IN-ECO RGH9028-2 User manual

Rotary Hammer

EN Rotary Hammer

RGH9028-2 RGH9028-2M URGH9028-2 RGH9028-26

RGH9028-28 RGH9028S-2 RGH9028-29

ingcoglobal

INGCO GLOBAL

2|English

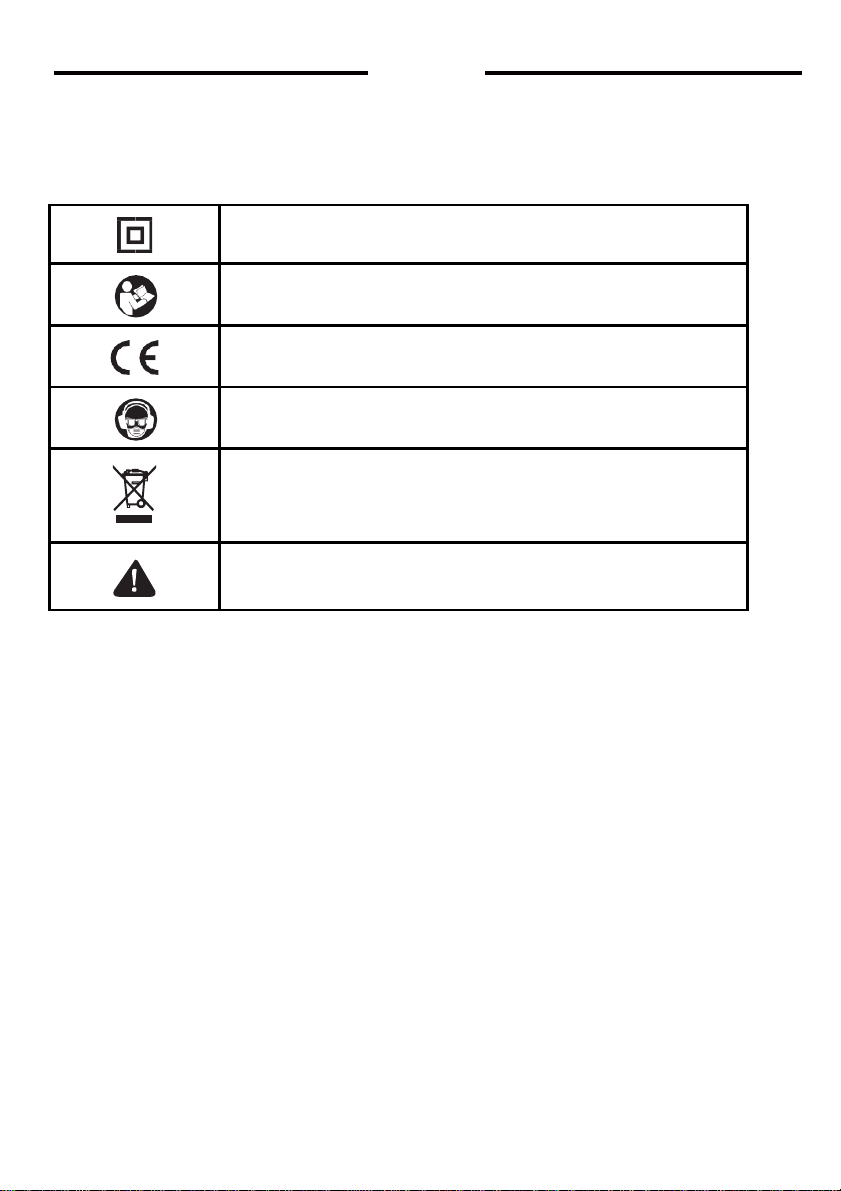

The symbols in instruction manual and the label on the tool

Double insulated for additional protection.

Read the instruction manual before using.

CE conformity.

Wear safety glasses, hearing protection and dust mask.

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist. Check with your Local Authority or

retailer for recycling advice.

Safety alert.

Please only use the accessories supported by the manufacture.

3|English

follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered and dark areas invite

accidents.

b) Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electricshock.

d) Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tools in a damp location is unavoidable, use

WARNING Read all safety warnings and all instructions. Failure to

GENERAL POWER TOOL SAFETY WARNINGS

4|English

a residual current device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-

position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

5|English

and must be repaired.

c) Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool. Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier tocontrol.

g) Use the power tool, accessories and tool bits etc. in accordance

with these instructions, taking into account the working

conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified repair person using

only identical. This will ensure that the safety of the power tool is

maintained.

Additional Safety Warnings

Hammer safety warnings

–Wear ear protectors. Exposure to noise can cause hearing loss.

–Use auxiliary handle(s), if supplied with the tool. Loss of control can cause

personal injury.

–Holdpowertoolbyinsulatedgrippingsurfaces,whenperforminganoperation

where the cutting accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make exposed metal parts of the

power tool "live" and could give the operator an electric shock.

6|English

Residual risks

Even when the power tool is used as prescribed it is not possible to

eliminate all residual risk factors. The following hazards may arise in

connection with the power tool’s construction and design:

a) Health defects resulting from vibration emission if the power tool is being

used over longer period of time or not adequately managed and properly

maintained.

b) Injuries and damage to property to due to broken accessories that are

suddenly dashed.

Warning! This power tool produces an electromagnetic field during

operation. This field may under some circumstances interfere with active or

passive medical implants. To reduce the risk of serious or fatal injury, we

recommend persons with medical implants to consult their physician and the

medical implant manufacturer before operating this power tool.

7|English

7

10

1

2

3

4

6

5

12

9

8

11

8|English

X

C

3

F

3

D

3

E

B

2 10

9

11

A

11

9|English

10|English

Hammer Safety Warnings

Wear ear protectors.

Exposure to noise can cause

hear- ing loss.

Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

Hold the tool by the insulated gripping surfaces when

performing operations where the application tool or

the screw could contact hidden wiring or its own power

cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the operator.

Use suitable detectors to determine if utility lines are

hidden in the work area or

call the local utility company

for assistance.

Contact with electric lines can

lead to fire and electric shock. Damaging a gas

line can lead to explo- sion. Penetrating a water

line causes property damage or may cause an

electric shock.

When working with the machine, always hold it firmly

with both hands and provide for a secure stance.

The

power tool is guided more secure with both hands.

Secure the workpiece.

A workpiece clamped with

clamp- ing devices or in a vice is held more secure

than by hand.

Always wait until the machine has come to a complete

stop before placing it down.

The tool insert can jam and

Product Features

The numbering of the product features refers to

the illustra- tion of the machine on the graphics

page.

1 Tool holder

2 Dust protection cap

3 Locking sleeve

4 Rotational direction switch

5 Lock-on button for On/Off switch

6 On/Off switch

7 Release button for mode selector switch

8 Mode selector switch

9 Button for depth stop adjustment

10 Depth stop

11 Auxiliary handle

12 Handle

*Accessories shown or described are not part of the

standard de- livery scope of the product. A complete

overview of accessories can be found in our

accessories program.

lead to loss of control over the power tool.

Product Description and

Specifications

Read all safety warnings and all instruc-

tions.

Failure to follow the warnings and

in- structions may result in electric shock,

fire

and/or serious injury.

Intended Use

The machine is intended for hammer drilling in

concrete, brick and stone, as well as for light

chiselling work. It is also suitable for drilling

without impact in wood, metal, ceramic and

plastic. Machines with electronic control and

right/left ro- tation are also suitable for

screwdriving.

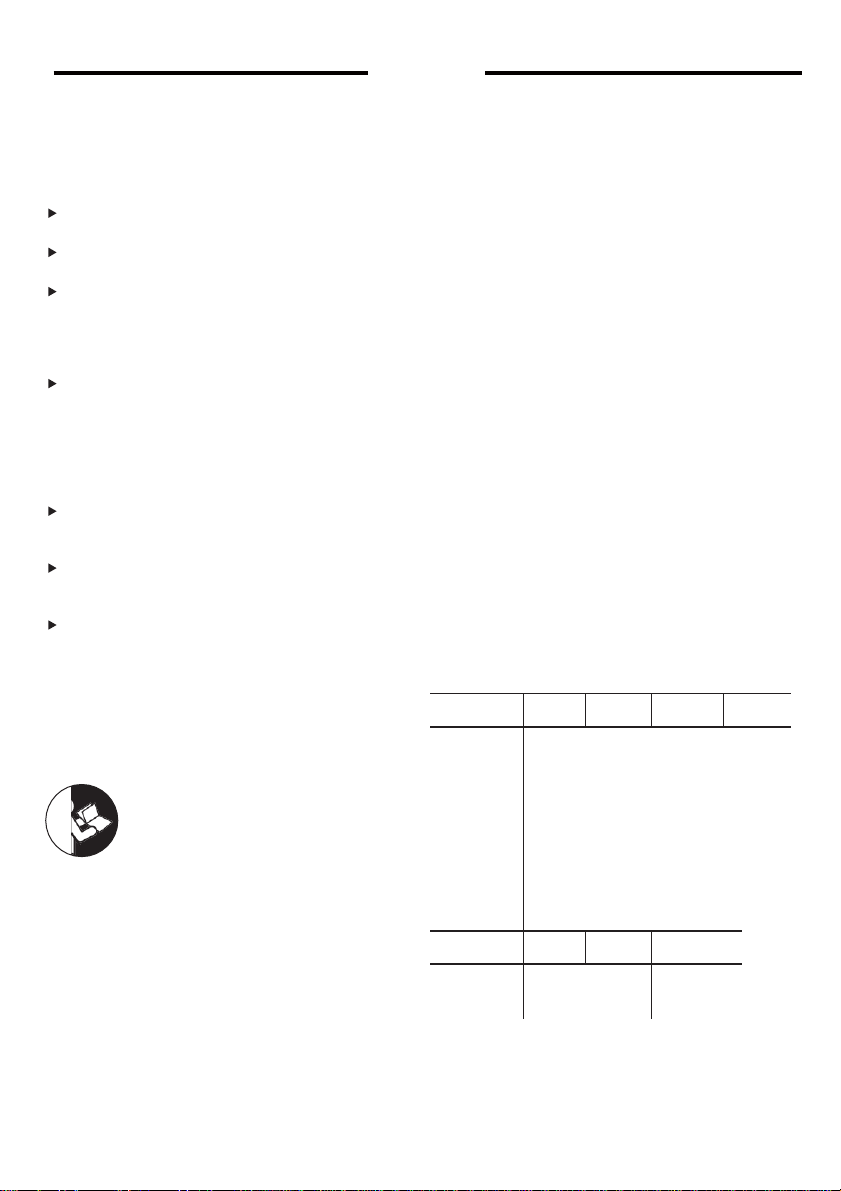

Technical Data

Model No.

RGH9028-2

RGH9028-26

(ISRAEL Plug)

RGH9028-28

(BS Plug)

RGH9028-2M

Rated voltage:

Rated input

power: No-load

speed: Impact

times: Drilling

capacity:

Concrete:

Steel:

220-

240V~50/60Hz

800W

0-

1100/min

0-

4000/min

26m

m

13m

m

Wood:

30mm

Model No.

RGH9028S-2

(SAA Plug)

RGH9028-29

(IRAM Plug)

URGH9028-2

Rated voltage:

Rated input

power: No-load

speed: Impact

times: Drilling

capacity:

Concret

e:

Steel

:

Wood:

220-240V~50/60Hz

110-120V~50/60Hz

800W

800W

0-1100/min

0-1100/min

0-4000/min

0-4000/min

26m

m

13m

m

1˝

1/2˝

30mm

1-3/16˝

11|English

Assembly

¥• Beforeanyworkonthepowertool

itself,pull

the mains plug.

Auxiliary Handle

¥• Operate your power tool only with theauxil-

iary handle 14.

Rotating the Auxiliary Handle

The auxiliary handle 14can beset toany position for a

secure and low-fatigue workingposture.

Turn thebottompartoftheauxiliary handle14incoun-

terclockwise direction and swivel the auxiliary handle

14tothedesiredposition.Thenretightenthebottom

partoftheauxiliaryhandle14byturninginclockwise

direction.

Payattentionthattheclampingbandoftheauxiliary

handleispositionedinthegroove onthehousingas

intended for.

Adjusting the Drilling Depth

Therequireddrillingdepth canbesetwiththedepth

stop 13.

Press the button for the depth stop adjustment 12and

Removing/inserting the Quick Change

Removing the Quick Change Chuck

Pullthelockringforthequickchangechunk6toward

therear,holditinthisposition andpullofftheSDS-plus

quick change chuck 2 or the quickchanpe keyless

chuck 1 toward thefront.

Afierremoving,protect thereplacement chuckagainst

contamination.

Inserting the Quick Change Chuck

Before inserting, clean the quick change chuck and

apply a light coat of grease to the shank end.

GrasptheSDS-plus quickchange chuck2orthequick

changekeylesschuck1 completely withyour hand.

Slidethe quick change chuck with aturning motion

ontothedrillchuckmountinguntiladistinctlatching

noise isheard.

Thequickchangechuckisautomaticallylocked.Check

thelockingeffectbypullingthequickchangechuck.

Changing the Tool

insertthedepthstopintotheauxiliaryhandle14.

The knurledsurface of thedepthstop13must face

downward.

Insert the SDS-plus drilling tool to the stop into the

SDS-plustoolholder3.Otherwise,themovabilityofthe

SDS-plus drilling tool can lead toincorrect adjustment

of the drilling depth.

Pulloutthedepthstopuntilthedistancebetweenthe

tip of the drill bit and the tip of the depth stop corre-

spond with the desired drillingdepth

The dust protection cap 4 largely prevents the entry of

drilling dustintothetoolholderduringoperation.When

inserting the tool, take care that the dust protection

cap 4 is notdamaged.

¥•

A damaged dust protection

cap

ahould be

changed immediately. We recommend having

thiscarriedoutbyanafter-salesservice.

Inserting SDS-plus Drilling Tools

TheSDS-plusdrillchuckallowsforsimpleandconve-

nientchangingofdrillingtoolswithouttheuseofaddi-

Selecting Drill ChucM and Tools

For hammer drilling and chiseling, SDS-plus tools are

required that areinserted in theSDS-plus drillchuck.

For drilling without impact inwood, metal, ceramic and

plasticaswellasforscrewdrivingandthreadcutting,

tools without SDS-plus are used (e.g., drills with cylin-

dricalshank).Forthesetools, akeylesschuck orakey

type drill chuck arerequired.

Note:DonotusetoolswithoutSDS-plusforhammer

drilling or chiseling! Tools without SDS-plus andtheir

drillchucksaredamagedbyhammer drilling orchiseling.

TheSDS-plusquickchangechuck2 caneasilybe

replaced against the quick change key- less chuck1

provided.

tional toole.

Insert the SDS-plus quick change chuck 2.

Clean andlightlygrease theshankendofthetool.

Insertthetoolinatwistingmannerintothetoolholder

until it latchesitself.

Check the latching by pulling the tool.

As a requirement of the system, the SDS-plus drilling

tool can move freely. This causes a certain radial run-

outatno-load,whichhasnoeffectontheaccuracyof

thedrillhole,asthedrillbitcentersitselfupondrilling.

Removing SDS-plus

Drilling Tools

Pushbackthelockingsleeve5andremovethetool.

12|English

Inserting Drilling Tools without SDS-plus

Note: Do not use tools without SDS-plus for hammer

drilling or chiseling! Tools without SDS-plus and their

drillchucksaredamagedbyhammerdrillingorchiseling.

Insert the quick change keyless chuck 1.

Firmly hold the retaining ring 6 of the quick change

chuck.Openthetoolholderbyturningthefrontsleeve

5 untilthetoolcanbe inserted.Tightlyholdtheretain-

ing ring 6 and firmly turn the front sleeve 5 in the

directionofthearrowuntiladistinctlatchingnoisecan

be heard.

Check the tight seating by pulling the tool.

Note:Ifthetoolholderwasopenedtothestop,then

thelatchingnoisepossiblymaybeheardwhileclosing

thetoolholderandthetool holder will notclose.

Inthiscase,turnthefrontsleeve 5 onceintheoppo-

site direction of the arrow. Afterwarcls, the tool holder

can be closed (tightened) apain.

Turnthemodeselectorswitch11tothe“Drilling" posi-

tion.

Removing Drilling Tools without SDS-plus

Firmly hold the retaining ring 6 of the quick change

chuck.Openthetoolholderbyturningthefrontsleeve

5 in the direction of the arrow until the tool can be

removed.

Operation

Starting Operation

•

Observecorrectmainsvoltage!Thevoltageof

thepowersourcemustagreewiththevoltage

specified onthetype plate of thepower tool.

Setting the Operating Mode

Theoperatingmodeof the power tool isselected with

the mode selector switch 11.

Note: Change the operating mode only when the

machine is switched off! Otherwise, the machine can

be damaged.

Tochange theoperating mode, push therelease but-

ton 10 and turn the mode selector switch 11 to the

requested position untilitcanbeheardtolatch.

Position for hammer drill-

ing in concrete or stone

Position for

drilling

without

impact in wood, metal,

ceramicandplasticaswellas

for screwdriving and thread

cutting

Vario-Lock position for

adjustment of the chiseling

position

Themodeselectorswitch11

doesnotlatchinthisposition.

Position for Chiseling

Reversing the Rotational Direction

Therotational directionswitch 7is usedtoreversethe

rotationaldirectionofthemachine.However,thisisnot

possible withthe On/Off switch 9actuated.

Right rotation: Turn the selector switch for drill-

ing/hammerdrilling 7onbothsides tothestopin

the positionR.

Left rotation: Turn the selector switch for drill-

ing/hammerdrilling 7onbothsides tothestopin

the position L.

Set the direction ofrotation for hammer drilling, drilling

andchiseling always to right rotation.

Switching On and Off

To start the machine, press the On/Off switch 9.

TolocktheOn/Offswitch,keepitpressedandaddi-

tionally push the lock-on button8.

Toswitchoffthemachine, releasetheOn/Offswitch

9.WhentheOn/Offswitch9islocked,pressitfirstand

then release it.

Setting the Speed/Impact Rate

Thespeed/impactrateoftheswitchedonpowertool

can bevariably adjusted, depending on howfar the

On/Off switch 9 is pressed.

Light pressure onthe On/Off switch 9 results in low

speed/impact rate. Further pressure on the switch

increases the speed/impact rate.

13|English

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working,always keep the machine

and ventilation slots clean.

A damaged dust protection cap should be changed im-

mediately. We recommend having this carried out by

an after-sales service.

–Clean the tool holder

1

each time after using.

If the machine should fail despite the care taken in manufac-

turingandtestingprocedures,repairshouldbecarriedout by

anafter-salesservicecentreforourpowertools.

14|English

RGH9028-2,RGH9028-2,URGH9028-2,RGH9028-2M

RGH9028-26,RGH9028-28,RGH9028S-2,RGH9028-29

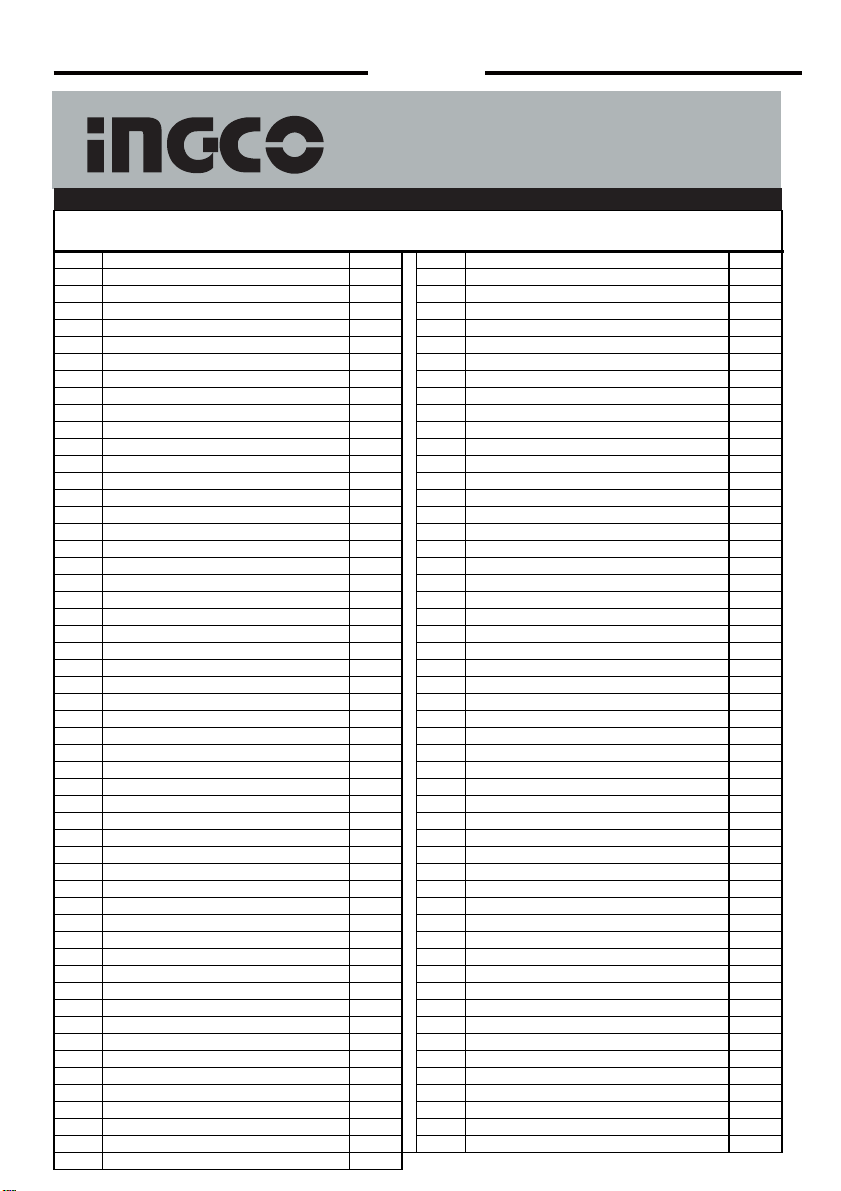

EXPLODED VIEW

15|English

SPARE PART LIST

RGH9028-2,RGH9028-2M,URGH9028-2,RGH9028-2M

RGH9028-26,RGH9028-28,RGH9028S-2,RGH9028-29

NO.

Part Description

Qty

NO.

Part Description

Qty

1

Dust Cap

1

54

O Ring

1

2

Dust Cap Washer 9.3X13X0.5

1

55

Cylinder

1

3

Snap Ring

1

56

Cylinder Pin Washer

1

4

Washer

1

57

Cylinder Pin

1

5

Snap Ring

1

58

O-Ring

1

6

Locking Sleeve

1

59

Holder Bushing

1

7

Thick Washer

1

60

Holder

1

8

Steel Ball

1

61

Press Fork

1

9

Washer

1

62

O-Ring

1

10

Spring

1

63

Bearing 609Z

1

11

Snap Ring

2

64

Bearing Press Plate

1

12

Drill Bit Cover

1

65

M4*8 Screw

2

13

Steel Ball

8

66

Gear Shaft

1

14

Keyless Chuck

1

67

Bearing 699Z

1

15

Connecting Bushing

1

68

Model Selector Fork

1

16

Chuck Adaptor

1

69

Fork Spring

1

17

Snap Ring

1

70

Needle Roller Bearing Hk0908

1

18

Snap Ring

1

71

Rocker Bearing

1

19

Ring

1

72

Needle Roller Bearing K15

1

20

Spring

1

73

33 Teeth Gear

1

21

Bushing

1

74

Spring

1

22

Chuck Sleeve

1

75

Spring Holder

1

23

St4.1*45 Self Tapping Screw

4

76

Position Washer

1

24

Torsional Spring

4

77

Rotor

1

25

Cylinder Housing

1

78

Insulation Washer

1

26

Oil Sea

1

79

Bearing 607Z

1

27

Bushing

1

80

Wind Guide

1

28

Needle Roller Bearing Hk3012

1

81

St3.7*17 Self Tapping Screw

2

29

Needle Roller Bearing Hk0709

1

82

Stator

1

30

Nine Teeth Washer

1

83

Inductor

2

31

St3.9*14 Self Tapping Screw

4

84

Bearing Bush

1

32

Flat Snap Ring

1

85

Gear Housing(Black)

1

33

Washer

4

86

Switch Contact

2

34

Spring

1

87

Carbon Brush Holder

1

35

O-Ring

1

88

Spring

2

36

Model Selector Pole

1

89

Carbon Brush

2

37

Model Selector

1

90

Stator Insert Line 120

2

38

Spring

1

91

Switch

1

39

Locking Button

1

92

Cable 2*0.75Mm

1

40

Big Gearing

1

93

Protective Sleeve Locating Sleeve

1

41

Connect Pipe

1

94

Rubber Sleeve

1

42

Pin

3

95

Press Cable Board

1

43

Clutch Disk

1

96

St4.1*16 Self Tapping Screw

5

44

Snap Ring

1

97

Back Cover(021C )

1

45

Oil Sea

1

98

Clamping Band

1

46

Thrust Ring

1

99

T Screw

1

47

Striker Shaft

1

100

Support Clamp

1

48

Striker Bushing

1

101

Locking Button Spring

1

49

O Ring

1

102

Locking Button

1

50

O-Ring

1

103

Depth Gauge

1

51

Holding Jacket

1

104

Auxiliary Handle

1

52

Snap Ring

1

105

Nut

1

53

Piston

1

This manual suits for next models

6

Table of contents

Other IN-ECO Rotary Hammer manuals

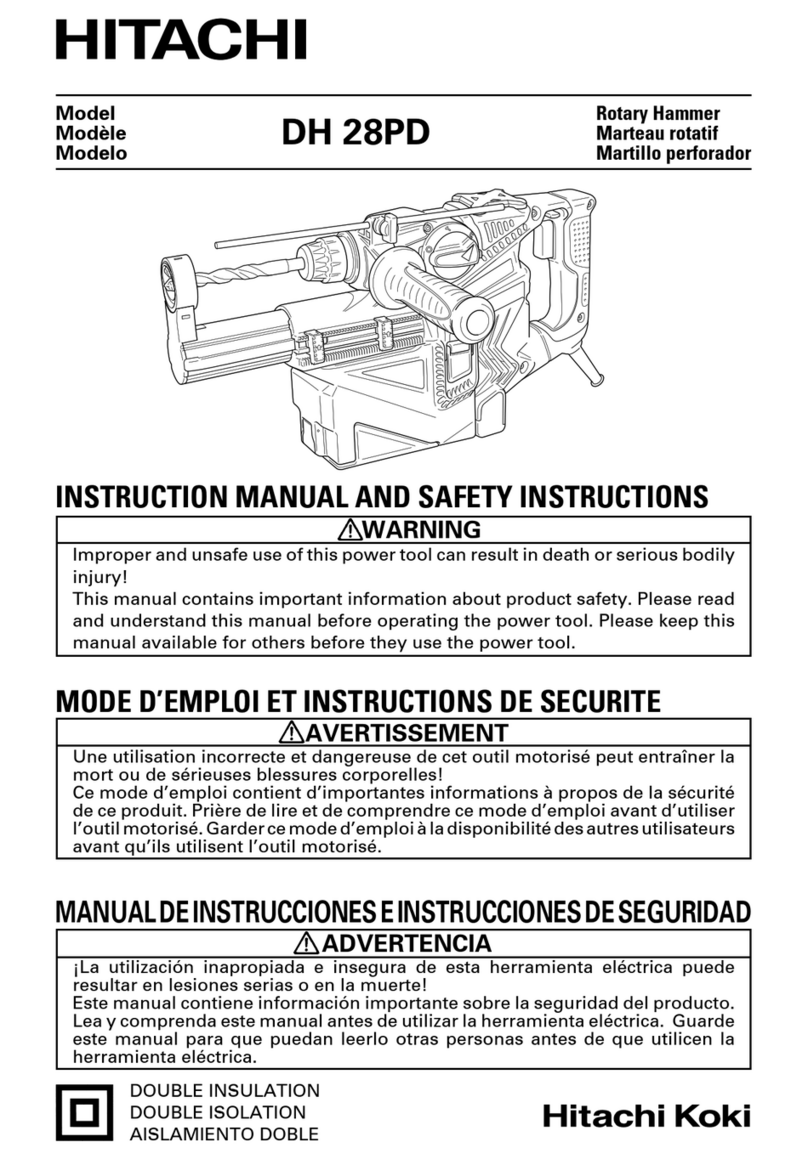

Popular Rotary Hammer manuals by other brands

Makita

Makita HR2800 instruction manual

Bosch

Bosch Professional GBH 18V-28 DC Original instructions

Makita

Makita CP100DSA instruction manual

HIKOKI

HIKOKI DH12DD Handling instructions

Hitachi

Hitachi DH 28PD Instruction manual and safety instructions

Bosch

Bosch Professional GBH 18V-45 C Original instructions