Industriarmatur SIPP Node 400 User manual

Popular Control Unit manuals by other brands

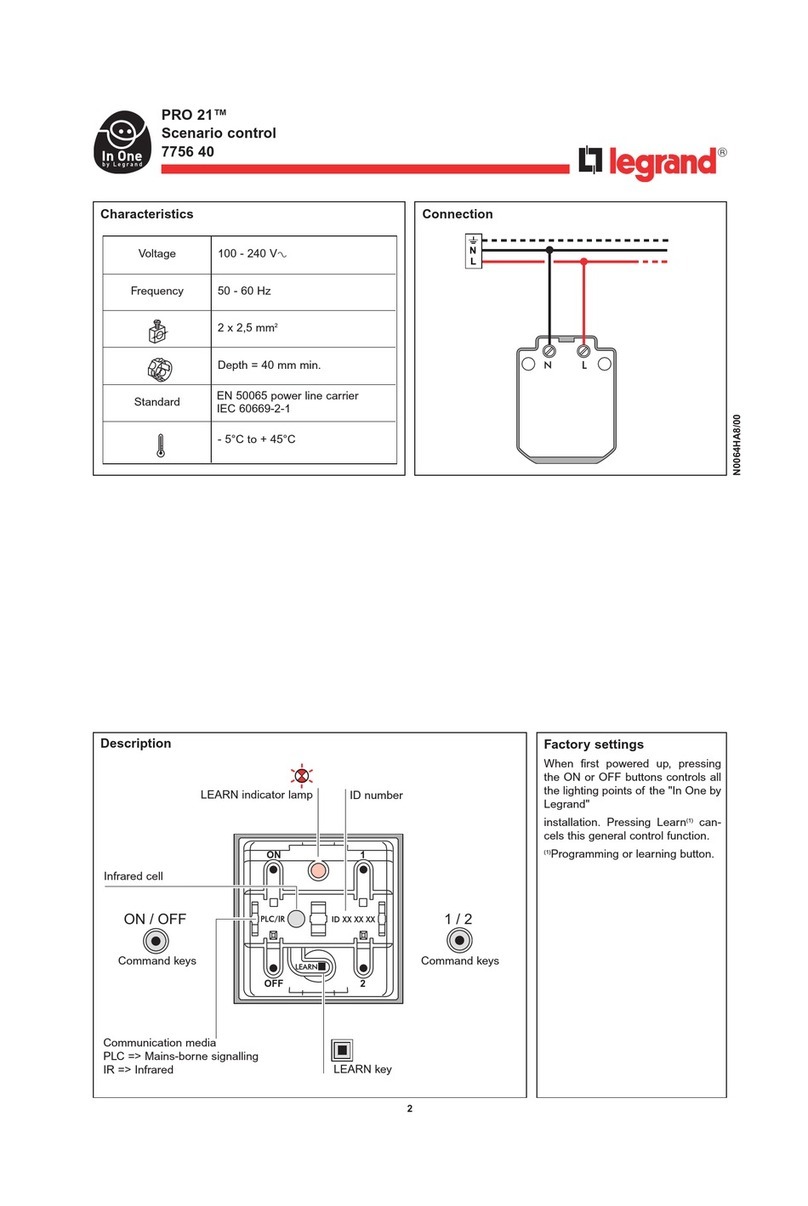

LEGRAND

LEGRAND PRO 21 7756 40 manual

Bandini Industrie

Bandini Industrie GiBiDi BA100 Instructions for installations

Phidgets

Phidgets PhidgetTemperatureSensor 1-Input User's product manual

Clamper

Clamper Solar SB 1000 18kA 3-4E/2S installation guide

Telit Wireless Solutions

Telit Wireless Solutions GL865-QUAD V4 Software user's guide

Festo

Festo MSE6-E2M Operating instruction

Atmel

Atmel ATBTLC1000 BluSDK user guide

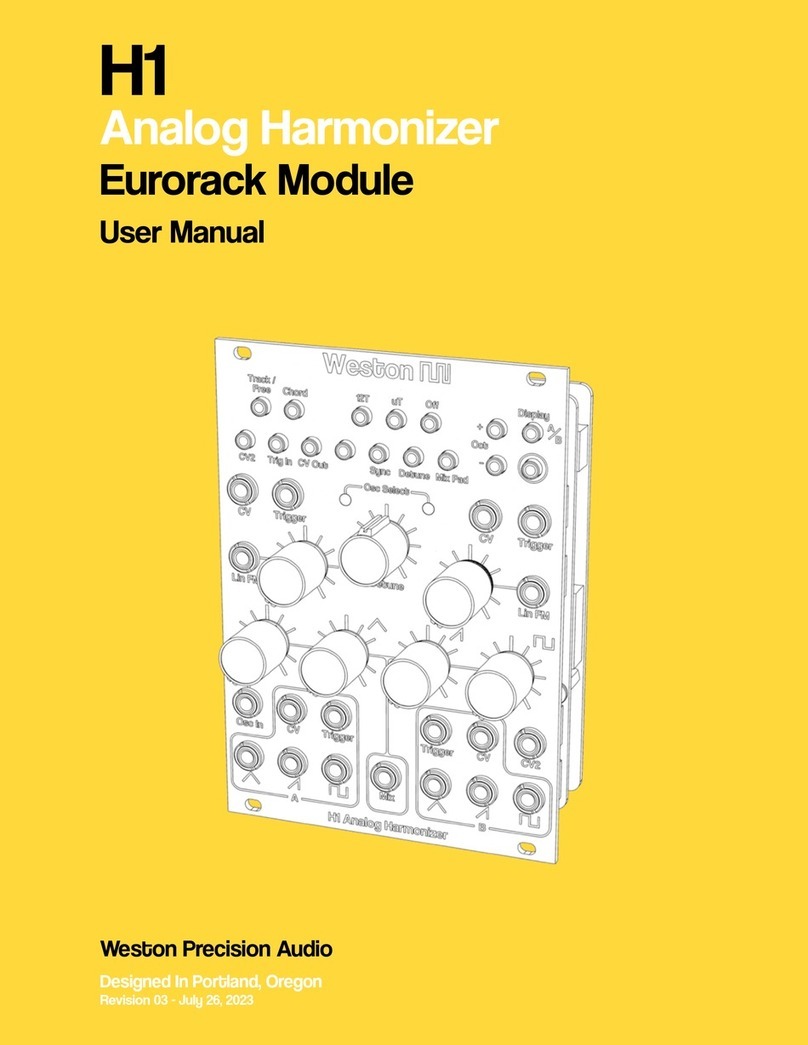

Weston Precision Audio

Weston Precision Audio H1 Analog Harmonizer user manual

Asco

Asco 290 Series Installation and maintenance instructions

TP-Link

TP-Link TL-SM321A installation guide

Simrig

Simrig SR2 user manual

VAT

VAT 10.8 Series Installation, operating, & maintenance instructions