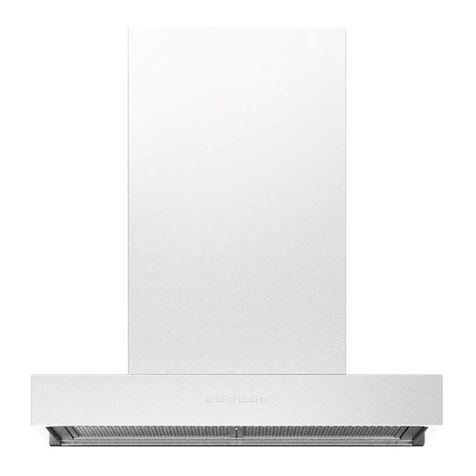

Exhausting cooker hood. The equipment is constructed in

accordance with European Standards and with the requirements

included in the following Directives: 2006/95EC ( Low Voltage

Directive), 2004/108 (Electromagnetic Compatibility).

1 INSTALLATION

Read the whole instruction booklet before installing and/or using

the hood.

With the hood correctly installed, the minimum distance between

the wall-mounted unit and the cooking surface of a gas stove

must be at least 62 cm.

With the hood correctly installed, the minimum distance between

the wall-mounted unit and the cooking surface of an induction

cooker must be at least 50 cm.

Please comply with all the regulations regarding air discharge.

The air must never be discharged into a duct used to discharge

the fumes produced by gas combustion appliances (not

applicable to hoods used in ltering mode).

The room must have sufcient ventilation when the hood is used

together with other appliances that use gas or other fuel.

During installation, we recommend you move the units

underneath it for better accessibility.

The hood is supplied with all the xings required to install it,

suitable for most wall units. Check anyway that the surface of the

wall units is adequate.

Installation must be carried out by competent and qualied

installers in compliance with the regulations in force.

The hood is provided with a plastic back spacer to adapt its depth

to that of the wall unit (from 30 to 35 cm). Proceed measuring the

depth of the wall unit side “X” (Fig. 1), deduct from this value the

depth of the hood that is 30cm. The difference is depth “A” (Fig.

1), the distance the spacer will have to be cut at with a cutter. If

the wall unit depth is 30 cm, no spacer is required.

At this point, x the already cut spacer to the hood (Fig. 2).

Fix the two brackets supplied to the unit internal walls, complying

with the distances shown (Fig. 3).

Insert the hood from the front; use the previously xed brackets

as guides that must be inside the seat located on the hood sides

(Fig. 4).

After positioning the hood correctly, x it to the guides with the 4

screws supplied (Fig. 5).

2 ELECTRICAL CONNECTIONS

This appliance must be connected to an earthed system.

Two types of connection to the network are possible:

With a standard plug connected to the mains cable and

inserted in an accessible system socket (that can be

disconnected during maintenance). Ensure the plug is

accessible also once the installation is completed.

Via a xed connection to the mains, placing in-between a

bipolar switch ensuring disconnection from the mains, with

a distance in the contact opening that allows complete

disconnection from the mains in the conditions of

overvoltage category III, in compliance with the installation

regulations. The earth connection (yellow-green wire)

must not be interrupted.

For voltages and frequency, check the data plate inside

the appliance.

If the power cable is damaged, it must be replaced by the

manufacturer or by its technical service centre or, anyway,

by a qualied person, in order to prevent any risk.

3 USE

This hood can be used in extracting or ltering mode.

Extracting (expulsion to the outside). Kitchen fumes are

expelled through the piping (not supplied with the hood)

connected to the motor discharge.

The piping must never be connected to combustion discharge

pipes (stoves, boilers, burners, etc.).

The use of long pipes, with many bends, corrugated and with a

diameter smaller than the motor outlet’s will cause a decrease in

extracting performance and an increase in noise.

Filtering (recycling). The fumes pass through the carbon

anti-odour lter (not supplied with the hood) to be puried and

recycled in the kitchen. The use of the carbon anti-odour lter

reduces the hood performance, we therefore recommend the

hood is installed in extracting mode.

4 OPERATION

This hood has been designed to prevent the formation

of condensation on its lower surfaces when it is installed

over an induction cooker.

Unlike a gas stove, an induction cooker heats only the

pans containing the food and not the surrounding area, so

the surfaces of the hood remain cold.

When the hot cooking fumes go up, they hit the hood cold

surfaces, condense and therefore release the humidity in

the air that quickly transforms into small water drops that

inevitably fall on the cooking surface and food, carrying

with them fat and impurities.

To prevent this from happening, all the lower surfaces of

the hood are heated by a system of internal and therefore

invisible resistors, so the hood lower surfaces getting

warm, even without switching the cooker on, is quite

normal and does not show that the product is not working

properly.

To switch the hood on, rst open the fume ap using the

relative handle in the lower part. Lightly pull downwards

and then extract ap “A” fully (Fig. 6). A special sensor will

automatically switch the hood off when you try and close

the ap with the hood on.

The controls consist of keys to switch the TL lamp on, to

switch speed one on and switch extractor T1 off, to select

the T2-T3-T4 running speeds and to activate the anti-

condensation function T5 (Fig. 7). The anti-condensation

function comes automatically on when the hood is switched

on with key T1, it can anyway be switched on and off with

key T5.

To switch the motor off, press T1 only once if the hood is

operating in 1st speed, twice if it is running at other speeds.

The internal fat lter is not heated to allow condensating

most of the humidity in the air, this surface will therefore

show some drops that are collected in a special tray.

This container should be emptied every time you nish

cooking. To empty the container, rst of all open fume ap

“A” (Fig. 6), with the hood switched off, pull lever “B” (Fig.

8), located in the back of condensate tray “C” downwards

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS FOR COOKER HOOD H15 MODELS

230-240 Vac - 50 Hz