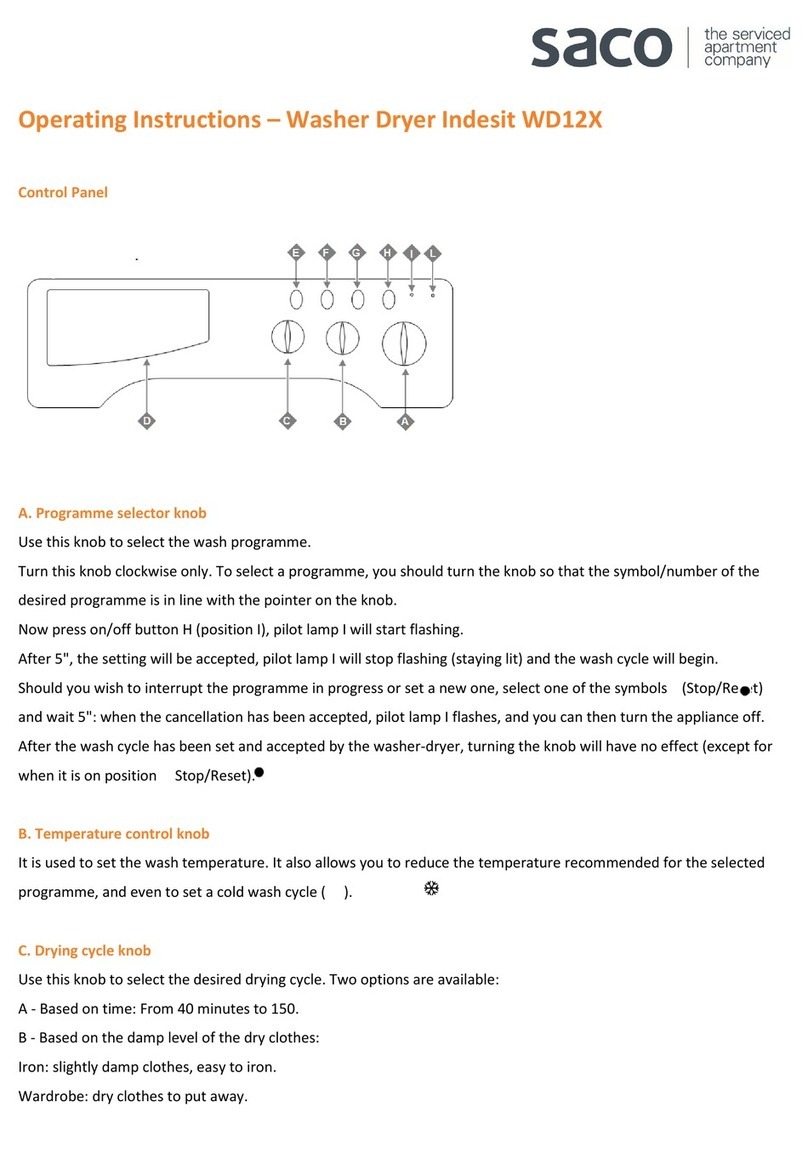

E

A

B

C

D

FGHIL

The washer-dryer is equipped

with an extra compartment 4

(provided as an accessory) for

the bleach, to be inserted in

compartment 1.

Easyiron

This function allows your

washing to come out of the

machine without creases,

making it much easier to iron.

Youcanuseitwithprogrammes

3-4 (Cotton), 5-6 (Synthetics)

and9(Delicates).

Press this button in

programmes5-6-9 andthewash

cycle will come to a stop on

symbol .Youcan complete it

by pressing button Eagain.

Notes:

- this function should not be

used when button G(stain

removal) has been pressed.

-If you also want to run the

drying cycle, this button is

enabled only if combined with

level (Iron).

Slow spin

Use this button to reduce the

spinning speed from 1200 to

600rpmforthe cotton and linen

programmes and from 850 to

600 rpm for the synthetic

fabrics programmes.

Stain removal (see page 8)

Thanks to this command, the

washer-dryer will carry out a

more intensive wash that

optimisesthe effectivenessofthe

liquid additives, thus allowing

more resistant stains to be

removed. When you press the

stainremoval button,youcannot

activatethepre-wash.

Here I’m in command

Understandingthecontrol panel

Making the right choice is important. And it’s easy.

Programme selector knob

Usethisknobto select the wash

programme.

Turnthisknob clockwiseonly.

To select a programme, you

should turn the knob so that the

symbol/number ofthedesired

programme is in line with the

pointeron theknob.

Now press on/off button H

(position I), pilot lamp Iwill start

flashing.

After 5", the setting will be

accepted, pilot lamp Iwill stop

flashing(stayinglit)andthewash

cyclewillbegin.

Should you wish to interrupt the

programme in progress or set a

new one, select one of the

symbols (Stop/Reset)andwait

5" : when the cancellation has

been accepted, pilot lamp I

flashes,andyoucanthenturnthe

applianceoff.

Afterthewashcyclehasbeenset

and accepted by the washer-

dryer, turning the knob will have

noeffect (exceptforwhenit ison

position Stop/Reset).

Temperature control knob

Itisusedto set the wash tempe-

rature in the recommended

programmetableonpag.4.Italso

allowsyoutoreducethetempe-

rature recommended for the

selected programme, and even

to set a cold wash cycle ( ).

Drying cycle knob

Use this knob to select the

desired drying cycle. Two

optionsareavailable:

A- Based on time:

From40 minutesto150.

B- Based on the damp level of

thedryclothes:

Iron

:slightly damp clothes,

easy to iron.

Wardrobe

: dry clothes to

put away.

Extra dry

:verydry clothes,

recommendedfortowellingand

bathrobes.

A cooling stage is foreseen at

the end of the drying cycle.

Detergent dispenser

Itisdividedinto3compartments:

1.Detergent for pre-wash;

2.Detergent for the main cycle

wash;

3.Fabricconditioner.

3

Instructionsforinstallationanduse

On-off

When button H is pressed, the

washer-dryer is switched on,

when it is not the machine is

switched off.

Turning the appliance off

does not cancel the selected

programme.

On-off lamp / door locked

LampIflashes slowly whenthe

appliance is switched on and

awaiting instructions and at the

endofacycle,indicatingthatthe

door can be opened. It flashes

quickly when the door should

not be opened. A steady light

means the appliance has

accepted the selected

programme.

Drying cycle lamp

When this lamp is on, it means

that knob Chas been set on a

dryingcycle andatthe endofthe

washcycle,theappliancewillrun

theselected tumbledryingcycle.

The detergent dispenser with the

additional bleach compartment

is here.

MAX

12

4

3