CONTENT

1INTRODUCTION......................................................................................................... 3

1.1 Conformity ............................................................................................................ 3

1.2 Intended use......................................................................................................... 3

1.3 General safety information..................................................................................... 3

1.3.1 Photosensitive epilepsy....................................................................................3

1.3.2 Eye safety.......................................................................................................4

2GETTING STARTED................................................................................................... 4

2.1 Scope of delivery................................................................................................... 4

2.2 Commissioning...................................................................................................... 4

3OPERATING INSTRUCTIONS HARDWARE ............................................................... 5

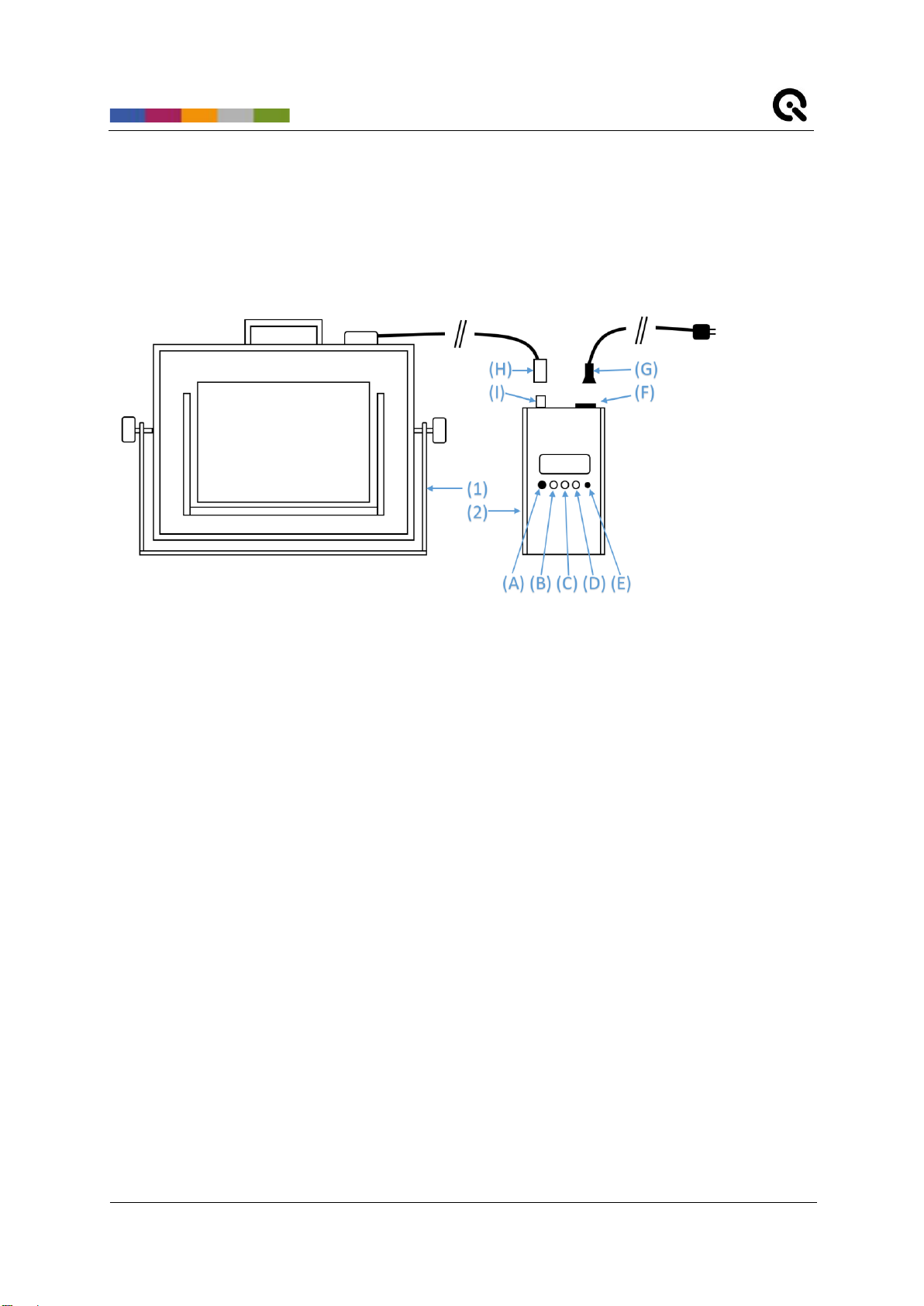

3.1 Overview............................................................................................................... 5

3.2 Connecting the hardware....................................................................................... 5

3.3 Starting the system................................................................................................ 6

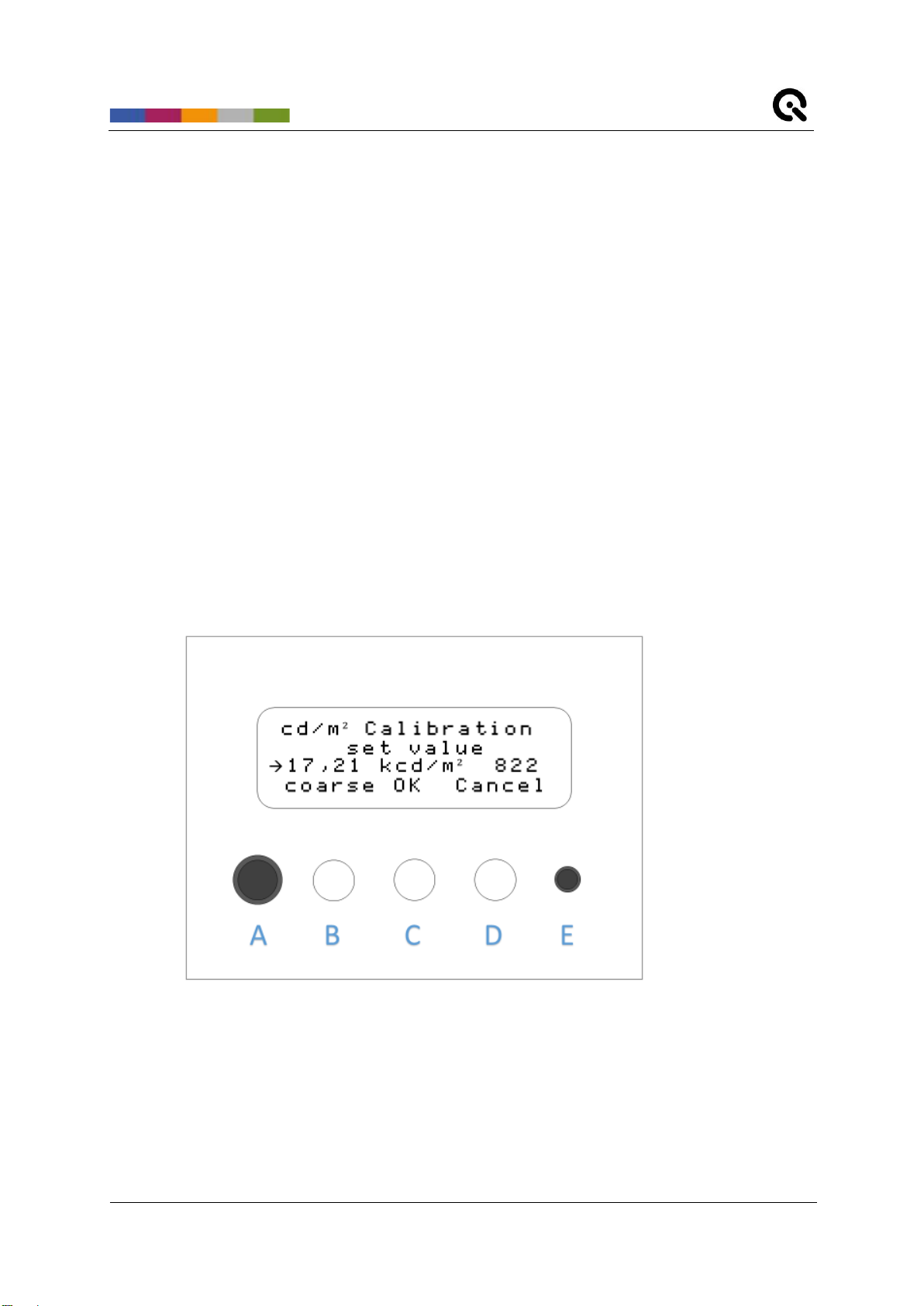

3.3.1 Calibration.......................................................................................................6

3.4 Continuous illumination.......................................................................................... 6

3.4.1 Power modes ..................................................................................................7

3.4.2 PWM (Pulse Width Modulation)........................................................................7

3.4.3 Setting the illumination level.............................................................................9

3.4.4 Intensity stabilization........................................................................................9

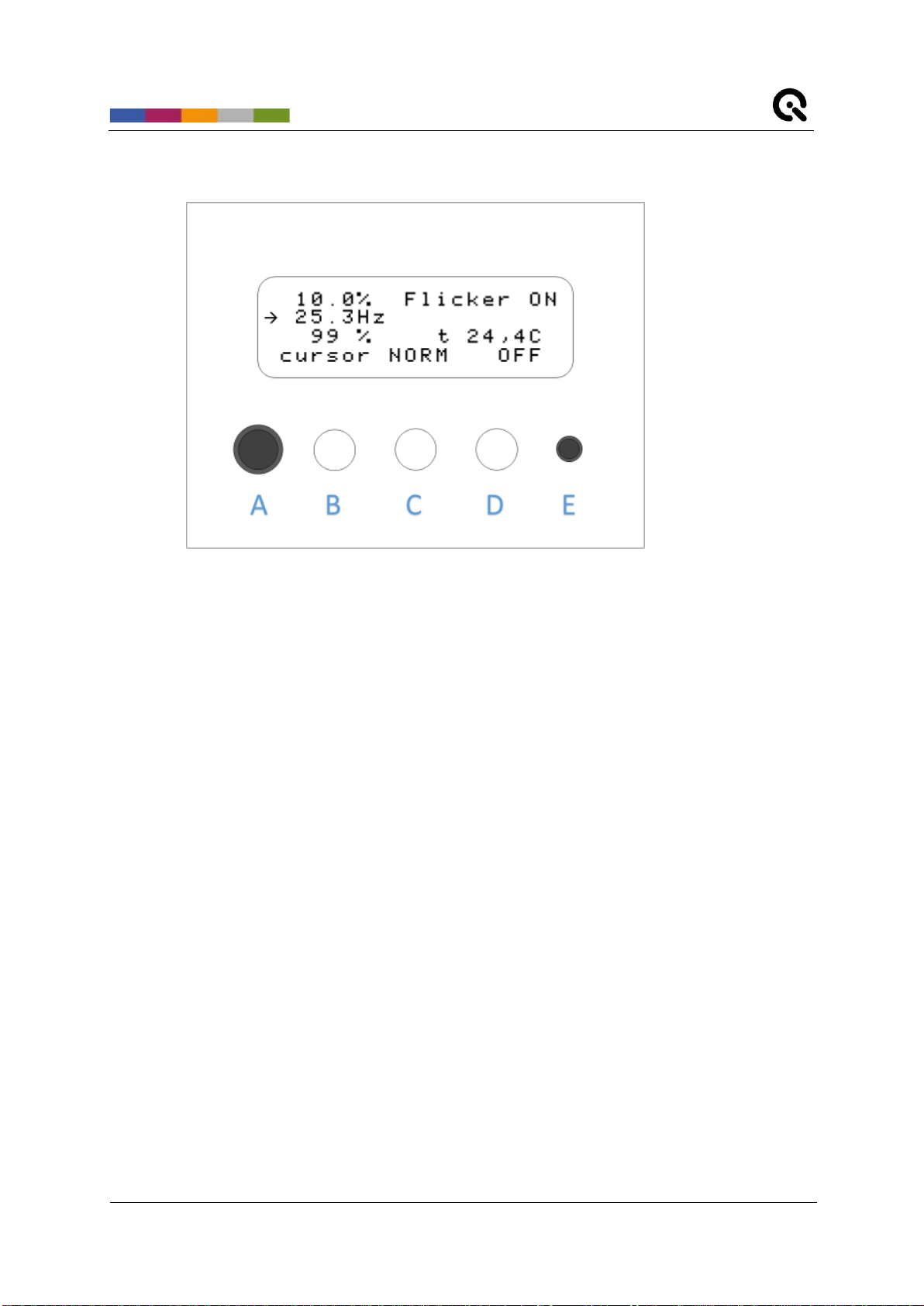

3.5 Flicker..................................................................................................................11

4ADDITIONAL INFORMATION....................................................................................13

4.1 Maintenance ........................................................................................................13

4.1.1 Fuse replacement..........................................................................................13

4.2 Storage and transport...........................................................................................14

4.3Disposal instructions.............................................................................................14

5TECHNICAL DATA SHEET........................................................................................14