Improved Racing EFR-100 User manual

For contact information, visit www.improvedracing.com

Copyright © 2008-2021 Improved Racing Products, LLC. All rights reserved.

Rev 210429

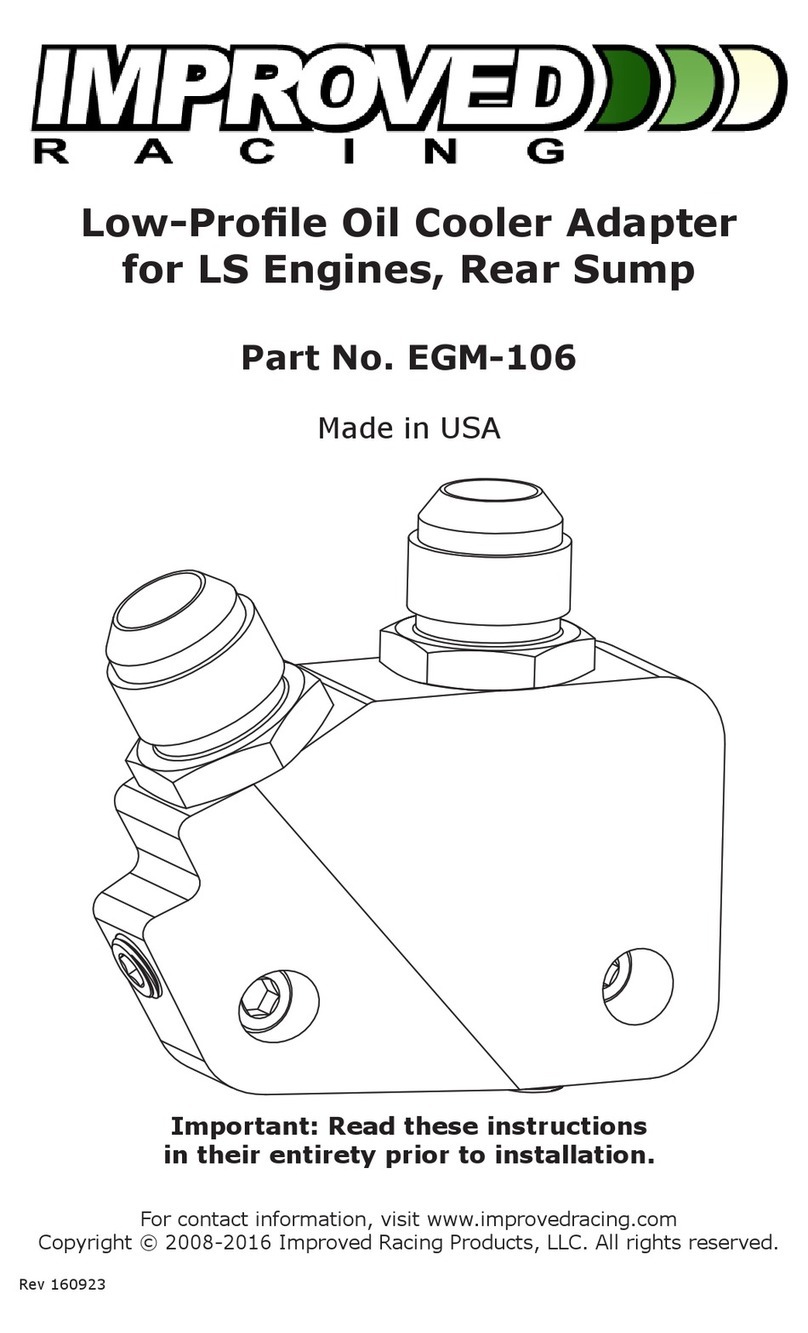

REMOTE OIL FILTER & COOLER

ADAPTER, 4.6L & 5.4L FORD

MODULAR V8

PART NO. EFR-100

MADE IN USA

Important: Read these instructions in their

entirety prior to installation.

For contact information, visit www.improvedracing.com

2

APPLICATIONS

• All vehicles with 4.6L & 5.4L Ford Modular V8 engines including:

◦1996-2010 Ford Mustang GT

◦1995-2010 Ford F-Series trucks

◦1992-2012 Ford Crown Victoria

◦1990-2011 Lincoln Towncar

◦1996-2014 Ford E-Series vans

◦Other vehicles with modular engines swapped-in

• EFR-100 is designed for remote oil lter systems only.

◦ImprovedRacingrecommendslocatingtheremoteoilltermount

onasturdypartofthevehiclesuchasthechassis,rewallorbumper.

• EFR-100canbeusedwithorwithoutanoilcooler.

◦TherecommendedoilltermountisPart#ENV-140(non-thermo-

static, oil cooler optional).

◦TherecommendedthermostaticoilltermountisPart#ENV-170

(thermostatic,mustuseoilcooler).

• EFR-100 has two 1/4”-18NPTsensorportsforthefactoryoilpressure

sensorandoneforanaftermarketsensororfeedline(SeeFigure2).

•

EFR-100 has one 1/8”-27NPTsensorportforanaftermarketsensor(See

Figure 2).

INSTALLATION NOTES

•

Vehicleslistedbelowrequirea1.75”radiatorbarbtting(Part#OB-16-

28)andEFR-800siliconeradiatorhosebecausethefactorylowerradia-

tor hose does not reach.

◦1992-2012 Ford Crown Victoria

◦1990-2011 Lincoln Towncar

◦1996-2004 Mustang GT

•

1996-2004MustangSVTCobraandMustangMach1useaninlinecoolant

thermostatonthelowerradiatorhoseandrequires:

◦A1.75”to1.50”rubberreducer(Part#RHR-175-150)isrequired

toconnectthemodiedEFR-800hosetotheOEMenginethermostat.

◦

Cut the EFR-800 silicone radiator hose with a sharp cutting tool

along the green dotted line shown in Figure 1.

For contact information, visit www.improvedracing.com 3

KEEP GREEN SIDE

CUT HERE

Figure 1 - Cut Line for EFR-800 Radiator Hose: SVT Cobra & Mach 1 Trims

• Vehicleslistedbelowrequirethe1.50”radiatorbarbtting(Part#OB-

16-24),1.50”to1.75”rubberreducer(Part#RHR-175-150),andradia-

torhose(Part#EFR-800).

◦1996-2004MustangSVTCobra,CobraR,andMach1trims

◦EFR-800comeswithinstructionsforhosemodication

•

Vehicleslistedbelowmayreusethefactorylowerradiatorhosebutmust

usetheoptional1.50”radiatorhosetting(Part#OB-16-24).

◦1995-2010 Ford F-Series trucks

◦2005-2010 Ford Mustang GT

For contact information, visit www.improvedracing.com

4

STANDARD PARTS LIST

Item Qty Part Number Description

11 EFR-100-01 Remote Oil Filter & Cooler Adapter

34HSC-1058 M8x1.25 x 20mm Mounting Screws

41 PP-04S 1/4”-18NPTPlug

51 PP-02S 1/8”-27NPTPlug

61HRG-1018 AS568 -135 O-ring for Coolant Port

72HRG-1019 AS568 -119 O-ring for Oiling Ports

OPTIONAL CONFIGURATION PARTS

Qty Required

for EFR-100 Part Number Description

1

OB-16-24

-OR-

OB-16-28

-16SAEStraightThreadO-ringto1.50”HoseBarb

-OR-

-16SAEStraightThreadO-ringto1.75”HoseBarb

2

OM-10-08

-OR-

OM-10-10

-OR-

OM-10-12

-10SAEORBto-8SAE37°MaleFlareAdapterFitting

-OR-

-10SAEORBto-10SAE37°MaleFlareAdapterFitting

-OR-

-10SAEORBto-12SAE37°MaleFlareAdapterFitting

1 EFR-800 SN95MustangV8ReplacementSiliconeRadiatorHose

(SeeInstallationNotesonPage2andPage3)

TECHNICAL SPECIFICATIONS

Maximum Operating Temperature 302°F(150°C)

Minimum Operating Temperature -22°F(-30°C)

Maximum Operating Pressure 300psi(20.68bar)

Dimensions (W x H x D) 3.20”x5.72”x1.00”

(8.1cmx14.5cmx2.54cm)

Coolant Fitting Port -16SAEStraightThreadJ1926-1(ISO11926-1)

O-ring Port, 1-5/16”-12UN

Oil Fitting Ports

2x-10SAEStraightThreadJ1926-1(ISO11926-

1) O-ring Port, 7/8”-14UNF

Sensor Fitting Ports 1 x 1/8”-27NPT

2 x 1/4”-18NPT

For contact information, visit www.improvedracing.com 5

Housing Material CNC-Machined6061-T6BilletAluminum

Housing Finish MIL-A-8625TypeIIAnodize,Black

Mounting Hardware

ISO4762,12.9ClassAlloySteel,Zinc-Plated,

M8x1.25x20SocketScrew,6mmHex-Drive

1/8”-27 NPT Plug Info

Zinc-PlatedSteel,AcrylicSealant,

3

/

16

”Hex-Drive

1/4”-18 NPT Plug Info Zinc-PlatedSteel,AcrylicSealant,1/4”Hex-Drive

Adapter O-ring (Coolant Port) AS568-135Size,VitonRubber(75A)

Adapter O-ring (Oil Ports) AS568-119Size,VitonRubber(75A)

BEFORE YOU BEGIN

WARNING: NEVER work under a vehicle supported only by a jack.

NEVER PLUG THE FLUID PORTS ON EFR-100.

WARNING: Running the engine with plugged ports on EFR-100 will

block oil ow and result in catastrophic engine damage.

NEVER use EFR-100 without a remote oil lter plumbed.

WARNING: Running an engine without an oil lter will circulate debris

that can harm internal engine parts.

WARNING: This product should only be installed by a qualied me-

chanic. Improper installation could result in severe engine damage.

WARNING: Never secure hoses to moving components.

Usezip-tiesandP-clampstoensurenohosespinch/rubontheexhaust,

engine, suspension components and chassis.

Ensureheatexchangersareisolatedfromvibration.

Pre-llheatexchangerstopreventdrystartup.

Lubricateall37°aresontheadapterttingsbeforenaltightening.

Wraptaperedpipe(NPT)threadswithTeon(PTFE)tapeorapplythread

sealant to seal the threads.

For contact information, visit www.improvedracing.com

6

LubricateO-ringspriortoinstallationtopreventdamageandensurea

leak-free seal.

Usealuminumtoolstoavoiddamagingthealuminumttings.

PORT IDENTIFICATION

NotetheportidenticationanddirectionsofowillustratedinFigure2

below.

There are two 1/4”-18NPTportsforthefactorypressuresenderorturbooil

supply lines. There is one 1/8”-27NPTportforaftermarketsensors.Any

unusedportsmustbepluggedwiththeincludedNPTplugs.

IN FROM

FILTER / COOLER

CONNECT THIS PORT TO

THE OUTLET OF THE FILTER

OR OIL COOLER

OUT TO FILTER

CONNECT THIS PORT

TO THE INLET OF THE

OIL FILTER

1/4NPT

PORTS

ACCEPTS OEM

PRESSURE SENDER

1/8NPT

PORT

AFTERMARKET

SENSORS

Figure 2 - Port Descriptions

For contact information, visit www.improvedracing.com 7

OIL LINE ROUTING AND FLOW DIAGRAMS

WARNING: Pay close attention to the oil line routing. Incorrect line

routing will impede oil ow to the engine.

• SomeexampleowcongurationsusingImprovedRacingremotelter

mounts are presented in Figure 3 through Figure 5.

• OilltermountsfromotherbrandswillhaveINandOUTportsindiffer-

entcongurations.

• BecertainofwhatportisINandwhatportisOUTonyourremotelter

mounttoensureoilowstoyourengineproperly.

IN

OUT

ENV-140

CLEAN OIL

FILTERED OIL

RETURNS TO

TOP PORT

Figure 3 - Remote Oil Filter Only (No Oil Cooler)

IN

OUT

ENV-140

MADE IN USA 170726

Figure 4 - Non-Thermostatic Remote Oil Filter with Oil Cooler

For contact information, visit www.improvedracing.com

8

ENGINE

COOLER

ENV-170

185°F THERMOSTAT

Figure 5 - Thermostatic Remote Oil Filter with Oil Cooler

PREPARING FOR INSTALLATION

1.

Raise the front of the vehicle and support with automotive-approved

frame stands, lift, or ramps.

WARNING: NEVER work under a vehicle supported only by a jack.

2. Removeanyunderbodypanelsnecessarytoaccesstheoillter.

3. Placeadrainpanunderthelter,removetheoillterandallowtheoil

to drain.

Caution: Oil may be hot!

For contact information, visit www.improvedracing.com 9

4.

Removethefrontbumpercoverandheadlightstogainaccesstothe

frontbumper.

5. Place a drain pan under the lower radiator hose connection at the radia-

tor.

6. Use channel-lock pliers to release and slide away the hose clamp on the

lower radiator hose at the radiator connection.

7. Remove the hose from the radiator to drain the coolant.

Ifthehoseisstuck,useaplastictooltoloosenthehosefromthebarb.

8. Use channel-lock pliers to release and slide away the hose clamps at the

engineandcoolantoverowtankconnections.

9. Remove the lower radiator hose from the vehicle completely.

10.

Unplugthewireharnessfromthepressuresensoronthefactoryoillter

manifold.

11.

Use a

13

/

16

”tool to remove the pressure sensor from the factory manifold.

12. Use a 10 mm socket wrench to remove all four screws from the factory

manifold,thencarefullyremovetheoillterandcoolantmanifoldfrom

theengineblock.

13. Inspectandcleantheengineblock’ssealingsurface.

Sealing surface must be clean and smooth for O-rings to seal properly.

INSTALLING THE OIL COOLER ADAPTER

1.

Clean the threads on the factory pressure sensor. Wrap the threads

threetofourtimeswithTeontapeorapplyTeonthreadsealantand

install into one of the 1/4”NPTportsshowninFigure2.

2.

Install the provided 1/4”NPTplugintotheunusedsensorportonEFR-100

ifnoothersensorsarebeingused.

3.

Install the provided 1/8”NPTplugintothebottomsensorportonEFR-100

ifnoothersensorsarebeingused.

4.

InstallthecoolantbarbttingandoilcooleradapterttingsintoEFR-100.

Torquethecoolantbarbttingto30lb-ft(41N-m).Torquetheoilline

adapterttingsto20lb-ft(27N-m).

LubricatetheO-ringswithengineoiltopreventO-ringdamage.

5. Ensure that three O-rings are inserted into the glands of EFR-100 prior

toinstallation.HRG-1018andHRG-1019shouldbeinsertedintothe

glands as shown in Figure 6.

For contact information, visit www.improvedracing.com

10

HRG-1019

HRG-1018

Figure 6 - HRG-1018 and HRG-1019 O-Ring Placement

6.

Usea6mmhextoolandtheHSC-1058mountingscrewstosecure

EFR-100totheengineblock.

Do not pinch or damage the O-rings.

7. TorqueallHSC-1058screwsto25lb-ft(33N-m).

8. Install the lower radiator hose and clamps.

ConsulttheInstallationNotesonPage2andPage3forvehiclespecic

tmentandparts.

EFR-800 HOSE MODIFICATION FOR 1996-2004

MUSTANG SVT COBRA & MACH 1 TRIMS

1. InstallthecorrectlycuthoseontothebarbttingofEFR-100.

2. Insert the reducer into the cut end of the hose and secure to the inline

thermostat with the included worm clamp.

3. Usea7mm(9/32”)tooltosecurethehoseontothebarbusingthepro-

vided worm clamp.

INSTALLING THE REMOTE OIL FILTER MOUNT

1. Securetheremoteoilltermounttothevehicle.

2. Plan,measure,cut,andassembletheoilsystemlines.

3. ConnecttheoillinestotheEFR-100andtheremoteoilltermount.

For contact information, visit www.improvedracing.com 11

4. Torquethettingsto20lb-ft(27N-m).

5. Pre-llanewoillterwithoil,lubricatethesealandinstalltheoillter

ontotheremoteoilltermount.

INSTALLING AN OIL COOLER (OPTIONAL)

1. Plan,measure,cut,andassembletheoilsystemlinesthatwillconnect

theoilcoolertotheremoteoilltermountand/ortheEFR-100.

2. Connect the lowest oil cooler port to the OUT TO COOLER port of the

oilltermount.

3. Torquethettingsto20lb-ft(27N-m).

4. Connect the next oil line to the oil cooler.

5.

Leave the highest from ground level line disconnected from the oil cooler

sothatthecoolercanbepre-lled.

RefertoFigure2throughFigure5forplumbinghelp.

6. Torquethettingsto20lb-ft(27N-m).

7. Pre-lltheoilcoolerwithengineoilusingatubeandfunnel.

8. Connecttheremainingoilline(s).

9. Torquethettingto20lb-ft(27N-m).

10. Secure the oil cooler to the vehicle.

COMPLETING THE INSTALLATION

1. Checkthatallttingsareconnectedandtightened.

2. Check the engine oil level and add oil if necessary.

3.

Relltheengine’scoolantsystemusingthemanufacturer’sapproved

methodforyourspecicvehicle.

Consultthevehicle’sfactoryservicemanualforthecorrectcoolant

specicationsandrellprocedure.

4. Removethefuelpumpand/orignitionfuse(s)sothattheenginedoes

not start when turned over.

Consultthevehicle’sfactoryservicemanualforthefuse(s)location.

5. Cranktheengineoverforvesecondstobuildoilpressure,repeating

thiscyclethreetovetimes.

6. Reinstallthefuse(s).

7.

Start the engine to check for leaks or strange noises while the engine

For contact information, visit www.improvedracing.com

12

gets up to normal operating temperature.

8. Turn-off the vehicle, inspect the engine oil and coolant levels and add oil

or coolant as needed.

9.

Takeadrivewithoutreinstallingthebumpercover,ifpossible,andverify

that no leaks or noises occur.

10. Verify that the car does not overheat to ensure coolant levels are prop-

erlylled.

11. Reinstallthefrontbumperandallunderbodypanelsafterasuccessful

test drive.

12. Inspect all parts for loosening or leaks after 100 miles of driving.

Installation is now complete. Thank you for purchasing an Improved

Racing product!

Table of contents

Other Improved Racing Adapter manuals