PLASTIC WELDING

Basic requirements for plastic welding. TIME, TEMPERATURE & PRESSURE

Most plastics used today are thermoplastics, which are generally suitable for

repair by welding.

Four basic rules for plastic welding are suggested:

1. Weld with like material.

Only like materials can be welded, i.e. PP with PP.

2. Correct temperature. The plastic should be pre-heated. Select the right

temperature matched to the material being repaired.

3. Even pressure.

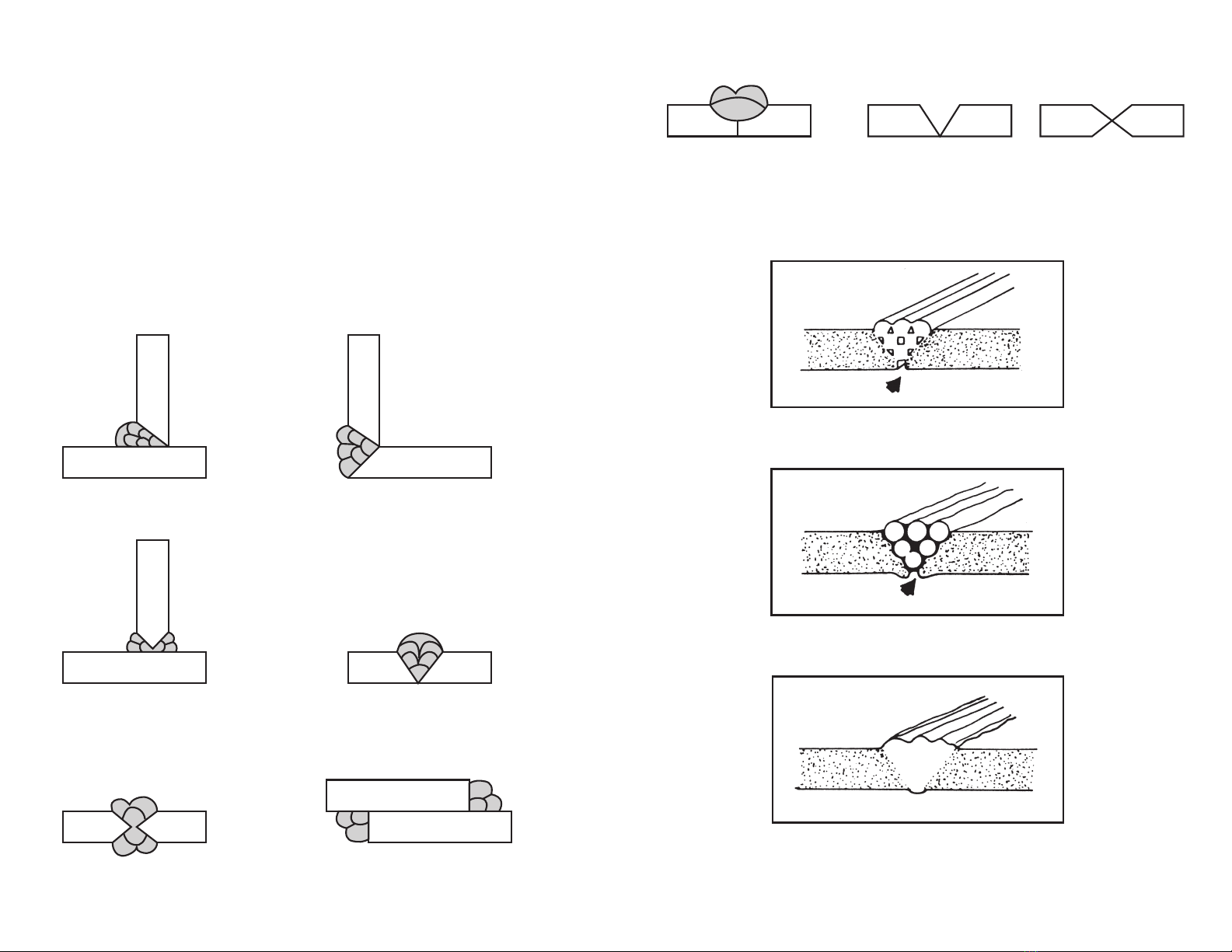

When welding with rods, the pressure is applied by

pressing on the welding rod. For overlap welding of films and tarpaulins, the

necessary pressure is applied with the help of the optional pressure roller.

4. Constant welding speed. To achieve a good weld, an even working

speed should be maintained. When welding plastics with the Master

Proheat, the following three variables are critical to achieve a good weld.

TIME, TEMPERATURE & PRESSURE

• Time. If you move the heat tool too fast or too slow, the quality of the weld

will be compromised. Maintain constant speed during the welding process.

• Temperature. Set the welding temperature for the plastic that you are

welding. Adjust the temperature and airflow to obtain the best setting

combination for the plastic you are working with. Locking-in the setting

enables you to maintain the set temperature throughout the welding pro-

cess. The Master Proheat Model PH-1400 has the ability to tightly control

and lock-in the temperature through an on-board electronically controlled

temperature and air speed system. See the heat gun instruction manual

on how to lock-in settings.

• Pressure. Pressure is applied by pushing down on the welding rod while

welding or, if butt welding, on the two edges that are being overlap welded

together. Master Appliance Corp. manufactures precise welding tips that

help the welder apply equal pressure throughout the welding process.

Thermoplastic welding temperatures.

There are different types of plastic so it is important to identify the type you are

working on in order to make sure that the proper welding rod is used. Thermo-

plastics can be formed with heat and retain their shape after cooling and can be

easily welded. Thermosets (Duroplastics and Elastomers) cannot be welded.

Duroplastics are hardened with heat and their shape cannot be changed with

heat. Elastomers (rubber) can be formed with heat but cannot be welded.

MASTER

PROHEAT

®

Plastic Welding Kit

Each Welding Kit Includes:

PH-1400

• Dial-in LCD display of temperature and airflow settings

• Dial-in temperatures in 10 increments 130 F to 1,000 F

• Dial-in airflow from 4 to 16 CFM (113 to 453 l/min)

• Control system prevents overheating when using specialty attachments

• Temperature & airflow lock-in feature

• Assembled in USA

• One Compact, Lightweight,

Easy to Use, Master

Proheat® Model PH-1400

Heat Gun

• 5 Starter Welding Rod

Assortment

• 6 qty– 1/8” Dia., 9” Long,

Round PVC Welding Rod

• 6 qty– 1/8” Dia., 9” Long,

Round PP Welding Rod

• 6 qty– 1/8” Dia., 9” Long,

Round ABS Welding Rod

• 6 qty– 1/8” Dia., 9” Long,

Round HDPE Welding Rod

• 6 qty– 1/8” Dia., 9” Long,

Round LDPE Welding Rod

• Speed Welding Tip

• For welding rod up to

6mm dia.

• Slit nozzle

• To melt plastic welding rod

• 3/8” Reducer

• To adapt welding tips to

• 5/8” Reducer

• To provide concentrated

airflow

• 1 ¼” Shrink Attachment

• Reflects air around shrink

tubing or pipe

• Plastic Welding & Proheat

Instruction Manuals

• Informative How to Use

Instructions

• Heavy Duty Storage &

Carrying Case

• Safely & conveniently stores

Kit contents

PH-1400WK