IMI Hydronic TA-SCOPE User manual

310 297-02 EN

08.2017

TA-SCOPE

TA-SCOPE

3

Contents

End User License Agreement.......................................................................................................................5

Introduction .................................................................................................................................................7

Instrument and Measuring Equipment..........................................................................................................8

Guide to Manual and Instrument..................................................................................................................9

Handheld 9

Abbreviations 9

Display and Keypad...................................................................................................................................10

Handheld...................................................................................................................................................10

Display Information Bar Icons 10

Keypad Keypad Icons 10

Functional Contents 11

DpS-Visio ..................................................................................................................................................12

Measuring Preparations .............................................................................................................................14

Prerequisites for Balancing with TA-SCOPE 14

Switch on/off the units 14

Wireless Communication 14

Connect / Disconnect Measuring Equipment 15

Calibration of Dp Sensor 16

Handwheel 16

Connections for Cables 16

Hydronic Functions....................................................................................................................................17

Quick Measure ..........................................................................................................................................18

Measure Flow 18

View Saved Measurements 19

Flow Adjustment – Computer Method 19

Measure Differential Pressure (∆p) 20

Measure Temperature 20

Measure Power 21

Hydronic Networks ....................................................................................................................................23

Navigate Hydronic Networks 23

Edit Existing Network 23

Delete Network 24

Create a Hydronic Network 24

Balancing...................................................................................................................................................25

Balance a Hydronic Network with TA-Diagnostic 25

Balance a Hydronic Network with TA-Wireless 26

Modify or Define New Module 28

Troubleshooting .........................................................................................................................................29

Diagnose a Hydronic Network with TA-Diagnostic 29

Use the Required Dp on Circuit Troubleshooting Wizard 29

Data Logging.............................................................................................................................................30

Start a New Logging 30

Download Loggings 31

View Loggings 31

Support Functions .....................................................................................................................................33

Fluid ..........................................................................................................................................................34

Change Fluid 34

Hydronic Calculator ...................................................................................................................................35

Calculate Flow/Kv/Dp (∆p)/Power/DT (∆T) 35

Calculate Valve Opening 35

Recommend Pipe Dimension 35

Recommend Valve Dimension 36

Unit Conversion 36

Contents

TA-SCOPE

4

Settings .....................................................................................................................................................37

Information ................................................................................................................................................39

PC Communication ...................................................................................................................................40

Transfer of Data 40

Software Upgrade 40

Instrument Care and Service......................................................................................................................41

Batteries – Capacity & Charging 41

Filter Cleaning 42

Calibration Certificates 42

Guarantee..................................................................................................................................................43

FCC Notification and ETL Markings ...........................................................................................................44

Technical Specifications .............................................................................................................................45

Accessories ...............................................................................................................................................46

Note! The products, texts, photographs, graphics and diagrams in this brochure may be subject to alteration by

IMI Hydronic Engineering without prior notice or reasons being given. For the most up to date information about

our products and specifications, please visit www.imi-hydronic.com.

IMI Hydronic Engineering AB, 524 80 Ljung, Sweden.

!

TA-SCOPE includes software licensed from OMRON SOFTWARE Co., Ltd.

Advanced Wnn©OMRON SOFTWARE Co., Ltd. 2002 – 2010.

All rights reserved.

Contents

Warning! Beware of hot fluid in the valve. Always follow the sequence described in the manual

when connecting and disconnecting the measuring equipment.

!

Water temperature over 52°C (125°F) can cause severe burns instantly or death from scalds. Always consider

the risks of injury from hot water before starting any measurement on a heating system and follow relevant local

legislation, regulations, standards and good industry practice for working with pressurised hot water systems.

Always use appropriate personal safety equipment when working on a heating system. Examples of appropriate

safety equipment include (but are not limited to) a face shield, heat resistant rubber gloves and boots and a long

sleeved apron (long enough to cover the tops of the boots). Always wear your boots inside your trouser legs to

prevent/minimise any hot water flowing into your boots. IMI Hydronic Engineering will not take any responsibility

for injury howsoever caused by hot water during measurement.

Warning! The surface on the Dp Sensor can be hot while measuring on hot media.

Always use suitable safety equipment.

!

Warning! Both Handheld and Dp Sensor contain batteries which require charging. The supplied

multi-charger from IMI Hydronic Engineering must be used!

Warning! Do not open the instrument. This can damage the instrument and void your guarantee!

See page 43 for further information.

!

!

CAUTION! Read the user manual before using the product.

!

TA-SCOPE

5

End User License Agreement

By using TA-SCOPE or the Software, you acknowledge that you have read this agreement (“Agreement”),

understood the content of it and agree to be bound by the terms of this Agreement. If you do not agree to the

terms of this Agreement, you are not permitted to use TA-SCOPE or the Software.

This Agreement is entered into between IMI Hydronic Engineering and the “End User”.

1. Definitions

“Documentation” means the manual, the tutorial and other materials related to the Software, provided to the End

User.

“End User” means any person or company who is entitled to use the Software according to this Agreement.

“Software” means the software, Documentation, including any updates and upgrade thereto, for the TA-SCOPE

which is provided to an End User under this Agreement.

“TA-SCOPE” means the instrument manufactured and sold by IMI Hydronic Engineering used for hydronic

balancing and troubleshooting of HVAC systems, currently named TA-SCOPE.

2. License grant

2.1 Subject to the terms and conditions set forth in this Agreement and the payment of all applicable fees

charged by IMI Hydronic Engineering for TA-SCOPE, IMI Hydronic Engineering grants End User a non-exclusive,

non-transferrable license to use the Software on a single TA-SCOPE devise, provided however that this

Agreement does not grant End User any title or right of ownership in or to the Software.

2.2 The Software shall be used only for End User’s own computing requirements in accordance with the terms and

conditions set forth herein, and only in combination with the TA-SCOPE.

3. Restricted use

3.1 End User shall not use the Software for any purposes other than the use specified in Section 2.2.

3.2 End User shall not make, have made or permit its employees or third parties to make, any copies or

verbal or media translations of the Software, in whole or part, for any reason. End User shall not use or allow the

Software to be used, directly or indirectly, in any manner that would enable any person or entity to copy or use the

Software or part thereof.

3.3 End User shall not use the Software on any TA-SCOPE that End User does not own or control, and End

User may not distribute or make the Software available to any third party. End User may not assign, transfer, rent,

lease, lend, sell, redistribute or sublicense the Software.

3.4 In case End User permanently transfers all of its rights to the TA-SCOPE device, End User may include

the license granted hereunder in such transfer, provided, however, that End User retains no copies of the

Software, End User transfers all of the Software (including all component parts, the media and printed materials,

any upgrades, all platforms, this Agreement, the serial numbers, and, if applicable, all other software products

provided together with the Software), and End User ensures the recipient to agree and be bound by the terms of

this Agreement.

3.5 END USER SHALL NOT MODIFY, DISASSEMBLE, DECOMPILE, RECREATE OR GENERATE ANY

SOFTWARE OR ANY PORTION OR VERSION THEREOF UNLESS AND TO THE EXTENT PERMITTED UNDER

APPLICABLE MANDATORY LAW.

3.6 End User shall not remove, erase or hide from view any copyright, trademark, confidentiality notice, mark or

legend appearing on TA-SCOPE or in the Software or any form of output produced by the Software.

3.7 IMI Hydronic Engineering reserves its right to continuously without notification: (i) verify the validity of each

license used by an End User; (ii) evaluate the Software; and (iii) to automatically update the Software.

End User License Agreement

TA-SCOPE

6

4. No warranties

4.1 THE SOFTWARE IS PROVIDED “AS IS” WITH NO WARRANTIES WHATSOEVER. IMI HYDRONIC

ENGINEERING DOES NOT, EITHER EXPRESSED, IMPLIED OR STATUTORY, MAKE ANY WARRANTIES,

CLAIMS OR REPRESENTATIONS WITH RESPECT TO THE SOFTWARE, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OR CONDITIONS OF QUALITY, PERFORMANCE, NON-INFRINGEMENT, MERCHANTABILITY,

OR FITNESS FOR USE FOR A PARTICULAR PURPOSE. IMI HYDRONIC ENGINEERING FURTHER DOES

NOT REPRESENT OR WARRANT THAT THE SOFTWARE WILL ALWAYS BE AVAILABLE, ACCESSIBLE,

UNINTERRUPTED, TIMELY, SECURE, ACCURATE, COMPLETE AND ERROR-FREE.

4.2 THE ENTIRE RISK ARISING OUT OF THE USE OR PERFORMANCE OF THE SOFTWARE REMAINS WITH

END USER, E.G. END USER ASSUMES FULL RESPONSIBILITY FOR ITS USE OF THE SOFTWARE AND ANY

INFORMATION ENTERED, USED AND STORED THEREON. END USER ASSUMES FULL RESPONSIBILITY FOR

ENSURING THAT DATA IS NOT INADVERTENTLY MODIFIED, DELETED, DESTROYED OR DISCLOSED.

4.3 TO THE EXTENT NOT PROHIBITED BY APPLICABLE LAW, IN NO EVENT SHALL IMI HYDRONIC

ENGINEERING BE LIABLE FOR ANY PRODUCT LIABILITY, LOSS OF OR DAMAGE TO REVENUES, PROFITS

OR GOODWILL OR OTHER SPECIAL, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES OF ANY KIND,

RESULTING FROM IMI HYDRONIC ENGINEERING’S PERFORMANCE OR FAILURE TO PERFORM PURSUANT

TO THE TERMS OF THIS AGREEMENT, OR RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OR LOSS OF USE, LOSS OF DATA OR LOSS OF ANY SOFTWARE OR OTHER MATERIALS DELIVERED,

INCLUDING, WITHOUT LIMITATION, ANY INTERRUPTION OF BUSINESS, EVEN IF END USER HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

5. Intellectual Property rights

5.1 IMI Hydronic Engineering is the owner of all copyright, trademarks, patents, trade secrets and any other

intellectual property rights which subsist in or relate to the Software and these properties shall always remain

vested in IMI Hydronic Engineering.

5.2 Nothing in this Agreement shall be construed as a sale of the Software. Any and all rights not expressly

granted by this Agreement to the End User are reserved by IMI Hydronic Engineering.

6. Term and termination

6.1 The license granted hereunder shall commence upon the execution of the agreement between IMI Hydronic

Engineering and the End User’s acceptance of the terms and conditions herein contained, and shall continue in

effect unless terminated earlier pursuant hereto.

6.2 The license granted hereunder is effective until terminated by End User or IMI Hydronic Engineering. IMI

Hydronic Engineering has the right to terminate the Agreement immediately if End User fails to comply with any

term of this Agreement. Upon termination of the Agreement, End User shall cease all use of the Software, and

destroy all copies, full or partial, thereof.

7. Disputes and governing law

7.1 Any dispute, controversy or claim arising out of, or in connection with, this Agreement, or the breach,

termination or invalidity thereof, shall be finally settled by arbitration administered by the Arbitration Institute of

the Stockholm Chamber of Commerce. The Rules for Expedited Arbitrations of the Arbitration Institute of the

Stockholm Chamber of Commerce shall apply, unless the institute – taking into account the complexity of the

case, the amount in dispute and other circumstances – determines, in its discretion, that the Arbitration Rules of

the Arbitration Institute of the Stockholm Chamber of Commerce shall apply. In the latter case, the institute shall

also decide whether the arbitral tribunal shall be composed of one or three arbitrators. The seat of arbitration shall

be Gothenburg, Sweden. The language of the arbitration shall be English.

7.2 This Agreement shall be governed by and construed in accordance with the laws of Sweden, excluding its

conflict of laws principles providing for the application of the laws of any other jurisdiction.

End User License Agreement

TA-SCOPE

7

Introduction

TA-SCOPE is a tough, effective balancing instrument for accurate measuring and documenting of differential

pressure (∆p), flow, temperature and power in hydronic systems.

Wireless functionality and an easy-to-use interface ensure quicker and more cost-efficient balancing and trouble

shooting.

TA-SCOPE links effortlessly to the PC software – HySelect – gaining the maximum benefit from recorded data and

enabling professional report writing and automatic software upgrades.

TA-SCOPE consists of two main components:

Handheld unit – computer based unit programmed with the IMI TA valve characteristics. Straightforward functions

with easy-to-follow instructions on the colour display.

Differential Pressure Sensor unit – the DpS-Visio communicates wirelessly with the Handheld and has an OLED

display for showing its status, measured data and other information.

Introduction

TA-SCOPE

8

Instrument and Measuring Equipment

23 24 25 26 27

1 Handheld unit (Hh)

2 Dp Sensor unit (DpS-Visio)

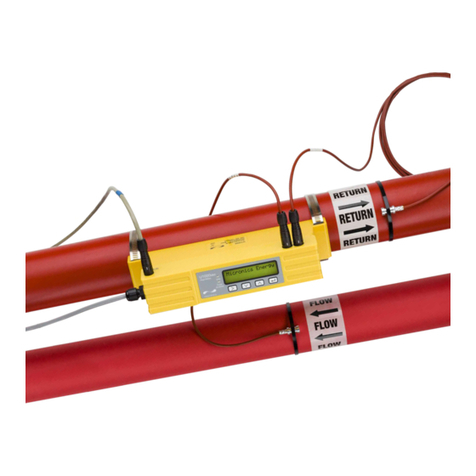

3 Digital Temperature Sensor (DTS)

4 Measuring hoses, 500 mm, red/blue

5 Safety pressure and temperature probe

(SPTP)

6 Safety pressure probes (SPP)

7 Measuring hoses with twin needle,

150 mm

8 Flashlight

9 Mirror

10 Chucks for older valves, red/blue

11 Allen Keys 3 mm/5 mm

12 Spanner for measuring points on older

valves

13 Presetting tool TBV-C,-CM, (-CMP)

14 Spare filters (4 pcs)

15 Chain for mounting

16 Neckstrap

17 USB-cables for connection;

A. Hh-PC

B. Hh-DpS-Visio / PC - DpS-Visio

18 Multi-charger for Handheld, Dp Sensor(s)

and TA-SCOPE Relays

19 DC cables (2 pcs; 1 Ø2,35 for Hh,

1 micro USB for DpS-Visio)

20 AC cable (EU, UK, US or AU/NZ)

21 Cable wrapping

22 Case

23 USB stick with manual and HySelect

software

24 Calibration certificates for DpS-Visio,

DTS and SPTP

25 Quick Guide

26 SPTP/SPP stickers

27 Guarantee/Service/Calibration form

Instrument and Measuring Equipment

TA-SCOPE

9

Guide to Manual and Instrument

Guide to Manual and Instrument

General Instrument Instructions

TA-SCOPE facilitates effortless performance of all hydronic functions through easy to navigate menus.

Handheld

The display is divided into three areas, the Information bar, the Main display and the Function keys.

1 – Information bar

Icons on the Information bar display details of battery status, connection type and

intensity.

2 – Main display

Instructions on how to carry out hydronic functions are shown on the Main display.

3 – Function keys

The three top keys on the key board are used for selecting options shown in the lower

part of the Main display. The options vary depending on which menu is currently shown.

Keypad

• The keypad has alphanumeric keys. Select a letter by repeatedly pressing the key

until the desired letter appears. Prolonged press enters a digit.

• Dot key works as caps lock. For a dot keep the key pressed until a dot appears.

• The zero key works as a space bar.

Entering Information in Menus

• When entering values to an input field in a menu, navigate to the desired row and start typing.

• Cycle the options in the input fields.

• Change units from the menu for any of the hydronic functions by navigating to the desired row and cycle

the units.

• Increase/decrease values like valve size, time, date direct from the input field by cycling the options.

• To prevent entering a too high or too low value TA-SCOPE automatically corrects values in the input fields. The

maximum/minimum value will appear in red, accompanied by a beep.

Tips! The numbers 1-9 can be used to shortcut the menus in the main display.

!

Special Menu Features

If multiple temperature sensors are connected when measuring, cycle the

sensors by navigating to the temperature row and press enter. An icon

on the display indicates which of the sensor is currently showing temperature

reading.

The temperature to be considered for fluid properties can be taken either from

one of the connected temperature sensors or from direct input in the fluid

screen. Navigate to the icon beside the fluid field and press enter to cycle

amongst the available options.

Abbreviations

Hh Handheld unit

DpS-Visio Differential Pressure Sensor unit

DTS Digital Temperature Sensor

SPTP Safety Pressure and Temperature Probe

SPP Safety Pressure Probe

Dp / ∆p Differential Pressure

DT / ∆T Differential Temperature

q Flow

P Power

T Temperature

TA-SCOPE

10

Display and Keypad

Handheld

Display Information Bar Icons

Keypad Keypad Icons

Information Bar Icons

Keyboard Icons

Function key

Options depend on text in display

On/Off

Flow adjustment (Computer method)

Short cut button

Return/Escape

Enter

Navigation up/down

Navigation right/left

Alphanumeric

0-9, A-Z plus symbols

Battery status bar

Charging of battery

Battery symbol

Handheld

Dp sensor DpS-Visio

Wireless communication

Intensity of wireless signal

Wireless signal set to Off

Connection by cable

Dp sensor (older version)

Information Bar Icons

Keyboard Icons

Function key

Options depend on text in display

On/Off

Flow adjustment (Computer method)

Short cut button

Return/Escape

Enter

Navigation up/down

Navigation right/left

Alphanumeric

0-9, A-Z plus symbols

Battery status bar

Charging of battery

Battery symbol

Handheld

Dp sensor DpS-Visio

Wireless communication

Intensity of wireless signal

Wireless signal set to Off

Connection by cable

Dp sensor (older version)

Display and Keypad

TA-SCOPE

11

Functional Contents

Quick Measure

Page 18

Measure Flow

Measure Differential Pressure (∆p)

Measure Temperature

Measure Power

View Saved Measurements

Hydronic Networks

Page 23

Navigate Hydronic Networks

Add New Network

Edit Network

Delete Network

Measure, Balance & Log Functionality

Balancing

Page 25

Prerequisites for Balancing

Balance a Hydronic Network with TA-Diagnostic

Balance a Hydronic Network with TA-Wireless

Modify or Define New Module

Troubleshooting

Page 29

Diagnose a Hydronic Network with TA-Diagnostic

Use the Required Dp on Circuit Troubleshooting Wizard

Data Logging

Page 30

Set Parameters for Logging

Perform Logging

Download logging from Dp Sensor

View Loggings in Handheld

Display Logging as Graph/List

Fluid

Page 34

Fluid Type

Temperature

Select Additive

Additive Concentration

Define Other Fluid

Hydronic Calculator

Page 35

Calculate Flow-Kv-Dp

Calculate Power-Flow-DT

Calculate Valve setting

Select Pipe / Valve

Conversion of Units

Settings

Page 37

Instrument Setup

Wireless Signal

Language

Power Saving

Information

Page 39

Instrument Information

Software Version

Battery Capacity

Display and Keypad

TA-SCOPE

12

Display and Keypad

DpS-Visio

The display is divided into three areas, the Information bar, the Main display and the Function keys.

LED for battery status

Information bar

Icons on the Information bar display details of battery status, connection

type and intensity.

Main display

Shows status and measurement, page 13, 22 and 38.

Function keys

Arrow button

- Press button to start measurement or change settings

On/Off button

- Long press for switching unit on or off

- Short press for display on or off

Navigate button

- Jump between menus

Note! Never leave water in the Dp Sensor unit when risk of freezing exists (i.e., in the car during

winter).

!

TA-SCOPE

13

DpS-Visio – Main screen sequences

Navigate button

Short press: Browse between menus described here.

Long press: Entering setting menu. See page 38.

Home

DpS-Visio type (5 or 10 bar)

Software version number

Battery level

Logging progress (Replaced by when a logging is waiting to start)

Logging

Logging progress (Replaced by when a logging is waiting to start)

Progress in time versus Total logging time

Time-step

Last logged values

Info

Software version number

Wireless software version number

Serial number

Battery

Battery level

Battery installation date

Battery voltage

Battery current (+ when charging)

Calibration

Dp range

Date of last factory calibration

Date of next recommended factory calibration

Display and Keypad

TA-SCOPE

14

Measuring Preparations

Prerequisites for Balancing with TA-SCOPE

TA-SCOPE is one of the components in the powerful IMI TA methodology for balancing of hydronic systems.

The ultimate goal of every heating and cooling installation is to provide the desired indoor climate at the lowest

possible energy cost. This requires a fully controllable hydronic system. Achieving full hydronic control depends on

meeting three key conditions:

• Design flow must be available at all terminals.

• Differential pressure (∆p) across control valves must not vary too much.

• Flows must be compatible at system interfaces.

The best way to attain these conditions is to perform a balancing procedure using TA-SCOPE. Balancing ensures

that the plant actually performs as specified by the designer and operates the way the designer intended.

Switch on/off the units

The Handheld and Dp Sensor units are switched on and off individually.

The Handheld Information bar displays details on intensity of wireless signal and battery status for the connected

units.

Handheld

Press on the keypad during 1 second to switch on/off.

Dp Sensor

Press during 1 second to switch on/off.

Sleep Mode

Once the screen has dimmed and been set to sleep mode the Handheld unit is still active, touch any key to return

directly to the last screen used.

If a unit is switched off whilst in sleep mode and then started again the start position is the main menu and

previous actions are interrupted.

If a Dp Sensor is actively performing a logging function, it will automatically go into sleep mode after 15 minutes.

The logging process will then continue whilst in sleep mode.

If a Dp Sensor is not actively performing a logging function, the unit will automatically switch off if it does not

detect its paired handheld within 30 minutes.

Adjustments of display settings and sleep mode are performed in the Settings menu, see page 37.

Wireless Communication

On delivery TA-SCOPE is prepared for wireless communication.

No adjustments of settings or other actions are required.

If required the Handheld and Dp Sensor units can be connected via cable.

Wireless communication uses radio frequency and is therefore not

allowed in areas where other vital electronic devices can be disturbed,

i.e., near medical equipment and implanted cardiac pacemakers, in health

care facilities, aircrafts, blasting areas, areas with potentially explosive

atmospheres and other areas posted “turn off two-way radio”.

Cut the wireless connection from the Settings menu. is displayed on the

antenna icon in the Information bar and the antenna led of the Dp Sensor

stops flashing.

When reactivating the wireless function the units should initially be

connected with the cable to establish radio communication. If wireless

communication stops due to the units being out of radio range, they will

automatically reconnect when back within radio range as long as the

Wireless Signal option is set to On.

Measuring Preparations

TA-SCOPE

15

Connect Alternative Dp Sensor

Any Handheld and Dp Sensor can become a wireless pair. This may be particularly useful in companies with

several TA-SCOPE instruments. Establish communication between your Handheld unit and the Dp Sensor you

currently wish to work with.

1 Connect the units with the cable and check that wireless option in Settings menu is set to On.

2 Wait until the wireless icon is displayed on the Information bar.

3 Disconnect the cable and wireless communication is established.

Connect / Disconnect Measuring Equipment

The measuring equipment is colour coded to ensure valid data is collected, red indicates high pressure and blue

indicates low pressure.

First – connect the Safety Pressure Probes (SPP) to the measuring hoses which shall be connected to the Dp

Sensor, pay attention to the colour indications.

Second – connect the Safety Pressure Probes to the measuring points on the valve,

which are also colour coded.

Make sure the safety catches lock behind the thread on the measuring point.

When disconnecting, press the safety catches at the Safety Pressure Probe and pull to

release.

Each hydronic function in TA-SCOPE requires a specific set-up of

measuring hoses and temperature sensors.

On screen diagrams will be displayed on the Handheld for guidance.

The Dp Sensor can either be hanged by the hoses or by the accessory

(15) chain in the pipes.

Tips! Wireless range Handheld – Dp Sensor. Range in open space – approximately 70 meters.

Range inside a building – approx. 20-30 meters.

!

Measuring Preparations

Note! When using the combined Safety Pressure and Temperature Probe (SPTP), do not forget

to connect the data cable to one of the two temperature probe connections on the Dp Sensor.

Warning! Beware of hot fluid in the valve. Always follow the sequence described here when

connecting and disconnecting the measuring equipment.

!

Warning! The surface on the Dp Sensor can be hot

while measuring on hot media. Always use suitable safety

equipment.

!

!

TA-SCOPE

16

Calibration of Dp Sensor

To achieve correct measuring values calibration of the Dp Sensor is always required prior to measurements of

flow and differential pressure (∆p).

Air pockets might be left in the hoses and these are vented through calibration to maintain optimal accuracy.

TA-SCOPE automatically performs calibration when needed.

Handwheel

Each IMI TA balancing valve has a handwheel for determining valve

opening. The digital read out displays the number of turns.

Below the valve to the left is completely shut and displays 0.0 and

the valve to the right is open by 2.3 turns.

Connections for Cables

Handheld connections

1 Charger

2 USB to PC

3 Temperature probe (SPTP or DTS)

4 USB to Dp Sensor

Dp Sensor Connections

1 Temperature probe 1 (SPTP or DTS)

2 Temperature probe 2 (SPTP or DTS)

3 Charger and USB to Handheld

Measuring Preparations

123 4

123

TA-SCOPE

17

Hydronic Functions

Overview of Hydronic Functions

TA-SCOPE enables various alternatives for exploring and diagnosing hydronic systems. On screen diagrams will

guide you through the physical set up of the measurement equipment as required for the hydronic function you

would like to perform.

The hydronic functions then enable the system data to be used effortlessly in many flexible and useful ways.

The main hydronic functions of TA-SCOPE, where system data can be collected and applied, are as follows:

Quick Measure – Straightforward function to measure flow, differential pressure (∆p), temperature and

power. To be used when only one or a few valves are of interest. The function does not require any

predefinition of network or module.

Hydronic Networks – Complex networks created in HySelect are easily downloaded to TA-SCOPE.

Use a network for measuring and balancing at any time; during commission, for control and inspection.

All hydronic functions can be applied to a selected valve from a Hydronic Network.

Balancing – The powerful TA-Wireless and TA-Diagnostic methods for balancing hydronic systems.

TA-Wireless makes use of two Dp Sensors with wireless technology to easily perform balancing of a

hydronic module. With TA-Diagnostic, you measure all valves in a module. The method calculates a Dp

diagnostic for the module and correct valve openings to attain design flows.

Troubleshooting – Software wizards take you step-by-step through the process of locating and

diagnosing problems and errors in hydronic systems, e.g., Dp (∆p) analysis.

Data Logging – Measurement during a predetermined period of time to analyse any fluctuations in flow,

differential pressure (∆p), temperature and power. The logged data is stored and listed or displayed as a

graph, both in TA-SCOPE and HySelect.

Hydronic Functions

TA-SCOPE

18

Quick Measure

Explanation of Function

Use Quick Measure for measuring flow, differential pressure (∆p) and temperature in a waterborne heating/cooling

system. The function also provides a measuring method for estimating power.

Quick Measure is the preferred method for separate measurements on a few selected valves. For example when

performing control or inspection of a balanced system.

Measure Flow

1 Connect measuring equipment depending on desired measurement.

The Measure Flow function enables a combined measurement of

differential pressure (∆p), flow and temperature. More connecting details on

page 15.

2 Navigate to Quick Measure in the main menu and press enter.

3 Navigate to Measure Flow and press enter.

4 Optionally input Design Flow. Navigate to and type the given design

flow for the terminal. While measuring the deviation is given in percent besides

the entered design flow.

5 Define valve. Navigate to and press enter.

6 Select input field for Type and press enter.

7 Navigate to desired valve type and press enter.

8 Continue by defining Family and Valve in the same way.

9 Make valve settings valid by pressing the function key Done. Valve settings are

visible in the Measure Flow menu. Valve size can easily be changed from here,

navigate to and cycle the options. Type and family stays the same.

10 Input Valve Opening. Navigate to and type the number of turns stated

at the digital read-out at the handwheel, more handwheel details on page 16.

11 Define fluid in . Press enter and navigate to input fluid temperature and properties. Press enter.

12 Freezing point is stated below the temperature input field and the auto correction function indicates if the allowed

limits are exceeded. More Fluid details on page 34.

13 Press function key Done to make fluid definition valid.

14 Press function key Measure to start measuring.

15 After the calibration cycle is done the measurement begins and values are displayed for Differential Pressure (∆p),

Flow and optional Temperature if the temperature sensor(s) is connected.

16 If multiple temperature sensors are connected, cycle the sensors by navigating to the temperature row and

press enter. An icon indicates which of the sensors is currently showing a temperature reading.

17 Press function key Hold to pause the measuring, and press Continue to resume.

18 Save measurements

• Press function key Save to store the measured data for future needs.

• Enter a name for performed measurement. Date and time is automatically added.

• If the name entered is already used, an overwrite request is displayed.

• Optionally enter a description.

• Press function key Save, the measurement is saved and measuring menu appears again.

19 End measurement by exiting the menu, press and disconnect the measuring points according to page 15.

Note! Remember to always update fluid properties according to the system currently being

measured.

!

Tips! Short cut to increase/decrease valve size and valve turns from the measuring menu

– press when the input field is in focus.

!

Quick Measure

TA-SCOPE

19

View Saved Measurements

1 Select View Saved Measurements from the Quick Measurements main menu, press enter.

2 Measurements are displayed in a list showing reference i.e., the entered name, type of measurement and date/time.

3 Press function key View to open up details on the measurement in focus.

4 Delete measurements one by one using the function key Delete.

5 Delete all saved measurements from the function key Options and navigate to Delete all quick

measurements, press enter.

Flow Adjustment – Computer Method

TA-SCOPE enables a method for correcting the flow to attain desired flow for terminals with a given design flow.

TA-SCOPE will lead you through the process.

1 Whilst measuring on a valve press or function key Option and navigate to Flow Adjustment (Computer

Method), press enter.

2 Shut the valve and press function key Done.

3 Measurement will continue and display differential pressure (∆p) for the closed valve.

4 TA-SCOPE automatically calculates a new handwheel position in order to attain design flow.

5 Adjust handwheel accordingly and press function key Recalculate.

6 If needed, perform further calculations and handwheel adjustments to reach the desired flow.

7 Finish the adjustment by pressing function key Quit.

Kv-mode for non-IMI TA valves

TA-SCOPE is supplied containing an up-to-date database of IMI TA valves. However measurements on non-IMI

TA valves are also possible. Instead of selecting a IMI TA valve the Kv-value can be used.

1 Press function key Options, navigate to Switch to Kv-mode, press enter.

2 icon is shown instead of and the valve properties can not be adjusted.

3 Once in Kv-mode, quick measurement operations are continued in Kv-mode until you switch back to IMI TA valve

mode.

Change Units

Default units in TA-SCOPE are automatically preset according to your market. However all units can be changed

depending on your personal preferences.

1 Press function key Units to change any of the units.

2 Navigate up and down in the list.

3 Cycle the alternatives or press enter to display the alternatives and enter to select.

4 The function key Reset will bring back the default unit for the one in focus.

5 Press function key Reset all to set the default units for all parameters.

6 Return to measuring menu by pressing function key Quit or from the keypad.

Quick Measure

Tips! Easily change units directly from the measuring menu – navigate to the measurement

row e.g., Flow and press repeatedly to cycle available units.

!

TA-SCOPE

20

Measure Differential Pressure (∆p)

1 Connect the measuring equipment according to page 15.

2 Navigate to Quick Measure in the main menu and press enter.

3 Navigate to Measure Dp and press enter.

4 After the calibration cycle is done the measurement begins and the

Differential Pressure (∆p) is displayed.

5 It is possible to save measured data, see item 18 (page 18) in the Measure

flow section.

6 End measurement by exiting the menu, press and disconnect the

measuring points according to page 15.

Measure Temperature

TA-SCOPE enables three ways to connect the temperature sensors. The

Dp Sensor has two connections and Handheld one. The icons to the left

indicates for each row on the display which sensor the data comes from.

1 Connect the required temperature sensors.

2 Navigate to Quick Measure in the main menu and press enter.

3 Navigate to Measure Temperature and press enter.

4 The temperature sensor(s) begins to measure directly.

5 If two sensors are measuring, the temperature difference – DT (∆T) is

displayed. DT (∆T) can optionally be set as hidden. Press function key

Options.

6 Possible to save measuring data, see item 18 (page 18) in the Measure

Flow section.

7 End measurement by exiting the menu, press and disconnect the

temperature sensors from the test points.

Quick Measure

Table of contents