IMER USA COMBI 350 Guide

OPERATING,MAINTENANCE,SPAREPARTSMANUAL

09/2003 - R5

- Cod. 3214816 -

IMER U.S.A. Inc.

207,LawrenceAvenue

South San Francisco, California 94080

(650) 872-2200

COMBI 350

SAWINGMACHINE

2

IMER U.S.A. Inc.

COMBI350

DearCustomer,

Congratulationsonyourchoiceofpurchase:IMERsawsaretheresultof

yearsofexperienceandisequippedwithallthelatesttechnicalinnovations.

WORKINGINSAFETY

Toworkincompletesafety,readthefollowinginstructionscarefully.

-ThisOPERATIONANDMAINTENANCEmanualmustbekeptonsite

bythepersonincharge,e.g.theSITEFOREMAN,andmustalwaysbe

availableforconsultation.

-Themanualistobeconsideredintegralpartofthemachineandmust

bekeptforfuturereference(EN292/2)untilthemachineisdisposedof.

Ifthemanualisdamagedorlost,areplacementmayberequestedfrom

thesawmanufacturer.

-Themanualcontainsimportantinformationregardingsitepreparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experienceandknowledgeofthemachinepriortouse.

-Toguaranteecompletesafetyoftheoperator,safeoperationandlong

life of equipment, follow the instructions in this manual carefully, and

observeallsafetystandardscurrentlyinforceforthepreventionofaccidents

atwork(useofsafetyfootwearandglovesinaccordancewithS.I.N°3073

of30/11/92).

Pay special attention to warnings bearing the following symbol.

Safetyglasses ora protective visor mustbe wornatall

times.

MAKE SURETHAT SIGNSARE LEGIBLE.

Itisstrictlyforbiddentocarryoutanyformofmodification

tothesteelstructureorworkingpartsofthemachine.

-IMERINTERNATIONALdeclinesallresponsibilityfornon-compliance

withlawsandstandardsgoverningtheuseofthisequipment,inparticular;

improperuse,defectivepowersupply,lackofmaintenance,unauthorised

modifications,andpartialortotalfailuretoobservetheinstructionscontained

inthis manual.

2. DESIGNSTANDARDS

COMBI 350 saws are designed and manufactured according to the

followingstandards:I.E.C.34.4;EN89/392(91/368/CEE);CEIEN60204.

3.NOISEEMISSIONLEVEL

Operatorexposuretosoundemissionlevels(continuoussoundpressure

levelsequalto A weighting);theCOMBI350sawnoiseemissionlevel

duringcuttingis93dB(A)withcontinuousrimblade.

4.CUTTINGSPECIFICATIONS

ThissawmodelhasbeenspeciallydesignedbyIMERforcuttingstone,

ceramics, marble, granite, concrete and similar materials. Only water-

cooleddiamond bladeswithcontinuous orsegmentededgesmustbe

used. Under no circumstances must dry cutting blades be used or

materials other than those specified above. IMER INTERNATIONAL

declines all responsibility for damage caused by improper use of the

abovemachine.

TECHNICAL DATA COMBI 350

350/600 350/1000

Blade rpm rpm 2150 2040 / 2150

Blade diameter inc 14''

Blade mounting hole inc 1''

Motor rating Hp 3.0 1.5 / 3.0

Motor rpm rpm 3450 3260 / 3450

Cutting table

dimensions inc 20'' x 31'' 20'' x 46''

Overall dimensions inc 47'' x 34'' x 51'' 63'' x 34'' x 51''

Overall dimensions for

transport inc 51'' x 28'' x 37'' 67''x 31'' x 37''

Weight lb 253 287

Weight for transport lb 298 342

Blade rotation

direction(seen from

blade clamping flange) ANTI - CLOCKWISE

Current A 11 13.4 / 11

Voltage V 230 115 / 230

Frequency Hz 60

5.CUTTINGCAPACITY

- Max. thickness (inc): 5'' (90°); 3'' (45°)

- Workpiece width (inc): max. 20'' ; min 2''

-Length: COMBI350/600 COMBI350/1000

thk. x l (inc) 1''x24'' 1''x 40''

3''x 22'' 3''x 38''

(*) 90° cut from above

5''x 21'' 5''x 37''

5''x28'' (*) 5'' x43''(*)

(**) 45° 45 x 21'' (**) 70 x 37'' (**)

6.WARNING

-Donotloadthesawwithworkpiecesthatexceedthespecifiedweight

(max.90lb).

-Ensurestabilityofmachineandworkpiecebefore,duringoraftercutting.

Install supplementary support surfaces at the same height as the

worktable.

- Respect the environment; use suitable receptacles for collection of

coolingwatercontaminatedwithcuttingdust.

7. SAFETYPRECAUTIONS

IMER saws are designed for work on construction sites and under

conditionsofnaturallightandinworkshopsunderconditionsofnatural

orartificial lightingof minimum500 LUX.

Fig. 1 MACHINE LAY-OUT

1 TELESCOPIC LEG

2 SPRAY GUARD

3 MOTOR

4BLADE SUPPORT

ARM

5 WATER PUMP

6 GUIDE

7 MAIN SWITCH

8 WORKTABLE

9 WATER TANK

10 BLADE GUARD

11 EARTHING SCREW

12 HEAD BLOCKAGE

Fig. 1 - Machine Lay-out

3

IMER U.S.A. Inc.

COMBI350

The machine must never be used in environments

subject to risks of explosion and/or underground sites.

-IMERsawsmayonlybeusedwhenfittedwithallrequiredsafetydevices

which must be in perfect condition.

- Never use makeshift and/or faulty power cables.

- Make electrical connections on the construction site where they will

not be subject to damage. Never stand the saw on power supply cables.

- Lay power cables where they are not subject to risk of damage or

contact of connectors with water. Only use connectors fitted with water-

spray protection (IP55).

- Repairs to electrical installations must only be carried out by qualified

technicians. Always ensure that the machine is disconnected from the

powersupplyandiscompletelyimmobileduringrepairsandmaintenance

operations.

-Connectthemachinetoasuitableequipotentialearthing

plant on the construction site with wire braid of minimum

16 mm² section. The connection point is identified by a

screw welded to the frame (see Fig.1), and on the rating

plate by the

earthingsymbol.

-Stopthesawonlybymeansofthemainswitch.

-Thesymbolshownonthelabel(seeleft)indicatesthe

warning ENSUREALLPROTECTIONDEVICESARE

INSTALLEDANDINPERFECTCONDITIONBEFORE

SWITCHINGONTHEMACHINE

8.ELECTRICALSAFETY

IMERsawscomplywithEN60204-1;andarefittedwith:

-protectiondeviceagainstautomaticre-startafterpowerfailure;

-Short-circuitcutoutdevice;

-Motoroverloadcutoutswitch.

9.TRANSPORTATION(Ref.Fig.2)

WARNING!Alwaysremovetheplugfromthepowersocket

beforemovingthesaw,andlockheadsupportcarriagemovement

bymeansoftherelativeknob(ref.3).Totransportthemachineuse

slingingequipmentwith4ropelegs,fixingthehookstotherelative

attachments.

10.INSTALLATION(Ref.Fig.2)

Fix the hooks to the relative attachments on the machine and lift the

machineoutofitspackage.

-Unlockthelegsbyslidingoutsplitpins(ref.2)andpins(ref.1).

-Lockthelegs atworkingheight.Refitthe pinsinthe leg supportsand

insertthe splitpins.

-Installthemachineonacompletelyevenandstablesurface.

11.ELECTRICALCONNECTION

Ensurethatthereisanoverloadcutoutdevicefittedup-

lineonthepowerline.Ifnecessary,installanIMERquickconnect

residualcurrentcircuitbreaker(RCCB)(codeno.1169245available

inkitformfor 230Vmachines).

Ensure that the mains voltage corresponds to that specified for the

machine: 230V/60Hz - 115V/60Hz.

AllpowersupplyinstallationsmustcomplywithCEI64-

8standards(harmoniseddocumentCENELECHD384).

Theelectricalpowercablemustbesuitablysizedtoavoidvoltagedrops.

Cabledrums(withcollectorrings)mustnotbeused.

Cabledimensionswillvaryaccordingtothestart-upcurrentandlengthof

cable.Ingeneralcablesizesof4mm²aresufficientforlengthsupto160

ft.Afterinstallationalwayscarryoutvoltagetestingunderloadconditions,

both at start-up and during operation. During operation,voltage drops

mustneverexceed5%.Inthecaseoflongercablesorapowersupply

network subject to variations, use cables with a section of at least 6

mm². Cables used on construction sites must be fitted with suitable

externalsheathingthatisresistanttowear,crushingandextremeweather

conditions.

12.MACHINESTART-UP

Beforeconnectingthemachinetothepowersupply:

1-Ensurethatthemetalstructureisconnectedtoanearthingplant as

indicatedinSection7 SafetyPrecautions .

2-Ensurethatthetankcontainssufficientcoolingwater.

3 - Ensure that the power circuit corresponds to the requirements as

indicatedinSection11 Electricalconnections

4-Connectthemachinetothepowersupply.

5 - Set the switch to 1 and when the motor is started return to

position 0 after ensuring that cooling water reaches the blade.

6 - Check that the direction of blade rotation corresponds to that

indicatedbythearrowonthebladeguard.

7-Ifallisinorder,proceedwithcutting.

13.EMERGENCYSTOP

-Intheeventofemergency,stopthemachinebypressing

thestopcontrolswitch.

-Themotorisfittedwithanoverloadcutoutdevice.Ifthe

motor overheats, it will automatically shut down. Allow motor to

coolbeforere-starting.

-Themotorisprotectedagainstautomaticre-startafter

interruptionsduetopowerfailure.Toresumeoperation,whenpower

isre-connected,repeatmachinestart-upprocedure.

14.BLADEINSTALLATION(Ref.Fig.3)

Bymeansofahexwrenchno.10,removefrontscrews(ref.1)andloosen

theothertwoscrews(ref.2)whichsecurethebladeguard.Turntheguard

clockwisetogainaccesstothesecuringscrew(ref.4).Useahexwrench

no. 13 toremove the screw (turn anti-clockwise). Remove the mobile

flangeandcheckthattheflanges,discshaftandbladearenotdamaged.

-Neverusewornblades.

- Only use blades that are designed for the number of

revolutionsindicatedonthemachineratingplate.

-Checkthatbladerotationcorrespondstothatindicated

onthe bladeguard.

Centrethebladeagainstthefixedflange,positionthemobileflangeand

tighten the securing screw by means of a hex wrench no. 13 (turn

clockwise).Returntheguardtoitsoriginalpositionandlockbymeansof

screws(ref.1and2).

- Ensure that the blade guard is locked securely into

position.

- WARNING! An incorrectly installed blade, or a screw

insufficientlytightenedcanprovokedamagetothemachineorinjury

to persons.

- Note that the blade must have an external diameter of

350 mm., a central hole diameter of 25.4 mm and max.thickness of

3 mm.

- Check that the blade to be used is suitable for the

material to be cut.

15.USE

Leavea spaceof 5ftaround the machinetooperate in

fullsafety.

-Donotallowotherpersonstoapproachthemachineduringcutting.

- Never use the machine in fire-risk areas. Sparks can cause fire or

explosions.

-Makesurethatthemachineisswitchedoffbeforepositioningorhandling.

-Alwaysensurethatthebladeisfreeofanycontactbeforestart-up.

-Ensurecorrectinstallationofallprotectivedevices.

-Ensurethatbladerotationcorrespondstotheindications

onthe bladeguard.

Beforestartingwork,fillthewatertank.Topupduringoperationwhenever

necessary: N.B. the pump suction hose must always remain

immersed in water.

Insertthepluginthepowersocket.

WARNING!

Forsafetypurposestheremovalofprotective

guardsfromthemachineisstrictlyprohibited!

Themachineisprotectedagainstoverload.

WARNING!

Alwaysswitchoffthemachinebeforecarrying

outbladeadjustment.

15.1VERTICALBLADEMOVEMENT(Ref.Fig.4)

Toraiseorlowertheblade,slackenknob(ref.2)byturningitanti-clockwise.

Setbladesupport(ref.1)totherequiredpositionandlockbytightening

theknobfully(ref.2).

Ensure that the locking knob is tightened fully before

starting work.

15.2 BLADE POSITIONINGFOR 45° CUTS (Ref.Fig.5)

Slackenknob(ref.1);theblade supportarm(ref.2)is unlockedand

so can be set to its limit position, i.e. inclined at 45° with respect to

4

IMER U.S.A. Inc.

COMBI350

the worktable. Tighten the knob fully to lock into position.

Tobringthebladebacktotheverticalposition(pos.0)carryouttheabove

operationsinreverseorder.

Ensurethatthelockingknob(ref.1)istightenedfullybefore

startingwork.

15.3CUTTING

- Before cutting, check that the blade is aligned with the cutting

line.

- Place the workpieceon the worktable snuglyagainst the fence.

- Start the motor and wait until the water reaches the blade to

begin cutting.

- Start cutting movement by pulling the carriage towards you

by means of the relative handle (ref.1 fig.6).

As cutting thickness increases, the blade is subjected to

greater stress. To avoid overloading the motor, the operator should

continually check blade feed speed. The speed will also depend on

the characteristics of the material being cut (hardness, toughness

etc.).

15.3.1CUTSWITHBLADELOWEREDFROMABOVE

(Ref.Fig.8)

Bring the blade support to its highest position and lock. Position the

workpieceontheworktable.Startthemachine,unlockthebladesupport

andbegin vertical cutting untilthe blade reaches its lowest point. Lock

thesupportoncemoreandproceedwithhorizontalcutting.

15.3.2BLADECHANGE

Tochangethebladerefertosection14.BLADEINSTALLATION.

Do not use blades for wood or segmented disks with

slots wider than 5 mm.

16. MAINTENANCE

- WARNING!

Always switch the machine off and

remove the plug from the power socket before carrying out

any maintenanceoperations .

- Always check that the protective guards are in the

correct position andin perfect condition.

-Asthereisthecontinuousriskofinadvertentdamage

to the electric cables, these must be checked regularly each

time before the machine is used.

-WARNING! If the electric motor or control panel

are removed for maintenance, it's necessary to replace

the relevant seals in order to guaranty the right degree

of protection and safety against water penetration inside

to the electric circuits.

Neverleavethemachineoutintheopen.Makesurethatit isstored

in a sheltered area away from extreme weather conditions.

Replace worn or faulty components with original spare parts.

- WARNING! Recommend product for cleaning

and lubrificating the mechanical parts of the saw:

WD-40

16.1 TANK CLEANING ON WORK COMPLETION

On completion of work, empty the tank and remove. Clean

thoroughlyto removecuttingresidue.

16.2TANKREMOVAL(Ref.Fig.7)

Lift the tank (ref.1) to detach from its supports (ref.2) and remove

from the side indicated by the arrow.

16.3WORKSURFACECLEANING

Always keep work surfaces clean. Residual dirt can impair cutting

precision.

16.4GUIDE RAILCLEANING

Thehorizontalguideelementsonthecarriageareprotectedagainst

dirtbuild-up byscrapers.Howeverweadvise thoroughcleaningof

theguide rails to ensure correct operation.

WARNING! Do not use any type of lubricant on the

guide rail.

FAULT CAUSE REMEDY

Motor does not start

when switch is

turned

- Defective power

cable

- Plug not inserted in

socket correctly

- Power cable from

plug to control panel

detached

- Loose wire inside

motor circuit board

- A wire has become

disconnected inside

the panel

- Faulty main switch

-The overload safety

device has been

activated.

- Check power cables

- Ensure correct

connection

- Connect cable- re

-Connect wire

- Remake the connection

- Replace switch

-Wait for a few minutes

and then try restarting

the machine.

Vertical blade

movement not

smooth

- locking knob too tight - Slacken knob

Blade inclination not

smooth - locking knob too tight - Slacken knob

Horizontal carriage

movement not

smooth

- Locking knob too

tight.

-Incorrect guide wheel

adjustment .

- Slacken knob

- Adjust (Chapter 16.8)

Lack of cooling water

supply to blade Refer to section: "cleaning and maintenance of

cooling circuit"

Blade does not cut

- Incorrect blade

rotation

- Blade is worn

- Remove the blade and

refit in the position as

indicated on the blade

label.

- Fit new blade

Motor starts but

blade does not rotate Belt is broken Replace drive belt, see

Chapter 16.6

16.5 CARRIAGE CLEARANCE ADJUSTMENT (Ref. fig.9)

LATERAL ADJUSTMENT: turn adjustment screw 1 gradually

clockwise using a hex wrench no.3, so that the internal roller

comes into contact with the bar. Take care not to exert too much

pressure. Repeat the same operation with the other adjustment

screws according to the order indicated in the figure. Adjust

vertical clearance by means of the screws located on the lower

partofcarriage(A).On completion,ifcarriagetravelis notsmooth,

slacken the adjustment screws by turning the wrench anti-

clockwise; if clearance has not been eliminated repeat the above

operation.

16.6CLEANINGANDMAINTENANCEOFCOOLINGCIRCUIT

-Ifwaterdoesnotreachthebladestopthemachineimmediatelytoavoid

bladedamage.

-Afterswitchingoffthemachineensurethatthewaterlevelissufficient.

- If necessary, after disconnecting the machine from the power supply

checkthatthetap,hoseandpumpfilterarenotblocked

-Ifnecessary,checkthattheimpellerrotatesfreely(afterextendedperiods

ofdisuse)

-Ifnecessary,removethepumpandcheckthatthepump/motorcoupling

isinperfectcondition.

16.7DRIVEBELTREPLACEMENT

-Disconnectthemachinefromthepowersupply

-Removethewaterhoseconnectionbylooseningthehoseclamponthe

bladeguard.

-Removetheblade,thetwoflanges,thebladehalf-guardsecuringscrews,

the locking knob (ref.1, chart 02) and remove the blade external half-

guard(motorside).

-Removethebladeshaftwithpulleyfromthebearing(ref.27,drawing02)

andfitintothebearingofthehalf-guardpreviouslyremoved(ref.14,chart

02).

-Fitthenewbeltontothetwopulleysandrefitthebelttensioner.

- Refit the seal on theedge of the guard and ensure that it is in good

conditionandthatthetwolocatingpinsareinthecorrectposition.

-Refittheguardinsertingthebladeshaft intothe bearing(ref.27,chart

02)takingcaretoalignthescrew(ref.51,drawing02)locatedontheslot

of the head fulcrum (ref.19, drawing 02) with the locking handle hole

(ref.1,drawing02).

-Jointhetwobladehalf-guardsusingthetwolocatingpinstoaligncorrectly.

- Screw in the two blade half-guards by tightening diagonally opposite

screwsalternately.

-Screwinandtightenthelockinghandlebeforeinstallingtheblade.

17.TROUBLESHOOTING

N.B.:Before carryingout any maintenanceoperations,

switchoff themachine,settheswitchto 0 andremovetheplug

fromthepowersocket.

5

IMER U.S.A. Inc.

COMBI350

Fig.8

Fig.6

Fig.4

Fig.2

Fig.7

Fig.5

Fig.3

Fig.9

6

IMER U.S.A. Inc.

COMBI350

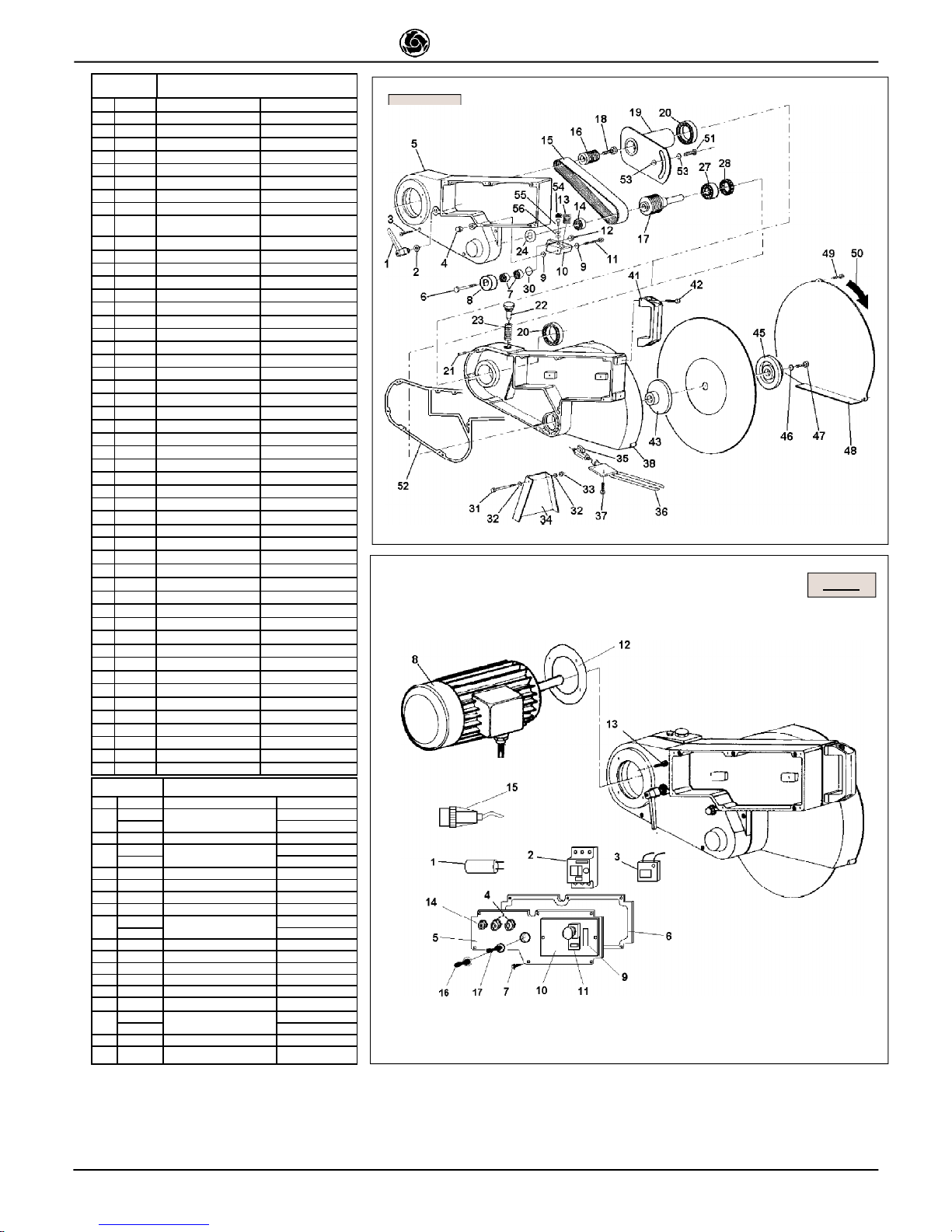

18. SPARE PARTS

:All orders for spare parts must indicate the following: 1 - Type of machine.2 - Part number and position number of each part.3 - Serial number and year

of manufacture reported on the machine's identification plate.

SYMBOL: Interchangeability (example):Pos..1 P.n. 3204530 was installed on machincs up to N° 5240 and Pos.1.1 P.n. 3204520 installed on machine N° 5241 onwards. Pos. 1.1 is

interchangeable ( ) with Pos. 1.Pos. 1 and Pos. 1.1 are not interchangeable if the ( ) symbol appears in the table.

Rif. Cod. I F GB D E Note

1 3204530

Riduttore Réducteur Reducer Untersetzungsgetriebe Reductor 5240

2 3204520

Riduttore Réducteur Reducer Untersetzungsgetriebe Reductor 5241

AK 012 - AK013 TAB 1 - FR AME ASSEMBLY

RIF. COD. USA DETAILS RIF. COD. USA DETAILS

1 3205730 BOLT 5737 12X100 27 2223924 NUT AUTOBL.DIAM.6

2 2224380 WASHER 6593 Ø12X25 28 3205470 END STOP SX

3 3204743 HANDWHEEL 29 3205471 END STOP DX

4 2224340 WASHER 6592 Ø10X20 30 2222515 BOLT 5931 M 8X16

5 3205699 BOLT 5911M10x600 31 3214696 FRAME COMBI 600

6 3232701 ROTARY BLADE ARM DX 3214713 COMBI 1000

7 3232703 CARRIAGE DX 32 2228840 PIN

8 2222137 BOLT 5739 M16x50 33 3201517 COLLAPSIBLE LEG

93232746

3205457 GUIDE BAR COMBI 600

COMBI1000 34 3205577 WATER RUN-OFF TRAY COMBI 600

10 2265675 DAMPER 3205469 COMBI 1000

11 3205502 PIN 35 3204818 DRUM

12 3206209 BEARING 6001 2RS 36 2235428 PLUG

13 3206521 SPACER 37 3208737

3209317 PUMP 230V-60Hz

115V-60Hz

14 3232736 PIN 38 2292365 TUBE

15 2222088 BOLT 5737 M8X40 39 3206318 SUPPORT

16 3205464 FRONT SCRAPER 42 3214195 SPRAY GUARD

17 3232704 CARRIAGE SX 44 2223921 NUT AUTOBL.M 12

18 2223570 NUT 5588 M 8 45 2222056 BOLT 5739 M 10X25

19 2222021 BOLT 5739 M 6X16 46 2223650 NUT 5588 M 10

20 2228820 PIN 47 2241570 SPANNER

21 3205465 REAR SCRAPER 48 3205788 SPANNER

22 2222061 BOLT 5739 M 8X20 49 3206210 WHEEL

23 3232702 ROTARY BLADE ARM 50 2204421 BEARING 6201 2RS

24 3205481 CUTTING TABLE COMBI 600 DX 51 3206085 HANDWHEEL

3205467 COMBI 1000 DX 52 3207219 GONIOMETER

25 3205482 CUTTING TABLE C OMBI 600 SX 53 3205465 FILZ

3205468 COMBI 1000 SX 54 3205464 FILZ

26 2222545 BOLT 5931 M 6X30 55 3201015 PLUG

7

IMER U.S.A. Inc.

COMBI350

AK014 TAB. 2 MOBILE HEAD ASSEMBLY

RIF. COD. USA DETAILS

1 2284827 HANDLE

2 2224380 WASHER 6593 Ø12X25

3 2222541 BOLT 5931 M 6X25

4 2223045 NUT M10 5721-69

5 3232761 COVER

6 3214191 BOLT 5737 M10X50

7 3214655 BEARING 6000 2RS

8 3203910 ROLLER 6592 Ø10X20

9 3214198 WASHER "SS"DIN988

10X16X1,6

10 3214193 BELT TENSIONER ARM

11 2222148 BOLT 5737 M 10X65

12 2223920 NUT AUT. M10 7474

13 3214202 SPRING

14 3206514 BEARING 6203 2RS

15 3204737 BELT

16 3204736 PULLEY

17 3206739 BLADE SHAFT-PULLEY

18 2222016 BOLT 5739 M 6X20

19 3232740 HEAD FULCRUM

19 3206488 HEAD FULCRUM

20 2204510 BEARING 6009 2RS

21 2228820 PIN 6x14

22 3204788 PIN

23 3204787 SPRING

24 3207366 COMPENSATING RING

27 2204540 BEARING 6205 2RS

28 3232759 OIL SEAL RING 35X52X7

31 2222544 BOLT 5737 M 6X60

32 2224531 WASHER 6593 Ø 6X18

33 2223924 NUT AUTOBL. M 6

34 2247898 SPRAY GUARD

35 3205635 VALVE

36 3232763 TUBE

37 2222709 BOLT 5739 M 5X10

38 3232762 SUPPORT

41 2284826 HANDLE COMBI600-MASONRY

42 2222515 BOLT 5931 M 8X16

43 3204777 INNER FLANGE

45 3204776 OUTER FLANGE

46 2224140 WASHER 6593 Ø 8X18

47 2222060 BOLT 5739 M 8X20

48 3204775 BLADE COVER

49 2222021 BOLT 5739 M6X16

50 3207128 LABEL

51 3203914 BOLT TTQ M12X80

52 3232742 GASKET

53 3206131 WASHER 3545 Ø16x35x1,4

54 3213268 SHOCK ABSORBER

55 2222537 BOLT M6X10 Z

56 2224530 WASHER 6592 Ø 6X12.5

AK014 TAB . 3 ASS E MB LY OF MOTOR

RIF. C OD. U SA DETAILS

13214262 CA PAC ITOR 115V /60HZ

2285601 230V/60HZ

2 3207920 CONTACTOR

33207927 COIL 115V/60HZ

3207924 230V /60HZ

4 3201503 C A BLE-CLAMP

5 3207933 COVER

6 3232743 GASK E T

7 3200412 BOLT

83207934 MOTOR 115V /60Hz

3207937 230V /60Hz

9 3205924 LABE L

10 3207929 JUNC TION B OX

11 3207928 P USH

12 3232270 GASK E T

13 1222252 B OLT

14 3201217 C ABLE-C LA MP

15 3207184 PLUG 115V/60Hz

3208070 230V /60Hz

16 3206171 SW ITC H C OV E R

17 3206170 WATE R PUMP S W ITC H

TAB. 2

TAB. 3

8

IMER U.S.A. Inc.

COMBI350

AK014 TAB. 4.1 ASSEMBLYOF MOTOR

RIF. COD. USA DETAILS

13203680 MOTORFLANGE 115V/60Hz

3204830 230V/60Hz

22222970 BOLT 115V/60Hz

2222911 230V/60Hz

32223352 NUT 115V/60Hz

2223280 230V/60Hz

43213619 CASING AND STATOR 115V/60Hz

3216622 230V/60Hz

53214262 CAPACITOR 115/60 MF80 V250

2285601 230/50 MF35 V450

6 2281955 TERMINALS 115/60 230/60

72227900 SPLITRING 115V/60Hz

2237340 230V/60Hz

82204390 BEARING 115V/60Hz: 6204 2Z

2204391 230V/60Hz: 6205 2Z

9 2229325 KEY 6X6X25 6604

10 3203681 ROTOR 115V/60Hz

3204829 230V/60HZ

11 2291495 COVER 115V/60Hz

2291494 230V/60HZ

12 2227097 OILSEALRING 115V/60Hz

3214031 230V/60HZ

13 2291453 MOTORFAN 115V/60Hz

2291454 230V/60HZ

14 2291281 FANCOVER 115V/60Hz

2291282 230V/60HZ

15 2216321 GASKET

16 3213032 COVER

17 3204411 CABLE CLAMP IP68 PG16

18 3214028 SEALRING Ø18,8X1,8 (PG16)

19 2222465 SCREW TRILOB.M5X15

20 3203262 RATINGPLATE 115V/60Hz

3203980 230V/60Hz

21 2288792 RIVET

22 3203678 MOTORFLANGE 115V/60hZ

TAB. 1 - WHEEL KIT

Rif. Cod. GB DETAILS

1 2226700 SPLIT PIN

2 2211150 WHEEL

3 3206261 LEFT TUBE GUIDE

4 3206262 RIGHT TUBE GUIDE

5 2222082 SCREW 5739 M 10X60

6 2223650 DISK 5588 M10

7 3206641 WASHER 6592 28X50X2

8 3206260 WHEEL TUBE

Fig.19 USA

L1 PHASE LINE CONDUCTOR

NNEUTRAL LINE CONDUCTOR

PE PROTECTION CONDUCTOR

I1 THERMO-MAGNETIC CUTOUT DEVICE

C1 MOTOR CAPACITOR

K1 COIL

M1 BLADE MOTOR

M 2 PUMP MOTOR

I 2 SWITCH

OPTIONAL

Wheel Kit (TAB. 1)

Fig. 19 - Wiring Diagram

Assembly of motor

(TAB. 4.1)

ONE YEAR WARRANTY

We warrant to the original purchaser that the IMER equipment described herein

(the "equipment") shall be free from defects in material and workmanship under

normal use and service for which it was intended for a period of one (1) year from

the date of purchase by the original purchaser.

Our obbligation under this warranty is expressely limited to replacing or repairing,

free of charge, F.O.B. our designated service facility, such part or parts of the

equipmentas ourinspectionshalldiscloseto bedefective.Partssuchasengines,

motors, pumps, valves, electric motors, etc. furnished by us but not manifactured

by us will carry only the warranty of the manifacturer. Transportation charges or

duties shall be borne by the purchaser. This shall be the limit of our liability with

respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been

damaged by reason of accident,negligence, unreasonable use, faulty repairs, or

which has not been mantained and operated in accordance with our printed

instructions for our equipment. Further, this warranty is void if the equipment, or

any of its components, is altered or modified in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OF FITNESS FORAPARTICULAR PURPOSE.

Wemakenootherwarranty,representationorguarantee,norisanyoneauthorized

to make one on our behalf. We shall not be liable for any consequenzial damage

of any kind, including loss or damage resulting, directly or indirectly, from the use

or loss of use of the machine. Without limiting the generality of the foregoing, this

exclusionfromliabilityembracesthepurchase'sexpensesfordowntime,damages

for which thepurchaser may be liableto other persons, damages to property, and

injury or death of any persons.

This warranty shall not be deemed to cover maintenance parts, including but not

limited to blades, belts,hoses, hydraulic oil or filters, for which we shall have no

responsability or liability whatsoever.

IMER U.S.A., Inc.

207LawrenceAvenue

SouthSanFancisco,California 94080

(650) 872-2200

Table of contents