Incite Fire SYNCRO User manual

Australia Version 2 – March 2016

Product Manual

Analogue

Addressable

Syncro View

Serial LCD Repeater Panel

SYNCRO

Syncro_View_AUS_v2.0.docx Page 2 of 12

Contents

1Introduction 2

2Safety and mounting 2

2.1 Safety 2

2.2 Mounting 3

3Technical specification 4

4Syncro View fascia 5

5Connecting to the circuit board 6

6Power and data connections 6

6.1 Data Termination 6

6.2 Power Supply 6

7Addressing the units 7

8Processor and watchdog reset switches 8

9Connections to Syncro View 8

10 Adding a Syncro View to the Syncro panel 9

11 Revision Details 11

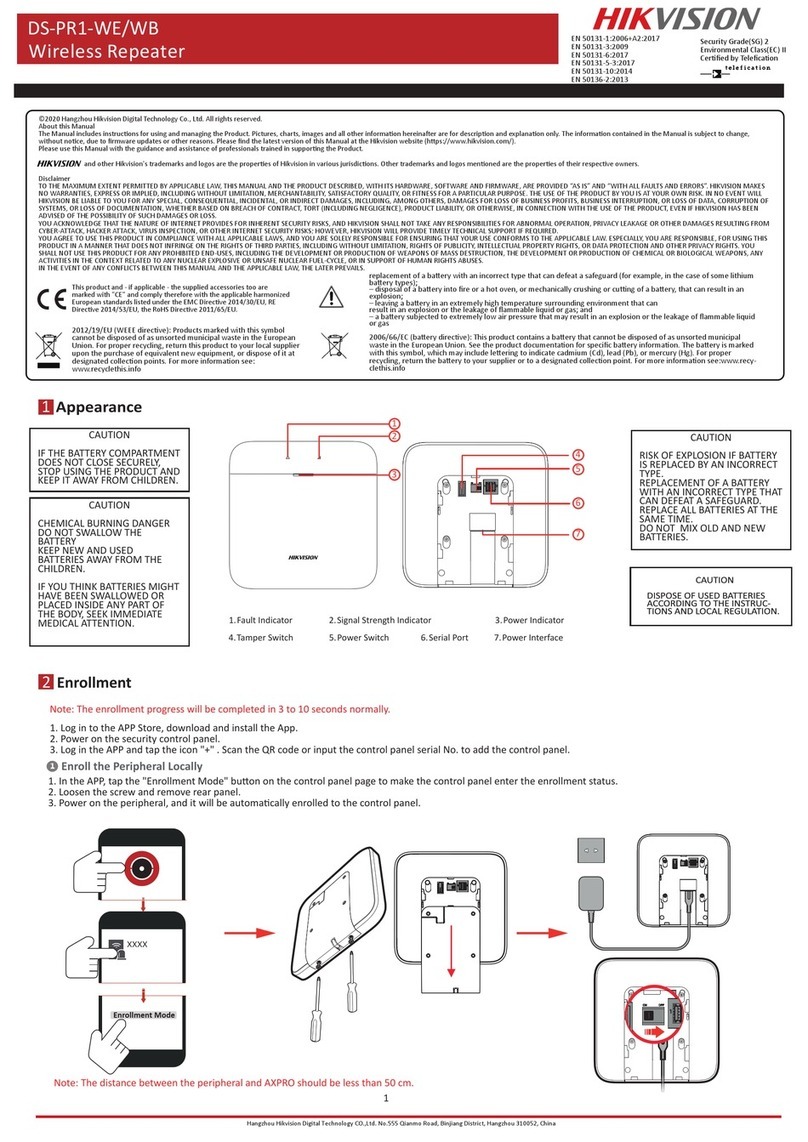

1Introduction

The Syncro View fire alarm annunciator is designed to provide indication and control of the status of the Syncro

analogue addressable fire control panel at a remote or multiple remote locations or provide a more compact and

pleasing user interface for the fire alarm system in areas where a large control panel would be obtrusive.

The Syncro View provides the same indications and controls as the Syncro fire control panel to which it is

connected and can take full control of network systems if the control panel to which it is connected is configured

to do so.

The Syncro View repeater panel will be overridden and cannot take control of the panel to which it is connected

if the main control panel is at access level 2.

The Syncro View buzzer will follow the buzzer operation of the host panel to which it is connected. Therefore

silencing the buzzer at the host panel will also silence the buzzer on the Syncro View repeater(s) connected to

that panel.

2Safety and mounting

2.1 Safety

Suppliers of articles for use at work are required to ensure as reasonably as is practical that the article will be

safe and without risk to health when properly used. An article is not regarded as properly used if it is used

‘without regard to any relevant information or advice’ relating to its use made available by the supplier.

This product should be installed, commissioned and maintained by trained service personnel in accordance with

the following:

(i) Local regulations for electrical equipment in buildings

(ii) Codes of practice

(iii) Statutory requirements

(iv) Any instructions specifically advised by the manufacturer

As an installer you are requested to take such steps as are necessary to ensure that you make any appropriate

information about this product available to anyone concerned with its use.

The mains powered version of this equipment is designed to be operated from 230V 50Hz mains supplies and is

of class 1 construction. As such it must be connected to a protective earthing conductor in the fixed wiring of

the installation and a readily accessible double pole disconnect device shall be incorporated in the fixed wiring.

Failure to ensure that all conductive accessible parts of this equipment are adequately bonded to the protective

earth will render the equipment unsafe.

Syncro_View_AUS_v2.0.docx Page 3 of 12

2.2 Mounting

Surface mounting units should be mounted on a dry, flat surface, at eye height to the display and in a level

position such that the enclosure is not distorted.

Screws or bolts of a minimum of 4mm diameter must be used to mount the enclosure in all three mounting

positions.

Suitable fixings should be used at all fixing points such that the unit is securely mounted and is not liable to

move once fixed.

Units should not be mounted in another enclosure or near sources of excessive heat.

Cables should be connected using suitable cable glands. If additional cable entry points are required, all swarf

and debris caused by drilling of additional cable entries must be cleared before power is applied.

Syncro_View_AUS_v2.0.docx Page 4 of 12

3Technical specification

Table 1 - Electrical specifications

Construction

18SWG Mild steel - IP30 rated

Cable entry

20mm knockouts 5 in top, 5 in rear and 1 in the

side

Finish

BS 00-A-05 light grey, fine texture.

Weight

5Kg maximum

Mains supply (Mains powered models only)

230V AC +10% - 15% (20 Watts maximum)

Mains supply fuse (Mains powered models only)

2 Amp, 20mm, glass HRC

Power supply rating (Mains powered models only)

0.75 Amps total including battery charge 28V +/-

2V

Maximum ripple current (Mains powered models only)

200 millivolts

Battery type (Yuasa NP) (Mains powered models only)

Two 12 Volt 1.9Ah sealed lead acid in series

Battery charge voltage (Mains powered models only)

27.6VDC nominal

Battery charge current (Mains powered models only)

0.2A maximum

Battery fuse (Mains powered models only)

200 milliamp, 20mm, glass

Maximum current draw from batteries (Mains powered models

only)

0.095 Amps

24V supply (24V DC models only)

21 to 30V DC

Quiescent current of panel in mains fail

0.03A

Serial data connection

2 core RS485 (Up to 1200 metres total cable

length)

Maximum terminal capacity

2.5mm²

Max number of units on each Syncro panel serial bus

15

Maximum number of units to be powered from Syncro Aux 24V

output

4

Syncro_View_AUS_v2.0.docx Page 5 of 12

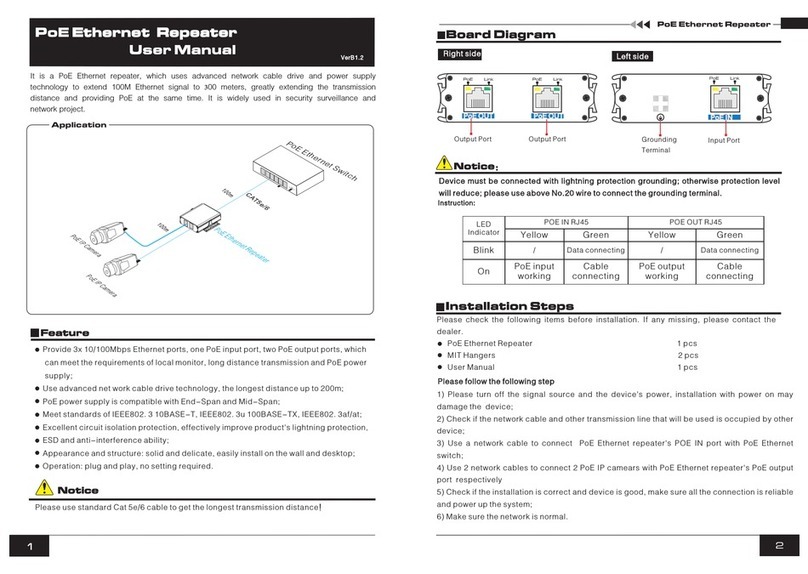

4Syncro View fascia

Models with enable controls keyswitch

Models without enable controls keyswitch.

Syncro_View_AUS_v2.0.docx Page 6 of 12

5Connecting to the circuit board

All connections for field wiring are to a single row of terminals along the bottom of the circuit board.

Shielded fire alarm cable such as FP200 and metal cable glands must be used for all connections to the unit. The

resistance of any core of the data cable must not exceed 25 ohms. The shield of the cable must be bonded

securely to the enclosure via the metal gland.

Wiring should enter the enclosure at the top or back of the unit using the knockouts provided and be formed

tidily to the appropriate terminals.

Terminals are capable of accepting wires of up to 2.5mm2.

Wiring must not go across the front of the circuit board. If cable entries need to be in positions other than at the

knockouts provided, wiring must be fed well away from the surface of the circuit board.

6Power and data connections

Each unit requires two cores for power and two cores for data transmission to and from the control panel. A four

core cable may be used for these connections. All of these connections are polarity conscious and care should be

taken to match the polarity with the corresponding terminals at the control panel. Mains powered versions require

only a two core cable to the control panel and a local mains supply.

6.1 Data Termination

Up to 15 units can be connected to a Syncro control panel. In and out terminals for data and 24V DC are provided

on each unit.

All units are supplied with a push on jumper fitted at position J3 on the left hand side of the PCB. This jumper

connects a terminating resistor which needs to be in place at the last unit on the data line. If more than one unit

is to be fitted, then the jumpers must be removed from all units except the last one.

If there is only one unit fitted then the jumper should be left in place. The COMMS LED will flash quickly while

the unit is communicating correctly with the control panel and will be off if the unit is disconnected or connected

incorrectly.

6.2 Power Supply

Mains Connection

Select the required operating voltage (115/230) via the selector switch adjacent to the

mains input. The mains is connected to the PSU via a fused terminal block marked with

live, neutral and earth symbols. It is imperative that the equipment is soundly earthed

and this connection should be made and checked first.

Following connection of the live and neutral cables and with no other connections made,

the unit should be powered and the battery output measured at around 28 volts DC (For

nominal 24V setting) or 14 volts DC (for nominal 12V setting.)

Load Connection

A maximum load of 750mA can be drawn with either 24V or 12V settings. (The

recommended maximum continuous load is 500mA.) Terminals are provided for

connection to the load and are marked + and -. The voltage at these terminals under

normal conditions (i.e. off load) should be around 28.5 to 29 volts DC (for nominal 24V

setting) or 14 to 14.5 volts (for nominal 12V setting.) With the mains power off, connect

the load cables.

Double check the load connection for correct polarity before switching on mains. After

switching on mains check the voltage at the load for correct polarity.

Do not connect or disconnect the wiring to the load terminals with mains or battery power

on.

Syncro_View_AUS_v2.0.docx Page 7 of 12

Fault/Healthy Connection

Switched -VE outputs are available for signalling of power fault and power healthy

indication marked PO (power on) and PF (power fault). Under normal circumstances

(mains and battery connected and fuses intact) the -VE appears at the PO terminal.

Failure of the mains or battery supply will transfer the -VE to the PF terminal.

A volt free changeover contact is also available for fault/healthy signalling which can be

used to switch other voltages or signals.

750mA typical wiring connections (always read safety notice at front of manual before

making any connections)

7Addressing the units

To enable the control panel to know whether any units that should be connected have been disconnected and

indicate a fault condition, each unit must be allocated an address. The address switch should never be set with

all switches off.

This is done by setting a binary number from 1 to 5 on the 4 way, DIL switch located at the bottom of the PCB.

The order of the addresses is not important but each unit must be allocated a different address.

The switch settings for each of the addresses are shown below.

Syncro_View_AUS_v2.0.docx Page 8 of 12

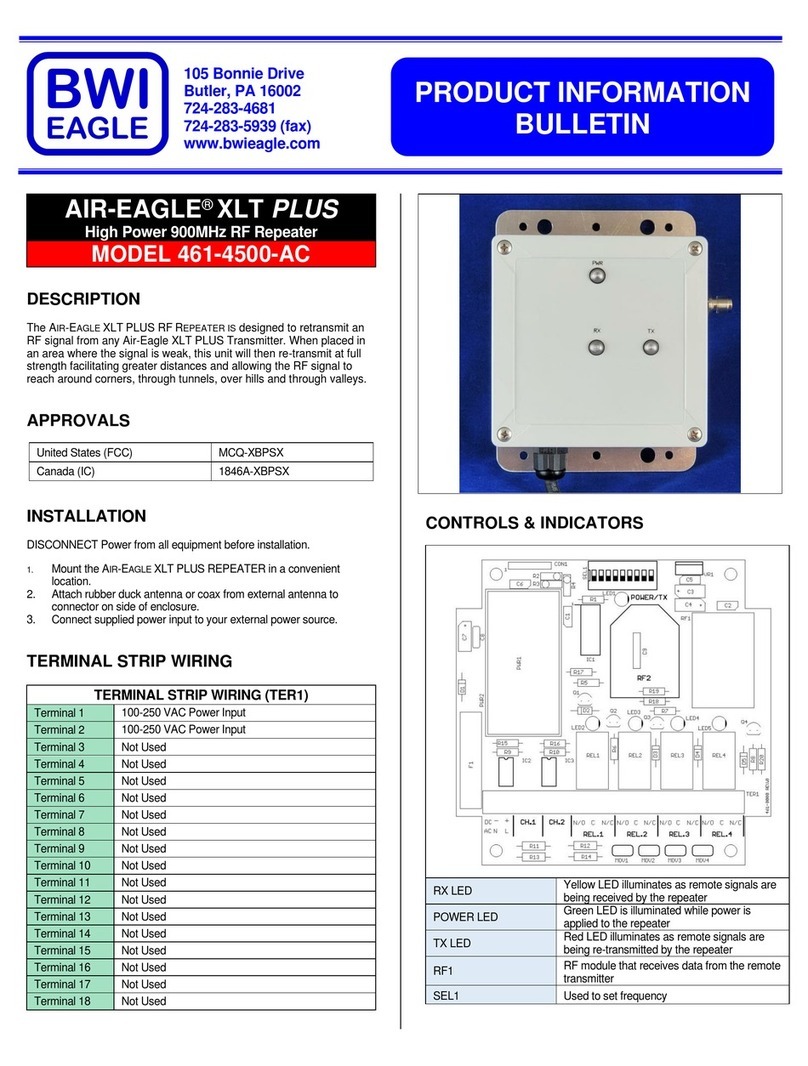

8Processor and watchdog reset switches

The Syncro VIEW is controlled by a microprocessor, which will re-start itself and continue to run if it stops for

any reason due to severe electrical interference such as an electrical storm.

To ensure that the unit is not being subjected to continual, undue interference which may affect its proper

operation, a watchdog (W/DOG) LED indicator is latched on and a fault condition signalled to the control panel.

If a processor re-start has occurred. this latched fault condition will need to do a reset by pressing the W/DOG

RESET button on the bottom of the PCB.

A switch is also provided to manually re-start the processor PROC RESET. This switch can be used while the units

are connected to the system to ensure that the unit starts up and establishes communication with the panel in

a controlled and expected manner.

9Connections to Syncro View

Syncro_View_AUS_v2.0.docx Page 9 of 12

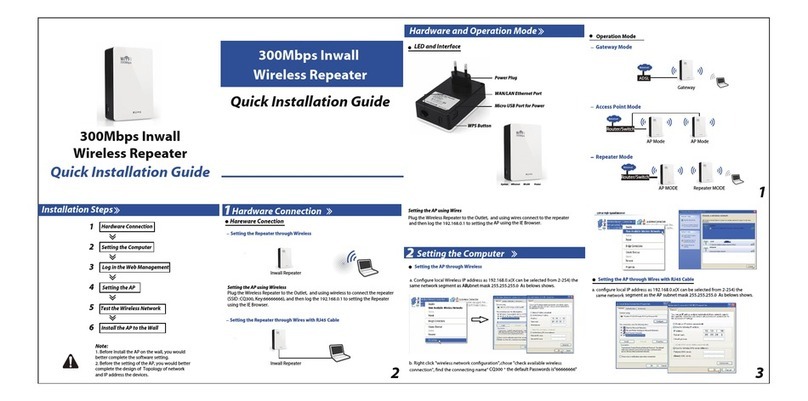

10 Adding a Syncro View to the Syncro panel

The Syncro View repeater must be added to the system by configuring the Syncro panel using the Loop Explorer

configuration utility.

Click on the site name in the left hand window pane to show the option to add panels or repeaters to the system.

If no panels are already added to the configuration then first add the type of panel required by double clicking

on it in the lower panel.

Add a Syncro view repeater by double click on the View Repeater Icon.

Double click on the panel to which the View repeater is to be connected.

Syncro_View_AUS_v2.0.docx Page 10 of 12

The Syncro View repeater is now shown in the centre window pane.

Right click the Syncro View and select “edit settings” to give the Syncro View a panel name (location) and an

address on the serial bus. This address should be different for each Syncro View added and different to any other

I/O boards that may exist on the serial bus.

Once the configuration file has been loaded into the panel the panel will now expect to see a Syncro View at the

address allocated to it and will show a fault condition if the Syncro View is not fitted or is removed.

Syncro_View_AUS_v2.0.docx Page 11 of 12

11 Revision Details

Revision

Number

Reason

Date of issue

v1.0

Initial Release

V2.0

Change of Incite Sydney address. Add power supply details into section 6

and corrected PO connection on section 9 drawing

29/03/2016

Sydney

Block Y, Unit 1, 391 Park Road, REGENTS PARK NSW 2143

Mail: PO Box 508 GYMEA NSW 2227

Phone: 1300 INCITE (1300 462 483) | 02 9644 7144

Fax: 02 9644 7255

Email: sales@incitere.com.au

Technical support: support@incitere.com.au

Melbourne

Address: Unit 120, 45 Gilby Road, MT WAVERLEY VIC 3149

Phone: 03 9544 2211

Fax: 03 9544 2212

Email: salesvic@incitere.com.au

Brisbane

Address: 25 Jeays Street, BOWEN HILLS QLD 4006

Phone: 07 3252 5366

Fax: 07 3252 4099

Email: salesqld@incitere.com.au

Perth

Address: 19 Halley Road, BALCATTA WA 6021

Phone: 08 9349 2972

Email: saleswa@incitere.com.au

Table of contents

Popular Repeater manuals by other brands

Altronix

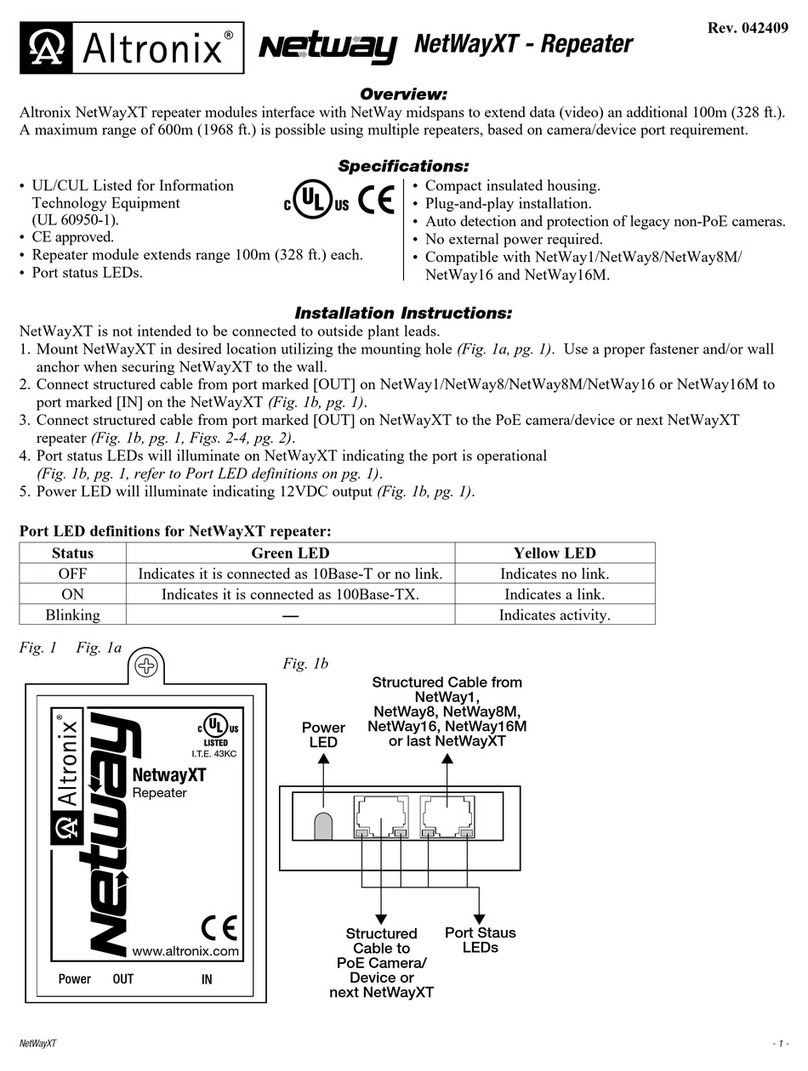

Altronix NetWayXT instruction manual

Amped Wireless

Amped Wireless SR600EX Setup manual

Patriot

Patriot Ritron RRX-450 Maintenance/repair/operating manual

Ziton

Ziton ZP2-ER-C installation manual

Bosch Rexroth

Bosch Rexroth IndraControl VAC 01 operating instructions

Relcom

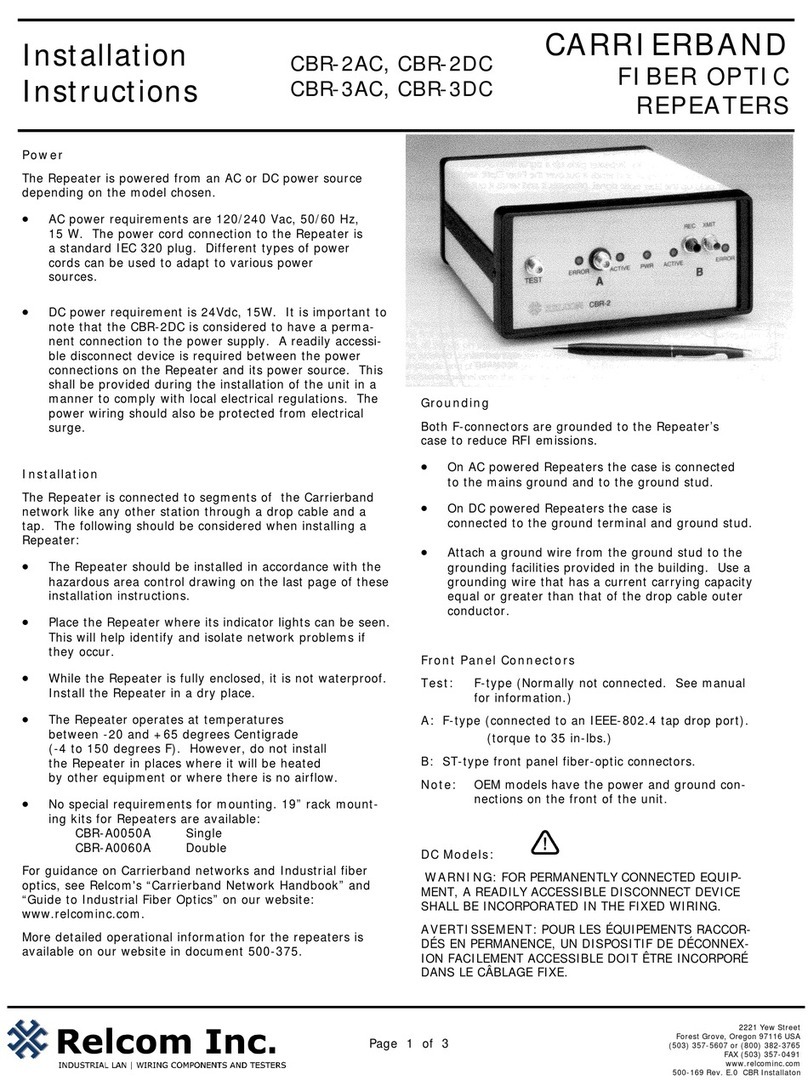

Relcom CBR-2AC installation instructions