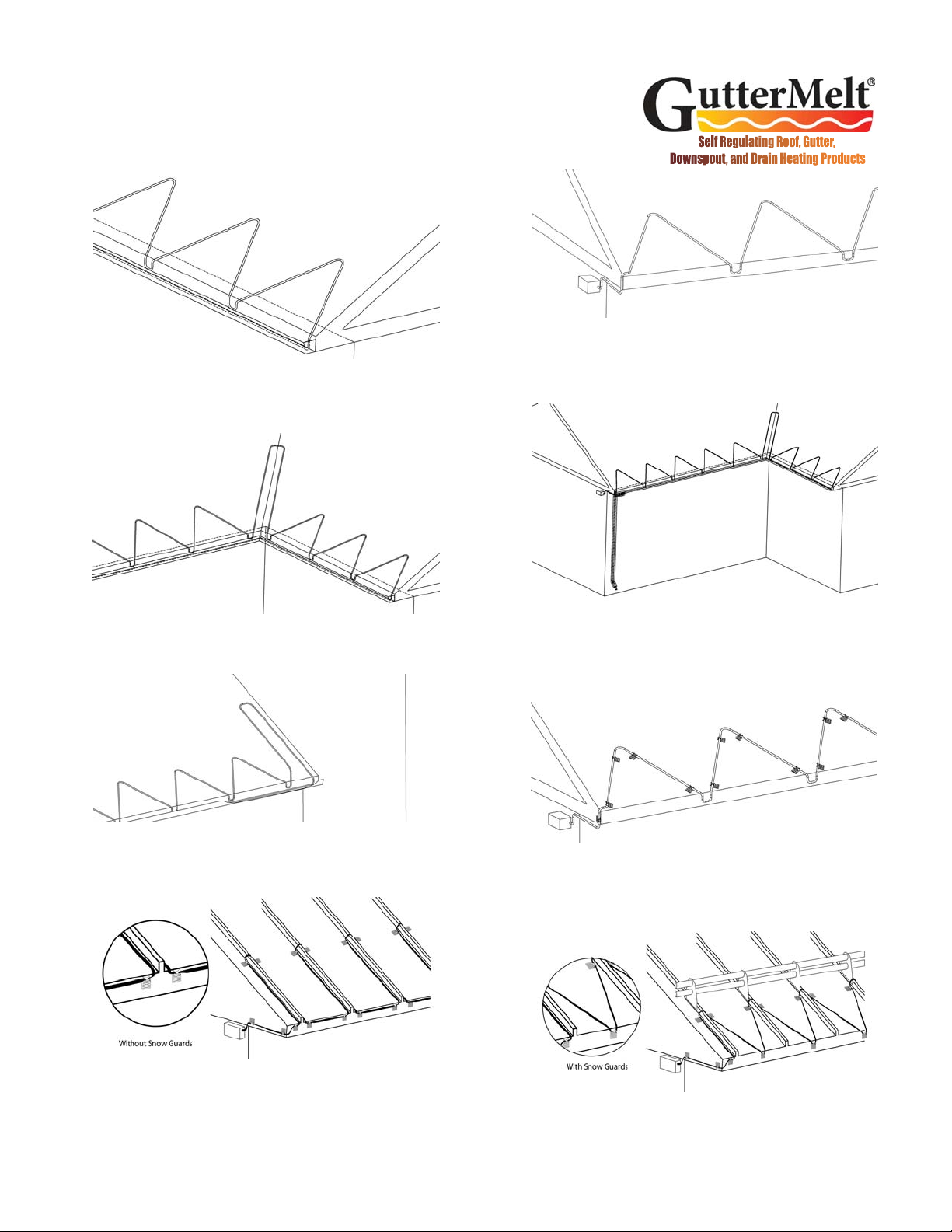

Sloped Roof with Gutter. Run GutterMelt®up the roof until it extends

6” to 12” inside the exterior (cold) wall. Extend at least 2 to 3 inches into

the gutter with each loop.

Valleys. Extend GutterMelt®a minimum of two-thirds of the way up each

valley with a double run of GutterMelt®, as shown above.

Roof Intersection. Extend a loop of GutterMelt®a minimum of two-

thirds of the way up the slope, positioning the cable not more than 2 to 3

inches away from the adjacent wall.

Sloped Roof without Gutters. Heatizon recommends heated gutters

and downspouts to provide a continuous path for water. If a gutter is not

used, extend a drip loop of GutterMelt®cable past the shingle overhang

to allow water to drip free of the roof edge.

Roof Clips on a Sloped Roof with Asphalt Shingles. (Heatizon Part #

HT386530 or HT386530R)are attached with a screw or nail, GutterMelt®

cable is installed, then a water-sealing caulking is applied around the

clips, screws, and nails to prevent leaks.

Sloped Roof with Gutter and a Valley. Extend GutterMelt®a minimum

of two-thirds of the way up each valley. Extend the GutterMelt®into the

gutter. If there is no gutter, the GutterMelt®cable should extend past the

shingle overhang to allow water to drip free of the roof edge.

Standing Seam Roof without Gutters. Heatizon recommends heated

gutters and downspouts to provide a continuous path for water. The

cable is installed up and down each seam traveling to the next seam

along the roof face to protect it from sliding snow.

Standing Seam Roof without Gutters but with Snow Guards.

Heatizon recommends heated gutters and downspouts to provide a con-

tinuous path for water. If snow guards are used a zig zag pattern can be

used below the snow guards since the snow guards provide protection

for the cable. Install roof clips along the front face of the roof eave from

water to drain from the roof.

8

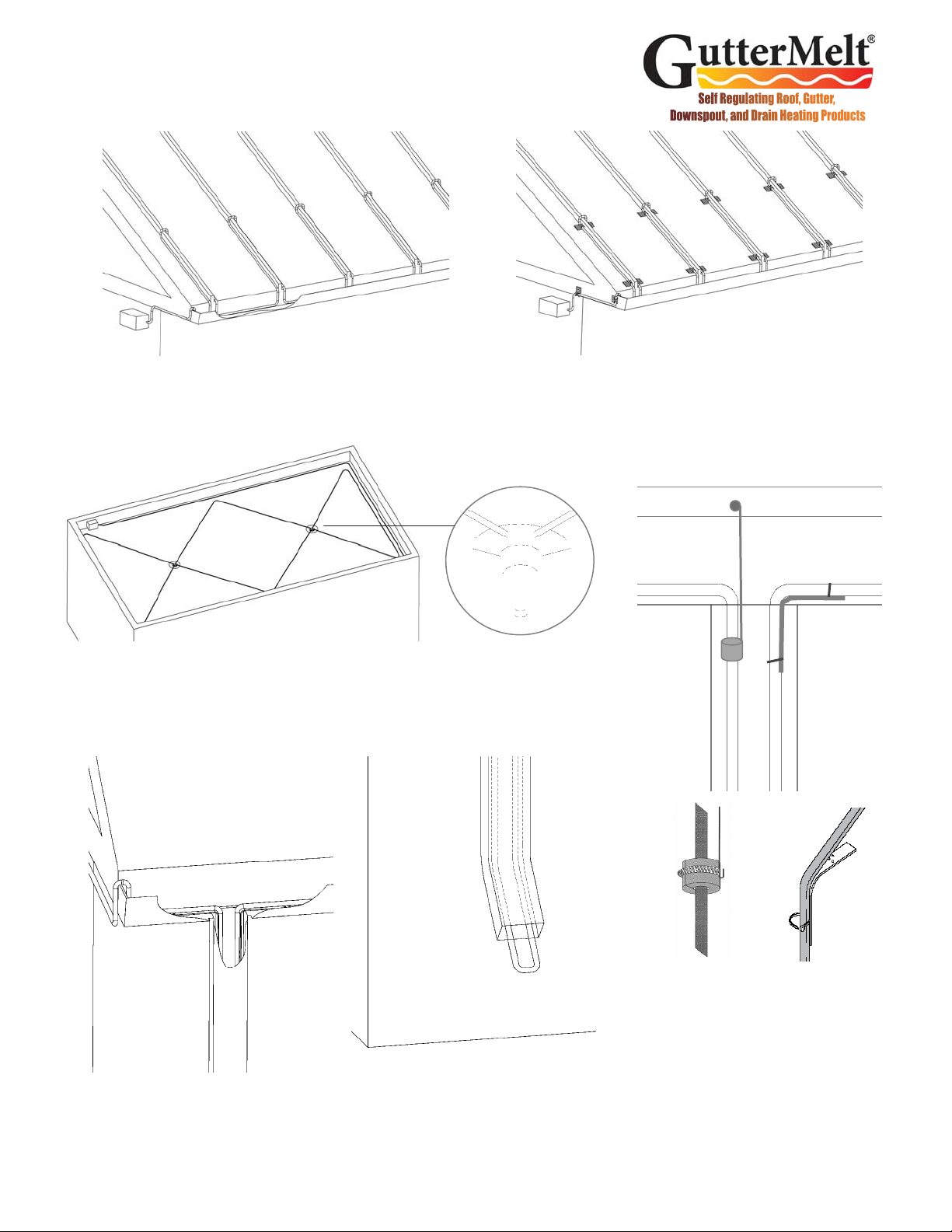

Roof Clips on Standing Seam Roof with Gutter. Roof Clips

are attached using Roof Clip Adhesive (Heatizon Part #

HT386530AD). Attach the clips to the roof and allow adhesive

to cure before threading cable through the clips.

Standing Seam Roof with Gutter. Run GutterMelt®up the

seam until it extends 6” to 12” inside of the exterior (cold) wall.

Extend at least 2 to 3 inches into the gutter with each loop.

Downspout Attachments and Sharp Edge

Protection. Use Downspout Hanger Kit

(Heatizon Part # HT386411) or Downspout

Hanger Bracket Kit (Heatizon Part #

HT386412) to attach GutterMelt®in down-

spout or drain to prevent damage to cable.

Downspouts. A continuous path for melt water can be maintained by running the Gut-

terMelt®inside the downspout to the bottom, and extend a small drip loop at the bottom

of the downspout. If the downspout drain extends below grade, GutterMelt®Cable

should extend into a heated area or below the frost line to effectively protect downspouts

and drains.

Downspout

Hanger Kit

Downspout Hanger

Bracket Kit

GutterMelt®SR Cable Layout Design Guidelines

Flat Roof. Position GutterMelt®heating cable around the perimeter of a flat roof. Run

GutterMelt®in valleys from the perimeter to the drain and extend the GutterMelt®

cable into drains and downspouts so that cable extends at least 12 inches into interior/

heated space.

9

GUTTERMELT® ACCESSORIES

Part Number Product Usage/Description

HT386530 Roof Clips,

Steel

•Use to attach GutterMelt® heating cable to roof surface

•Five (5) Double or ten (10) Single Clips per package

•Accommodate approximately 7 linear feet of GutterMelt®

cable

•Attached with a mechanical fastener or approved adhesive

sealant

HT386530R Roof Clips,

Aluminum

•Use to attach GutterMelt® heating cable to roof surface.

•HT386530R includes 10 clips—enough for approximately

7 eave feet of GutterMelt® cable

•Attached with a mechanical fastener or approved adhesive

sealant

HT386411

Downspout

Hanger Kit

•Use to suspend GutterMelt® heating cable in a gutter,

downspout or drain

•Attached with a mechanical fastener

•Includes three (3) downspout hanger assemblies

•Prevents heating cable from being damaged at gutter-to-

downspout and other transition points

HT386412

Downspout

Hanger Bracket

Kit

•Used to suspend GutterMelt® in downspout or drain

•GutterMelt® is secured to angled bracket; no fasteners

required

•Includes UV resistant plastic wire ties

•Includes two (2) downspout hanger bracket assemblies

•Prevents heating cable from being damaged at gutter-to-

downspout and other transition points

HT386521M End Seal Kit

•Use to terminate and seal the non-powered ends of

GutterMelt® heating cable

•Materials for three (3) end seals

•Provides water resistant seal

HT386505M Power

Connect Kit

• Use to terminate one powered end of GutterMelt® heating

cable into a junction box and to seal off one non-powered

end of cable

• Used for a hard-wired connection to supply power

• Includes materials for one (1) power connection assembly

• Includes one (1) end seal for non-powered cable end

HT386513 Splice Kit

• Connect two heating cables together

• Creates a water-resistant connection

• Spice Kit contains materials for two (2) splice connections

HT386513T Tee Kit

• Connect heating cables together to make a tee connection

• Creates a water-resistant connection

• Tee Kit contains materials for four (1) Tee connection

• Includes one (1) end seal for non-powered cable end

• Includes sealant and wire ties

10

GUTTERMELT® ACCESSORIES

Part Number Product Usage Description

HT393473

10 Amp,

120VAC Plug in

Cord Set with

GFCI

•Used to terminate one GutterMelt® cable

•Includes one (1) connection assembly, one (1) end seal assembly,

and 1200 Watt three (3) foot cord

•Will work with up to 75 feet of 12W 120VAC, 100 feet of 9W

120VAC, or 190 feet 5W 120VAC GutterMelt® SR Cable

•Contains GFCI with 30mA test and reset

•Power “ON” indicator light

HT393473-120

20 Amp,

120VAC Plug in

Cord Set Kit

with GFCI

•Used to terminate one GutterMelt® cable

•Includes one (1) connection assembly, one (1) end seal assembly,

and 2400 Watt eight (8) foot cord

•Will work with up to 150 feet of 12W 120VAC, 200 feet of 9W

120VAC, or 300 feet 5W 120VAC GutterMelt® SR Cable

•Contains GFCI with 30mA test and reset

•Power “ON” indicator light

•Requires NEMA5 20 Amp Outlet Receptacle

HT393473-120-15

15 Amp,

120VAC Plug in

Cord Set Kit

with GFCI

•Used to terminate one GutterMelt® cable

•Includes one (1) connection assembly, one (1) end seal assembly,

and 2400 Watt eight (8) foot cord

•Will work with up to 115 feet of 12W 120VAC, 150 feet of 9W

120VAC, or 300 feet 5W 120VAC GutterMelt® SR Cable

•Contains GFCI with 30mA test and reset

•Power “ON” indicator light

•Requires NEMA5 20 Amp Outlet Receptacle

HT393473-PT

15 Amp,

120VAC Plug-

in Pig Tail Set

•Used to terminate one GutterMelt® cable

•Includes one (1) connection assembly, one (1) end seal assembly,

and eight (8) foot cord

•Will work with up to 115 feet of 12W 120VAC, 150 feet of 9W

120VAC, or 300 feet 5W 120VAC GutterMelt® SR Cable

•Standard Nema5 plug on one end, stripped wires on other end

HT393473-240

20 Amp,

240VAC Plug in

Cord Set with

GFCI

•Used to terminate one GutterMelt® cable

•Includes one (1) connection assembly, one (1) end seal assembly,

and 4800 Watt eight (8) foot cord

•Will work with up to 305 feet of 12W 240VAC, 390 feet of 9W

240VAC, or 660 feet of 5W 240VAC GutterMelt® SR Cable

•Contains GFCI with 30mA test and reset

•Power “ON” indicator light

•Requires NEMA6 20 Amp Outlet Receptacle

HT386530AD Roof Clip

Adhesive

•A 10.3 oz cartridge adhesive that is versatile, high strength, one

part, hard setting, pick proof, with superb tensile strength

•2000 psi tensile strength, tack free 18-24 hours, 50°F min install

•One cartridge covers about 30-40 roof clips

HT376548 Application

Tape •Used to secure GutterMelt® cable inside gutters or around pipes.

•Aluminum Application Tape, 150 ft. Roll

11

GUTTERMELT® ACTIVATION

Part Number Product Usage Description

M307

Plug In

Thermostatically

Controlled Device

Plugs into a 120VAC outlet and turns on

when temperature drops to 38ºF or less.

M325 Timer—12-hour

12 hour timer that can operate system from

0 to 12 hours. Features “hold” position; No

power required.

M326A

Temperature Moisture

Sensor - One 30A

Contact

Activates System when moisture is detected

and temperature is below set point. Leaves

system on for up to 6 hours. Requires 100-

277VAC, Switches up to one 30A Loads.

M326A-2Z

Temperature Moisture

Sensor - Two 30A

Contact

Activates System when moisture is detected

and temperature is below set point. Leaves

system on for up to 6 hours. Requires 100-

277VAC, Switches up to two 30A Loads.

M326ARS

Temperature Moisture

Sensor - with Gutter

Mounted Sensor - One

30A Contact

Activates System when moisture is detected

and temperature is below set point. Leaves

system on for up to 6 hours. Requires 100-

277VAC, Switches up to one 30A Loads.

M326CDP

Snow & Ice Sensor/

Controller Display Panel

option

Snow & Ice Sensor/Controller Display Panel

option for M326A Series Sensor line. Can

control, monitor and override the Ice and

Snow Sensor/Controller from remote

locations. Monitor the status, operating

mode and activation state of the sensor.

Requires no batteries or AC power - uses

power from the snow sensor. May be

installed as much as 800 feet away from the

snow sensor.

M336 Series Electronic Temperature

Controller

Electronic Temperature Controller with liquid

crystal display to produce constant readout.

Touch keypad to program wide set point

temperature range (-30°F to 220 °F) and

differential adjustment (1°F to 30°F).

Remote temperature sensing up to 400 feet.

Requires 120VAC or 240VAC to operate.

Also available with 2 Stage Temp Control.

12

GUTTERMELT® ACTIVATION

Part Number Product Usage Description

M330 Relay

Panel Series Heatizon Relay Panel

30A & 50A

Heatizon Relay Panel requires 120V, for

120/208/240/2 /480 VAC; Also accepts

activation devices that switch 12V DC.

Contains four relays, master rocker switch, and

four auto/manual area rocker switches. M330

switches up to four 30AMP loads. M330-50

switches up to four 50AMP loads. M330-G

Model includes GFEP.

M330G Relay

Panel Series Heatizon Relay Panel

30A & 40A with GFEP

Heatizon Relay Panel requires 120V, for

120/208/240/2 /480 VAC; Contains four

relays, master rocker switch, and four auto/

manual area rocker switches. M330-G

switches up to four 30AMP loads. M330G-40

switches up to four 40AMP FLA loads. Both

include GFEP.

M530 Series

Heatizon Contactor

Panel 50A with and

without GFEP

The M530 Contactor Panel Series can control

1-8 circuits at 208/240/480 VAC, or 1-16 circuits

at 120/277/600 VAC and is compatible with

many Heatizon activation devices. The M530

do not include GFEP.

M346 Heatizon Monitor

Station Selector Box

Allows up to 12 zones/panels to be activated

and monitored by one activation device.

Provides two different delay features. Powered

by 12VDC, provides 24VAC for activation

device as well as up to 12 circuits of monitoring.

M332 Gutter Controller

Gutter Controller allows Heatizon Systems Line

Voltage Cables to be turned on and off

whenever a Tuff Cable or ZMesh system is

turned on and off. Designed to fit over a

standard electrical outlet box. Switches

120/208/240/277 VAC.

M435

Roof, Gutter and Pipe

Moisture

Sensor, Outdoor

Temperature Sensor

and Controller.

Gutter/Roof Deicing with Moisture Sensor,

Outdoor Temperature Sensor and Controller.

Designed to lay in gutters or hang in

downspouts and pipes. The moisture sensor

detects moisture while the outdoor temperature

sensor monitors ambient temperature. Included

up to 2 zones and 3 output relays with 16A load

switch capability.

M515/M515G

Temp Control J-Box

120/277VA

Activates System when temperature is below

set point. 0°- 50°F : Temperature Selection

5°F Temperature Differential. Automatic

Activation for reliable system operation.

Switches 120/277 VAC 50/60hz. FLA 20A

@120VAC - FLA 16A @277VAC.

M516/M516G Temp Control J-Box

208/240VAC

Activates System when temperature is below

set point. 0°- 50°F : Temperature Selection

5°F Temperature Differential. Automatic

Activation for reliable system operation.

Switches 208/240 VAC. 30A @208VAC - 30A

@240VAC

13

Design and Installation

Typical Components of a GutterMelt®SR system include:

•GutterMelt SR heating cable

•Activation device, automatic or manual

•Power connect Kit(s) and End Seal Kit(s)

•Roof Attachment Clips with fasteners and/or adhesive

•Downspout Hanger Kits

•Relay Panel or Contactor Panel for larger projects

Necessary Information:

•Length of eaves, gutters, and downspout drains to be heat traced

•Distance from eave edge to inside the outside wall

•Voltage Available

•Type of Roof covering material

Draw a sketch of the area where GutterMelt®SR snow melt will be

installed. The sketch should show all measurements and dimensions

in order to determine the area to be snow melted. Determine the

location for the GutterMelt®SR temperature/moisture sensor or other

activation device.

Note: GutterMelt®SR is designed for snow melt applications

and to provide a path for water to exit the roof, gutter, and

downspout drain.

STEP 1 PLAN THE LAYOUT

Note: Make certain to plan for the movement of the water created

when GutterMelt®SR melts snow and/or ice from the roof, gutters

and/or downspouts to an acceptable refreeze location.

Annual Maintenance

Remove all debris from gutters and downspouts.

Verify the integrity of the GutterMelt®SR by conducting a visual inspection

and checking the insulation between the heating elements and the ground

shield with a Megohmmeter. Record the value if it exceeds 20 megohms

for GutterMelt®SR Cable. If damage to GutterMelt®SR Heating Cable is

discovered, and/or the Megohmmeter test yields a megohms reading less

than 20, then correctly repair or replace the GutterMelt® SR with new cable

prior to energizing.

Warning: Always disconnect power to GutterMelt® SR and its

activators prior to handling, replacing and/or servicing.

MEASURE AND

RECORD

RESISTANCE

14

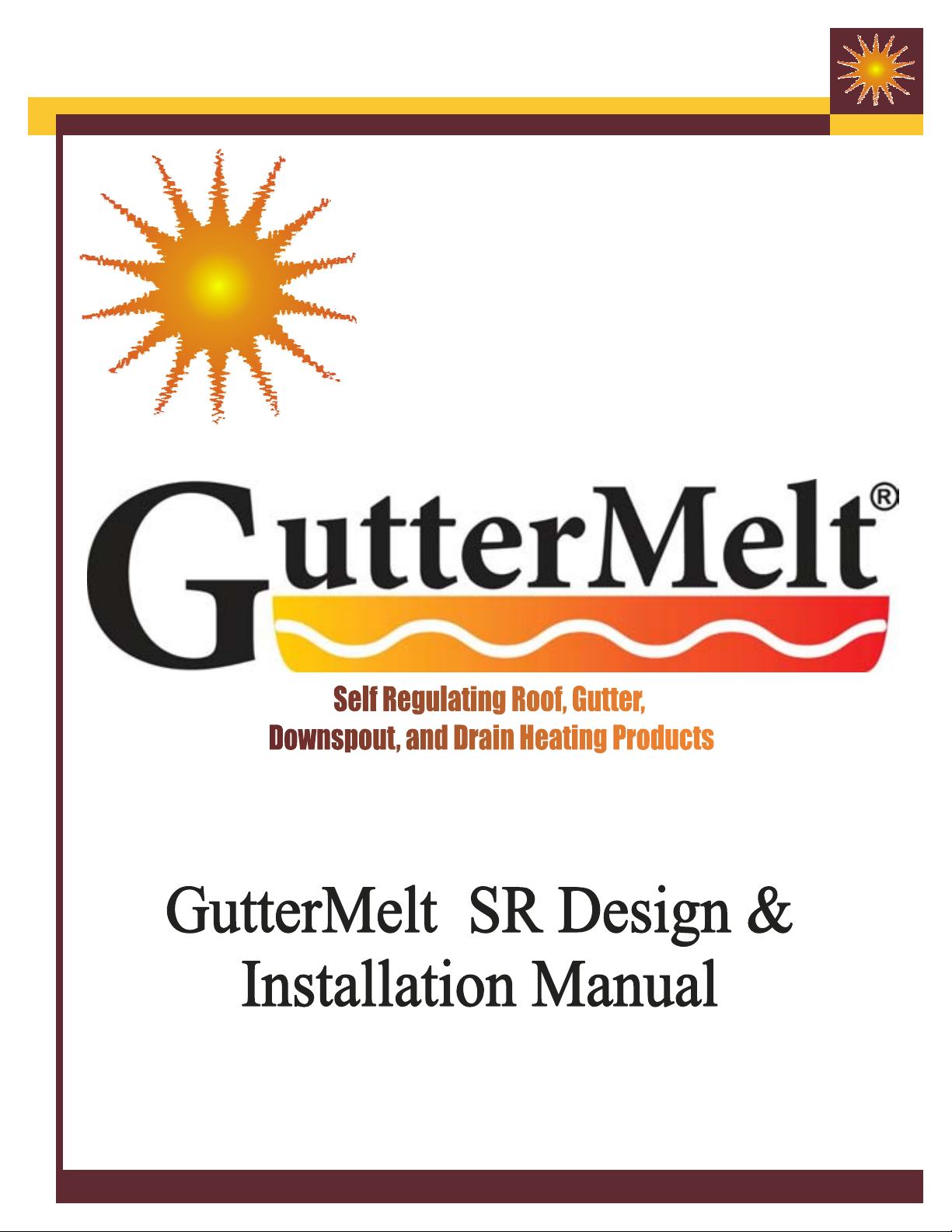

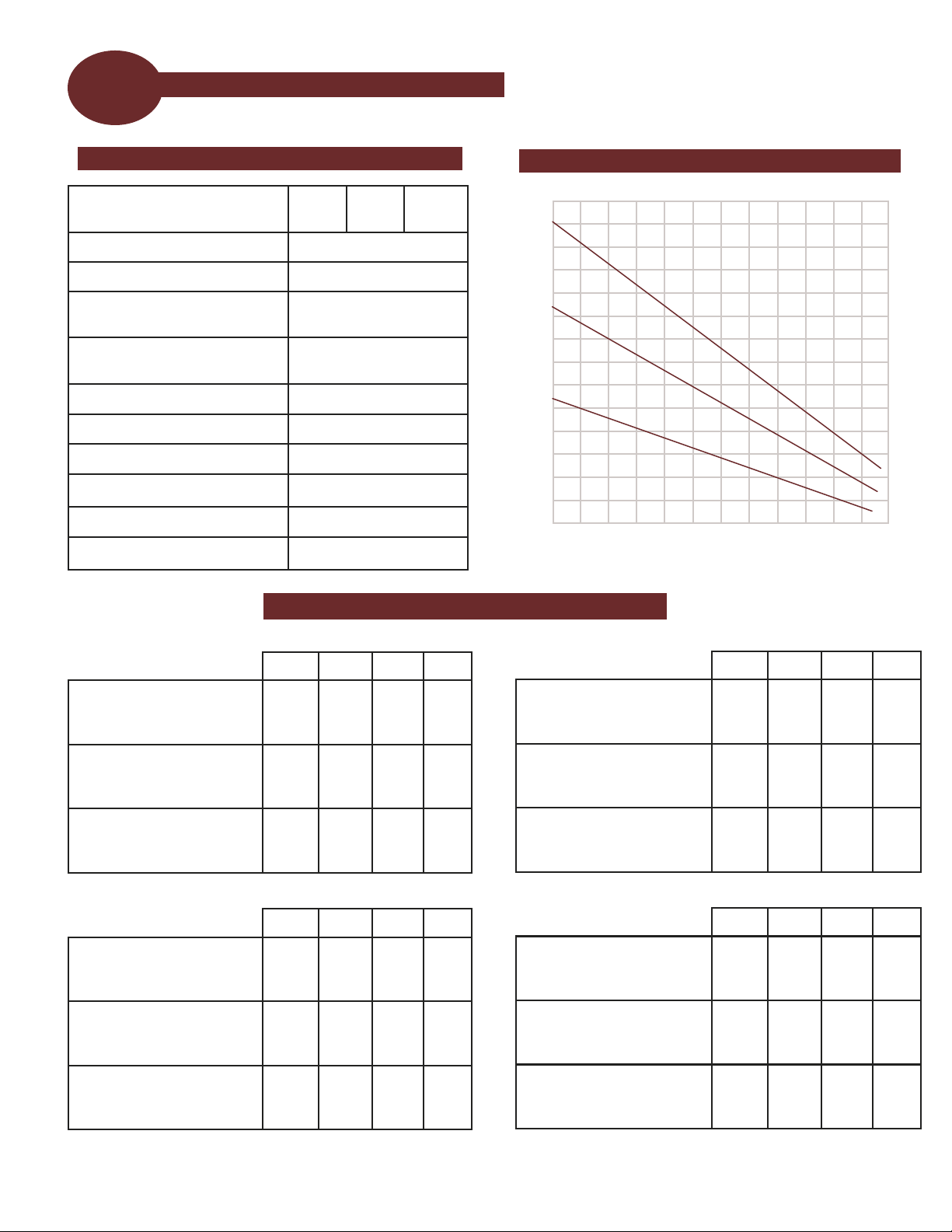

STEP 2 GUTTERMELT®SR SPECIFICATIONS

FIGURE 1

PERFORMANCE RATINGS POWER OUTPUT CURVE

BREAKER SIZING AND MAX CIRCUIT LENGTH

0 50 70 90 110 130 150

2

0

4

6

8

10

12

14

15A 20A 30A 40A

5GM1 If started at 40ºF

0ºF

-20ºF

300

200

180

—

270

230

—

330

330

—

—

—

9GM1 If started at 40ºF

0ºF

-20ºF

150

95

85

200

125

100

210

190

170

—

210

210

12GM1 If started at 40ºF

0ºF

-20ºF

115

70

60

150

95

85

180

145

120

—

180

165

120 Volt Breaker Sizing vs Max Circuit Length (ft)

15A 20A 30A 40A*

5GM2 If started at 40ºF

0ºF

-20ºF

660

410

360

—

560

480

—

660

660

—

—

—

9GM2 If started at 40ºF

0ºF

-20ºF

295

195

170

390

250

225

420

375

340

—

420

420

12GM2 If started at 40ºF

0ºF

-20ºF

230

150

130

305

200

175

360

300

260

—

360

360

240 Volt Breaker Sizing vs Max Circuit Length (ft)

Temperature, ºF

Power Output, Watts/Ft

5GM

9GM

12GM

15A 20A 30A 40A*

5GM1 If started at 40ºF

0ºF

-20ºF

505

475

420

—

650

560

—

765

765

—

—

—

9GM1 If started at 40ºF

0ºF

-20ºF

320

210

185

425

270

245

455

405

370

—

460

460

12GM1 If started at 40ºF

0ºF

-20ºF

240

155

135

315

210

180

375

310

270

—

375

375

208 Volt Breaker Sizing vs Max Circuit Length (ft)

15A 20A 30A 40A*

5GM2 If started at 40ºF

0ºF

-20ºF

570

355

310

—

485

415

—

570

570

—

—

—

9GM2 If started at 40ºF

0ºF

-20ºF

270

180

155

355

230

205

385

345

310

—

385

385

12GM2 If started at 40ºF

0ºF

-20ºF

220

140

125

290

190

165

340

285

245

—

340

340

277 Volt Breaker Sizing vs Max Circuit Length (ft)

* Appropriate sized butt splices may need to be sourced separately

Watts per linear foot at 32°in

iced water 5 9 12

Cable type Self Regulating (SR)

Copper bus wire 22 AWG Min

Maximum maintenance

temperature 185ºF (85ºC)

Maximum intermittent

exposure temperature

212ºF (100ºC)

T rating: T5

Voltage AC 120, 208, 240, 277

Maximum length Refer to product label

Approximate thickness/width 0.25” x 0.50”

Bending radius 1”

Minimum spacing 2”

Standard spacing along eave 18” to 24”

15

STEP 4 PREPARE AREA

Design and Installation

Ensure that the roofing material, gutters and/or downspout drains

have been properly installed, and that drainage has been satisfactorily

addressed.

Eliminate any nails, staples, or any other objects that may damage the

GutterMelt® SR Heating Element prior to installation.

Clean and dry the rain gutters so that the provided foil tape will adhere

to the bottom and hold the GutterMelt® SR cable in place.

Determine the location of the connection points between the power

supply and the GutterMelt®SR Cable.

Next, determine the location of the activation device.

Remember, an automated activator is the “eyes and ears” of the roof,

gutter, and downspout system. It is important that it be installed in a

location that will allow it to turn the roof deicing system “on” when it is

needed and “off” when it is not needed.

Manual activators require human action—as a result they should be

placed in a location that is convenient and easily accessible.

STEP 6 LOCATION SELECTION

STEP 3 CONTACT YOUR GUTTERMELT®SR SUPPLIER

Contact your GutterMelt® SR supplier for assistance in ordering the

material needed. When materials arrive, examine the GutterMelt®

SR roof deicing system design, and compare the list of materials

ordered to those received.

Remove the GutterMelt®SR Heating Element from the box. Using a

2500 Vdc Megohmmeter, check the insulation resistance of the

Heating Element to make certain it is greater than 20MΩ. Confirm the

Megohmmeter result by measuring the resistance with a Digital

Multimeter and record the value measured on Resistance Recording

Table at the back of this manual. Resistance measurement must be

taken several times during the installation process: Immediately upon

removal from the packaging and after installation of the heating

element. GutterMelt®SR should also be checked for electrical

continuity.

STEP 5 MEASURE & RECORD RESISTANCE

MEASURE AND

RECORD

RESISTANCE

16

Design and Installation

STEP 8 INSTALL GUTTERMELT® SR HEATING ELEMENT

Install the selected activator by carefully following the specific set of

instructions that were included in the packaging.

STEP 7 INSTALL THE ACTIVATOR

Warning: Do not allow the sensor conduit to cross the Gutter-

Melt®SR Heating Element. Do not allow any part of the activa-

tor to touch the GutterMelt® SR Heating Element.

Note: Always roll or uncoil the GutterMelt®SR to

unreel the heating element. Do not pull

GutterMelt®SR from the spool or coil. Never

energize GutterMelt®SR Heating Cable while it is

rolled or coiled on the spool.

Using the determined spacing of GutterMelt®SR Heating Element, and

the calculated length of GutterMelt®SR Heating Element, begin the

installation. Heatizon Systems recommends a maximum 2 foot

spacing along the eave edge for roof applications, and two runs of

GutterMelt® SR for gutter and downspout applications. Note that the

minimum distance between the GutterMelt®SR Heating Element runs

should not be less than 2 inches.

Install the GutterMelt®SR Heating Element so that the starting and

ending connection points and any activation sensor are in their desired

locations. Make certain that the power end of GutterMelt®SR Cable

returns back to the GutterMelt®SR Termination Box, Junction Box, or

Heatizon Relay Panel.

Begin laying the GutterMelt®SR Heating Element in and across the

area to be melted in evenly spaced runs.

Use Roof Clips purchased from your Heatizon Systems Distributor to

attach GutterMelt®SR to the roof covering material.

Use Foil Tape purchased from your Heatizon Systems Distributor to

attached GutterMelt® SR to the rain gutter.

Use Downspout Hangers purchased from your Heatizon Systems

Distributor to install GutterMelt® SR into the downspouts or drains.

Warning: Do not damage or subject the

GutterMelt®SR Heating Element to mechanical

or shear stress. Never cut or damage the

insulator on GutterMelt®SR Heating Element.

Do not allow GutterMelt® SR to cross or touch

gas lines or other electrical conductors.

Note: Visually check GutterMelt® SR Heating

Cable for breaks, cuts, nicks, etc. If damage has

been done to GutterMelt®SR Heating Cable or

any of its components, please file a claim with the

delivery service and call Heatizon Systems, 888-

239-1232.

MEASURE AND

RECORD

RESISTANCE

STEP 9 INSTALL GUTTERMELT® END KIT, POWER CONNECTION KITS

Commonly used connection kits and accessories are listed in this manual. See

www.heatizon.com for additional information.

After Installing GutterMelt®SR Heating Element take resistance

measurements. Using a 2500 Vdc Megohmmeter, check the insulation

resistance of the Heating Element to make certain it is greater than

20MΩ. Confirm the Megohmmeter result by measuring the resistance

with a Digital Multimeter and record the value measured on Resistance

Recording Table at the back of this manual. Resistance measurement

must be taken several times during the installation process:

Immediately upon removal from the packaging, after installation of the

heating element. GutterMelt®SR should also be checked for electrical

continuity.

17

Design and Installation

STEP 13 COMPLETE WARRANTY CERTIFICATE

Mail in the warranty certificate immediately after installing the GutterMelt® SR

system. Failure to complete the warranty card could void the manufacturer’s

warranty. The warranty is subject to the guarantee conditions listed on the

warranty certificate, and upon documentation that the required resistance

readings were completed. You may wish to keep a copy of the warranty card

for your reference.

STEP 10 CONNECT POWER SUPPLY & ACTIVATION

The connection of an acceptable ground fault protection device power supply and the activation device must be

done in accordance with the National Electrical Code (NEC) and the Canadian Electrical Code (CEC).

The braided shield from GutterMelt® SR Cable must be wired to Ground for all primary power installations.

Caution: Never energize GutterMelt®SR until:

1. The GutterMelt®SR Cable has been verified to be free of damage.

2. All splices and all power kit and end kit connections have been inspected.

3. A Megohmmeter Test has been used to verify a minimum of 20 MegOhms between the

heating element and the braided shield.

STEP 12 COMPLETE AND ATTACH LABELS

STEP 11 TROUBLESHOOTING

Problem: GutterMelt®SR Cable fails the Megohmmeter Test

Potential Causes:

• Check field installed power/end terminations and connection splices; correct as necessary

• Inspect the GutterMelt®SR Cable for damage to the insulator, exposed braided shield, and/or contact between

the braided shield and the core wire(s). Replace entire length of damaged GutterMelt®SR Cable

Call Heatizon Systems technical support @ 801-293-1232 if additional assistance is required.

Note: In the event the power/end termination or splices are not the cause of the failed Megohmmeter

Test and the GutterMelt®SR Cable has not been damaged in any way, remove and replace the

entire length of GutterMelt® SR. For Warranty claims, please return the entire length of GutterMelt®

SR to Heatizon Systems, with the end termination and power termination connections intact, for

evaluation prior to replacement.

Place the included labels in the following locations:

• Electrical Panel Label — Inside door at electrical service panel. This

label matches the information printed on the GutterMelt® SR Cable

• Stop Sign Warning Label — on or near the area to be heated by

GutterMelt®SR Cable

18

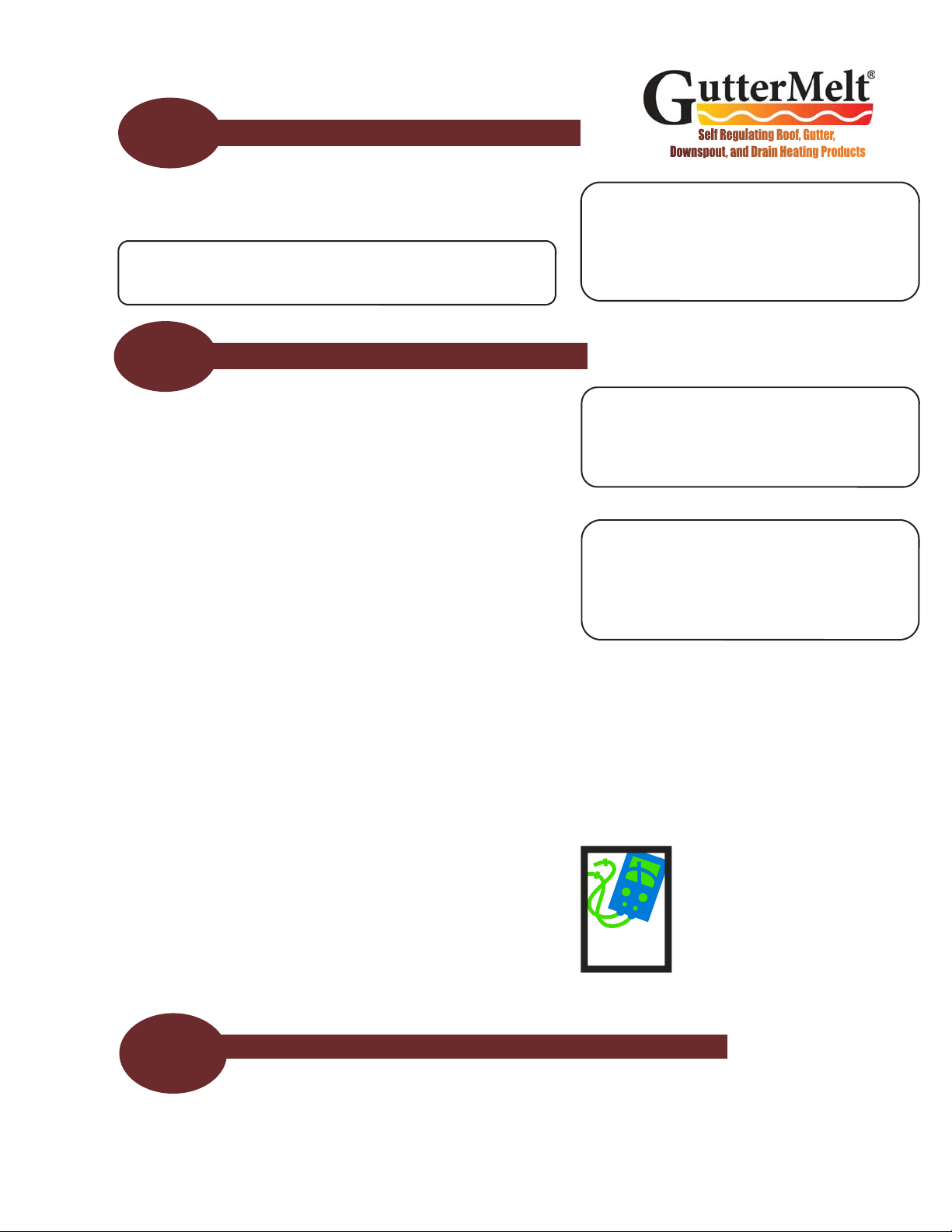

Resistance Recording Page

Use a Digital Multi Meter to measure continuity through the GutterMelt®SR Heating Element, and no

continuity between the heating element and the braided ground shield. GutterMelt®SR Cable should be

tested using a megohmmeter set at 2500 VDC at least twice. The measured value should not be less

than 20 Megohms. Record all test results below.

Prior to Installation (When

removed from Package)

After Installation of

GutteMelt® SR Heating

Element

MΩ@ 2500VDC

MΩ@2500VDC

Date Time

Date Time

Customer Warranty Information

MEASURE AND

RECORD

RESISTANCE

Name

Address

City State

Phone Email

Zip

Purchased Product Details

Watts Volts Ω

Watts &

Volts Ohms

Sq. Ft.

Model Size

Serial Number

(if applicable)

Manufacture

Date

19

Heatizon Systems warrants GutterMelt® SR Heating Element to be free from defects in material and workmanship for a period of ten (10) years and

Activation Device(s) for a period of one (1) year. Such warranty periods shall commence on the date of shipment by Heatizon Systems. If any parts are

found to be defective in manufacture during such time period, Heatizon Systems will, at its sole option, replace or repair defective parts.

This Limited Warranty applies only if articles sold hereunder (a) are selected, designed, and installed according to instruction and operation manuals

furnished by Heatizon Systems and installed in a “workmanlike manner” according to the building association standards adopted by Heatizon Systems,

(b) remain in their originally installed location, (c) are connected to proper power supplies, (d) are not misused or abused, (e) show no evidence of tam-

pering, mishandling, neglect, damage (accidental or otherwise), modifications or repair without the approval of Heatizon Systems, or damage done to

the product by anyone other than Heatizon Systems, and (f) are installed in accordance with applicable code requirements. Any warranty claims must

be made in writing, no later than one (1) month following expiration of the warranty period, and must be accompanied by the warranted part or compo-

nent. Any claim not made in such manner shall not be honored by Heatizon Systems.

This Limited Warranty does not cover:

1. The workmanship of any installer of Heatizon Systems radiant panel heating products.

2, Any Heatizon Systems radiant heating products that have a failure or malfunction resulting from improper or negligent operation, installation, acci-

dent, abuse, misuse, unauthorized alteration or improper repair or maintenance.

3. Any Heatizon Systems radiant heating products that have had components not purchased from Heatizon Systems integrated into or connected to

them.

4. Any labor costs for removal of alleged defective part(s) and/or reinstallation of replacement part(s), transportation to and from Heatizon Systems (if

necessary) and any other material necessary to perform the exchange or repair.

5. Any Heatizon Systems heating products that have not been properly registered by completion and return of the Warranty Registration Card attached

hereto within ninety (90) days of the date of sale..

DISCLAIMER OF WARRANTIES:

This warranty described above is in lieu of all other warranties, express or implied, including but not limited to any implied warranties of

fitness for a particular purpose and merchantability. Heatizon Systems expressly disclaims and excludes any liability for losses, expenses, inconven-

iences, consequential, incidental, indirect, or punitive damages for breach of any express or implied warranty. By installing and/or purchasing Heatizon

Systems products, you accept the terms of this limited warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above limitations and exclusions may not apply to you. This Limited Warranty gives you specific legal rights, and you may also have other

rights which may vary from state to state.

Heatizon Systems GutterMelt® SR Warranty

Mail: Heatizon Systems

4137 South 500 West

Murray, UT 84123

USA

Phone: (801) 293-1232

Toll Free: (888) 239-1232

Fax: (801) 293-3077

Email: [email protected]

Website: www.heatizon.com

How to make a Warranty Claim

1. Gather the following information:

•Date of purchase

•Who product was purchased from

•Date of installation, if installed

•Names and phone numbers of electrician/installer

•Completed resistance recording page from installation

•Serial number (if applicable) from product label

2. Contact Heatizon Systems for a Return Materials Authorization number, and information on the next

required steps to complete your warranty claim.

20

Mail: Heatizon Systems

4137 South 500 West

Murray, UT 84123

USA

Phone: (801) 293-1232

Toll Free: (888) 239-1232

Fax: (801) 293-3077

Email: [email protected]

Website: www.heatizon.com

Table of contents

Other HEATIZON SYSTEMS Heating System manuals

Popular Heating System manuals by other brands

International Thermal Research

International Thermal Research Oasis operating manual

CALEFFI

CALEFFI SATK50 Series quick start guide

Warmup

Warmup WHP1 installation manual

Mikrofill

Mikrofill Maxi Single Technical documentation

EngA

EngA ENGINEERED AIR HE Series Installation, operation and maintenance manual

HeatMat

HeatMat Mirror Demister installation instructions

Vectaire

Vectaire EVO220DC Installation, operating and maintenance instructions

BriskHeat

BriskHeat SLCBLSK instruction manual

Vents

Vents DVUT 300 HB user manual

aerauliqa

aerauliqa DWE4120 Installation, use and maintenance manual

Broan

Broan ERV140 ECM installation guide

Toyotomi

Toyotomi FR-700F Installation and operation instructions