IKM UMA-4856-010 User manual

USER MANUAL FOR SUBSEA SAW 60-200 mm

Document title : UMA-4856-010 Subsea Saw 60-200 mm

IKM TECHNOLOGY AS ref. : P4856

Customer ref. : Subsea Tool

Rev.

Date

Reason For Issue

Prepared

Checked

Approv

ed

01

04.06.2015

Issued for review

AH

LET

AH

02

13.06.2016

Update

KF

RH

KF

BTE.12-26 User Manual

Page 2 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

USER MANUAL FOR SUBSEA SAW 60-200 MM .......................................................... 1

1GENERAL INFORMATION........................................................................... 3

1.1 Abbreviations................................................................................................ 4

1.2 References................................................................................................... 5

2TECHNICAL SPESIFICATION ..................................................................... 6

3SAFETY ....................................................................................................... 7

3.1 General –Operations.................................................................................... 7

3.2 General –Hydraulic...................................................................................... 7

3.3 General –Mechanical................................................................................... 7

4OPERATIONAL DESCRIPTION................................................................... 9

4.1 Transportation .............................................................................................. 9

4.2 Preparation on the vessel prior to operations................................................ 9

4.3 Feed flow regulator..................................................................................... 10

4.4 Subsea use................................................................................................. 10

5MAINTENANCE.......................................................................................... 12

5.1 After operations .......................................................................................... 12

5.2 Periodic maintenance................................................................................. 12

6SPARE PART LIST .................................................................................... 13

7REVISION CHANGES................................................................................ 14

8CONTACT INFORMATION ........................................................................ 14

9APPENDIX ................................................................................................. 15

BTE.12-26 User Manual

Page 3 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

1 GENERAL INFORMATION

This manual is a user manual for the Subsea Claw Cutter tool.

The Subsea Saw has a rotating blade which is 600 mm in diameter. It is built to be used with a

Subsea ROV, controlled by manipulator and hydraulic supply from the ROV to drive the saw.

It is designed to cut steel pipes/profiles, armored cable and flexirisers. Standard blades to be

supplied with the saw are carbide and diamond types. The saw has claws to hold on to the object

which is being cut. Claws can be replaced if specific interface is required.

BTE.12-26 User Manual

Page 4 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

1.1 Abbreviations

HPU

Hydraulic Power Unit

ROV

Remotely Operated Vehicle

kg

Kilo gram

mm

Milli meter

BSP

British standard pipe

JIC

Joint industry council

CCM

Cubic centimeter

LPM

Liter per minute

Nm

Newton meter

CCW

Counter clockwise

BTE.12-26 User Manual

Page 5 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

1.2 References

Doc nr

Description

Rev.

Issued

Can be found

4859-010 rev-03

Drawing of Subsea Saw 60-200 mm

03

16.10.15

Appendix A

Hydraulic Schematic

Appendix B

Tooling ref/track record:

Emas, IKMS, C-Innovation, Envirent

BTE.12-26 User Manual

Page 6 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

2 TECHNICAL SPESIFICATION

The Subsea Saw main components is steel frame, cutting blade, claws with hydraulic cylinders to

hold on to object being cut and char-lynn 2000 serie motor (305ccm) attached to an cylinder which

regulates the cutting feed.

Hydraulic supply and control of the Subsea Saw is by means of and through the ROV system.

Recommended cutting diameter is set to 60-200 mm.

Weight:

In air: 101 kg.

In water: 80 kg.

Maximum dimensions:

Width: 716 mm.

Length: 1455 mm.

Height: 423 mm.

Saw blade: Ø600 mm.

Hydraulic/motor:

Motor: CHAR-Lynn 2000 serie, 305 ccm.

Working pressure: 205 bar (310 MAX).

Flow: 76 LPM

RPM: 226 RPM

Torque: 565 Nm

Connections: JIC ½ - 20” male.

Regulator: 672878 QV-06/1 Flow Control

For more information about the motor see the CHAR-Lynn manual.

BTE.12-26 User Manual

Page 7 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

3 SAFETY

3.1 General –Operations

Only authorised people and qualified personnel should work on the system, and take suitable

precautions to prevent any potential injuries. Always adhere to authorised working practices, and

use the correct tools for the job. To facilitate this, make sure that these are available before

commencing the test.

Ensure that the working area is kept clear and uncluttered.

3.2 General –Hydraulic

Do not work on pressurised systems. Hydraulic systems contain a large amount of stored energy

when pressurised, therefore the system (including any accumulators) should be de-pressurised,

and the power pack switched off, prior to working on the system. Exceptions to this would be

system adjustments to components requiring the presence of pressure and/or flow.

Any personnel authorised to work on the system must have a complete understanding of the

operation of the hydraulic system, so that they will be aware of any system liable to remain

pressurised or hazardous in any other way. Ensure that all personnel are clear of any

mechanical/hydraulic system likely to move if pressure to system actuators is released or applied.

Do not attempt to tighten any leaking fittings whilst under pressure. A hose/fitting rupture could

result, leading to injury from flying components and/or oil jets.

Regularly inspect fittings and pipe-work for mechanical damage. If any such damage is found, the

item must be repaired or replaced as necessary before pressure is applied to the system. Do not

allow damaged fittings to remain in service.

Take care when inspecting, commissioning, repairing or maintaining the system to avoid jets of oil

issuing from open orifices; pipe ends etc. if pressure is applied. Particular care should be taken to

protect the eyes.

Hydraulic components may be heavy and slippery when covered in oil. Ensure that adequate

protective clothing and footwear is used.

Any moving component should be treated with caution when the system is pressurised during

operation, and especially during on-deck testing and repair. Keep clear of all moving components,

and take all necessary precautions to avoid injury when working on these systems by preventing

movement of any components likely to cause injury.

3.3 General –Mechanical

Beware of and keep clear of all moving components. Do not work on the system whilst power is

applied, or if there is any potential for components to move.

Ensure that all load bearing components are adequately and regularly inspected. If damage is

found the component must be repaired/replaced as necessary. Do not allow damaged

components to remain in service.

BTE.12-26 User Manual

Page 8 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

Always ensure that items are correctly and adequately supported before removal, and that

authorised lifting equipment and procedures are used.

Note: trying to lift heavy components in an awkward position by hand without the assistance of

correct lifting equipment, or lifting any component without adopting the correct stance, can lead to

serious injury.

Ensure that when working within or underneath the machine that your presence is known to your

supervisor. If working underneath the machine, always ensure that there are no loose or

unsupported assemblies, components or tools above.

BTE.12-26 User Manual

Page 9 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

4 OPERATIONAL DESCRIPTION

The following description is a generic description of preparation and use of the Subsea Claw

Cutter. Customers are advised to adapt the following information to their own specific operations

and specific work area.

4.1 Transportation

Make sure that the saw is properly strapped in the transport box, example of how to do this is

shown in the pictures below:

4.2 Preparation on the vessel prior to operations

➢Unpack all parts and check for transport damages

➢Verify that all parts on equipment list is present

➢Check the cutting blade for damage.

BTE.12-26 User Manual

Page 10 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

➢Check that the blade is installed correctly, not loose and correct direction.

➢Check all hoses and fittings for damage and leaks.

➢Check that all bolts are in place and tight.

➢Connect the hydraulic hoses to the ROV corresponding hydraulic system.

➢Ensure that the piston on the feed cylinder is fully retracted.

Function test:

➢Do not start the saw on deck without securing the area.

➢Run the clamp cylinders to full stroke.

➢Time the motor feed rate.

➢If the motor feed rate is to fast/slow, adjust it using the feed flow regulator and try again.

(This is also dependent on the ROV flow and pressure).

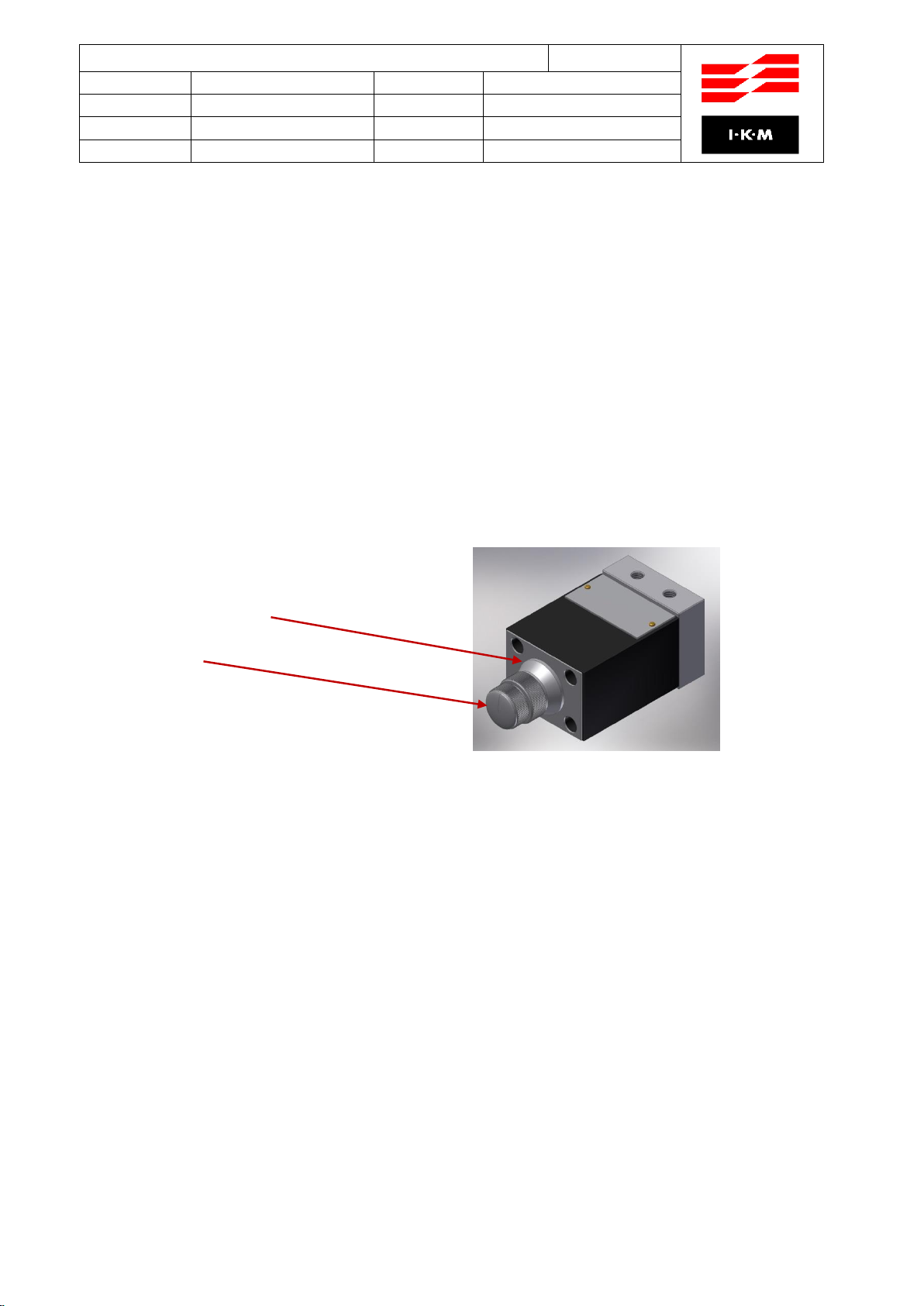

4.3 Feed flow regulator

Adjustment flow wheel:

Locking wheel:

➢The regulator is located on the right hand side, it can be seen in the drawing in Appendix A

sheet 2 (item 23 on part list).

➢The regulator can be adjusted to change the feed rate.

➢Start by loosening the locking wheel CCW while holding the adjustment flow wheel from

turning.

➢Adjust the flow wheel in small increments.

➢Apply adequate lubrication to thread and spring washer. Recommended lubrication: Aqua

lube/aqua shield.

➢Make sure spring washer is in place before tightening together again.

4.4 Subsea use

➢Ensure all the checks and preparations have been performed.

➢Ensure the saw is securely fastened to the ROV using the designated ROV handles.

➢OR it is securely connected to a crane.

➢Lower the saw into position.

BTE.12-26 User Manual

Page 11 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

➢Run the clamp Actuators to lock it around the area of object to be cut. (Ensure it is securely

fastened)

➢Run the saw, this will cause the feed cylinder to activate.

➢Perform the cut.

➢When the cut is finished retract the saw blade.

➢Retract the cylinders for the clamp.

➢Return to deck and perform “After operations maintenance”, ref chapter 5.

BTE.12-26 User Manual

Page 12 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

5 MAINTENANCE

Repair and maintenance work on the saw shall only be performed by qualified personnel,

specifically trained on this equipment.

5.1 After operations

➢Plug hydraulic hoses to prevent hydraulic leaks and dirt to enter the hydraulic system.

➢Clean the tool with fresh water. Apply an anti-corrosive layer on the tool when it is clean,

WD40 or similar.

➢Check hydraulic hoses, bolts, etc.

➢Check the cutting blade for damage.

➢When stored make sure the cylinders is fully retracted, to avoid corrosion.

➢Place tool in its original transport case/storage box and secure with straps.

5.2 Periodic maintenance

➢Start with “After operations” maintenance procedure.

➢A careful review of the entire tool is mandatory. This includes a visual check of the tool with

hoses and a function test. Be sure that there is no leaks and that the feeding rate is correct.

➢Replace or fix parts if needed. Damaged paint must be repainted.

BTE.12-26 User Manual

Page 13 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

6 SPARE PART LIST

➢Cutting blade

➢Hydraulic hoses and connections.

➢Nuts and bolts.

➢Handles

➢Claws

➢

BTE.12-26 User Manual

Page 14 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

7 REVISION CHANGES

8 CONTACT INFORMATION

All enquiries relating to the tooling should be addressed to:

IKM Technology AS

Nordlysveien 7,

N-4340 Bryne

Norway

Phone, 24/7 : +47 51 80 05 20

Revision

Procedure change

Author

01

Original version

AH

02

Update

KF

BTE.12-26 User Manual

Page 15 of 19

Dok.ID:

010984

Issue date:

2014.12.29

Approved date:

2015.02.13

Rev.no:

002

Author:

Gabrielsen Trine (Technique)

Owner:

IKM Administrator

Approved by:

Reinsnos Jostein (Technique)

Company:

IKM Technique AS

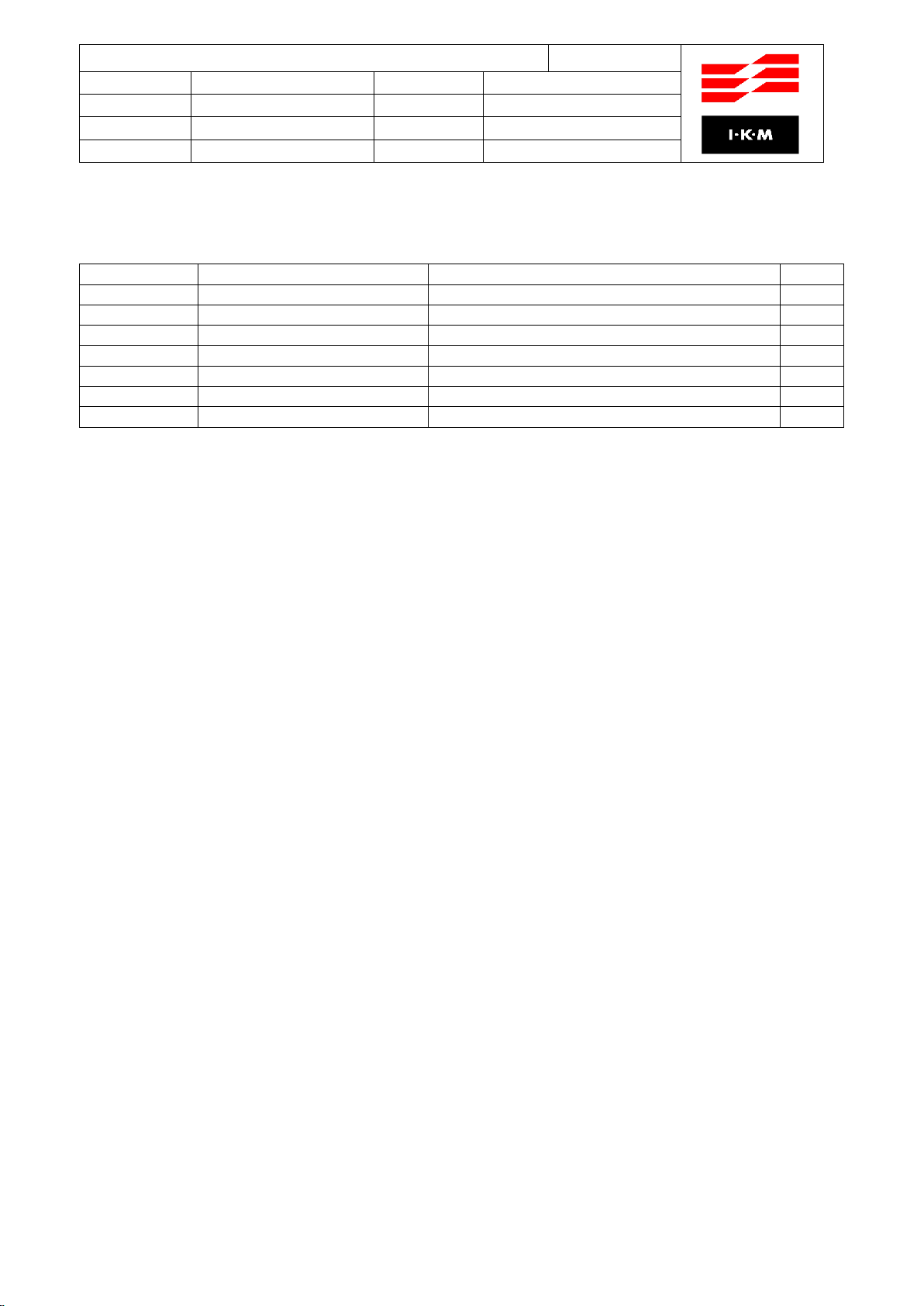

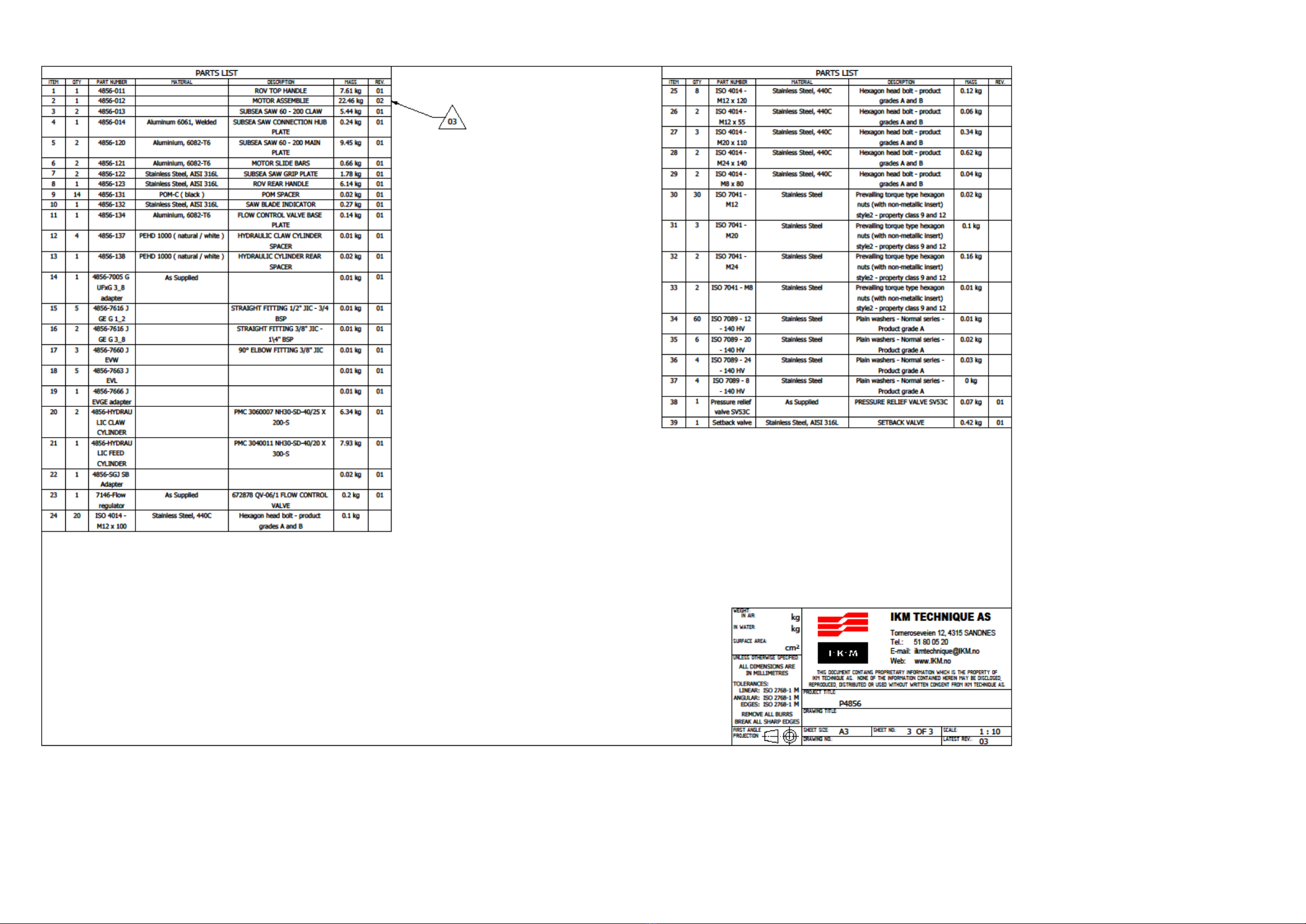

9 APPENDIX

Doc number

Description

Rev

Appendix A

4856-010 rev-03

Drawings Subsea Saw 60-200 mm

03

Appendix B

Hydraulic Schematic

Appendix A

Appendix A

Appendix A

Appendix B

Table of contents

Other IKM Saw manuals