impro HRR901 User manual

MODEL NUMBERS: HRR900-0-1-GB-XX

HRR901-0-1-GB-XX

Quad Receiver

433.92 MHz 4-Channel RF Receiver

INSTALLATION MANUAL

SPECIFICATIONS

Working Environment

Water resistance ....................

Designed to work in an indoor or outdoor

environment similar to IP44, the Impro Quad

Receiver is water resistant

Power Source

Input Voltage................................

11V to 15 V DC (Polarity sensitive)

Power Requirements

Current (mA)

Power (W)

12 V DC .................................

60

0.7

NOTE: When upgrading or replacing a legacy “ImproX UHF Receiver”, make sure

to reconnect using a 12V DC supply.

INSTALLATION INFORMATION

CAUTION: These two models of the Impro Quad Receiver only support

connection to the Impro IXP220 Controller, IXP20 Controller, iTRT

(Intelligent Twin Reader Terminal), MfT (Multi-function Terminal), TA

(Time Attendance Terminal), and the Impro UniScan and FlexiScan

Controllers.DO NOT attempt to connect this Receiver to an Impro

(DT) Door Terminal.

Accessories

Find the following when unpacking the Quad Receiver:

•The Quad Receiver consists of a glass-filled nylon Base with the PCB attached by

four screws, a glass-filled nylon Top Cover (press-down firmly to clip into the

base).

•A black gland plate for power, data and RF (in the case of the HRR901) lines into

the unit (this needs to be drilled to accommodate the wiring during installation).

•An extra Serial Number Label.

General

Impro TA Terminal Considerations

When installed with the Impro TA, the Terminal can be placed in one of two modes:

Channel 1 and 2 Mode or Channel 3 and 4 Mode. If you place the Terminal in Channel

1 and 2 Mode then Channels 1 and 2 of the Impro Quad Transmitter (TRK900-1-1-GB-

XX) are processed. Channel 1 is processed as the Terminal’s Primary Fixed Address

and Channel 2 is processed as the Terminal’s Secondary Fixed Address. This

scenario also applies to Channel 3 and 4 Mode. Using the Impro TA as an example,

refer to Figure 1 for clarification.

Upgrading or replacing legacy UHF Receiver

When upgrading from or replacing a legacy UHF receiver, it is important to do the

following:

•Change the DC supply voltage from 5V to 12V (12V is available on IXP220, IXP20

or iTRT)

•When connecting to an IXP220, IXP20, iTRT, Mft or TA, ensure that the “Legacy”

link is in place. (There is no need to change any DIP Switch settings.)

Figure 1: TA Internal Division Showing Channel 1 and 2 Mode and

Channel 3 and 4 Mode

HRR300-0-0-GB-01 April 2013 Page 2

Maximum Data Communications Distance

The maximum cable length between the Impro Quad Receiver and the Terminal or

Controller is 150 m (164 yd.), using a good quality multi core cable. The cross-sectional

area of the cable conductors must be at least 0.21mm2(24 AWG) for each of the “-“, “+”

and “D” conductors. To mitigate interference, cables should be a screened multi core

cable.

Solder a 2.5 mm2(13 AWG) grounding wire to the Host end of the screen drain wire

(insulate the soldered joint so that it is not left exposed) and route this wire to the

nearest Electrical Mains EARTH terminal – most often this may be same power socket

used by the DC Power supply for the Controller.

NOTE: The Quad Receiver (Device) end of the screen drain wire must not be

connected to anything.

Serial Number Label

The loose Serial Number Label (packaged with the Receiver) identifies the model of

Receiver and its Serial Number.

Installation Considerations for Best Performance

When installing the HRR900-0-1-GB-XX, it is important to consider the location and

environment for achieving optimum performance.

Location

Mounting the Impro Quad Receiver or Antenna mid-distance between the expected

point of entry and exit may balance the available operational range between both

locations.

Line-of-Sight

Locating the Impro Quad Receiver or Antenna within line-of-sight of the expected point

of entry and exit may result in greater received signal strength, increasing the

operational range.

Integrated Antenna (HRR900-0-1-GB-XX)

Mounting this Impro Quad Receiver on (or close to) conductive, ferrous materials,

damp surfaces (i.e.: walls) or electrical equipment can affect the overall performance of

the Impro Quad Receiver by either blocking, absorbing or interfering with the

transmitted signal from the Quad Transmitter.

Due to the radiation pattern of the integral antenna, it is preferable to install the Impro

Quad Receiver in a high position, with its integrated antenna pointing down. If this is

not possible, then consider using the HRR901-0-1-GB-XX with an external antenna that

meets the requirements of the installation.

HRR300-0-0-GB-01 April 2013 Page 3

External Antenna (HRR901-0-1-GB-XX)

This model is recommended when an installation calls for special antenna

considerations. This Impro Quad Receiver has its internal antenna bypassed and is

configured for direct connection to any of the various suitable antenna types available

(i.e.: high gain, Omni-directional, yogi etc.). An appropriate antenna must be selected

by the installer to complete the installation.

External Antenna Basic Requirements

Frequency ..............................

433.92 MHz

Impedance .............................

50

Ω

Connector ..............................

SMA Male (Straight preferred)

Transmit-Receive (Reciprocity) Trouble Shooting:

The Impro Quad Receiver has a built-in LED RSSI (Received Signal Strength Indicator)

bar graph. Before permanently mounting the Quad Receiver (or the external antenna

for HRR901) to a surface, it is recommended that the RSSI is checked with the

receiving antenna temporarily held in its proposed mounting position, and the Impro

Quad Transmitter at the expected point of entry or exit.

RSSI (Received Signal Strength Indication)

Strong .......

Installation is perfect, no need to change anything

Average.....

Installation is good enough for nominal operation

Weak

.........

Consider installing the Quad Receiver in another location to

improve operation

No Signal ..

There is no reception at the current location. Refer to all of the

above installation considerations or check the installation for faults

Figure 2: Radiation Pattern for the HRR900’s integrated antenna

In Figure 2, the 3-D isometric radiation pattern (extreme right) is achieved with the

HRR900 Impro Quad Receiver mounted flat against the wall, right near the top, with the

internal antenna facing downwards. The green volume represents the direction of

maximum sensitivity.

HRR300-0-0-GB-01 April 2013 Page 4

Four Channel Operation

When using the Impro Quad Receiver and a single Impro (iTRT) Intelligent Twin

Reader Terminal (XRT910-0-0-GB-XX, XRT920-0-0-GB-XX, IPS920-0-0-GB-XX or

IPS921-0-0-GB-XX), only two Push-buttons on the Impro Quad Transmitter (TRK900-1-

1-GB) are available for use.

To use all four of the Quad Transmitter’s Push-buttons, connect two Impro (iTRT)

Intelligent Twin Reader Terminals (XRT910-0-0-GB-XX, XRT920-0-0-GB-XX, IPS920-

0-0-GB-XX or IPS921-0-0-GB-XX), to the Quad Receiver, see Figure 3.

Figure 3: Using Four Channels

Impro FlexiScan Controller

When using the Quad Receiver with the FlexiScan Controller (HCM991-0-0-GB-XX),

EACH of the four Quad Transmitter buttons (when “added” to the Tag Database) are

mapped to each the FlexiScan’s four relays respectively. The “Legacy link” must be

REMOVED from the Quad Receiver PCB. See Figure 9 for wiring details

Impro UniScan Controller

When using the Quad Receiver with the UniScan Controller (HCM990-0-0-GB-XX), all

four Quad Transmitter buttons will trigger the UniScan's single relay ONLY with the

Quad Transmitter buttons that have been “added” or "enrolled”. The “Legacy link” must

be REMOVED from the Quad Receiver PCB when connected to a UniScan Controller.

See Figure 10 for wiring details.

HRR300-0-0-GB-01 April 2013 Page 5

Cable Gland Plate Drilling Procedure:

•Remove the Housing Cover ensuring that the Gland Plate remains in its

position in the slot in the base of the housing.

•Make a mark on the Gland Plate corresponding exit points that will have the

wires run NEXT to, and NOT OVER the Impro Quad Receiver PCB (if using

the built-in antenna, this area must be kept cleared of any objects).

•Remove the Gland Plate and drill a 2mm pilot hole through the mark/s.

•Select a drill size for a snug fit around the cable/s to be used and drill the

hole/s to the final size/s required.

Mounting the Impro Quad Receiver

CAUTION: Make certain that you mount the Impro Quad Receiver on a

vibration-free surface.

Select the mounting position of the Impro Quad Receiver, considering accessibility and

routing of wires – and test to ensure the RSSI reading is adequate. (See Transmit-

Receive (Reciprocity) Trouble Shooting on page 4.)

Secure the housing to a vertical mounting surface, using suitable screws and wall

plugs, nuts and bolts, rivets or double-sided adhesive tape.

HRR300-0-0-GB-01 April 2013 Page 6

Connecting the Impro Quad Receiver

Figure 4 to 10 show typical electrical connection diagrams for the Receiver.

Figure 4: Impro Quad Receiver Connected to the IXP220 Controller

HRR300-0-0-GB-01 April 2013 Page 7

Figure 5: Impro Quad Receiver Connected to the IXP20 Controller

HRR300-0-0-GB-01 April 2013 Page 8

Figure 6: Impro Quad Receiver Connected to the Impro iTRT

HRR300-0-0-GB-01 April 2013 Page 9

Figure 7: Impro Quad Receiver Connected to two Impro PT/TA Terminals

HRR300-0-0-GB-01 April 2013 Page 10

Figure 8: Impro Quad Receiver Connected to the Impro MfT

HRR300-0-0-GB-01 April 2013 Page 11

Figure 9: Impro Quad Receiver Connected to the Impro FlexiScan Controller

HRR300-0-0-GB-01 April 2013 Page 12

Figure 10: Impro Quad Receiver Connected to the Impro UniScan Controller

HRR300-0-0-GB-01 April 2013 Page 13

GUARANTEE OR WARRANTY

This product conforms to our Guarantee or Warranty details placed on our Web Site, to

read further please go to www.impro.net.

User Notes

HRR300-0-0-GB-01 April 2013 Page 14

User Notes

HRR300-0-0-GB-01 April 2013 Page 15

This manual is applicable to both variants of the Impro Quad Receiver,

HRR900-0-1-GB-XX and HRR901-0-1-GB-XX.

(The last two digits of the Impro stock code indicate the issue status of the product).

HRR300-0-1-GB-01 Issue 2

April

2013

Impro QR\English Manuals\LATEST ISSUE\Quad

Rec-insm-en-02.docx

s

HRR300-0-0-GB-01 April 2013 Page 16

This manual suits for next models

3

Table of contents

Popular Receiver manuals by other brands

Sony

Sony STR-DA50ES - Fm Stereo/fm-am Receiver operating instructions

Carlson

Carlson NR3 user manual

LKM

LKM LKM75X Manual relating to the system components

Inovonics

Inovonics EN4216MR Installation and operation manual

Pioneer

Pioneer Elite VSX-43 operating instructions

Denon Professional

Denon Professional DN-700AVP Protocol manual

SatLab

SatLab SLC user manual

Sony

Sony STR-DG500 - Multi Channel Av Receiver Specifications

ADEMCO

ADEMCO 5881L - Ademco 8 Zone Wireless Receiver installation instructions

Toshiba

Toshiba HD-S23 owner's manual

Axxera

Axxera AV6225BH owner's manual

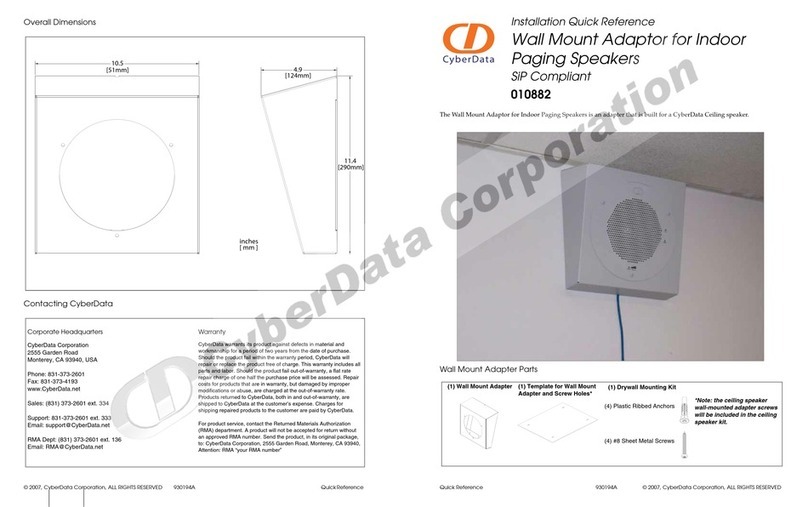

CyberData

CyberData Wall Mount Adaptor 010882 Installation quick reference