Incra Shop Stop User manual

First:

Loosen screw

Horizontal stop rod

Second:

Slide stop rod

2

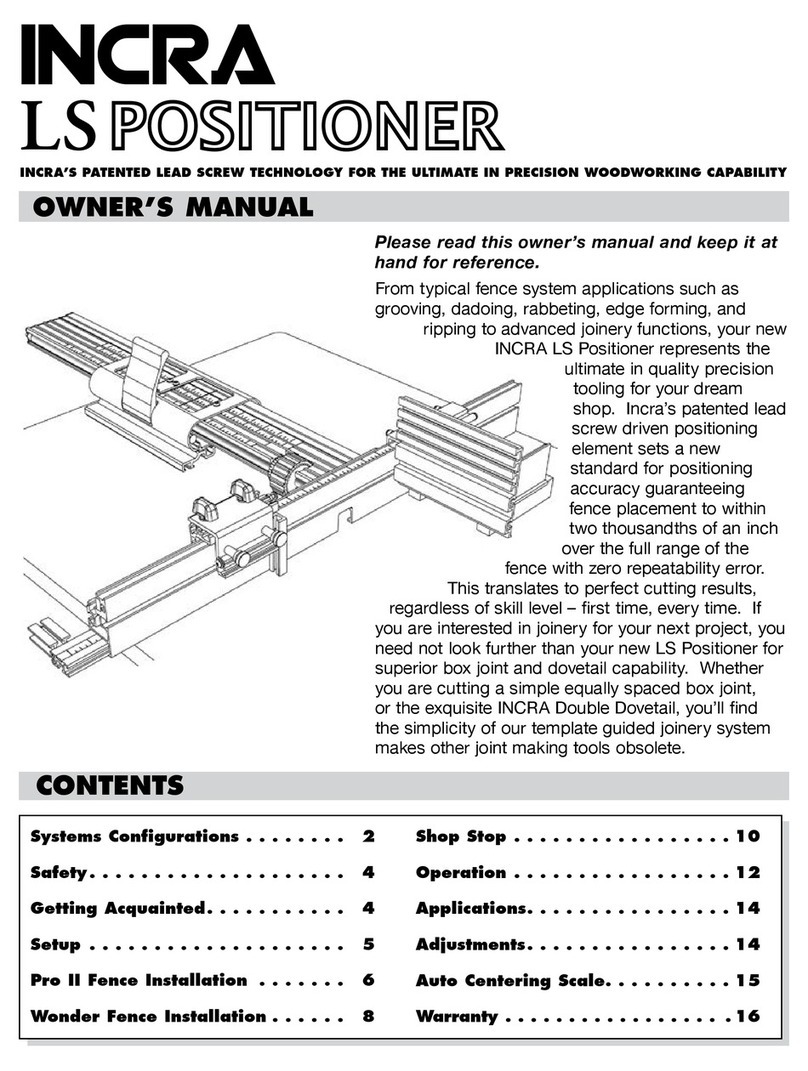

INCRA Woodworking Tools & Precision Rules

Expandable two-piece

body to accommodate

wooden subfences

Micro

adjust

screw

INCRA saw

tooth rack

Vertical T-bar

slides up or

down to

accommodate

different fence

heights

Horizontal rod moves in and

out to extend stop surface

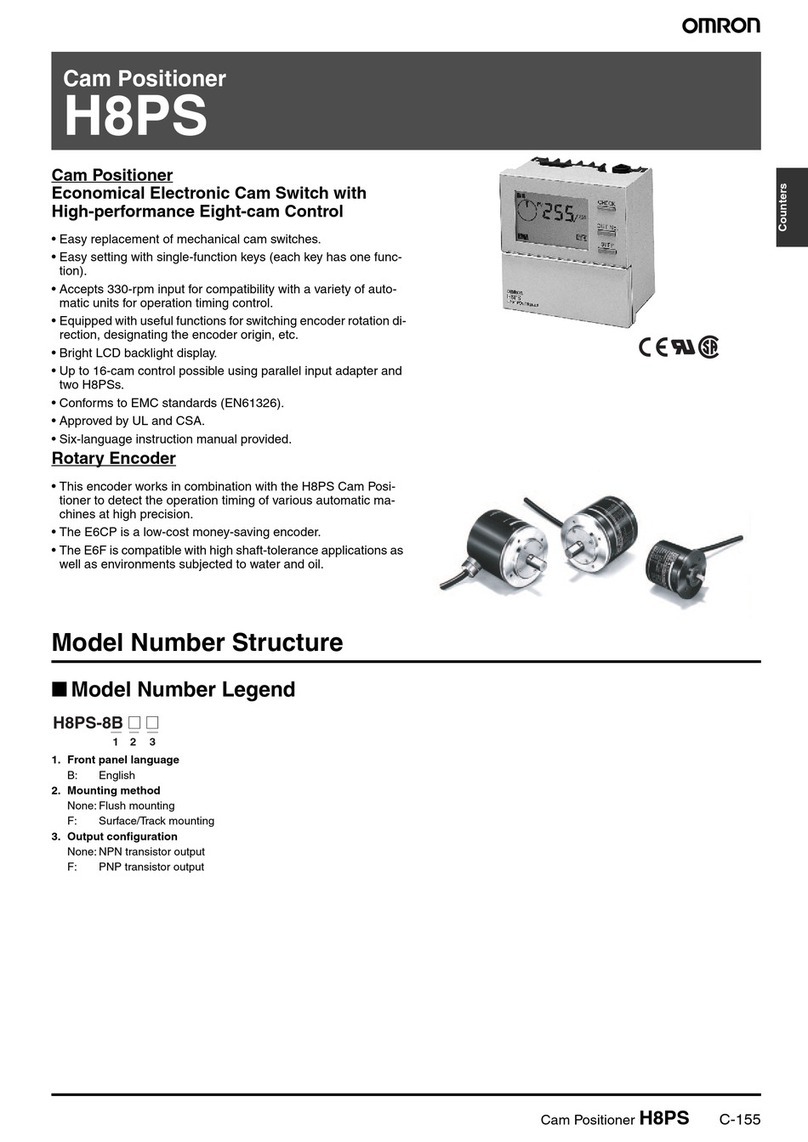

FEATURES

The INCRA Shop Stop comes equipped with two

interchangeable and reversible stop surfaces – a vertical stop

arm which can be adjusted up or down to accommodate

different fence heights, and a horizontal stop rod which can be

useful in extending the stop surface forward beyond the actual

body of the stop. Further, by removing the stop rod and stop

arm, user-made wooden stop pieces can be screwed into the

T-slot to provide the perfect stop surface for even the most

unusual wood profiles. The two-piece expandable Shop Stop

body design allows you to add

3

⁄

4

" thick wooden sub-fences to

your INCRA fence for zero clearance applications without

compromising the use of the stop. The patented incremental

positioning of INCRAʼs sawtoothed racks allows perfectly

repeatable stop locations at any multiple of

1

⁄

32

", while the

micro adjust screw permits easy fine adjustments anywhere

between the

1

⁄

32

" tooth spacing. (See Fig. 1)

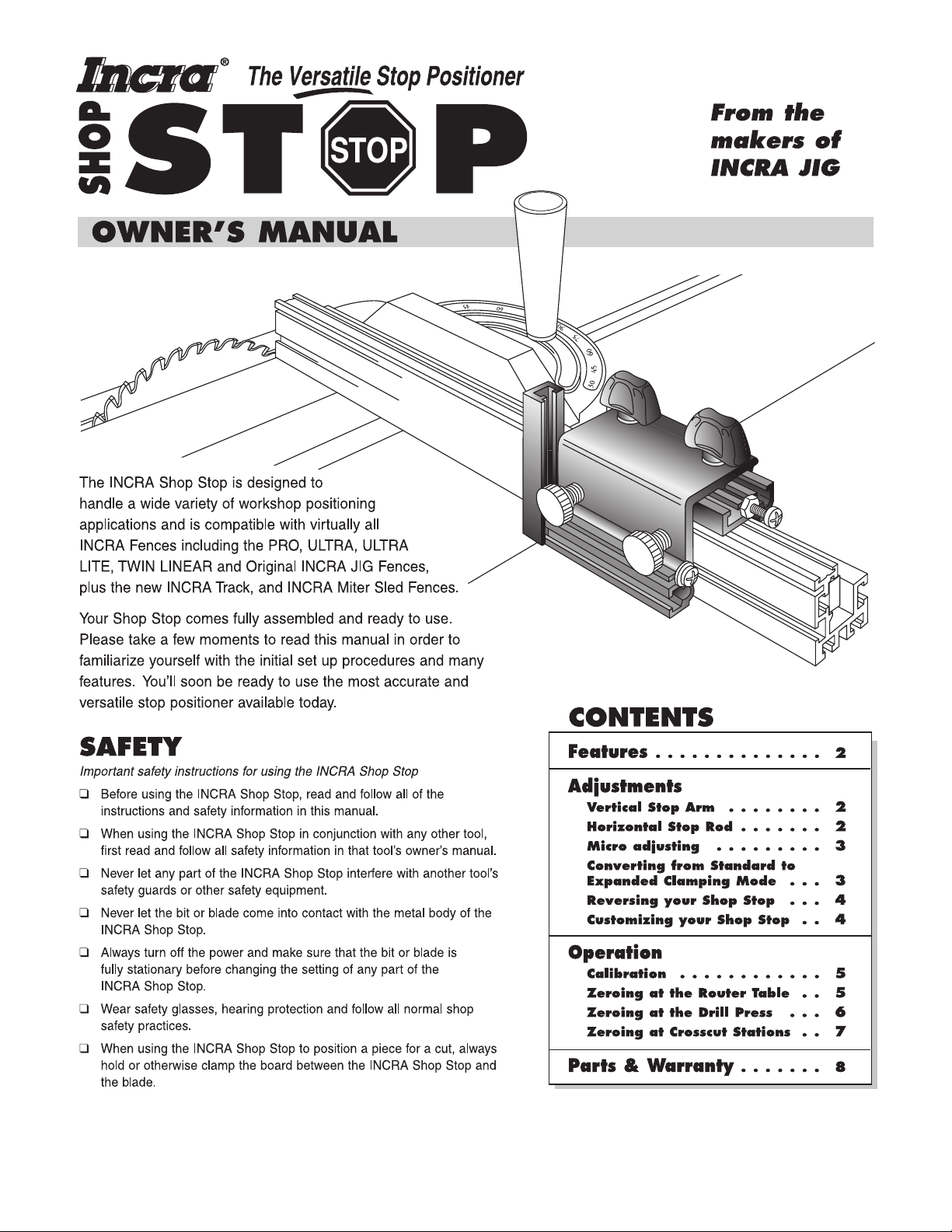

ADJUSTMENTS

When adjusting

the vertical stop arm,

leave a small gap

between the end of the

stop arm and the router

table, drill press or table

saw top. This provides

clearance for sawdust.

Vertical stop arm

First:

Loosen screw

Second: Slide vertical

stop arm up or down to

desired position Indexing lip

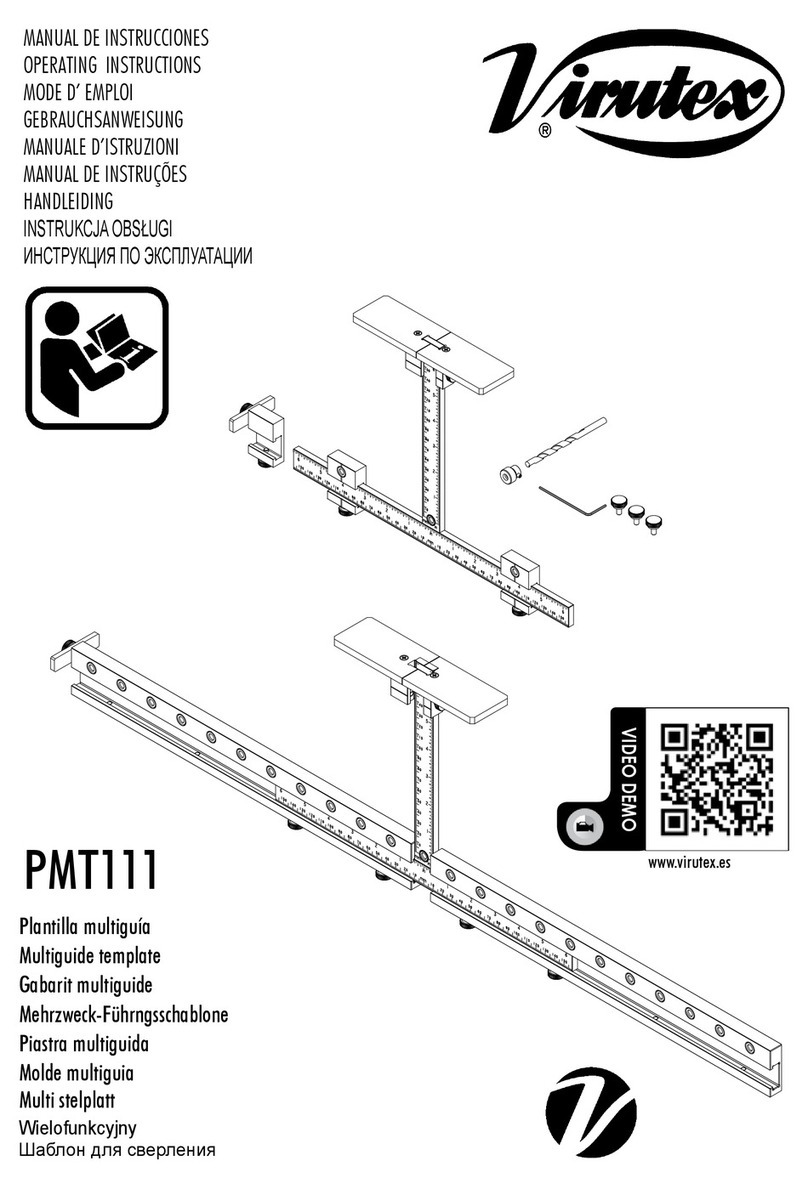

Horizontal Stop Rod:

The horizontal stop rod is held in place by a #10-32 x 3⁄8"

machine screw. To adjust the position of the stop rod, loosen

the screw and slide the rod as necessary, then retighten the

screw (Fig. 4)

Vertical Stop Arm:

To adjust the vertical stop arm up or down, loosen the

machine screw as shown in Fig. 2 and slide the stop arm to

the desired position. As you tighten the screw, make sure

the indexing lip on the stop arm is pressed against the face

of the stop body. (Fig. 3)

CAUTION: Always unplug the

motor before zeroing your Shop

Stop to any power tool.

FIG. 1

Shop Stop features

FIG. 2

Adjusting vertical stop arm

FIG. 3

Top view of stop arm position

FIG. 4

Adjusting

horizontal

stop rod

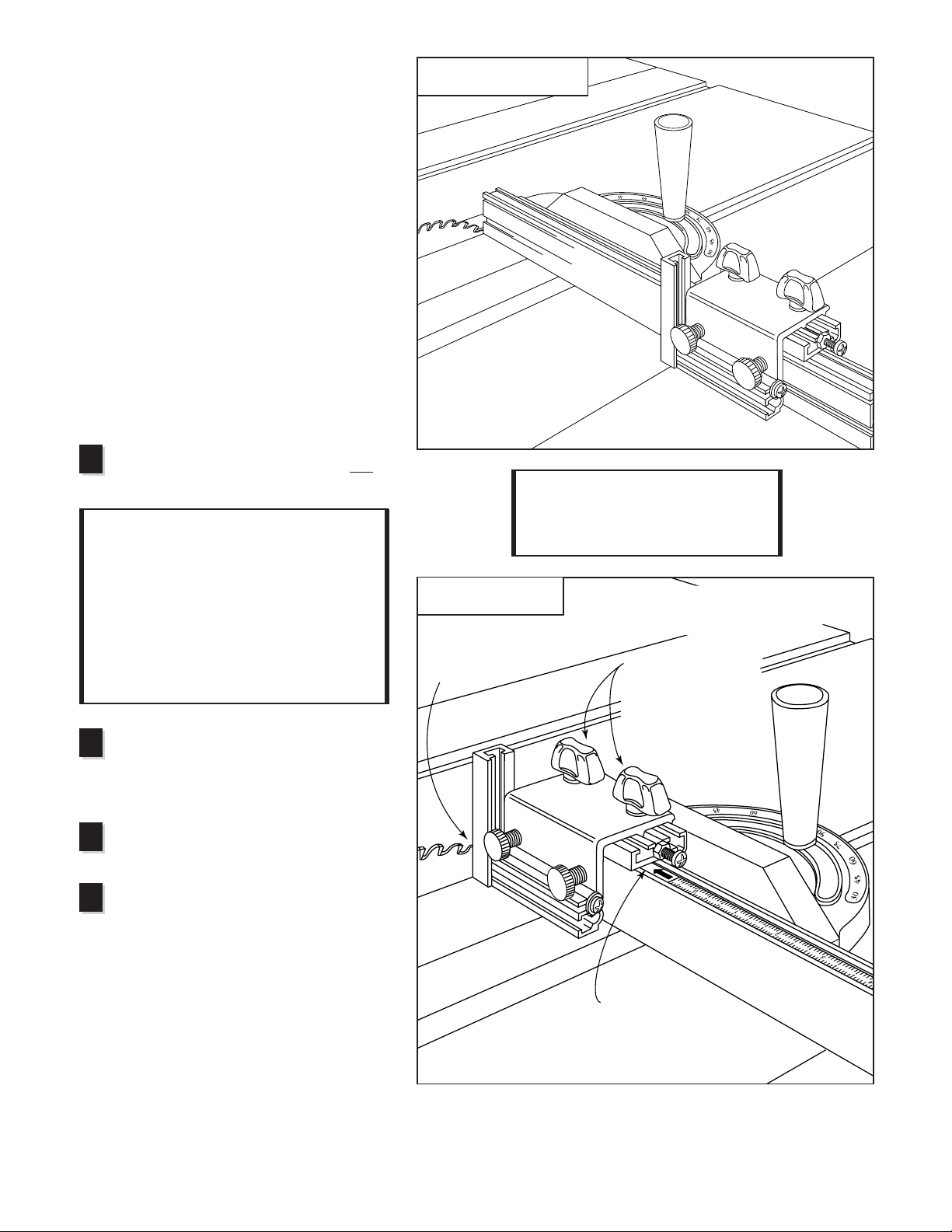

Micro adjusting:

Fine-tuning the position of your Shop Stop relative to a

cutter is easy and accurate. Just loosen the two black

thumbscrews on top of the Shop Stop body about

1

⁄

8

turn,

then turn the machine screw located at the end of the Shop

Stop (Fig. 5). Each full turn of the screw moves the stop

exactly

1

⁄

32

". Turning the screw clockwise moves the stop

surface closer to the cutter. To move the stop surface away

from the cutter, turn the screw counterclockwise as you

push the stop body toward the screw. Always tighten the

two black thumbscrews after micro adjusting.

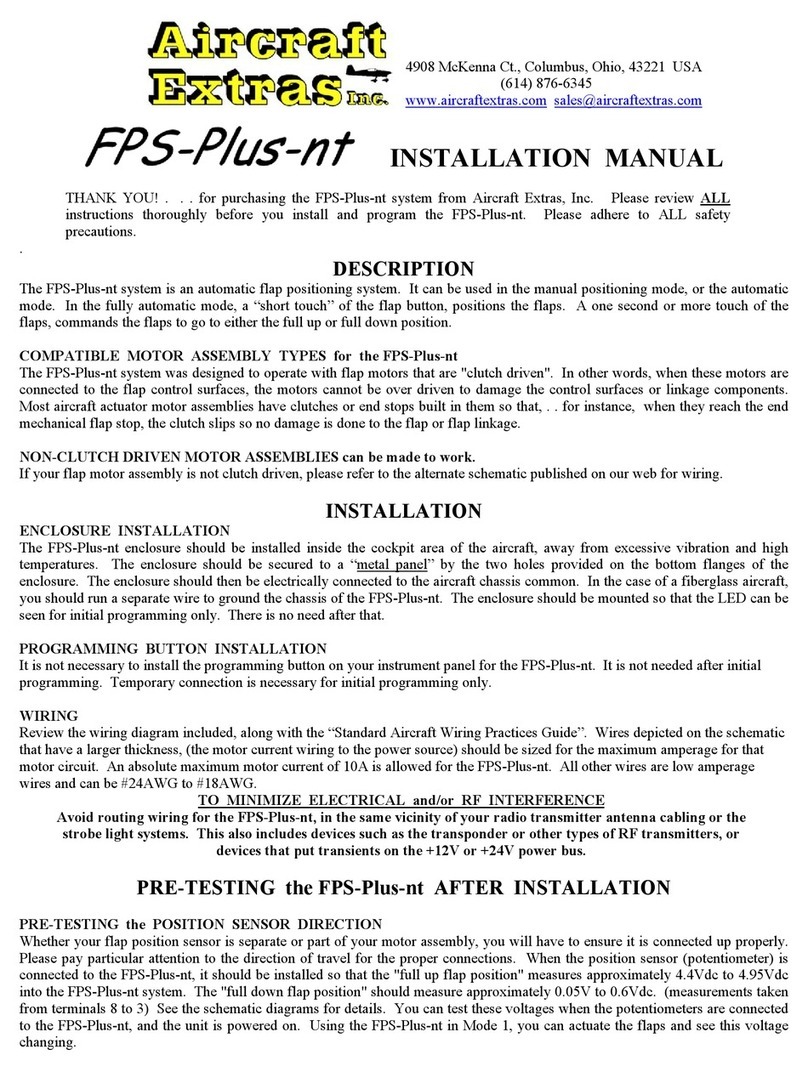

Converting from standard to expanded

clamping mode:

Your INCRA Shop Stop comes assembled in the standard

clamping mode. This setup will clamp to virtually any of the

INCRA Fences including the ULTRA, ULTRA LITE, TWIN

LINEAR and Original INCRA JIG Fences plus the New INCRA

Miter Sled and the INCRA Track. In the standard mode you

can even clamp the Shop Stop directly to any piece of

3

⁄

4

"

plywood or hardwood. Youʼll find this feature perfect for those

occasions when you want to extend the length or height of

your INCRA fence with a

3

⁄

4

" subfence. A second “expanded”

clamping mode allows the use of your Shop Stop after attaching

a wooden auxiliary fence to your INCRA Fence. (Fig 6).

Adding a wooden auxiliary fence to your INCRA Miter Sled,

chop saw, or INCRA JIG Fence can be very beneficial in that it

provides zero clearance between the cutter and the fence. A

zero clearance auxiliary fence often translates to safer and

cleaner cuts since the smaller opening provides more support

for the workpiece at the cut.

The two piece design of the INCRA Shop Stop permits use of

a

3

⁄

4

" thick wooden auxiliary fence without interfering with the

stop's ability to clamp to your INCRA Fence. To change the

stop to expanded mode, loosen the two black thumbscrews

and slide the stop body (red) off of the stop cap (gold). Now

slide the two rectangular nuts on the stop body into the

alternate T-slot on the cap. (See Fig. 7) Tighten the two

clamping knobs.

Attach the auxiliary fence as described in your INCRA

Fence ownerʼs manual.

INCRA Shop Stop Manual

3

First: Loosen both black thumbscrews.

Leave white thumbscrews fully

tightened if already installed on fence.

Second:

Turn micro adjust

screw clockwise to

move the stop

toward the cutter.

Turn counter-

clockwise and slide

stop body toward

micro adjust screw

to move stop away

from cutter.

Stop body

Third: Retighten both

black thumbscrews

3/4" wooden

auxiliary fence

FIG. 5

Micro adjusting

FIG. 6

Expanded clamping mode

Shop Stop

shown in expanded

clamping mode

Stop

body

Loosen black thumbscrews

and slide stop body off of cap

Large gap

Reassemble stop body

to stop cap as shown

Standard Mode Expanded Mode

FIG. 7 Converting from standard to expanded clamping mode

Stop cap

Note:

For auxiliary fence applications where

incremental use of the Shop Stop is required, use

3

⁄

4

" hardwood or plywood and make sure that the

auxiliary fence is no taller than your INCRA Fence.

Stop cap

Small gap

Reversing your Shop Stop:

At some cutting stations it may be desirable to reverse

the stop surfaces of the INCRA Shop Stop. This allows

the Shop Stop to function as either an infeed or outfeed

stop at the router table, or on either side of the blade at a

chop saw or radial arm saw.

To reverse your Shop Stop, first move the micro adjust

screw to the opposite end of the gold stop cap and

tighten the nylon nut against the aluminum. Remove and

reverse the #10-32 x 3-

1

⁄

2

" machine screw that holds the

vertical stop arm to the red stop body. Replace the stop

arm on the opposite end of the stop body. Make sure the

indexing lip on the arm wraps around the front of the stop

body (Fig. 3) and that the arm is flat against the end of

the body. Tighten the machine screw. (Fig. 8)

#10-32 nylon

hex nut

Stop

body Vertical

stop arm

Hex nut

slides into

T-slot on

vertical

stop arm

#10-32 x 1"

micro adjust

screw

Stop cap

4

INCRA Woodworking Tools & Precision Rules

FIG. 9

FIG. 8

Reversing the Shop Stop

#10-32 x 3 1⁄2"

machine screw

#10 flat washer

FIG. 10

#10-32 hex nuts

1⁄4"

diameter

hole

#10-32 x 3⁄4"

machine screws

1⁄2"

3⁄16"

3⁄4" or

more

Note:

Should you ever remove the

micro adjust screw, make sure to

tighten the nylon nut against the

aluminum when replacing it. The

nylon nut keeps the micro adjust

screw from vibrating loose during

cutting operations.

Example of user-made

wooden stop surface

designed to position

boards with mitered ends

1⁄2"

FIG. 11

Customizing your stop

DETAIL 11A

#10

flat

washer

1⁄2"

Customizing your Shop Stop:

By removing both the vertical stop arm and the

horizontal stop rod, user-made wooden stops

can be attached to the front face of the stop.

Youʼll find this feature useful when you want the

stop surface to match an odd-shaped wood

profile or a mitered board end. Fig. 11 describes

just one example of a user-made stop. By gluing

two pieces of wood together, an “L” shape can be

produced which can be cut to match the desired

profile and then screwed into the T-slot. The “L”

feature on the block can be glued on to protrude

up, down, in or out as desired.

Reversible

stop surface

Note:

Whenever reversing

the Shop Stop, always make

sure the stop surface

selected (vertical arm or

horizontal rod) protrudes at

least

1

⁄

8

"

in front of the end

of the gold stop cap.

Otherwise taller workpieces

will be stopped by the gold

stop cap rather than the

selected stop surface.

Reversible

stop surface

2"

INCRA Shop Stop Manual

5

First: Slide a

square cut board

up to contact the

“high spot” on the

router bit

Second: Clamp

the Shop Stop to

the fence with the

stop surface as

close as possible

to the board.

Micro adjust

screw

Third: Loosen black thumbscrews 1⁄8

turn, then rotate micro adjust screw

clockwise until stop surface touches

end of board. Tighten the

black thumbscrews.

Fourth: Slide scale to

read directly under end

of gold stop cap. Use

one of the initial

scale settings

described

in Fig.13.

FIG. 12

Follow these steps for

zeroing at the router table

OPERATION

FIG. 13

Slide scale on your fence to one of three initial positions

ASlide scale to 0" for

a direct readout of

dimension “A” (total

length of cut)

BSlide scale to “minus

1⁄2of bit diameter”

for a direct readout

of dimension “B”

CSlide scale to “minus

bit diameter” for

direct readout of

dimension “C”

Zeroing at the Router Table:

For most applications at the router table you will be using your Shop Stop on

the outfeed fence to limit the length of a cut relative to the front end of a board.

Follow the steps in Fig. 12 below.

Calibrating the Shop Stop

for your Workstation:

In order for your INCRA Shop Stop to

accurately locate your workpiece for a cut, you

must first “zero” your Shop Stop to the bit or

blade and position the sliding scale on your

fence. Zeroing is often just as simple as

clamping your Shop Stop to the fence with the

stop surface just touching the bit or blade. You

want the stop surface to be zero distance from

the cutter, so a little micro adjusting might be

required. Once this zero position is found, slide

the scale on your INCRA Fence to read “0”

directly under one end of the gold stop cap. This

approach, however, wonʼt handle every situation

in the shop. Sometimes, as in the case of a

router or drill bit, it becomes necessary to use an

indirect approach to setting the initial scale

position. For zeroing at the router table, drill

press and crosscut stations, a step-by-step

approach ensures an easy and accurate setup.

See Figs. 12 thru 15 for the steps.

Note:

The vertical stop arm is the stop

surface illustrated in all of the examples to

follow, but donʼt rule out the use of the

horizontal rod for your stop surface.

Once the Shop Stop is zeroed to the router bit

as shown in Fig. 12, you now have the choice

of setting the sliding scale on your INCRA

Fence to one of three initial positions.

See Fig. 13.

6

INCRA Woodworking Tools & Precision Rules

1

2

If youʼre not using the horizontal rod on

your Shop Stop as the stop surface, it can

be used as your drill press set up rod.

3

Second: Install 1⁄4" set up

rod and slide square cut

board up to touch 1⁄4" rod

Third: Clamp the Shop Stop

to the fence with the stop

surface as close as possible

to the board.

Fourth: Loosen black

thumbscrews 1⁄8turn,

then rotate micro adjust

screw clockwise until

stop surface touches

end of board. Tighten

thumbscrews.

Fifth: Slide scale to read

negative 1⁄8" directly under

end of gold stop cap.

Micro adjust

screw

1⁄4" diameter “set

up” rod or 1⁄4"

diameter drill bit

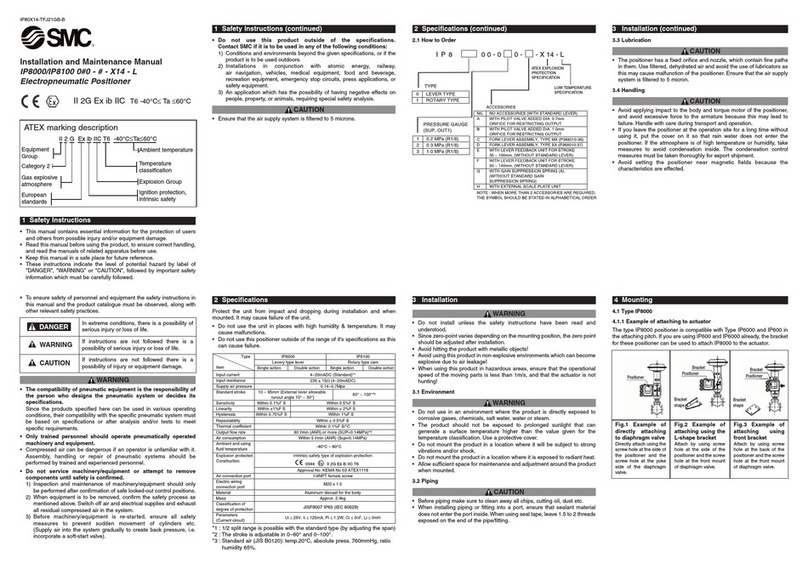

FIG. 14

Zeroing at the drill press

First: Set the distance

between your INCRA

fence and the center of

the bit as required by

your project.

4

5

Zeroing at the Drill Press:

Zeroing at the drill press is really the same as zeroing at a

router table. Stop locations at a drill press, however, are almost

always located relative to the center of the bit, not the edge of

the bit. Because of this, and the fact that drill bits are available

in so many different sizes (decimal, 64ths, metric, letter and

number), it is a good idea to use a specific “set up” rod or drill

bit each time you zero your Shop Stop. The “set up” rod should

have a diameter that is some multiple of

1

⁄

16

". In the steps

following weʼll use a

1

⁄

4

" rod for the set up.

Set the distance between your INCRA Fence and the

center of the drill bit as required by your project. An

INCRA JIG at your drill press makes this step really easy.

Otherwise use a bradpoint drill bit and a ruler, or mark drill

center lines on your workpiece and use these lines to

initially position your INCRA Fence.

Install a short length of

1

⁄

4

" steel rod in your drill press (a

1

⁄

4

" twist drill bit will also work well). Place a square cut

piece of scrap stock against the fence with the end of the

board against the

1

⁄

4

" rod.

Lock the INCRA Shop Stop to the fence with the selected

stop surface (vertical arm or horizontal rod) as close as

possible to the end of the board.

Loosen the two black thumbscrews about

1

⁄

8

turn,

then rotate the micro adjust screw clockwise until the

stop surface touches the end of the board. Tighten the

black thumbscrews.

Slide the scale on your fence to read minus

1

⁄

2

of the

set up rod diameter. In this case, since we used a

1

⁄

4

"

diameter set up rod, weʼll slide the scale to read

negative

1

⁄

8

" directly under the end of the gold stop cap.

(The scale can be set to read under either end of the

gold stop cap.) Use the end that gives the best visibility.

When set to this initial position, the scale reading at any

subsequent Shop Stop location will give you a direct

readout of the distance from the end of the workpiece to

the center of the hole.

Loosen the black thumbscrews about

1

⁄

8

turn then rotate the micro adjust screw

clockwise until the stop surface touches the

teeth on your saw blade. Tighten the

thumbscrews.

Slide the scale on your fence to read 0"

directly under the end of the gold stop cap.

(Use the end farthest from the saw blade)

Now at each subsequent setting of your

Shop Stop, the scale will give a direct

readout of the distance between the stop

surface and the saw blade.

Zeroing at Crosscut Stations:

There are several stations in the shop where

crosscutting operations can take place – the radial

arm saw, chop saw, sliding miter saw, and the table

saw. The radial arm saw, chop saw and sliding

miter saw are all similar in that the workpiece is held

against a stationary fence as the blade is moved

through the cut. At the table saw, crosscutting is

accomplished with the help of a miter gauge or by

using a crosscut box. In these approaches the

workpiece is held against a fence that is moved,

guided by the miter slots in the table saw, over a

stationary blade. In any case, accessorizing these

tools with an INCRA Track and INCRA Shop Stop

makes accurate crosscutting effortless.

Zeroing at these tools is easy.

Here’s how:

With the saw unplugged, raise the blade about 1"

and clamp the Shop Stop to your INCRA fence with

the stop surface as close as possible to the blade.

Position fence far enough away from the

blade to comfortably clear the blade at ALL

cutting angles. CAUTION: Always unplug the

motor before zeroing your Shop

Stop to any power tool.

INCRA Shop Stop Manual

7

Second: Clamp stop to

fence with stop surfaces

as close as possible to

saw blade. Third: Loosen black

thumbscrews about 1⁄8

turn, then rotate micro

adjust screw clockwise

until stop touches teeth

on saw blade. Tighten

black thumbscrews.

Fourth: Slide scale to

read 0" directly under

end of gold stop cap.

FIG. 15

Typical crosscut application

1

2

3

First: Position fence far enough away from

the blade to comfortably clear the blade

at all cutting angles

4

Note:

Depending on the distance of the

end of the fence to the blade (as determined

in Step 1 above), one of the white thumb-

screws may overhang the end of the fence

when zeroing. Just be sure that during any

cutting operation, the Shop Stop is

positioned sufficiently far enough away from

the blade for safe finger clearance, and that

both white thumbscrews are engaged

against the fence surface.

FIG. 16

Zeroing at the tablesaw

Made in America by:

Taylor Design Group, Inc. ■P.O. Box 810262 ■Dallas, Texas 75381 ■Web Site: www.incra.com 0199

Printed in the U.S.A. © 1999, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

PRODUCT INFORMATION

For a product information update on the complete

INCRA line of tools, please see your nearest dealer. If

you are unable to locate a store nearby, or if you have

trouble finding a particular product, we will honor your

order directly.

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 418-4811 Fax: (972) 243-4277

Web Site: www.incra.com

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any

defects due to faulty material or workmanship, or at our option, replace the product free of charge.

Please return the failing component only, postage prepaid, along with a description of the problem to

the address below. This warranty does not apply to parts which have been subjected to improper use,

alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will

replace it free of charge for as long as you own your tool. Return the damaged rack, transportation

prepaid, and allow 1 to 2 weeks for delivery.

NOTE:

Replacements cannot be sent unless damaged racks have been received by Taylor Design Group.

PARTS AND OPTIONAL ACCESSORIES

Part # Part Description Price

SHOPSTOP INCRA Shop Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 32.95

Add a second Shop Stop to your INCRA Fence or INCRA Track for mortising and other applications

TRACK18 18" Track Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 27.95

TRACK36 36" Track Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 42.95

TRACK52 52" Track Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 52.95

Add one or more individual INCRA Track Sections for placing the ShopStop on both sides of the

cutter, or extending the stopping range. Track sections include incremental racks, sliding scales, and

complete mounting hardware.

TRACKSYS18 18" Track

plus

Shop Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 52.95

TRACKSYS36 36" Track

plus

Shop Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 72.95

TRACKSYS52 52" Track

plus

Shop Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 82.95

Buy the complete INCRA Track System and save. Includes specified length of INCRA Track section,

INCRA Shop Stop, incremental racks, sliding scales, and complete mounting hardware.

8

INCRA Woodworking Tools & Precision Rules

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, Texas 75381

Tel: (972) 242-9975 Fax: (972) 242-9985

www.incra.com

Table of contents

Other Incra Valve Positioner manuals

Popular Valve Positioner manuals by other brands

Flowserve

Flowserve Logix 520MD+ User instructions

ERIKS

ERIKS ECON 3300 NCS Series Installation & operating manual

Aircraft Extras

Aircraft Extras FPS-Plus-nt installation manual

Festo

Festo CMSH manual

Samson

Samson TROVIS 3730-1 Mounting and operating instructions

Samson

Samson TROVIS 3730-3 Mounting and operating instructions