8

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations dierent

from those intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

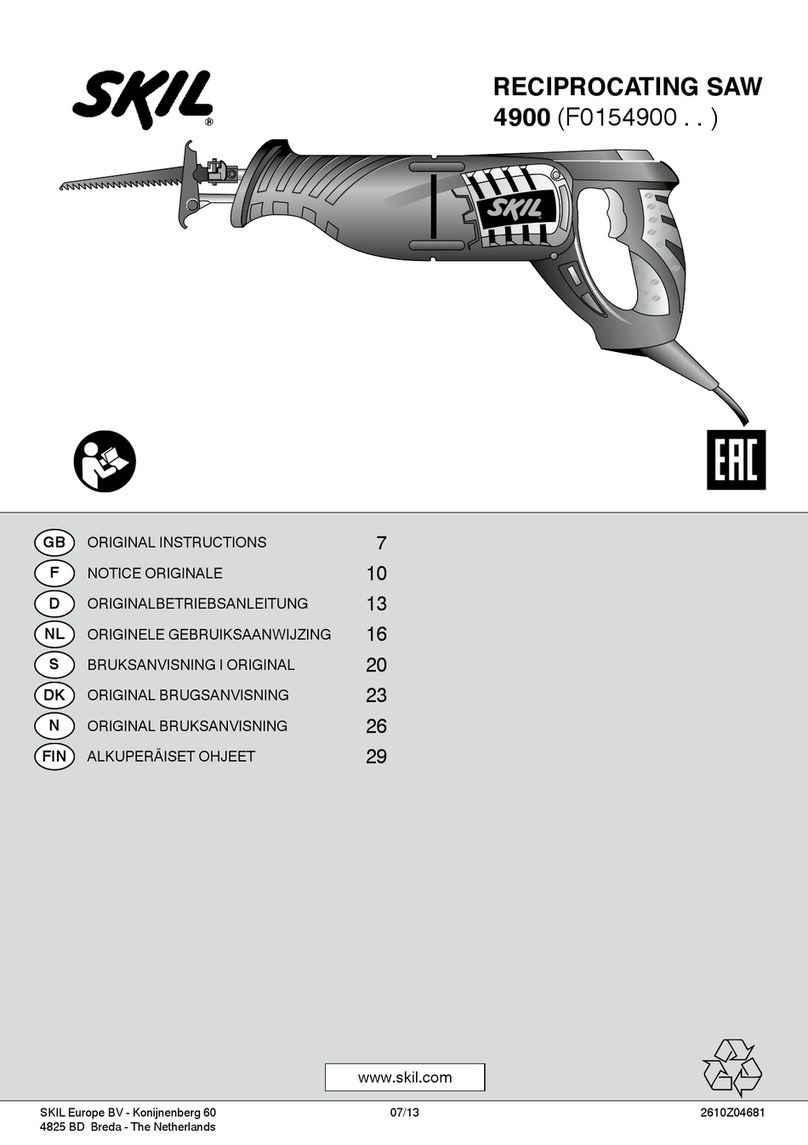

SAFETY INSTRUCTIONS FOR RECIPROCATING SAWS

• Avoid damage that can be caused by screws, nails and

other elements in your workpiece; remove them before

you start working

• Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the tool (tools with

a rating of 230V or 240V can also be connected to a

220V supply)

• Use completely unrolled and safe extension cords with a

capacity of 16 Amps (U.K. 13 Amps)

• In case of electrical or mechanical malfunction,

immediately switch o the tool and disconnect the plug

• SKIL can assure awless functioning of the tool only

when the correct accessories are used which can be

obtained from your SKIL dealer

• Use only accessories with an allowable speed matching

at least the highest no-load speed of the tool

• This tool should not be used by people under the age of

16 years

• Do not work materials containing asbestos (asbestos

is considered carcinogenic)

• Dust from material such as paint containing lead, some

wood species, minerals and metal may be harmful

(contact with or inhalation of the dust may cause allergic

reactions and/or respiratory diseases to the operator or

bystanders); wear a dust mask and work with a dust

extraction device when connectable

• Certain kinds of dust are classied as carcinogenic (such

as oak and beech dust) especially in conjunction with

additives for wood conditioning; wear a dust mask and

work with a dust extraction device when connectable

• Follow the dust-related national requirements for the

materials you want to work with

• Keep hands away from cutting area and the blade;

keep your second hand on barrel grip H 2 (if both

hands are holding the saw, they can not be cut by the blade)

• Do not reach underneath the workpiece (the proximity

of the blade to your hand is hidden from your sight)

• Never hold piece being cut in your hands or across

your leg (it is important to support the work properly to

minimise body exposure, blade binding, or loss of control)

• Use clamps or other equipment to secure and

support the workpiece (holding the workpiece in your

hand or against your body may lead to loss of control)

• Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord (contact with a

“live” wire will also make exposed metal parts of the tool

“live” and shock the operator)

• Use suitable detectors to find hidden utility lines or call

the local utility company for assistance (contact with

electric lines can lead to re or electrical shock; damaging a

gas line can result in an explosion; penetrating a water pipe

will cause property damage or an electrical shock)

• Do not use a dull or damaged blade (bent blades can

break easily or cause kickback)

• Keep hands away from between the tool housing and

blade clamp D 2 (the blade clamp can pinch your ngers)

• Ensure that blade clamp D 2is tight before making

a cut (a loose clamp may cause the tool or blade to slip

with loss of control as a result)

• Wear protective glasses and hearing protection 4

• Use protective gloves when removing the blade from

the tool (the saw blade may be hot after prolonged use)

WHEN CONNECTING NEW 3-PIN PLUG (U.K. ONLY):

• Do not connect the blue (= neutral) or brown (= live) wire

in the cord of this tool to the earth terminal of the plug

• If for any reason the old plug is cut o the cord of this tool,

it must be disposed of safely and not left unattended

USE

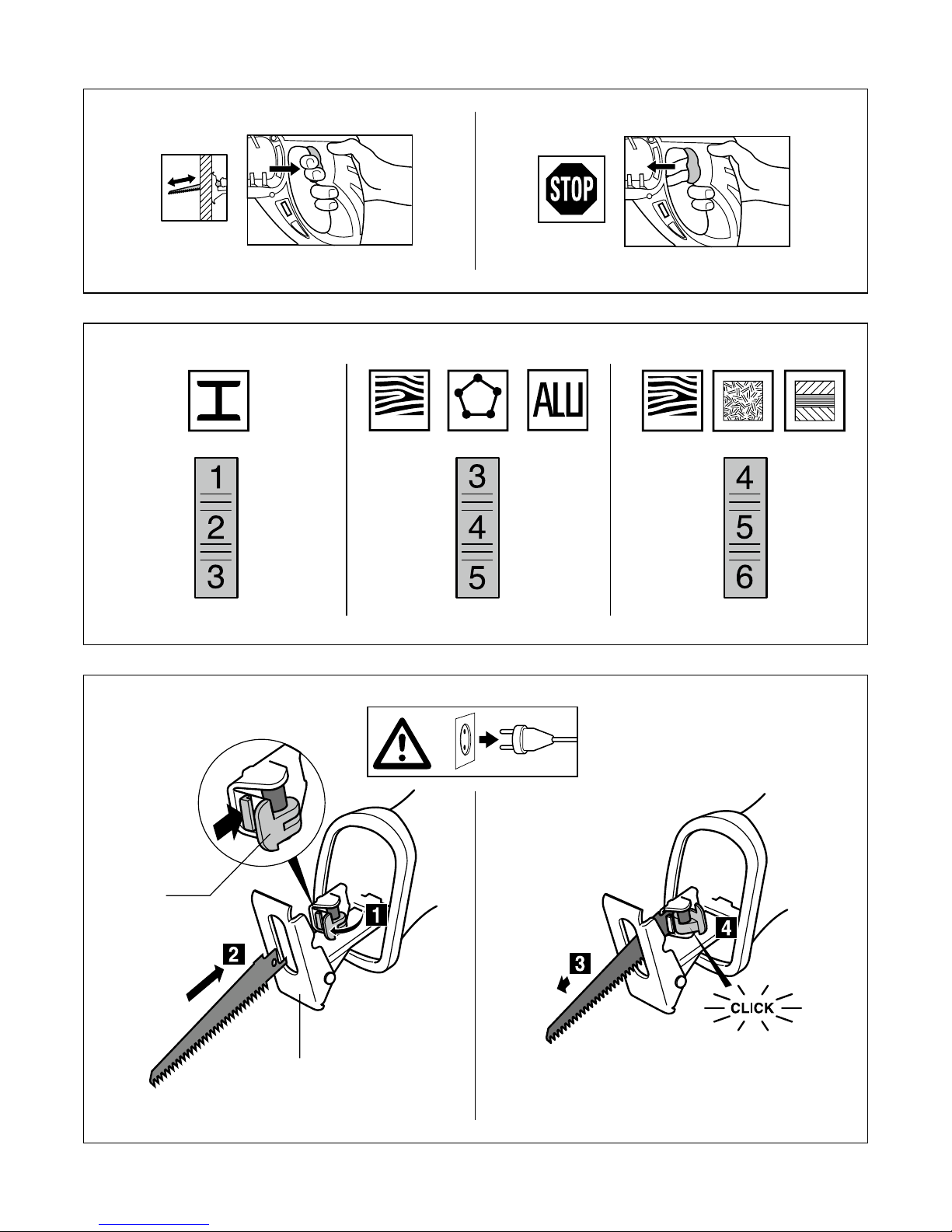

• On/o 5

• Speed control

With wheel C 2 the sawing speed can be adjusted from

low to high (6 positions)

• Adjusting sawing speed to material used 6

! if the tool does not run with wheel C 2in position

1, select a higher sawing speed and lower the

sawing speed while the tool runs

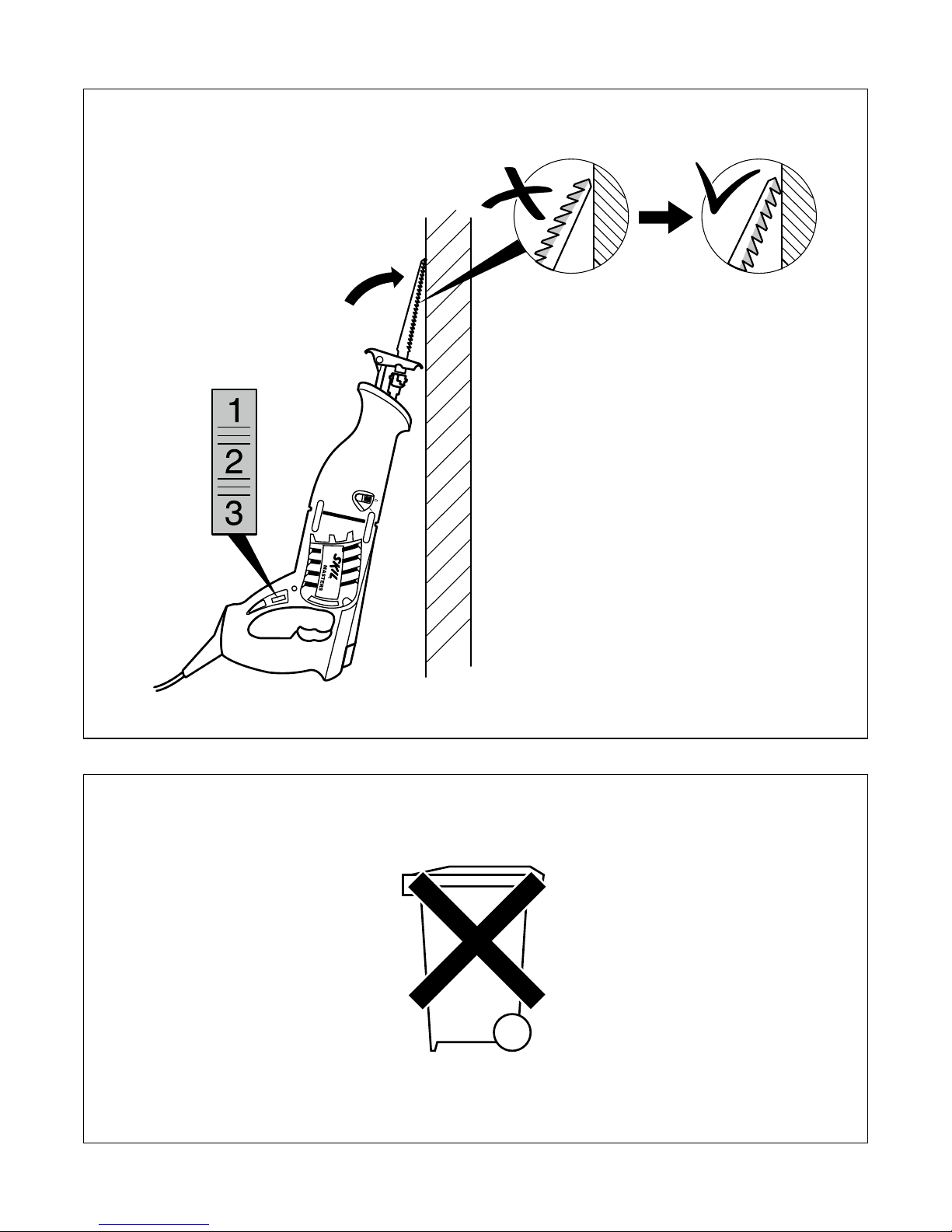

• Mounting saw blade 7

! disconnect the plug

- press blade clamp D forward and hold it in that position

- insert blade (with teeth facing down or up) to full depth

- release blade clamp D

- pull out blade somewhat until clamp D clicks into a

square position

- push in and pull out blade to check whether it is

locked correctly

! ensure that blade clamp D 2is tight before

making a cut (a loose clamp may cause the tool

or blade to slip with loss of control as a result)

! ensure that the front end of the blade extends

through footplate E for the entire stroke length

• Removing saw blade 8

- press blade clamp D forward and hold it in that position

- pull out blade

- release blade clamp D

• Adjustable footplate 9

- footplate E tilts in order to keep as much of its surface

in contact with the workpiece

- adjust footplate by holding the saw rmly and turning

footplate to desired position

• Blade storage compartment 0

- ensure that storage compartment F is closed to

prevent blades from falling out

• Operating the tool

! securely clamp the workpiece

- mark the cutting line on the workpiece

- select desired sawing speed with wheel C 2

- connect plug to power source (light B turns on

indicating that the tool is receiving power) !