Ilsintech Keyman S1 User manual

Other manuals for Keyman S1

2

Table of contents

Other Ilsintech Welding System manuals

Popular Welding System manuals by other brands

Chicago Electric

Chicago Electric 68888 Owner's manual & safety instructions

EWM

EWM TIGSPEED OSCILLATION DRIVE 45 COLDWIRE operating instructions

INFRALAN

INFRALAN Splicer HS15 Series user manual

Sealey

Sealey Power WELDERS TIG170T instructions

Chicago Electric

Chicago Electric 91811 Assembly and operating instructions

Campbell Hausfeld

Campbell Hausfeld WF2050 Operating instructions & parts manual

EWM

EWM PHOENIX 301 CAR EXPERT PULS operating instructions

Lampert

Lampert PUK5.1 operating manual

CEA

CEA TREO 1800 Synergic MIG-MAG Operator's manual

Eastwood

Eastwood TIG 200 Assembly and operating instructions

ESAB

ESAB Ruffian ES 150G EDW instruction manual

Lincoln Electric

Lincoln Electric 45 Operator's manual

Abicor Binzel

Abicor Binzel MT 452 W operating instructions

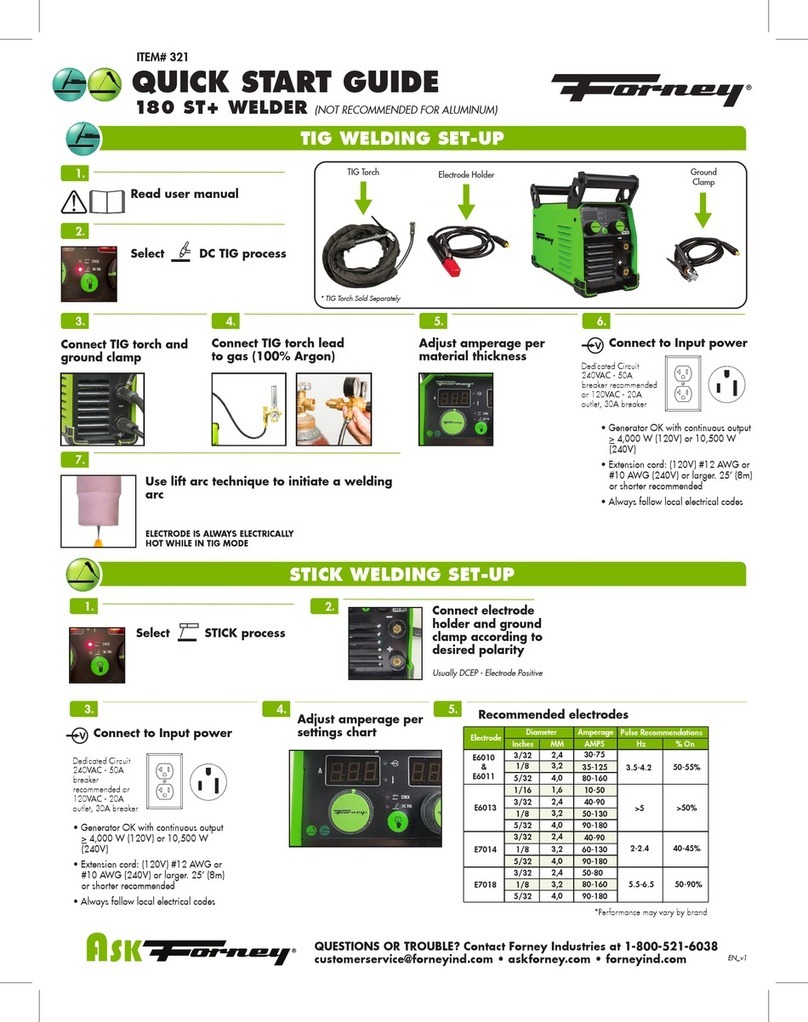

Forney

Forney 180 ST+ quick start guide

SBM

SBM Defort DWP-1000 user manual

Lincoln Electric

Lincoln Electric PRECISION TIG SVM186-A Service manual

Lincoln Electric

Lincoln Electric RANGER GXT IM856 Operator's manual

WARPP

WARPP INTIG 402 PULSE operating manual