Inca 2200 User manual

v

GarrettWade

CfJlflp1111y,

/"'

161

Ave

of

the Americas

New

York,

New

York

10013

Phone: (800) 221-2942

Fax:

(800) 566-9525

Inca Model 2200 12" Tablesaw

Siscer Tabitha Babbie invented

che

modern tablesaw, at

che

Harvard Shaker community in 1810. Imagine with what delight

che practical Shakers welcomed chis innovacion.

Nearly 2 centuries lacer, relatively

few

changes have been made in

che basic design; chere is a power source, cable and projecting

blade, and a fence. Necessicy, rime, and inventiveness have given

us precision bearings, che rile arbor, and che

mitre

guide.

In

addi-

tion

we

have superior blade and fence design, and improved safety

and sawdusc collection features. Combined, they make

che

cable-

saw che unquestioned workhorse

in

che

\Wadworkers' arsenal.

I

nca

had it's beginning over 100 years ago

as

an aluminum mold

and die maker, casting aluminum

in

precise shapes for ocher

industrial uses.

When

a handsaw manufaccurer

wcnc

ouc

of

busi-

ness leaving behind che dies for a 1

O"

handsaw, che company

was

quick ro

cake

advantage

of

the sicuacion. With all

che

expensive

dies already paid for,

it

was a simple matter ro produce the

machine, buc a risky venture into unknown selling cerricory.

The

experiment obviously paid off. And you are the benefaccor

of

over

60

years

of

cool

making experience. Originally engineered in

Switzerland,

che

Inca line is now produced

in

France and cakes

advantage

of

che common marker experience.

We thank

you

for buying che Inca Model

2200

12"Tablesaw.

We

believe you've made a wise decision.

The

design process combined

the

inpuc

of

Swiss engineers (renowned for their precision clock-

making), designers and woodworkers like you (both amateurand

professional)

co

create a user-friendly precision machine.

Designed for a lifecime

of

service, your new Inca Model 2200 12"

Table Saw, includes che

lacesc

assembly

of

advanced features.

Although you may be very experienced

in

using and setting

up

machinery, please cake

che

time

ro read

the

manual.

The

mosc

experienced woodworker will benefit by seeing old information in

a new

way.

While

che

Inca is similar ro ocher cable saws in use

and controls, chere are some things you may find new and useful

co

know before you

scare

ro work.

Firsc: Check ouc your new saw. Machines are generally shipped by

truck

.

When

che driver delivered your saw, you probably signed a

bill

of

lading acknowledging receipt.

Unpack and inspect your saw promptly.

If

anyching has been

dam-

aged in

shipment

it

is your responsibility

co

file a "concealed dam-

age claim".

Afcer che claim has been filed an inspecror will check

che

damage,

so you muse keep che shipping materials.

You

may make a "concealed damage claim" even

if

there

was

no sign

of

damage ro the box

ac

the cime

of

delivery,

bur,

you muse

do

ic

prompcly. After che inspeccion,

we

will help you file a claim.

Moving

through

a

narrow

doorway:

Remove the crank handle

of

che angle adjustment wheel. Loosen che set screw in the lock collar

of

the

worm on che angle adjuscment mechanism. Work

che

rod

ouc

of

che machine.

Reverse accions ro reinstall.

Page

1

Where

To

Find

It

Accessories

17

Angle Scale

13

Angle Stops

15

Blades

17

Belt Tension

11

Crosscutting 9

Fence 4

Guard and splitter

14

Insert Places

14

Leveling Machine 3

Maintenance

15

Mitre Guide 5

Mascerfence, align 4

Parallel

12

Rail Lock Knob 4

Rear Clamp

15

Ripping 7

Scale, measuring 6

Specifications

17

Trunnions

13

legs, tables, blades, etc.

stop limits and scale

trunnion limits

sizes and teeth configuration

drive belt adjustment

mitre guides and sleds

uses and functions

2 kinds

of

guards

at

the blade

feet

lubrication

square

co

the blade

blade and fence

prevent rail from moving

on fence

How-to and why

front rail scale

mocor, speed, amps,

ecc.

keep clean, adjusting

SOME SUGGESTIONS FOR SAFE

WORK

HABITS.

DON'T

RUSH! The

wood

has

been waiting for years

co

be your

cable

or chair.

A

few

more minutes doing

it

right won't hurt.

NO

LOOSE

CLOTHING.

It

will gee caught in things or places which will lead

to

disaster. Shirt sleeves will catch blades or bits. Ties will be sucked into the

vortex.

DO

NOT

SMOKE while operating machinery.

DO

NOT

DRINK

and operate machinery.

DO

NOT

WORK

WHEN

YOU ARE TIRED

OR

DISTRACTED.

The number one cause

of

accidents

is

lack ofconcentration. you cannot con-

centrate when you are tired.

IF

IT LOOKS

AND

FEELS

RISKY, IT

IS.

Seek help; ask someone with more

experience.

Remember, you have spent

years

growing useful parts

of

your anatomy.

Don't

cue

pieces

of

it

off.

Fingers have many ocher uses.

The

exploded

view ofmachine pares attached

is

of

previous Inca model

2100SE. Model 2200 has the following changes:

1. New model

has

single drive belt.

2. Table miter

sloes

are now T-slocs, %"x

W'

3. There

is

no

longer a cucouc

in

the cabinet side

for

the mortise attachment.

4.

Tool

kit

is

not

as

shown on the exploded view.

All ocher parts and part numbers arc generally unchanged.

Page

2

Quick

Start

Procedure

If

you are already familiar with table saws, follow this procedure

for setting up your saw quickly.

Locate all the unattached parts

of

the saw, some

of

which are

shipped inside the saw body

These are the standard parts shipped with your saw:

2 Crank wheels with handles

Blade guard and splitter

Masterfence and Extrusion

Mitre Guide

The

Tool

Kit

contains:

Wrench

Blade

spacers

~·

r

Allen

Wrench

Arbor

locking

bar

QuickStart

l.

CHECK

THAT

THE

SHIPPING

BRACE

IS

REMOVED: A mecal

pedestal support under

che

mocor, held by one bole. Do

noc

operate

crank wheels with

ic

in place.

2. Mount

che

handles on che wheels: chey use an allen key

or

a nuc on

the handle shaft.

3. Mount wheels

co

shafts: Larger handle on front

co

adjust height.

Note:

Keyways

must

line

up.

4. Mount rails: Loosen all four scar knobs under cable

cop

Mount

che

MascerFence: Make sure che rear clamp

is

facing the rear.

S. Check: fence square

co

che blade?

6. Mount extrusion: Slides onto che bole heads on

che

fence. Accicude

is your choice.

Levelling

the

machine.

Each

of

che

four

feec

is accached

co

che

frame

with

cwo

socket head screws.

They pass through

che

sloes in

che

frame

so

feet may

be

raised or lowered.

If

you use a three-wheeled rolling support (such

as

HTC's) you can skip

chis seep.

1.

Find

che

foot

noc

couching

che

floor.

2. Loosen che

cwo

mounting

screws and gently lower

ic

until it and all

ocher feet are couching che floor. There

is

also a floor

mounting

bole

hole which you may use

co

bole your saw

co

che

floor. Before doing

chac,

run che machine

co

discover

if

che floor

ac

chac

point

is

"live".

Some floors have areas more prone

co

vibration chan ochers. Many peo-

ple also puc chin rubber pads under che feet

co

further dampen vibra-

tion.

(If

you have

bought

che

HTC

roller base, che leveling

is

auto-

matic, and nothing need be done.)

Page

3

Complete Assembly Details

1.

Attach

the

handles

co

the rims

of

the wheels.

2.

Put

the larger

of

the

two

crank wheels on the height adjustment rod at

the front

of

the machine.

Noce: The key in the shaft muse mate wich the keyway in

che

crank

wheel hub.

3. Puc the smaller wheel on the

side rod.

1.

Loosen all

four

black

scar

knobs

at

che

corners

of

che

saw

cable.

2.

Insert

the

rails

into

dove-

tailed

ways.

The wedge on each knob

muse

be

below

che

rail.

The front rail has

che

scale.

An

exclusive Inca feacure,

chese

guide rails allow the fence

and extension cables

co

be

used either left

or

right

of

che

blade

as

your work

requires.

1: Threaded bolt 2: spring 3: Wedge

4: washer 5: Knob

Turning

che

height crank clockwise will

raise

the blade.

Turning the

.angle

.c..mnk

clockwise will

I.ili

che

blade coward

450.

If

they become sciffand difficulc

co

turn,

ic

is time

co

clean

che

threads

by blowing or vacuuming and oiling.

(use

white

lithium

grease)

Note:

Whenever

you

raiJe,

tower

or

alter

the

blade

angle,

alwayJ

tooJen

the

tock-

ing

knobs

on

both

wheels

and

retighten

both

tocks

afterwards.

White

not

criti-

cal,

it

helps

the

saw

hold

an

angle

or

height

with

absolute

accuracy

for

repeated

cuts.

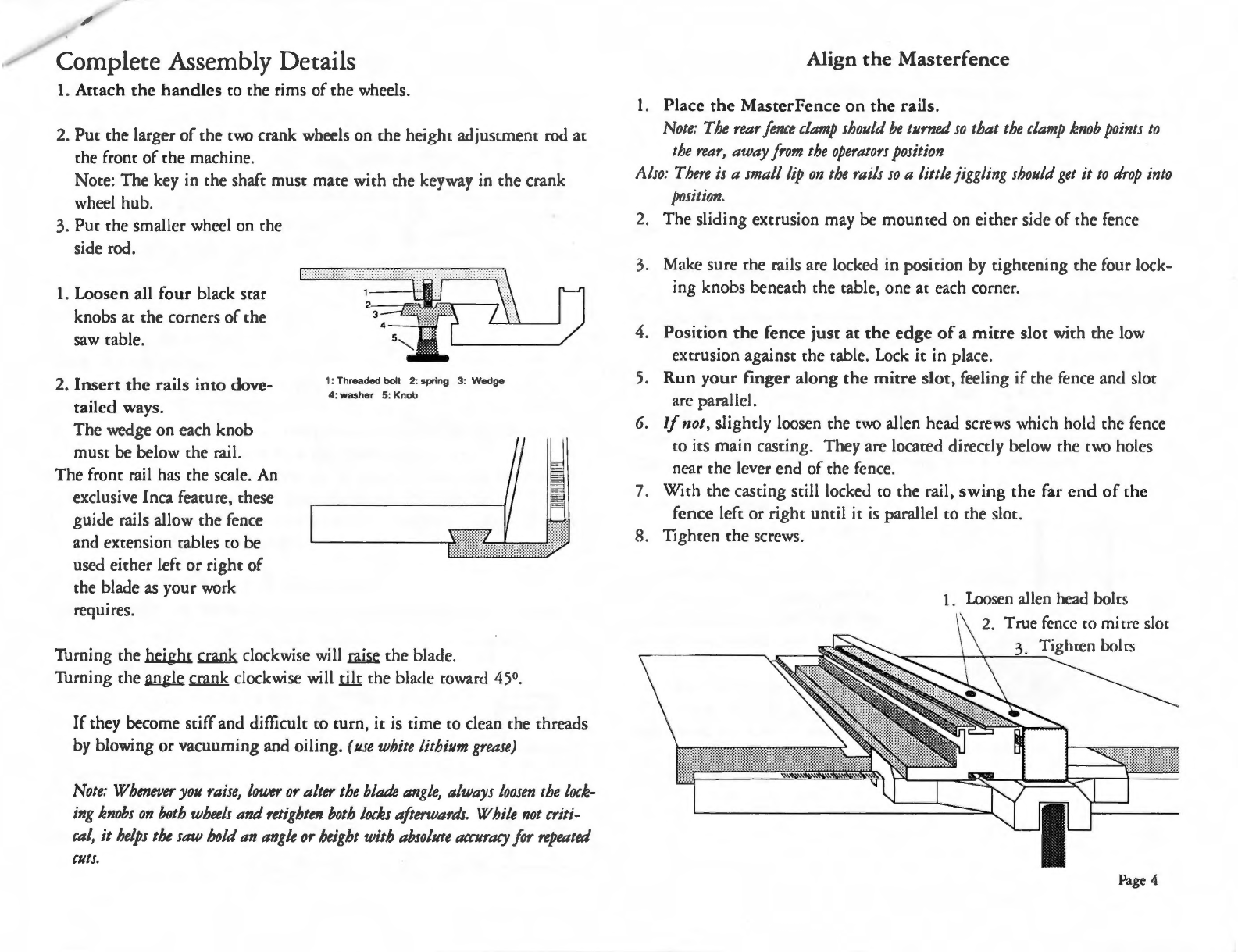

Align

the

Masterfence

I.

Place

the

MasterFence

on

the

rails.

Note:

The

rear

fence

clamp

should

be

turned

so

that

the

clamp

knob

points

to

the

rear,

away

from

the

operators

position

Also:

There

is

a small

tip

on

the

rails

so

a little jiggling

should

get

it

to

drop

into

position.

2.

The sliding extrusion may be mounted on either side of

che

fence

3. Make sure

che

rails are locked in posicion

by

cighcening the four lock-

ing knobs beneath

che

cable, one at each corner.

4.

Position

the

fence

just

at

the

edge

of

a

mitre

slot

wich

che

low

excrusion against the table. Lock

it

in place.

5.

Run

your

finger

along

the

mitre

slot,

feeling

if

che

fence and

sloe

are parallel.

6.

If

not, slightly loosen

che

cwo

allen head screws which hold

che

fence

co

its main casting. They are locaced directly below the two holes

near the lever end

of

the fence.

7. With the casting still locked

co

the rail,

swing

the

far

end

of

the

fence left

or

right until

it

is

parallel

co

che

slot.

8. Tighten the screws.

1.

Loosen

allen head

boles

True

fence

co

mitre slot

_-.......~-

-+--i.:

-

~3""-'._T...:ighrcn

bol

rs

Page4

/

Fence

Lock

1.

Lock

che

fence in place, only

ac

che fronc, by

pushing

down che locking

lever.

2.

Wich your hand near

che fronc rail,

cry

co

move

che

fence.

If

ic moves, release che

lever and readjusc che

cighcness

of

che

lock-

ing lever.

3. Turn che fence over

and you will be able

co

see

che mechanism.

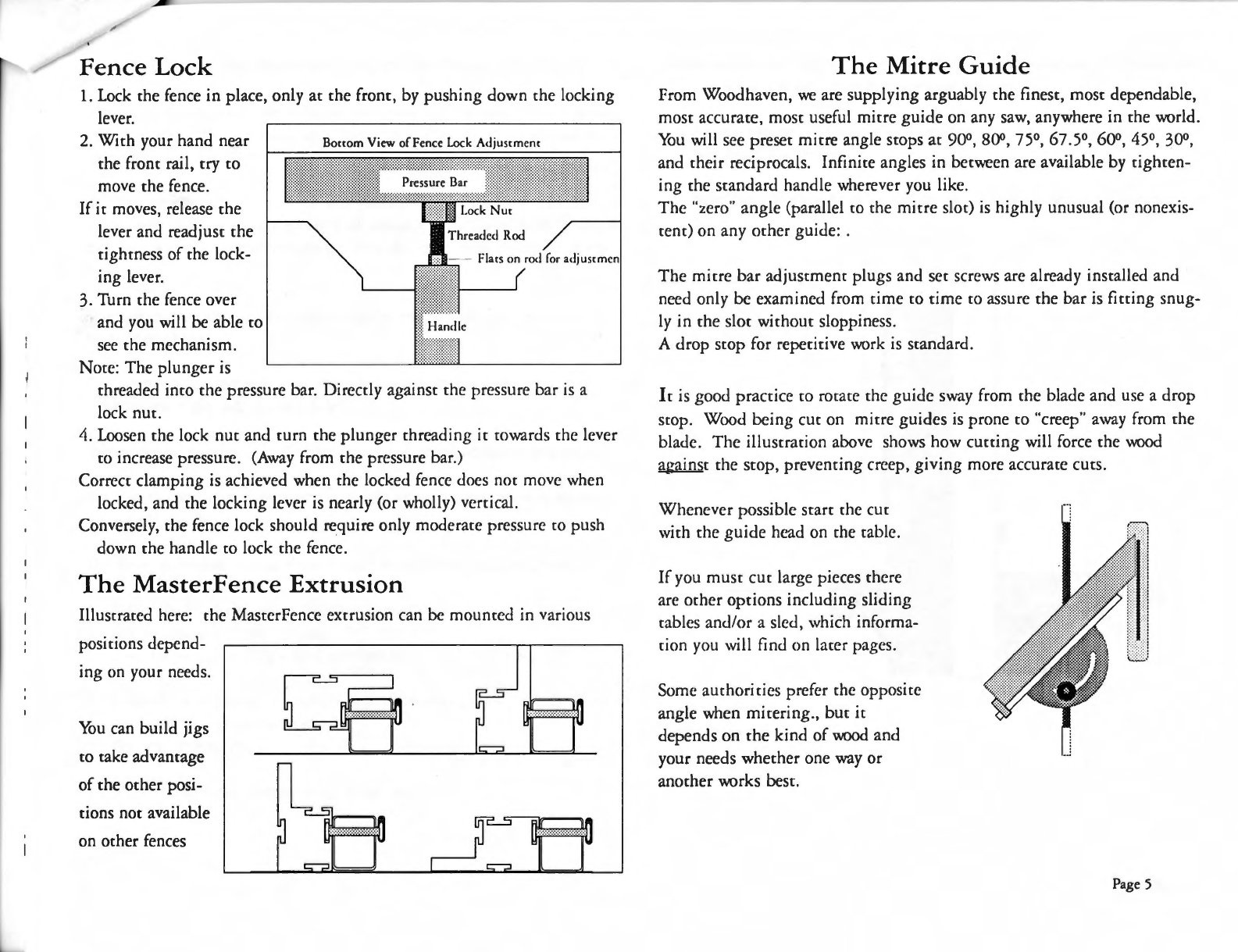

Nore:

The

plunger

is

Bonom

View

offence

Lock

Adjuscmem

chrcadcd inco chc pressure bar. Dircccly againsc chc pressure bar is a

lock nuc.

4. Loosen chc lock nuc and curn che plunger threading

ic

cowards chc lever

co

increase pressure.

(Away

from che pressure bar.)

Correcr clamping is achieved when

chc

locked fence docs nor move when

locked, and the locking lever is nearly (or wholly) vcrcical.

Conversely, che fence lock should require only modcracc pressure

co

push

down che handle

co

lock

che

fence.

The

MasterFence Extrusion

Illuscraccd here: che MasccrFcncc excrusion can be mounccd in various

positions depend-

ing on your needs.

You

can build jigs

co

cake advancage

of

che ocher posi-

tions nor available

on ocher fences

The

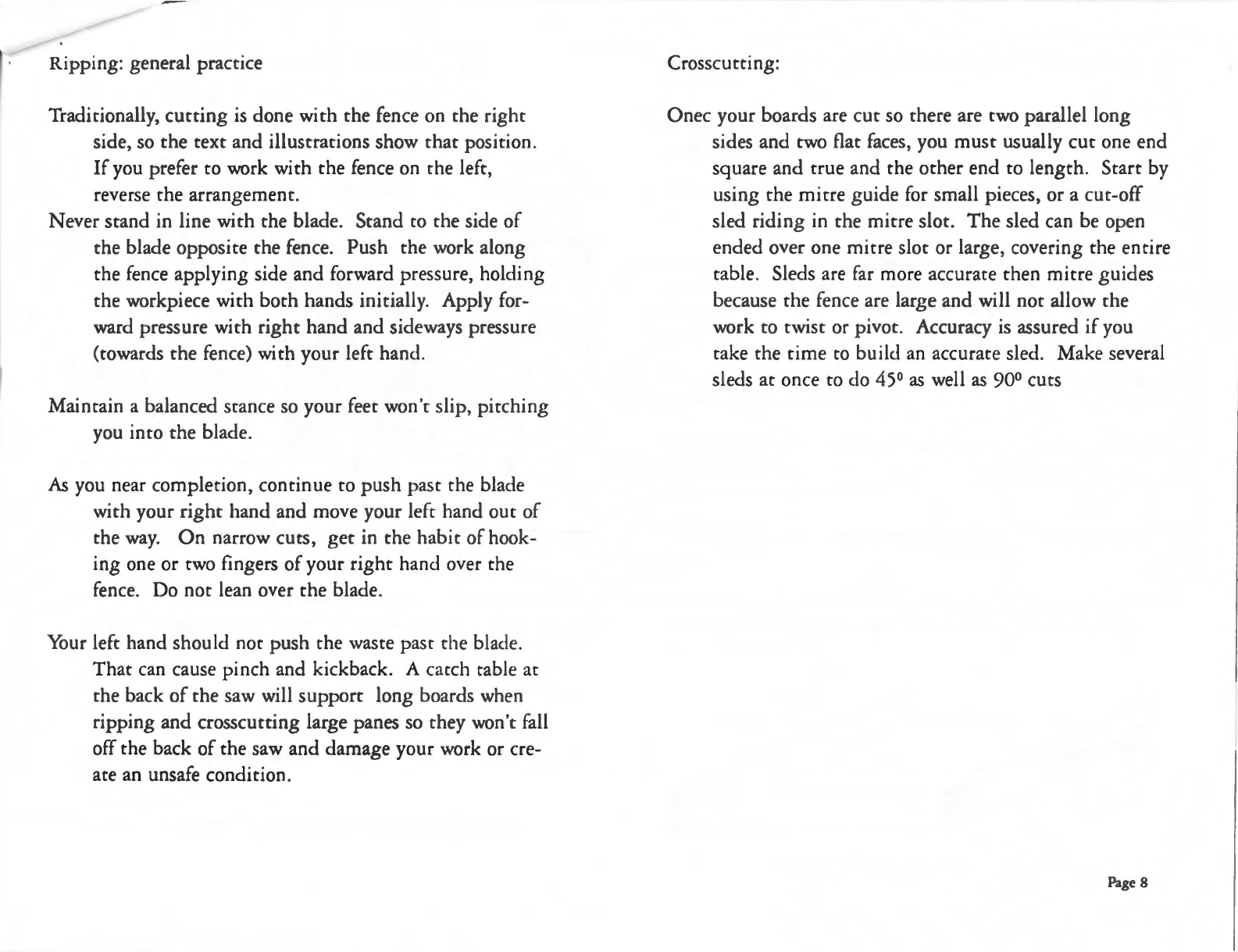

Mitre

Guide

From Woodhaven,

we

are supplying arguably che finesc, mosc dependable,

mosc accurace, mosc useful micrc

guide

on any saw, anywhere in che world.

You

will sec presec mi

ere

angle scops

ac

900, 800, 75°, 67.5°, 60°, 45°, 30°,

and chcir reciprocals. Infinice angles in bccwecn are available by cighcen-

ing che scandard handle wherever you like.

The

"zero" angle (parallel

co

che micre sloe)

is

highly unusual (or noncxis-

cenc)

on

any ocher guide: .

The

mi

ere

bar

adjuscmenc plugs and

sec

screws arc already installed and

need only be examined from rime

co

rime

co

assure che bar is ficcing snug-

ly in che sloe wichouc sloppiness.

A drop scop for repecicive work

is

scandard.

le is good praccice

co

rocace

chc

guide

sway from che blade and use a drop

scop. Wood being cue on micrc guides

is

prone

co

"creep" away from the

blade.

The

illuscracion above shows how cuccing will force chc

wood

against chc scop, prevcncing creep,

giving

more accuracc cues.

Whenever possible

scare

che cue

wich

chc

guide

head on

che

cable.

If

you muse cue large pieces there

arc ocher

options

including sliding

cables and/or a sled, which informa-

cion you will find on lacer pages.

Some auchoricics prefer

chc

opposicc

angle when mitering., bur

ic

depends on chc kind

of

wood

and

your needs whecher one way

or

anocher works besc.

Page

5

Adjusting

the

Rails

and

the

Front

Measuring

Scale

The

easy

adjustment

of

the rails and the measuring system

of

your new

INCA Model

2200

is the key

co

making your work faster, easier and more

accurate.

·

You

can set the rails and scale

so

chat you can always directly read

che

dis-

tance from fence

to

blade regardless

of

whether you choose

to

use a wooden

auxiliary fence or choose

to

measure from

che

left, right or center

of

the

blade.

The system also allows you

to

make rips

co

the maximum capacity left or

right

of

the blade

The

adjustments here arc

to

set che fence and scale for ripping with the

fence on the

right

side

of

the blade.

There are

nm

windows on the fence, and only one is exposed at a time.

The one

co

the right

of

the fence is visible when the extrusion is on the

left side

of

the fence.

The

fence extrusion should always cover the window

you

aren't using.

l.

Bring the fence extrusion

right

up

co

the blade,

just couching buc

noc

pressing, and lock

ic

in place.

Note:

(If

you

will

be

using

a

wood

auxiliary

fence,

it

should

be

on

now.)

2.

Slide the scale alone along the cop

of

che front rail until the arrow in

the window is

pointing

ac

the

"O".

You

are "zero'ed in".

3. Move the rear rail

co

complement the front rail.

(When

you

change

rail

position

or

move

the

fence

to

the

other

side

of

the

blade

you

will

repeat

this

exercise

to

make

the

scak

accurate.)

As

you can see, the scale can

be

readily aligned with any fence or auxil-

iary fence you choose.

Also you can align

it

co

read from either side,

or

center,

of

the blade or

cuccer.

Page

6

Part

3

Ripping

technique

is important in order

co

cut straight and true

It

may

seem

obvious

but

as

with all

saw

cuts, you

must

prepare

i!lll:JiJJ!

.li·:1:=J1'·1=1:::11:11:::111

1

;11ttlllll

f k

For the smoothest cut,

we

recom-

mend you set the blade height

so

that the gullet between teeth

is

level with the mp

of

the

wood

being cue.

If

you raise the blade mo high, the

teeth are exiting the wood at a

high angle which causes tear-out.

1.

Make sure the

wood

is level on the table

as

the

wood

approaches the

blade

Cautions:

If

the

wood

is

not

flat

it

can

cause

the

blade

to

suddenly

catch

the

wood

causing

sudden

shock

to

teeth

or

wood

Both

teeth

and

wood

can

shatter

with

unpleasant

results.

2. Support the work after

it

passes the blade

co

avoid losing control

of

the end

of

the cut.

Note:

A

catch

table

behind

your

saw

or

a

set

of

rollers

will

help

to

avoid ruining

valuable

work

and

help

prevent

injury.

3.

As

you push

wood

imo

the blade, be aware of the direction that you

are pushing the

wood.

As

the illustration shows, feeding the

wood

with some pressure

towards

the

fence insures that you will not inadvertently skew the

cut.

4. Your

Right

hand

pushes forward while your left hand keeps the

wood

tight

against the fence (as illustrated).

Pushing IQQ

fufil.

with

~

chick hardwoods can strain the momr which

will aucomatically

cue

off

if

ic

over-

heats.

Pushing too slow or srnpping risks:

l.

burning

the

wood

2. kickback.

Try for a consistent speed and effort.

Keep you hands

and

clothes

away

from the blade.

If

you

must

make

cuts near the blade, USE

THE

PUSH

STICK.

Working Blade Height: Should show only a few teeth above the work.

YES!

Page 7

Ripping: general practice

Traditionally,

cutting

is

done with the fence on the right

side, so the text and illustrations show

that

position.

If

you prefer to work with the fence on the left,

reverse the arrangement.

Never stand in line with the blade. Stand

to

the side

of

the blade opposite the fence. Push the work along

the fence applying side and forward pressure, holding

the workpiece with both hands initially. Apply for-

ward pressure with right hand and sideways pressure

(towards the fence) with your left hand.

Maintain a balanced stance

so

your feet won't slip, pitching

you into the blade.

As

you near completion, continue to push past the blade

with your

right

hand and move your left hand out

of

the

way.

On

narrow cuts,

get

in the habit

of

hook-

ing one or two fingers

of

your

right

hand over the

fence. Do not lean over the blade.

Your left hand should nor push the waste past the blade.

That

can cause pinch and kickback. A carch table at

the back

of

the saw will support long boards when

ripping and crosscutting large panes so they won't fall

off the back

of

the saw and damage your work or cre-

ate

an

unsafe condition.

Crosscutting:

Onec your boards are

cut

so

there are two parallel long

sides and two flat faces, you

must

usually

cut

one end

square and true and the other end to length. Start by

using the

mitre

guide

for

small pieces, or a cut-off

sled riding in the mitre slot.

The

sled can be open

ended over one mitre slot or large, covering the entire

table. Sleds are

far

more accurate then mitre guides

because the fence are large and will not allow the

work

ro

twist or pivot. Accuracy

is

assured

if

you

rake the

time

to

build

an

accurate sled. Make several

sleds ar once

to

do 45°

as

well

as

90° cuts

Page 8

Crosscutting

Techniques

The

Mitre

Guide

is

intended for relacively small work.

Absenc a posicive locking device holding che procraccor head in position,

large and/or heavy work may cause che head

co

cwisc.

In addicion

co

a scop

on

che

fence, many woodworkers

glue sandpaper

co

che face

of

che

fence

co

help avoid

creep.

Whenever possible

scare

che

cue

wich che

guide

head

on

che

cable.

If

you muse

cue

large pieces

chere are ocher options

including sliding cables

and a sled, illuscraced

here. t

1 a a t

1

The

sled

size

is

relevanc

co

che work you are doing. Keep in mind you

will

be

able

co

crosscut

as

well

as

micre

wich

chis device depending on

whac

auxiliary fences you incorporate.

I.

Lay

2 pieces

of

hardwood W' x %" x 24" in

che

mi

ere

sloes. They should

fie

quice well.

2. Raise chem slightly above che cable surface by puccing dimes under

chem fronc and back.

3. Spread a running bead

of

yellow

glue

along che

cop

of

each one.

4. Carefully lay a piece

of

14"

ply on

cop

of

chem

as

square

as

you can. (le

isn'c critical).

Note:

You

may

use

any kind

of

ply and

any

thickness.

We

chose

!1.4"

for

its

light

weight.

4. Weight che ply wich books or bricks or whacever.

Lee

dry for 2 hours or

more.

5.

Accach

a 2 x 4

on

edge

co

che

from and back by screwing

up

through

che ply inco che 2x. Be

as

square

as

you can. Use only one screw in each

end. Ic's a cemporary hold. Make sure

che

sled slides in che cracks.

1.

Wich che Blade lowered, turn on che saw and raise

che

blade

up

through

che sled. Don'c

lee

che sled move.

2. Wich che blade abouc

1"

above

che

cable, move

che

sled back

~nd

forth

elongacing che kerf.

Do

noc

cue chrough che 2 x 4's.

3. Used a square againsc che sloe you've cue

co

make che 2x's perfectly

perpendicular.

3. Afcer assuring perpendicularity, accach che 2 x 'i's wich more screws and

cue

through

chem.

You

now have a sliding cable which can give you

very accurace crosscucs.

Page

9

Reproducing

an

exact

cut

width.

Position the piece

to

be reproduced against the fence and

leave

some space next to the blade. 1" would be ade-

quate. Using the piece to be copied

as

a fence, cut a

piece

of

scrap. Do not move the fence.

The scrap will replace the piece and now any other piece

run through agaiinst the scrap will be aucomaticall

the same size

as

the original piece.

It

is

repeatable and requires no measurement,

no

set-up.

Steel die-makers use this technique to saw blockes

of

ply-

wood

to

precise dimensions.

Page

10

Aligning

and

Tuning

Best results always come from

machines

which are correctly

aligned

and

tuned

.

These

are

the

important

areas on which

we

recommend

periodic

checking

.

A.

Saw

blade

and

fence

parallel

to

the

mitre

guide

slots

B.

Blade

angle

stops

at

45°

and

90°

C.

Blade

angle

scale

D.

Splitter

and

guard

E.

Table

insert

plate

Alchough chese areas are aligned

ac

rhe facrory, mi

sa

lignmenc may occur

during

shipments,

and/or

afcer some period

of

use.

You

don'c need expensive cools

co

align and resc, buc you will need a good

cry

or

combination

square.

A good

cry

square wich a

3"-6"

blade will work nicely.

Test

the

square

on che oucside firsc. Some carpenters squares are

noc

accurate boch inside and outside.

Note:

All

adjustments

should he

made

with

the

saw

unplugged

for

safety.

DO

NOT

WORK

WHILE

:

A.

TIRED

B.

DRINKING

ANY

ALCOHOL

C.

DISTRACTED

D.

WEARING

LOOSE

CLOTHING

OR

TIES

DO

NOT

WORK

WITH:

A.

SAWDUST

ON

THE

FLOOR

B. LOOSE ELECTRICAL

CONNECTIONS

C.

LOOSE

WIRES

ON

THE

FLOOR

Belt

Tension

and

con

di

ti

on

The

drive belc has a break-in period. Afcer some hours

of

use

it

may loosen

and need

co

be censioned

in

order

co

gee full power from rhe mocor

wichour

slipping

.

1.

Unplug

the saw.

2. Tilcing che arbor for easier access.

3. Loosen rhe four boles which hold

the

mocor in place.

4.

Tighren

rhe sockec head screws in

the

ends

of

che tension bracket even-

ly

,

going

from one screw

co

che ocher,

making

only small

(Ya

turn)

adjusrmencs.

5.

When

you feel you have achieved correcc tension,

righten

the

four boles

char hold che mocor in place.

6.

Rorace che

blade

by hand

co

make sure the belc

is

nor

rubbing

or scrap-

tng.

7. Reconnect

the

power

and jog che

machine

on (on

and

off

quickly)

co

make sure chc blade

is

curning

in chc

ri

g

hc

direccion.

Tensioning screws

/

'\

-

/

"'

-

~

"'

\

I

IJ

......

Page

11

~

Disconnect

the

Power!

A.

The

saw blade and fence

must

be parallel

ro

the

mitre

guide

slots.

PINCHING

HERE

WILL

LIFT

WOOD

AND

THROW

IT

BACK

TOWARDS

OPERATOR

BLADE

ANGLED

TO

LEFT

WJLL

PULL

WOOOD

AW

AY

FROM

FENCE

For any

saw

co

cue

we

ll

and accuracely

ic

is

imporca

nc

ch

ac

chc

blade

be

parallel

co

chc

micrc s

loes

and

chc

fence.

The resulcs of misalignmenc are here illuscraced

Because

chc

micre

sloes

a

re

noc

movable, all chings a

rc

aligned

co

chem.

Wi

ch

che

blade a

nd

che

fence parallel

co

chc

mi

ere

sloes, ic follows

chac

chc

blade and fence arc parallel

co

ea

ch

ocher.

1.

Raise

the

blade

co

maximum height.

2.

Lay

a combinacion square (or a dcpch gauge) against

che che

mi

ere

sloe

so

chat

che

blade

is

directed coward

che

blade.

Note

: The

body

of

the

square

should

be

snug

to

the

lip

of

th

e

slot.

3.

Rocace

che

blade

wi

ch

chc

cry

square

bl

ade close

co

che

saw

blade

co

deccrmine whccher

che

blade wobbles or spins fairly

cruc.

If

fairly cruc, pick one

cooch

.

4. Mark

ch

ac

cooch

of

chc

saw

blade and

jusc

couch

chc

cry

squa

re

bl

ade

co

chac

cooch

as

ic

is

jusc

emerging from

chc

cable.

5.

Rocacc

chc

sa

w blade forward

uncil

chc

cooch

is

almosc

di

sa

p-

pearing. Measure again.

Not

e:

Do

not

adjust

th

esquare.

In

eac

h

case

the

try

squ

are

or

de

pth

ga

u

ge

must not press

aga

inst t

he

saw

blad

e.

ju

st a bare to

uch

.

If

che

square

pushes or docs

noc

cou

ch

chc

blade in

chc

second

posicion,

chc

saw

bl

ade muse

be

re-alig

ned

co

chc

micrc

sloes.

Page

12

~

·

Realign the

Trunnions

and Saw blade

The

Saw blade rorares

on

rhe

arbor

which

runs

rhrough

bearings,

which

are

held

by

the

trunnions.

The

trunnions

can

be

moved

laterally by

loosening

the

four alien head

bolts

ar

the

back

of

rhe saw.

Access

bolts

rhrough

rhe

four

openings

cut

in

the

ourer

cabinet.

1. Loosen chem

slightly.

\'(!

arning: (DO

NOT

REMOVE)

Use a wood bar 10 gently lap 1runnion

lefl or right

al

this poinl

2.

Move

the

trunnion

left

or

righr

as

appropriare

.

3.

Test

rhe

alignment

using

the

technique

already described

on

the

prcvi-

ous

page

4.

When

the

blade

is

parallel,

tighten

the

four boles.

Note

: The tightening

action

sometimes

causes

the

trunnion

to

move

slightly.

Test

agarn.

B. Blade

Angle

Stops

at

45°

and 90°

On

the

underside

of

the

cable

on

each

side

of

the

front

trunnion

arc scops

co

set

the

saw

angle

at

45°

and

90°.

The

scop is a socket head screw

and

lock

nut

secured

against

the

table

mp

casting.

Although

cops are faccory set,

make

it

a

habit

co

examine

your

machine

often

.

The

90° scop is accessible

through

the

blade

opening.

Easier access

when

che

arbor

is

tilted

co

about

25°

and

lowered

all

rhe

way.

The

45° scop is located

on

the

opposite

side

of

the

trunnion,

accessible

through

the

access door.

Check

that

chips

or

dirt

do

not

interfere

with

the

acrion.

C.

Adjust

the

Blade

Angle

Scale

With

the

arbor

at

90°,

The

red

arrow

should

point

co

0°.

If

not:

1. loosen

the

screws

that

hold

the

scale

2.

shift

the

scale

under

che

arrow

so ir

poinrs

co

90°.

Note:

The

scale

is

marked in

!12°

increm

e

nts

.

The

scale

can

be

read

to

increments

as

fine

as

!16°

(I0

minut

es

of

arc)

Observe

rhe

shoulders

on

each

side

of

rhe

red poinrer.

As

an

example

sec

any

intermcdi-

are

angle.

For inscance: 22°.

Slowly increase

the

angle.

When

the

right

shoulder

couches

the

next

available

mark,

you

have reached

22!.1,0,

or

22°,JO'

Continue

rnrning

and

when che

lefc

shoulder

reaches a

mark,

you will

be

at

22

2

/<,0,

or

22°,20'.

The

next

mark

will couch rhe red

arrow,

and

wi

II

be

wi

II be

22%

0 (20Y2°),

or

22°,30'

Not

illuscraced

bur

conrinuing,

right

shoulder

will

show

22o/dl

(20¥1°)

Then

left

shoulder

ar

22

~

0

,

and

finally

back

co

rhe

next

mark

at

the

arrow

for 23°.

Page

13

D.

Splitter and Guard

Your

Inca

2200

comes

with

a

splitter

in

place.

le is che mecal fin

mounced

behind

the

blade

and

adjuscable so chac

ic

will noc incerfere

wich any cuccing operacion.

Ofcen, while

ripping,

a board will cry

co

close che cue jusc

made

.

It

can

pinch

the

blade

catching

the

cccch

emerging

from

the

cable and life and

kick

back

the

wood coward

the

opcracor.

This

"

kickback"

can spoil a

good

cue

and

scare you

as

well.

Make

sure

the

splicccr is exactly lined

up

with

the

blade

and docs

noc

lean

co

one

side.

It

is

the

correcc thickness for a

kcrf

(saw cue)

of

w:

and

should

noc

affccc

the

wood which has

just

been cue except

under

the

pinching

conditions

above.

Use

the

splitter

and avoid

problems

.

Position

the

splicccr no

more

than

Ya"

behind

and W' below

the

blade

height.

To

use

the

Euro

safety

guard,

you muse replace

the

scandard

splitter

with

the

one packaged wich chc

guard.

Lock inco

position

inco

the

cop

of

rhc

arbor

casting,

with

rwo socket

hca<.J

screws

These

concrol

the

118

~

~~rirr:::.ighc

position

of

chc (

~~~/

·

':/'

',

A large bole

holds

rhe

splitter

co

i

cs

brackcc

and,

loosened,

allows rhc

splitter

ro

move

up,

down,

forward and

back.

The

guard

mouncs on cop

of

rhc spliccer

with

rhe

attached

lever bole. Back

out

the

screw and

re-tight-

en

through

the

splitter.

(NOTE:

the

splitter

is

thin

steel;

if

it

becomes

bent

you

can

bend

it

back

into

correct

position

.)

E.

Table Insert

Plate

The

Table Inserc Place

as

ic

comes from che faccory, should be exactly level

with

the

cop.

Unscrew

chc franc screw and life

up

the

franc

end

of

chc place and

pull

coward you.

The

rear cab will come

out

from

under

the

cable cop.

Inscallacion is

the

reverse

procedure.

There

are 8

sec

screws on

the

boccom

of

the

place

co

assist leveling and

f1arncss. Screwing chem in

or

out

will affect

the

level

ac

chat

position.

The

set screw in

the

cab

ac

the

rear

end

of

rhc place

applies

tension

on

the

place

co

minimize

vibration.

I . Back

off

chc

sec

screw in chc rear cab

and

sec

rhc place in

the

opcning.

2.

Adjust

the

ocher screws uncil

the

place lies

f1ac

and

even

with

the

cable

su rfacc.

3. Raise

the

sec

screw in chc cab uncil,

when

the

place is inserced,

the

fronc

end

should

rise above chc cable surface

about

Ya'';

then

press

down

and

righten

rhe

fronc

locking

screw.

Optional

Insert

Plates.

We offer a special

blank

inserc place for zero

clearance

or

for special

cutters

or

narrow

blades.

While

you may

make

your

own

wooden insercs,

we

recommend

Inca places which offer

better

fir

and

f1acness.

There

are also wide

slot

inscrc places for

dadoing

and

moulding

heads.

To

cut

a

slot

in

the

blank

plate:

Lower

the

blade all

the

way, inscall che

blank

inserc, and wich rhe

machine

running,

raise che blade

chrough

rhc

place.

file

chc edges smooch.

Carbide

cccch will

not

be

harmed

by

the

special sofc

aluminum

of

the

place.

(Do

not

use

standard

sreel blades

co

cut

the

sloe.)

Page

14

~

Good

Maintenance

is

very

important.

Jc

is

che key elemenc

which will keep your Inca saw

running

crouble-free for a lifetime.

Use

a non-silicone wax on che cable surface, where wood and mecal come

rogecher. Silicones can incerfere wich wood finishes.

Do

nor use.!! floor wax.

They

concain anci-slip ingrediencs which negaces

che purpose.

Use a whice lichium grease for

the

metal

co

mecal or

plastic

co

metal con-

cacc.

Duse off, blow off and vacu

um

every day

or

week,

depending

on frequency

of

use, all chc slides

and

incernal screws

and

slides.

The

Rear

Clamp

on chc back

of

che fence is nor necessary for day-ro-

day

operations

.

Yc>u

may leave

it

loose. Use

it

when you have a long run

of

repeated

ripping

wich heavy scock.

Or

when you a

rc

u

si

ng

a hold-

down

which exerts

downw

ard pressure

on

chc work, che

clamp

will pre-

venc

the

rear

of

the

fence from

rising

.

Dust

collection

is assisted by che aerodynamically

designed

blade

enclosure which efficiently

directs

dust

co

the

4"

exhaust

port.

We

strongly

recommend

you

connect

a

proper

dusc colleccion syscem.

The

dust

collecror

should

be raced

ac

595

CFM

or better. Duse collec-

tion

keeps

the

moving

pares csean and

working

smoochly.

Blade

Elevation

Despite

che use

of

a

dust

collcccor, wood resin will

eventually

cling

co

incernal pares. Week resin dries

co

a ha

rd

metallic

skin

and

incerferes with

moving

pares. Blade elevation will begin

co

feel sticky

and

difficult

as

che carriage moves

along

the

vercical slides

fore

and

aft

of

che blade.

Blade

Tilt:

The

saw

blade

carriage tiles

by

sliding

through

curved sloes

in

trunnion

places

at

the

fronc

and

rear

of

che saw incerior.

Keep

these

sloes clean.

Troubleshooting

Machine

will

not

start

Press reset buccon

on

switch

box.

With

power

disconnected,

check

wiring in

plug,

box

and

switch.

Concacc eleccrician for concinuicy resc

co

eliminate

all possible

electri-

cal

problems

before conca

cci

ng

dealer.

Machine

starts

but

shuts

off

immediately

If

circuit

breaker

trips

in power

panel,

it

may be char

wiring

is not

heavy

enough

co

ha

ndle

load

or

chat breaker

or

fuse

is

coo small for

load.

With

power

disconnected

, does blade

turn

by

hand?

Concacc

electrician.

Machine

runs

but

blade

scops

or

stalls

when

cutting

With

power

disconnccced, does che blade

turn

by

hand

? Is

the

arbor

nuc secure? Is che belc

ci

ghc?

\X-'ood

scops

at

back

of

blade

It

may be

hitting

che splicccr.

Make

sure

splitter

is even

with

blade

\Vood

binds

between

blade

and

fence,

burning

or

pulls

away

from

fence

Fence is

not

parallel

wi

ch

blade.

\Vood

feeds

very

slowly

and

burns

badly

I.

Blade is installed

backwards,

or

motor

is

running

in reverse.

or

2.

Wcx>d

is

pinched

between

blade and fence

..

Page

15

To

Tighcen che Scale:

IF

che scale moves coo easily

you may cighcen che

springs

.

Expose chem by

sliding

che

scale ouc

of

che wa

y.

Inserc a

flac

bladed screwdriver

under

the

spring

and bend

the

spring

down

over it

co

increase

the

bow.

Increase the

bow

in small

increments

lest

the

scale

become

s

co

difficult

co

move.

Miscellaneous

Information

Change

the Blade

1.

Inserc

the

plain

bar

into

the

hole in

the

right

hand

mitre

slot.

There

is a

corresponding

hole in

the

arbor

into

which

the

bar will

fie,

preventin

g

the

a

rbor

from

curning

.

2. Reach chrough

the

access

door

and

remove che

blade

cover, held in

place by

cwo

knurled

nucs.

3. Wich che 3

0mm

wrench, loosen che

arbor

nuc by

pulling

cowards you,

and remove

ic

and che oucer flange.

The

Ii

ring spacer is for scandard blades.

Height

and

Angle

Locks:

On

each adjuscmcnc crank, chcrc is a

locking device. Turn lefc

co

lock and reverse

co

unlock

.

Do

not

ovcr-cighcen, only firm

locking

is necessary.

The

machine

is

designed

co

keep

its

secting

with

the

locks loose, buc for

more

consiscent results,

we

recommend

tightening

both

locks before

CUtctng

.

Also

when

making

changes

in

height

and/or

angle

please

LOOSEN

BOTH

LOCKING

KNOBS.

They

are

interconnected

for

addicional security.

Ir

is imporcanc for

angle

change,

noc so imporcanc for heighc.

Note: Tightening

thes

e

knobs

can

affect

settings

to

a tiny

de

gr

ee

.

There

is

some

play builc

into

che system

co

allow componencs

co

operace

smoochly.

The

Fence

Extrusion

can be inscalled on che ocher s

ide

of

che

beam

by

removing

che

knob,

and

sliding

off

che excrusion.

Screw che

knob

on che opposi

cc

side

of

che beam.

Reinscall che excrusion.

There

are several posicions which che excrusion can cake.

Experimenc

co

see which is besc for your work.

Setting

Angles

Accurately

Y()Ll may need

co

sec

che blade cilc,

or

mitre

guide

ac

some parcicular

and

repeatable

a

ngle

.

Angle

scales are useful buc, for angles you regularly use, you mighc cry

chis:

By

cri

al and error, cue a block

of

well seasoned hardwood

or

parcicle board

ro che exacc

angle

you rcquire.

Make

ic

big

enough

robe

used as a

guide

for seccing your

mitre

g

uide

or

chc blade.

Now

you will have a

permanent

physical record and

gauge

of

che

angle.

Use

ic

co

cesc

sec-ups and

co

inscancly

sec

che

mitre

gauge

and/

or

bla

de

angle

if

you

don

'c cruse che indicacor.

Page 16

Optional

Accessories

Long Rails (78'')

(Srock#

210.309),

will allow

ripping

ca

pacity

of

50"

right

or left

of

che blade.

They

replace

standard

rails. Longer rails arc

available on special

order

.

Support

Legs (scock #

210

.

212)

arc a muse for

longer

rails, especially

if

you arc

using

cxccnsion cables.

Moulding

HeaJ

(scock #

210

.

052)

sec

includes 36 <lifferem cucccr

pro-

files. Muse be used in

conjunction

wich che safety hol<l-<lown for y

our

safety.

Inca

Shaper

&

Moulding

HolJ-Jown.

Moum

on

che

master

fence.

Exccnsion Table, MDF, 12" wide (scock #

210.110

)

Exccnsion Table, case a

lum

., 12"

wiJc

with roucer

moum

kic a

n<l

built

in

micrc sloe (scock

#210.213)

.

Exccnsion Table,

MDF,

24" wide (scock #

210

.403) wich

He

ave Duey

acrylic insert

9

~

"

x I PA

':

which will

hole.I

mosc

routers

up

co

5HP

.

Rip

Fence

Micro

A<ljuscer (scock #

210.007)

for infiniccsimal a<ljuscmems

wichouc effort. Attaches <lirccrly

co

chc Mascerfence.

Blank Table inscrcs (scock # 2 1

O.O

li

O)

for zero clearance a

n<l

ocher special-

ized uses.

Tenon

Jig,

(scock # 2

80

.5) Noc only will

ic

hole.I

work firmly in a vertical

position,

ic

guards

chc

blaJc

anJ

has scops for each

sic.le

of

che ccnon.

Sliding

Table, Excalibrc,

cwo

models: each fcacurcs

open

framework cable,

large miere fence will accach

ac

either

from

or

rear

of

chc cable.

Infinite

angle

locks

ac

oucboar<l edge.

Small

(scock #

210.401)

cable

32"x

26''.

With

fence

in

from,

crosscuts

co

28''. Fence

in

rear, crosscucs

co

4

9"

Large

(scock # 2 1O

.li

04) cable

32"

x 32''. Wich fence in

from,

crosscuts

co

37

''.

Fence in rear, crosscucs

co

62"

Suva

Gu

ard:

(210.207)

Made

co

chc specifications

of

che Swiss Safecy

Insurance

Board. Covers che blade wichouc conneccion

co

che cable.

Allows

grooving,

<la<loing a

n<l

ocher shallow cues.

BLADES AVAILABLE all

I"

bore

Ya

"

kcrf

12"

dia

.

li

OT

combo

. 98110.12 s

129.00

6

0T

combo

9811 4

.1

2

Sl39

.

00

3

0T

rip 98113.1 3 s

119.00

8"

blade stiffener

98109.0

I S3

2.50

8"

Da

e.lo

Sec

98117.12 S3

25.00

Alwa

ys

<lisconnecc power before any service

or

a<ljuscmem

Technical

Specifications

Blade

Size

Arbor

size

Max

cutting

height

at

90°

Max

cutting

height

with

tile

ac

4

5°

Table

size

Distance

to

blade

front

of

cable

arbor

speed

shaft

diameter

at

bearings

drive

dust

exhaust

weight

recommended

dust

collection

12"max.

l"

4"

23

A"

27"

wide

x

31"

deep

12"

34

00

rpm

1

Yi

"

gates

polyflex

belt

4"

port

3751bs

350

CFM

Page

17

And,

lase buc noc lease: here is your reward for

reading

chc whole

manual.

We arc delighccd you have chosen

Inca

for

your

shop.

We believe in

the

quality

of

Inca

and

cruse chc 5 Year

Warranty

won't be necessary.

Many

users have

sung

chc praises

of

Inca for years

and

lam

hoping

you will, coo.

If

you have chc inccresc

and/or

chc

rime,

you are

invited

co

become

pare

of

che Inca Users

Network,

a

group

of

Inca

owners

who wane

co

share chcir experiences and personal cips wich ochers.

Sometimes

a

sticky

problem

can be solved by a

phone

call

co

an "old

hand".

And, occasionally,

we

gee rcquescs from prospeccivc owners

co

sec a

particular

machine

or

calk

co

an experienced user. We would like

co

be

able

co

say, "there's a

guy

jusc

down

chc screec who has a

machine

jusc

like

yours,

and

he may be

able

help

you

with

a solucion." We've

only

begun

chis

program

reccncly, buc we've had responses from all

over chc councry. If you'd like

co

be a pare

of

che

Inca

Network,

write

and

cell us what machines you

own,

and

cheir age. We'd be

pleased

co

give

you a S25

Gift

Ccrcificace for

your

parcicipacion,

however limiccd.

Should

you experience any

problems

with

your Inca,

we

know

you'

ll

call us first. And we'll bend over

backwards

co

fix

ic.

Thank

you.

Garrccc Wade

C:uscomer Service

Dept

.

Page

18

SAWING

OR

DADOING

DADOING

DADOING

DADOING

11/32"

WIDTHS

11/32"

TO

17/32"

WIDTHS 17/32" TO

23/32'1WIDTHS23/32"

TO 7/8"

(9mm

to

13,Smm)

(

13

.

Smm

to

18

.

5mm)

(

18.Smm

to

22mm)

TO

13/64"

WIDE WIDTHS

5/32"

TO

(5mm)

(4mm

to

9mm)

CENTER

RING

OUTER INNER

FLANGE

FLANGE

SAW BLADE

(approx

. 1/8" •

3.175

mm

wide)

WIDTH

ANGLE

WIDTH

5/32" to 3/16" 22°

to

45°

(4mm

to5mm)

1/4"

to

9/32"

1/32"

to

7/16"

(9mm

to

llmm)

o0 to 45° 7/16" to 15/32"

(lmm to

12mm)

ANGLE

o0

to

45°

.o0

to

45°

~~

~

o0 to

450

12mm

Insert

%~

%

~

~~

llJ

14

-Step Spacer

~

3-Step Spacer

Standard WIDTH "

ANGLE

Sawing 9/32" to 11/32" o0 to 45°

Insert

~

)~

~

·

~

~

1

NARROW

~

DADO v

(max.

13/64"

..

5mm)

0°

to

45°

14mm

Insert

USE

THE

4-STEP

SPACER

USE

THE

J.STEP

SPACER

RIN

RING

AND

USE

THE

AND

USE

Hi/32"

(12rrm)

OR

STANDARD

SAWING

INSERT

/16"

(14rrm)

INSERT

PS

INDICATED

16mm

Insert

m2-Step Spacer

WIDTH

ANGLE

15/32"

to

17

/32" o0

to

45°

~

f'

~

22mm

Insert

USETHE2-STEPSPACER

RING

AND

USE

518"

(16rrm)

OR

7/'i5'

(22rrm)

INSERT

PS

INDICATED

GUIDE

FOR

CORRECT SELECTION OF SPACER RINGS

AND

TABLE

INSERT PLATES FOR

VARIOUS

CUTTING TOOLS

AND

ANGLES

INCA Form. Nr. 54.033.201 ©

1986

INCA Maschinen und Apparate

AG

/

28rnm

Insert

o0 to 45°

33mm

Insert

USE

NO

SPACER

RING

AND

USE

NO

SPACER

RING

AND

USE

1-1/8"(28mn)INSERT

USE

1-1/4

"

(33rrm)INSERT

NO

CENTER

RING

REQUIRED!

IN

THIS

INSTANCE

GENERAL

NOTES:

INSERT

SIZE

REFERS

TO

THE

WIDTH

OF

THE

SLOT

.

CHOQ3E

THE

TABLE

INSERT

WITH

THE

SMALLEST

a>ENI

NG

THAT

WI

LL

PERMIT

YOUR

CUfTING

TOOL

~~~;;;:;;~~f~i~~~~~;

D

TING

CUTTER

UPTHROUGHTHE

INSTALLED

BLANK

ll'l3ERT.

COVER

BLADE

WITH

GUARD

WHEN

PERFO

RM

ING

THIS

Al\ID ALLa>ERATIOf\S. •

Table of contents

Popular Saw manuals by other brands

Unitec

Unitec CSR-160 Owner's Manual and Operating Instructions

Skil

Skil 5080 Operating/safety instructions

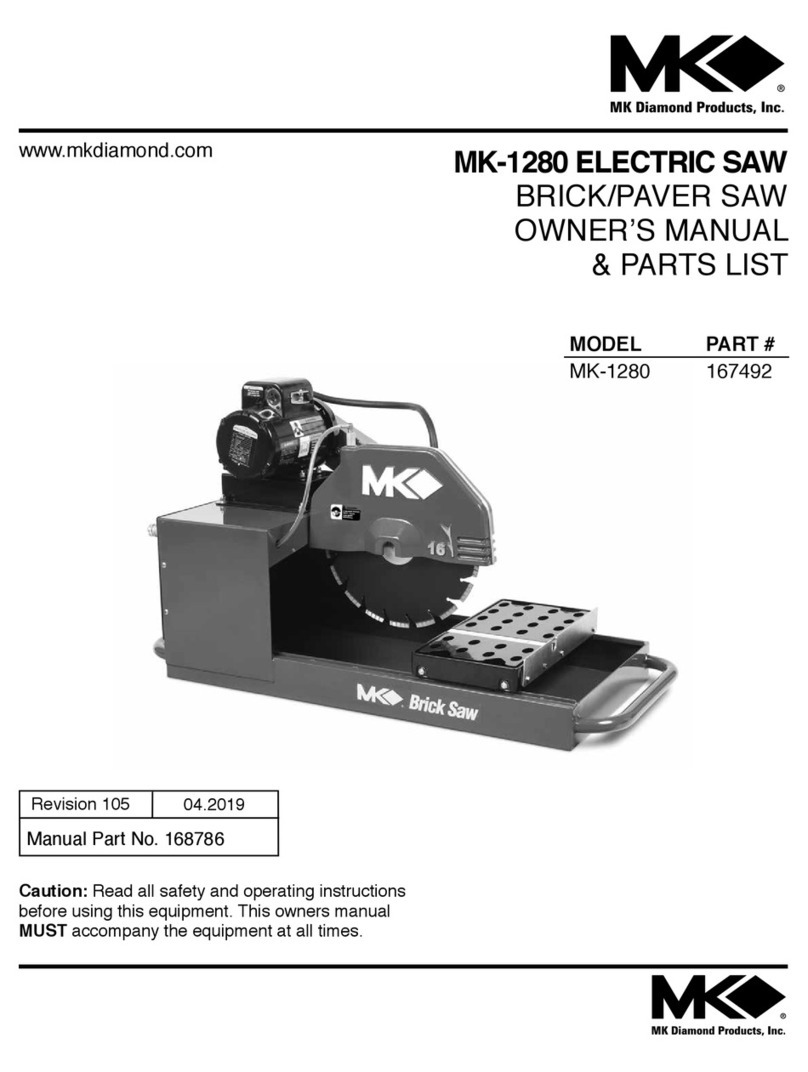

MK Diamond Products

MK Diamond Products MK-1280 Owner's manual & parts list

Parkside

Parkside ZKGS 2100 Operation and safety notes

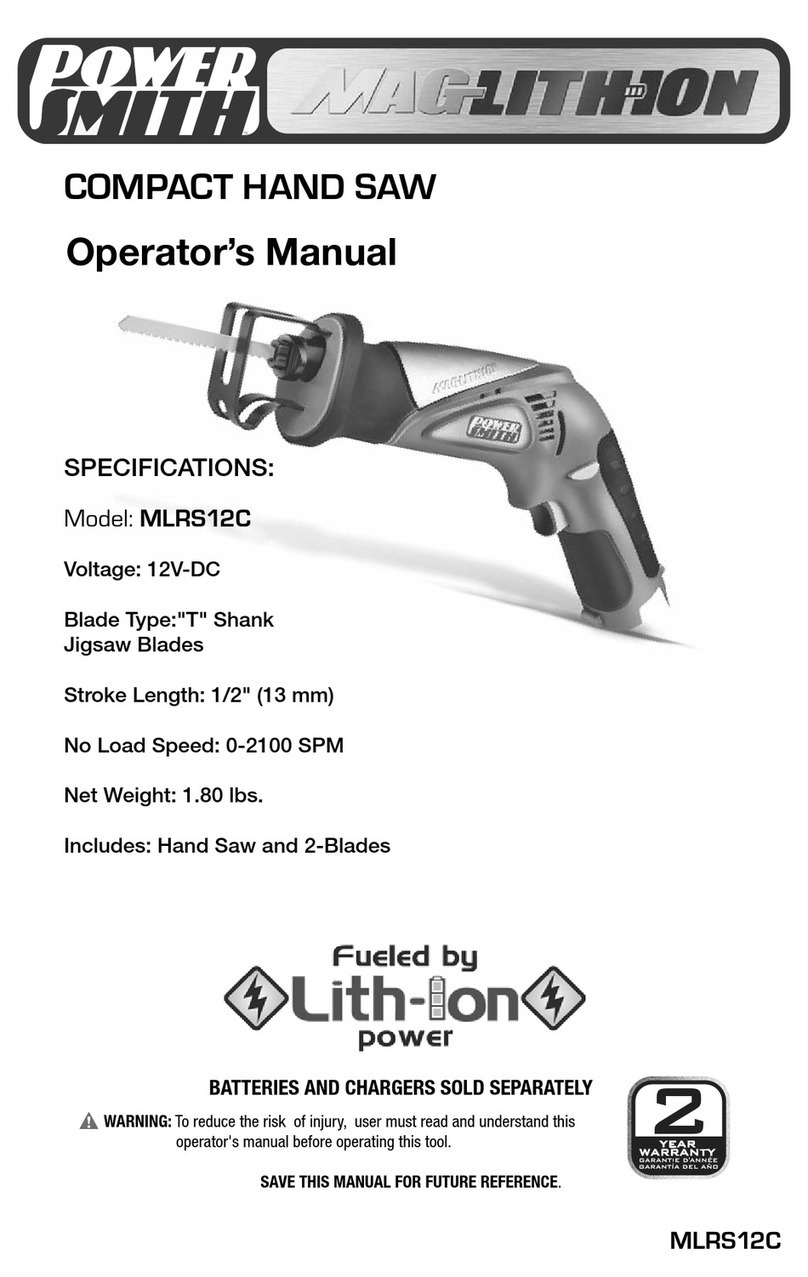

Richpower

Richpower MAG-LITHION MLRS12C Operator's manual

Grizzly

Grizzly G0771 owner's manual